Professional Documents

Culture Documents

Advanced Paper Cutting Machine Using ARM7: Sense

Uploaded by

chotichanduOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Advanced Paper Cutting Machine Using ARM7: Sense

Uploaded by

chotichanduCopyright:

Available Formats

International Journal of Engineering and Advanced Technology (IJEAT)

ISSN: 2249 – 8958, Volume-3, Issue-4, April 2014

Advanced Paper Cutting Machine using ARM7

S.S. Lavhate, Saurabh R. Keskar, Vishal P.Unhale, Avinash Sangale

Abstract- The proposed system will be an intelligent automated To overcome above problems intelligent paper

length measurement device composed of the rotary encoder, cutting machine controller can be used. It is semiautomatic

proximity switches, motor and embedded design consisting programmable unit equipped with very simple and user

microcontroller with digital circuitry etc. this device used as friendly control panel. It has got wide application area in

control panel of paper cutting machine, which is used to cut the

books or notebook manufacturing industry, corrugated box

various kind of paper products, plastic, thin film, leather, slice of

nonferrous metal etc. This system can be applicable in paper manufacturing industry, visiting cards or labels

cutting industry and proves how it can be a low cost solution in manufacturing industry etc.

the production practice. It has a 5” colour graphic display interface, memory for

Key Points: Cutting, Rotary encoder, Safety, touch screen. 64000 cut positions, automatic push out & air table control

which provides easiness in cutting and handling bulky jobs.

I. INTRODUCTION System provides production control by storing the operator’s

log of no. of cuts taken in a shift with date & time stamp.

Traditional hand lever cutting machine has drawbacks viz. it

doesn’t provide safety to operator. It is not user friendly as

III. OBJECTIVES OF THE PROJECT

every time user has to adjust the paper to desired cut

position and hold the paper before taking cut. It is very time 1. Objective of this project is to design, fabricate and

consuming and tedious process to take a job with different automate the paper cutting machine in such a way that the

cut size so such machine also accuracy job taken on this required length of paper of size a4 can be cut.

machine depends on operators skills. 2. The paper cutting machines generally available in the

To overcome problems advance paper cutting machine market are generally manual and if automatic then it is very

controller c be used. It is semiautomatic programmable unit costly. Objective is to develop, the kind of paper cutting

equipped with very simple and user friendly control panel. It machine which is automatic and less costly.

has got wide application area in books or notebook

manufacturing industry, visiting cards or labels IV. BLOCK DIAGRAM

manufacturing industry etc.

II. LITERATURE SURVEY

Clamp A

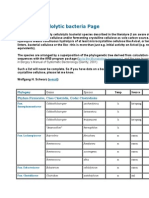

Traditional hand lever paper cutting machine has sense

drawbacks viz. it doesn’t provide any safety to operator. It is Motor direction control

not user friendly as every time operator has to do adjust the RM (Forward / Reverse)

paper to desired cut position & hold the paper before taking

the cut. It is very time consuming & tedious process to take

Knife

sense 7

a job with different cut sizes on such machine also accuracy

Motor speed control

of job taken on such machine depends on operator’s skill.

(Fast / Slow)

Ref. zero

sense

Air table nozzle

Rotary control

En.

Back Gauge stepper

Fig.1 Hand Lever Paper Cutting Machine (RS232) motor control

Manuscript received on April 2014. Touch

S.S.Lavhate, Associative Professor, Department of ETC, P.R.E.C. Loni,

screen

Ahmednagar, India

display for

Keskar Saurabh Rajendra, Department of ETC, P.R.E.C. Loni,

Ahmednagar, India input and

Unhale Vishal Popat, Department of ETC, P.R.E.C. Loni, Ahmednagar, output.

India

Sangle Avinash Ramchandra, Department of ETC, P.R.E.C. Loni,

Ahmednagar, India

259 Published By:

Blue Eyes Intelligence Engineering

& Sciences Publication Pvt. Ltd.

Advanced Paper Cutting Machine using ARM7

V. BLOCK DIAGRAM DISCRIPTION RS-232: To provide remote programming facility. Optional

Ethernet interface can be provided to increase the remote

Controller: - ARM7 is selected as controller. This

programming distance.

generation introduced the Thumb 16-bit instruction set

providing improved code density compared to previous

VI. PRINCIPLE OF DISPLACEMENT

designs. The most widely used ARM7 designs implement

MEASUREMENT

the ARMv4T architecture, but some implement ARMv3 or

ARMv5TEJ. All these designs use a Von Neumann Lead Screw:

architecture, thus the few versions comprising a cache do Usually using mechanical means viz. racks and pinions or

not separate data and instruction caches. Some ARM7 cores lead screws and rotary encoder, one can measure straight-

are obsolete. One historically significant model, line or linear motion. In our application we are using lead

screw for translating turning motion into linear motion. It is

the ARM7DI[1] is notable for having

often assumed that the pitch (threads per linear distance) is

introduced JTAG based on-chip debugging; the preceding precisely known. This assumes the pitch is constant at every

ARM6 cores did not support it. The "D" represented a JTAG location along the lead-screw.

TAP for debugging; the "I" denoted an Icebreaker debug

module supporting hardware breakpoints and watch points,

and letting the system be stalled for debugging. Subsequent

cores included and enhanced this support. It is a versatile

processor designed for mobile devices and other low power

electronics. This processor architecture is capable of up to

130 MIPS on a typical 0.13 µm process. The ARM7TDMI

processor core implements ARM architecture v4T. The

processor supports both 32-bit and 16-bit instructions via the

ARM and Thumb instruction sets

Rotary Encoder: A rotary encoder also called a shaft Fig.2 Lead Screw Motor Coupling

encoder is an electro-mechanical device that converts

Calibrating the number of pulses per unit of measure

the angular position or motion of a shaft or axle to an

involves selecting the proper transducer and may include a

analog or digital code. There are two main types: absolute

separate calibration step. The relationship between

and incremental (relative). The output of absolute encoders

resolution, lead screw pitch, and rotary encoder’s PPR is

indicates the current position of the shaft, making them

shown below.

angle transducers. The output of incremental encoders

provides information about the motion of the shaft, which is

typically further processed elsewhere into information such

as speed, distance, and position. Rotary encoders are used in

many applications that require precise shaft unlimited

rotation—including industrial controls, robotics, special

Example:

purpose photographic lenses,[1] computer input devices

Let lead screw pitch is 10 which means it moves the bed

(such as opt mechanical mice and trackballs), controlled 1/10th inch for every revolution. That means Linear

stress rheometers, and rotating radar platforms. displacement = 0.1″per revolution. Assume desired system

In this project rotary encoder is used for measurement of resolution is 0.000 1″ then required encoder PPR will be,

accurate displacement of the paper. 0.1/ 0.000 1 = 1000 counts per revolution.

Touch Screen:-A touchscreen electronic visual VII. FUNCTIONAL OVERVIEW

display that the user can control through simple or multi- Controller unit basically controls the position of the back

touch gestures by touching the screen with one or more gauge according set cut size. Unit cut size can accept cut

fingers. Some touchscreens can also detect objects such as size in millimetre unit or inch unit. Unit will have resolution

of 0.01mm measurement.

a stylus or ordinary or specially coated gloves. The user can

System will have five modes of operation –

use the touch screen to react to what is displayed and to

Setup Mode, Program Mode, Semi-Auto mode, Manual

control how it is displayed.

Mode, Teach Mode

In this project touch screen is used for giving inputs,

1. Setup Mode – It is a cutting machine configuration

selecting modes etc.

mode. Here user can set the machine configuration

Stepper Motor:-Stepper motor is used for the back gauge

parameters viz. lead screw pitch, rotary encoder PPR, min.

shifting, which shifts paper with accurate distance. Rotary

cut size, max. Cut size, knife change alarm, push out size,

encoder is attached to the stepper motor to measure distance

motor brake limit, position tolerance etc.

and give digital output.

2. Program mode – here user can create up to 200

DC motor:-DC motor is connected to knife through

programs each of which can have cut positions. Unit has

conveyor belt. DC motor controls knife movements. Motor

built in calculator which can be accessed during

speed is controlled by ARM.

programming to set the cut sizes. User can make program

for label cutting easily- just by feeding total paper size &

260 Published By:

Blue Eyes Intelligence Engineering

& Sciences Publication Pvt. Ltd.

International Journal of Engineering and Advanced Technology (IJEAT)

ISSN: 2249 – 8958, Volume-3, Issue-4, April 2014

label cut size. Operator can change the program setting on-

line or by remote programming through RS-232 or Ethernet.

Unique remote programming facility saves operator’s time

& hence production cost.

3. Semi-auto mode – This mode uses the program made in

program mode to execute the job with different cut sizes.

This mode saves operator’s time in taking jobs with variety

of cut sizes.

4. Manual mode – Here firstly user sets the cut size using

numeric keypad and then goes for execution Controller unit

is featured with colour graphic interface where user can

view the progress the process. It provides precise motor

motion control with the help of incremental encoder

feedback.

5. Teach Mode: This is most important mode of this system

that makes it advance. In this mode of operation, run time

user can create a program of variable cut sizes. In this mode

user first selects empty program and it operates unit same as

in manual mode only the difference is once cut is taken by

the operator, the achieved position gets saved as a cut size

inside the empty program selected.

VIII. PROPOSED MODULES:-

Controller: - ARM7

Rotary Encoder:-

External inputs: - RS-232

Stepper motor: - 15V

DC Motor: - 30V

Display Screen: - 5” Capacitive Touch Screen.

IX. ADVANTAGES:-

1. Reduction in cost as compare to conventional

machines.

2. Most main advantage is that machine and record

manual cut and repeat it.

3. Reduction of man power.

4. Fast cutting can be done in auto mode.

5. Gross error is reduced in great extent due to no direct

human interaction.

6. Instructions can be given by PC using RS232.

X. CONCLUSION:-

This system presents a different approach to make

traditional hand lever paper cutter machine intelligent.

Controller unit’s user friendly interface & Semi-automatic

mode saves operator’s time, increases productivity &

reduces production cost. Also machine can learn new cuts

by recording manual cutting.

REFERENCES

[1] Gheorghe Livinţ, VasilHorga, Marcel Răţoi and Mihai Albu

Gheorghe Asachi Technical University of Iaşi Romania.

[2] Abdel Azzeh, Richard duke “CAN control system for Electric

Vehicle”, ENZCon 2005, the 12th Electronics New Zeland

Conference. Manukau City, New Zealand, November 2005.

[3] Kumar, M. A.Verma, and A. Srividya, Response-Time

“Modeling of Controller Area Network (CAN). Distributed

Computing and Networking,

261 Published By:

Blue Eyes Intelligence Engineering

& Sciences Publication Pvt. Ltd.

You might also like

- Ijser: Arduino Controlled Automatic Paper Stamping MachineDocument3 pagesIjser: Arduino Controlled Automatic Paper Stamping MachineStefan SmarandacheNo ratings yet

- ILaser English 2019new (HQ) - CompressedDocument16 pagesILaser English 2019new (HQ) - CompressedWAREN COLOMBIA SAS MVD MAKINANo ratings yet

- Development of Semi-Automatic Lathe by Using Intelligent Soft Computing TechniqueDocument6 pagesDevelopment of Semi-Automatic Lathe by Using Intelligent Soft Computing TechniquePrabhataNo ratings yet

- Ijert Ijert: Analysis of Radial Cam With Roller FollowerDocument5 pagesIjert Ijert: Analysis of Radial Cam With Roller Followersmg26thmayNo ratings yet

- 58 62SmartRoboticArmDocument5 pages58 62SmartRoboticArmLakshmi PriyaNo ratings yet

- TurretPunches PDFDocument9 pagesTurretPunches PDFDamir F RastoderNo ratings yet

- Aco 08 DS 2020 08 31 en A4Document2 pagesAco 08 DS 2020 08 31 en A4omarrg7No ratings yet

- Intelligent Robot Motion Control & Data Acquisition System for Industrial Monitoring Using Image Processing Techniques (39Document3 pagesIntelligent Robot Motion Control & Data Acquisition System for Industrial Monitoring Using Image Processing Techniques (39ObiEuanNo ratings yet

- Smart Quill (By Sarath Kumar)Document39 pagesSmart Quill (By Sarath Kumar)sarathkumar.hi2947100% (6)

- Drawing Robot: Keyur Jain, Akash Nair, Prof. Shikha SinghDocument5 pagesDrawing Robot: Keyur Jain, Akash Nair, Prof. Shikha Singhhasan alsarrafNo ratings yet

- In-Sight Laser Profiler DatasheetDocument8 pagesIn-Sight Laser Profiler DatasheetKhalîl ÐkhílíNo ratings yet

- 3 Axis Drawing Machine PDFDocument5 pages3 Axis Drawing Machine PDFDhanar Tri AtmajaNo ratings yet

- Design and Fabrication of Portable Laser Cutting A PDFDocument5 pagesDesign and Fabrication of Portable Laser Cutting A PDFMohamad GhosenNo ratings yet

- Introduction To CNC MachinesDocument78 pagesIntroduction To CNC MachinesPRADYUM PALNo ratings yet

- Design & Implementation of Motion Controller For Industrial Paper Cutting MachineDocument7 pagesDesign & Implementation of Motion Controller For Industrial Paper Cutting MachineEditor IJRITCCNo ratings yet

- Vdocuments - MX - Durma Catalogue 1Document88 pagesVdocuments - MX - Durma Catalogue 1Vladimir BritoNo ratings yet

- Review On Design and Development of Robotic Arm Generation 1Document3 pagesReview On Design and Development of Robotic Arm Generation 1International Journal of Innovative Science and Research TechnologyNo ratings yet

- An Efficient Approach of Taking Quick and Simple Notes in The Air Through Smart Note TakerDocument9 pagesAn Efficient Approach of Taking Quick and Simple Notes in The Air Through Smart Note TakerRoney George100% (1)

- Imagingproblem PDFDocument9 pagesImagingproblem PDFhridoy bosuniaNo ratings yet

- Sub-Board Machine 分板机Document12 pagesSub-Board Machine 分板机Wembley OliveiraNo ratings yet

- 5 Degrees of Freedom Robotic Arm Controlled Using PS/2 MouseDocument3 pages5 Degrees of Freedom Robotic Arm Controlled Using PS/2 MouseerpublicationNo ratings yet

- Obstacle Avoidance Robot Using Arduino IJERTCONV6IS13197Document4 pagesObstacle Avoidance Robot Using Arduino IJERTCONV6IS13197Xaf FarNo ratings yet

- Defender BrochureDocument12 pagesDefender BrochureWayne HoppeNo ratings yet

- ZCC+Features ListDocument7 pagesZCC+Features ListMirjana EricNo ratings yet

- Alpine E200ls enDocument20 pagesAlpine E200ls ensanaNo ratings yet

- Study On Computer Numerical Control (CNC) MachinesDocument5 pagesStudy On Computer Numerical Control (CNC) Machinesandri enggopNo ratings yet

- GTTC ReportDocument27 pagesGTTC ReportDhavan Y Kumar100% (2)

- Observing Tool Bit Conditions in Turning Process Through Opencv Programming FunctionDocument9 pagesObserving Tool Bit Conditions in Turning Process Through Opencv Programming FunctionAmine SassiNo ratings yet

- Practical Exam I. SawDocument2 pagesPractical Exam I. SawPepC MalolosNo ratings yet

- Hand Gesture Control Robot - Benjula Anbu Malar M B, Praveen R, Kavi Priya K PDocument5 pagesHand Gesture Control Robot - Benjula Anbu Malar M B, Praveen R, Kavi Priya K PCarina FelnecanNo ratings yet

- tc6832 PDFDocument48 pagestc6832 PDFRogerio CastelhanoNo ratings yet

- HPRXD Plasma Cutter Performance from ART CNCDocument6 pagesHPRXD Plasma Cutter Performance from ART CNCWagner MenezesNo ratings yet

- CNCMachine Based Laser Engraver With Arduino UNODocument10 pagesCNCMachine Based Laser Engraver With Arduino UNOSteve JobNo ratings yet

- Tool inspection and measuring technology for maximum performanceDocument10 pagesTool inspection and measuring technology for maximum performanceAnil KumarNo ratings yet

- Automated Writing and Drawing Machine: M. Aditi S. Karpagam, B. Nandini, B. S. MuruganDocument3 pagesAutomated Writing and Drawing Machine: M. Aditi S. Karpagam, B. Nandini, B. S. MuruganDeepanshu VermaNo ratings yet

- Leather Cutting MachineDocument3 pagesLeather Cutting MachineJoni BobiNo ratings yet

- CNC PDFDocument125 pagesCNC PDFg1974611100% (1)

- Brochure 2DDocument12 pagesBrochure 2DaniketgunjalNo ratings yet

- Ijramt V4 I2 17Document5 pagesIjramt V4 I2 17naeemudheenm45No ratings yet

- Refine Brochure a4 Compact 2022 Gb Highres Single PagesDocument8 pagesRefine Brochure a4 Compact 2022 Gb Highres Single PagesOCTAVINo ratings yet

- Overview On The Object Rejection and Counting Machine: July 2017Document4 pagesOverview On The Object Rejection and Counting Machine: July 2017dhanshri kolekarNo ratings yet

- AI Nano CNC For High-Speed, High-Accuracy MachiningDocument24 pagesAI Nano CNC For High-Speed, High-Accuracy MachiningarashNo ratings yet

- Automatic drilling machineDocument9 pagesAutomatic drilling machineNuri MiraniNo ratings yet

- Ijsred V5i3p21Document11 pagesIjsred V5i3p21Samuel AbraghamNo ratings yet

- Takayama 2016Document4 pagesTakayama 2016Varun GuptaNo ratings yet

- Minor PublicationsDocument20 pagesMinor Publications20-311 AkhilNo ratings yet

- Datasheet CybTouch 8 PSe PS V2.x enDocument6 pagesDatasheet CybTouch 8 PSe PS V2.x enmajidsaee33No ratings yet

- Bluetooth Control Pick and Place Robot Using Arduino IJERTCONV10IS11043Document3 pagesBluetooth Control Pick and Place Robot Using Arduino IJERTCONV10IS11043Ernest ChiwaleNo ratings yet

- Design and Development of Automatic Coil Winding MachineDocument5 pagesDesign and Development of Automatic Coil Winding Machinesandeep sNo ratings yet

- Inventor HSM BrochureDocument9 pagesInventor HSM Brochureah.abdlsalamNo ratings yet

- Design and Implementation of 3 Axis CNC Milling MachineDocument7 pagesDesign and Implementation of 3 Axis CNC Milling Machineအောင် ချစ်သူNo ratings yet

- Remote Area Monitoring RobotDocument5 pagesRemote Area Monitoring RobotIJSTENo ratings yet

- 45 1514966110 - 03-01-2018 PDFDocument3 pages45 1514966110 - 03-01-2018 PDFEditor IJRITCCNo ratings yet

- Mtab AristopdfDocument1 pageMtab Aristopdfalagar krishna kumar0% (1)

- Mitutoyo - Mikrometry Laserowe Laser Scan Micrometer - E13004 - 2016 ENDocument40 pagesMitutoyo - Mikrometry Laserowe Laser Scan Micrometer - E13004 - 2016 END.T.No ratings yet

- 9 May2019Document4 pages9 May2019Jay Prakash Narayan VermaNo ratings yet

- Wohlenberg CuttersDocument16 pagesWohlenberg CuttersMOHAMEDELHELALYNo ratings yet

- H-2000-8309 High-Accuracy Machine Tool Probes With RENGAGE TechnologyDocument20 pagesH-2000-8309 High-Accuracy Machine Tool Probes With RENGAGE TechnologyConexion Consciente CcNo ratings yet

- CNC Router Essentials: The Basics for Mastering the Most Innovative Tool in Your WorkshopFrom EverandCNC Router Essentials: The Basics for Mastering the Most Innovative Tool in Your WorkshopRating: 5 out of 5 stars5/5 (3)

- Marine BiologyDocument1 pageMarine BiologychotichanduNo ratings yet

- NanotechDocument1 pageNanotechchotichanduNo ratings yet

- NanobiologyDocument1 pageNanobiologychotichanduNo ratings yet

- Automatic Paper Cutting Machine by Using Geneva Mechanism: Journal of Analysis and Computation (JAC)Document4 pagesAutomatic Paper Cutting Machine by Using Geneva Mechanism: Journal of Analysis and Computation (JAC)chotichanduNo ratings yet

- Towards Rapid Genotyping of Resistant Malaria Parasites: Could Loop-Mediated Isothermal Amplification Be The Solution?Document2 pagesTowards Rapid Genotyping of Resistant Malaria Parasites: Could Loop-Mediated Isothermal Amplification Be The Solution?chotichanduNo ratings yet

- Engineering Metralogy and Mesurements Local Author Vijayaragavan BookDocument283 pagesEngineering Metralogy and Mesurements Local Author Vijayaragavan BookTavi SharmaNo ratings yet

- Design and Analysis of Paper Cutting Machine Works On Geneva Mechanism Ijariie1940Document6 pagesDesign and Analysis of Paper Cutting Machine Works On Geneva Mechanism Ijariie1940narkuys syukranNo ratings yet

- Microbial Cellulases Production, Applications and ChallengesDocument13 pagesMicrobial Cellulases Production, Applications and ChallengessauldnegreiraNo ratings yet

- Bacteria Producing CellulaseDocument11 pagesBacteria Producing CellulasechotichanduNo ratings yet

- Isolation of Bacillus From Garden Soil PDFDocument11 pagesIsolation of Bacillus From Garden Soil PDFchotichanduNo ratings yet

- Isolation of Bacillus From Garden Soil PDFDocument11 pagesIsolation of Bacillus From Garden Soil PDFchotichanduNo ratings yet

- Product Manual - SSt-1500 v3.5Document119 pagesProduct Manual - SSt-1500 v3.5Meison EreipaNo ratings yet

- GSK GS LServo DriveUser Manual EfamaticDocument137 pagesGSK GS LServo DriveUser Manual EfamaticBagus AfandiNo ratings yet

- Liner EncoderDocument48 pagesLiner EncoderShahzad AnwarNo ratings yet

- 11-4 Troubleshooting: Alarm Display Error Conditions Status When Error Occurs Cause MeasuresDocument1 page11-4 Troubleshooting: Alarm Display Error Conditions Status When Error Occurs Cause MeasuresDominique KomeyNo ratings yet

- B3 Motor CatalogueDocument56 pagesB3 Motor CatalogueXuan Tien VuNo ratings yet

- Brochure - BONFIGLIOLI Motar For Roll Shutter - EN PDFDocument48 pagesBrochure - BONFIGLIOLI Motar For Roll Shutter - EN PDFsdvijayNo ratings yet

- Sharp Rotary Encoders Mar1986Document60 pagesSharp Rotary Encoders Mar1986Jules VERNESNo ratings yet

- CAPL tips for advanced usersDocument4 pagesCAPL tips for advanced usersMohammad FaizanNo ratings yet

- A6N Presen R6eDocument103 pagesA6N Presen R6eErick De La FuenteNo ratings yet

- CNC Machine Feedback Devices and Positioning SystemsDocument6 pagesCNC Machine Feedback Devices and Positioning Systemsio1_ro100% (1)

- Xilinx UG230 Spartan-3E FPGA Starter Kit Board User GuideDocument166 pagesXilinx UG230 Spartan-3E FPGA Starter Kit Board User GuideMosu MisuNo ratings yet

- Mechatronics Experiment List and DetailsDocument46 pagesMechatronics Experiment List and DetailsDnaneshwarNo ratings yet

- V Controller GeneralDocument212 pagesV Controller Generalattila_tamas4283100% (1)

- Incremental Encoder Output Signal OverviewDocument3 pagesIncremental Encoder Output Signal OverviewmicaNo ratings yet

- S SeriesDocument284 pagesS SeriestatoddoNo ratings yet

- Cat Linear Encoders 0717 PDFDocument44 pagesCat Linear Encoders 0717 PDFSSECECENo ratings yet

- AC Series Lift Control System: User ManualDocument62 pagesAC Series Lift Control System: User ManualCosmo MovieNo ratings yet

- Omniwheel Kiwi Drive Inverse KinematicDocument50 pagesOmniwheel Kiwi Drive Inverse KinematicHandriToarPangkeregoNo ratings yet

- ARL-300 Shaft Learning With Encoder-Installation Manual - enDocument14 pagesARL-300 Shaft Learning With Encoder-Installation Manual - enkizonimeisterNo ratings yet

- p059 Cj2-Series Datasheet enDocument78 pagesp059 Cj2-Series Datasheet eneftamargoNo ratings yet

- Omron E6CP AG5C C DatasheetDocument6 pagesOmron E6CP AG5C C DatasheetJavier RiveraNo ratings yet

- 1047 ErDocument34 pages1047 ErVO DUC ThaoNo ratings yet

- Food Processing & Automation EncoderDocument4 pagesFood Processing & Automation EncoderJortonNo ratings yet

- FasfasDocument8 pagesFasfasRifqi FirlianNo ratings yet

- Slyb 165 IDocument54 pagesSlyb 165 IMADDYNo ratings yet

- Ch 6 Displacement SensorsDocument103 pagesCh 6 Displacement SensorsMarey Morsy100% (2)

- Report - Custom ControllerDocument65 pagesReport - Custom Controllerapi-328908990100% (1)

- Stepping Motor EncoderDocument32 pagesStepping Motor EncoderAsistencia Técnica JLFNo ratings yet

- Encodere China PDFDocument84 pagesEncodere China PDFALEXANDRU ZANOAGANo ratings yet