Professional Documents

Culture Documents

Draft Relationships For Tillage and Seed

Uploaded by

vodounnouOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Draft Relationships For Tillage and Seed

Uploaded by

vodounnouCopyright:

Available Formats

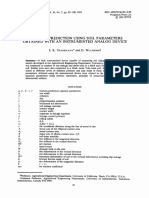

DRAFT RELATIONSHIPS FOR TILLAGE AND SEEDING EQUIPMENT

T. M. Harrigan, C.A. Rotz

ABSTRACT. A general model with machine- and soil-specific parameters is proposed to estimate the draft of tillage and

seeding implements under general conditions. Machine draft is estimated as a function of soil texture, implement width,

depth, and speed of operation for most major operations. The model requires little knowledge of specific soil conditions

but provides reasonable, average draft values for general conditions. Machine- and soil-specific parameters developed

from currently available draft information for most tillage and seeding operations are presented in convenient reference

tables. Keywords. Tillage, Seeding equipment, Draft, Machinery management.

D

raft information is frequently used in machinery components that allow a range of control over the amount

management to calculate power requirements of of crop residue left on the soil surface after tillage and

tillage and seeding operations. Farm managers combination tillage tools that combine multiple tillage

and consultants use draft or power data to match operations are now in common use. When seedbed tillage

tractors with implements and to estimate fuel requirements. is reduced or eliminated, the planter or drill becomes the

Farm system computer models often require draft and primary equipment used. Many planters are now designed

power data to select farm machinery, simulate the to cut through surface residue and in some cases to till a

performance of farming systems, and compare the zone of soil for the seed furrow. Draft requirements for

performance of alternative farming systems. Accurate these new tillage and seeding implements are different

information on draft requirements is needed to create valid from those published in the current machinery management

models. standards (ASAE, 1994a). An update of the ASAE draft

For 40 years, ASAE has published data on draft and data will provide a more accurate representation of current

power requirements of agricultural equipment for use by tillage and seeding practices.

machinery managers (Rotz and Muhtar, 1992). Periodic This article reviews available information on the draft of

updating of this data is required to maintain current and tillage and seeding equipment and develops a simple

useful information. Farming practices and machinery mathematical model for general use. Specific objectives of

change as new technology and information become this study were to develop:

available. New designs may also alter machine draft or • An equation with machine- and soil-specific

power requirements. A study was recently completed to parameters that estimates draft for tillage and

update the ASAE data on rotary power requirements (Rotz seeding operations across a range of soil textures.

and Muhtar, 1992). New information is also available from • A reference table of machine- and soil-specific

research and machinery manufacturers to update the ASAE parameters for major tillage and seeding

tillage and seeding equipment draft data. Since the last implements.

revision of the draft data occurred over 15 years ago, a

thorough review of available information for updating

ASAE Standards is required. PROCEDURE

Many changes in tillage and planting equipment have A model for general use was developed to estimate draft

occurred during the past 15 years. Conservation tillage of tillage and seeding equipment. For this model, draft was

practices are replacing moldboard plowing and seedbed defined as the force required to propel an implement in the

tillage on a large portion of the total crop area. Tillage tool direction of travel (ASAE, 1994d). Both functional draft

(soil and crop resistance) and draft required to overcome

rolling resistance of the implement were included with one

Article was submitted for publication in April 1995; reviewed and exception. For manure injection, the rolling resistance for

approved for publication by the Power and Machinery Div. of ASAE in pulling the tank spreader was not included. In this case,

July 1995. Presented as ASAE Paper No. 94-1533. standard procedures are available for calculating the draft

All programs and services of the USDA are offered on a due to rolling resistance. Rotary power is not often used in

nondiscriminatory basis without regard to race, color, national origin,

religion, sex, age, marital status, or handicap. tillage and seeding operations and therefore was not

The authors are Timothy M. Harrigan, ASAE Member, Visiting included. If used, rotary power can be calculated by

Associate Professor, and C. Alan Rotz, ASAE Member Engineer, documented procedures (Rotz and Muhtar, 1992) and

Agricultural Engineer, U.S. Dairy Forage Research Center, USDA- added to the power requirement due to draft to obtain the

Agricultural Research Service, Agricultural Engineering Dept., Michigan

State University, East Lansing. Corresponding author: Timothy M. total power requirement for the operation.

Harrigan, 220 Farrall Hall, Michigan State University, East Lansing, MI The draft force required to pull many seeding

48824-1323; telephone: 517-353-0767. implements and minor tillage tools operated at shallow

Applied Engineering in Agriculture

VOL. ll(6):773-783 © 1995 American Society of Agricultural Engineers 0883-8542 / 95 /1106-0773 773

depths is primarily a function of the width of the published for specific conditions and, based on a

implement and the speed at which it is pulled. For tillage comparison of reported data across soil textural groups, the

tools operated at deeper depths, draft also depends upon parameters were extrapolated to a wider range of

depth (Summers et al., 1986; Khalilian et al., 1988; conditions. If parameter estimates were not previously

Grisso et al., 1994) and geometry of the tool published, the draft/speed relationship was estimated from

(Upadhyaya et al., 1984). Wide variations in draft are published data of similar tools, and the ratio of the

common both within and between soil textural groups due coefficient of speed (B or C) to the constant (A) was

to soil moisture, residue cover, and other soil and machine maintained. Parameters selected were not necessarily the

physical characteristics (Bowers, 1989). means of available data. The values selected more closely

A simple function is proposed to model tillage draft represented the median values across the full range of

under general conditions where draft is a function of soil available data. These values were more representative of

texture, implement width, depth, and speed of operation. A typical operating conditions on the three major soil

form of this model was previously used by ASAE (1994a) classifications.

for reporting draft of a range of tillage and seeding In the proposed model, soil is categorized as fine,

implements and Summers et al. (1986) for reporting medium, or coarse rather than using traditional soil

moldboard plow, chisel plow, sweep plow, and disk harrow classifications such as clay or loam. Fine textured soils are

draft. Compared to using several different equations, this described as predominantly clay, medium textured are

simple equation with machine- and soil-specific parameters loamy soils and coarse textured are sandy soils. This

has the advantage of being easily understood and method of grouping soils has been used by Rotz and Black

convenient to use. (1985) and to a limited extent by others (Hunt, 1977;

White, 1977). This form of classification is currently used

D = FiX[A + B(S) + C ( S ) 2 ] x W x T D (1) by some tillage implement and herbicide application

equipment manufacturers.

where Because draft varies with machine design, machine

D = implement draft, kN (lbf) adjustment, machine age, and site-specific conditions

F = soil texture adjustment parameter including soil moisture and residue cover, a range in draft

i = 1 for fine, 2 for medium, and 3 for coarse values must be considered. Most often a typical value is

textured soils required; however, this value should be set within an

A,B, acceptable range. Both a typical value and an acceptable

and C = machine-specific parameters range of typical draft requirements are presented. Large

S = field speed, km/h (mph) fluctuations in draft occur as the machine moves through

W = machine width (m, ft), number of rows or the field, but this variation is not reflected in this range.

tools The range gives the expected variation of average or

TD = tillage depth (cm, in.) for major tillage tools, typical draft as machine and soil conditions not considered

1 (dimensionless) for minor tillage tools, and in the model vary.

seeding implements Parameter development for each implement type is

Although the same equation was used for all machines, presented through a summary of the available data for that

only one or two of the machine and soil-specific particular operation. Similarities among implement types is

parameters were used to describe the draft of any given also discussed as used to maintain consistency across

machine. implement types. A description of tillage tools and

This simple relationship was selected for a few reasons. components can be found in the ASAE Standards (1994b, c,

Most tillage draft data are published in the units of one or d). Implements commonly used for conservation tillage

two of these three parameters (A, B, and C). Equations were described by Siemens et al. (1992).

have been developed for specific implements such as the

moldboard plow which relate draft to site-specific

conditions (Eradat-Oskoui and Witney, 1982; Eradat- TILLAGE EQUIPMENT

Oskoui et al., 1982), but valid results require detailed SUBSOILERS

information about soil conditions. Information published in Subsoiler draft is affected by soil texture, strength and

the ASAE Standards requires a more general model which moisture content, tillage depth, operating speed, and

provides reasonable values for typical conditions without subsoiler geometry. Since subsoilers are designed to

knowledge of specific soil conditions. penetrate and shatter dense, high-strength soil layers, draft

The major effort in model development was determining tends to be highly variable. Draft in clay soils can be more

the machine parameters A, B, and C. Each parameter was a than twice that in sandy soils (Nichols and Reaves, 1958;

function of tillage tool design. The constant parameter A Frisby and Summers, 1979; Trouse and Reaves, 1980;

was a function of soil strength while the coefficient of Wildman et al., 1978). Curved (parabolic) or inclined

speed parameters (B or C) were related to soil bulk density. subsoil shanks typically create 10 to 20% lower draft than

Soil strength was assumed to decline and bulk density to vertical shanks at the same depth (Nichols and Reaves,

increase from fine to coarse textured soils. Using these 1958; Smith and Williford, 1988; Upadhyaya et al., 1984).

principles and a thorough review of published draft data, Garner et al. (1987) reported greater draft in soils with a

the functional form was identified and machine- and soil- shallow B-horizon. Subsoiler draft is reported as a positive

specific parameters were selected. linear function of depth (ASAE, 1994a; Garner and Wolf,

The primary source for new draft data was published 1981; Upadhyaya et al., 1984) and a quadratic function

research. In some cases, the machine parameters were

774 APPLIED ENGINEERING IN AGRICULTURE

with respect to speed (Owen, 1989; Upadhyaya et al., LIQUID MANURE INJECTORS

1984). Direct soil injection of liquid manure conserves nitrogen

Soil reactions to tillage tools is influenced by soil and greatly reduces the odor associated with surface

conditions and tool geometry. Tillage tines shatter soil at an spreading. Winged injector points reduce draft

angle from a point just above the tine tip to the soil surface requirements by creating more void space and permitting

(angle of crescent failure). The angle of crescent failure shallower injection than possible with narrow points

varies, but it generally ranges from 20° to 45° from vertical (Godwin et al., 1976; Negi et al., 1978). A winged injector

(Cooper, 1971; Spoor and Godwin, 1978; Koohestani and can inject nearly twice the manure volume at a given depth

Gregory, 1985; Gregory and M'Hedhbi, 1988). Below a as a narrow injector (Godwin et al., 1985). Winged

critical depth, soil only flows forward and sideways (lateral injectors also distribute the manure over a wider area and

failure) around the point, compacting soil in the area of the decrease the potential for root inhibition and nitrogen loss

point without increasing soil disturbance (Spoor and (Schmitt and Hoeft, 1986).

Godwin, 1978). The critical depth is a function of subsoiler Liquid manure injector draft data is not included in the

point geometry. Tines of similar width and rake angle have current ASAE data. Winged injector draft ranging from

about the same critical depth. The critical depth with a 1.5 kN (337 lbf) in loose sand to 6 kN (1350 lbf) in clay

narrow subsoiler point is typically about 30 cm (12 in.) loam was reported by Negi et al. (1978) for 30 cm (12 in.)

(Cooper, 1971), but this depth is likely deeper in clay than wide sweep injectors operating at a depth of 10 to 15 cm

sandy loam soils (Owen, 1988). In a given soil, the critical (4 to 6 in.). In a firm clay soil, draft of 5 to 6.2 kN (1124 to

depth is deeper in friable than in wet or plastic soil 1394 lbf) at a depth of 20 cm (8 in.) was reported by Lague'

conditions (Spoor and Godwin, 1978). (1991). Godwin et al. (1985) reported a draft of 5.4 kN

Winged attachments are often added to conventional, (1214 lbf) at a depth of 13 cm (5 in.). Hann et al. (1987)

narrow subsoiler points to increase soil shatter. Wings reported a higher draft (1.9 kN, 427 lbf) in the wheel track

increase both the critical depth (Owen, 1988; Spoor and of a loaded, 3028 L (800 gal) tanker than that behind an

Godwin, 1978; Mielke et al., 1994) and the amount of soil empty tanker (1.1 kN, 247 lbf) or an umbilical injector

disturbed (Spoor and Godwin, 1978; Ahmed and Godwin, (1 kN, 225 lbf). Scarborough et al. (1978) cited Horsfield

1983; Mielke et al., 1994). Spoor and Godwin (1978) (1974) indicating that compared to surface spreading,

measured draft and area disturbed with narrow and 30 cm slurry injection at a 20 cm (8 in.) depth with a narrow point

(12 in.) winged points at different depths. When winged required 13.4 kW (18 hp) per injector in addition to tanker

and narrow points were operated above the critical depth, rolling resistance.

the winged attachments more than doubled the disturbed The proposed liquid manure injector draft parameters do

area with only a 30% increase in draft. When operated not include tanker rolling resistance. Similar to subsoiler

below the critical depth of the narrow point, soil draft, the proposed parameters are a positive linear function

disturbance with the winged point was more than three of depth and quadratic with speed (table 1). To be

times that of the narrow point with only a 10% increase in consistent with subsoilers, draft in medium and coarse

draft. A shallow, winged shank leading a deeper, narrower textured soils is estimated as 70% and 45%, respectively, of

shank significantly increased soil disturbance, and the draft that for fine-textured soils. The proposed data for injector

required for the additional winged point decreased as draft in a fine-textured soil is similar to that reported by

tillage depth increased (Mielke et al., 1994). Reeder et al. Godwin et al. (1985) and Negi et al. (1978) for winged

(1992) reported that 25 cm (10 in.) wings increased draft injectors in clay loam and Lague (1991) in firm clay soils.

about 70% and 35 cm (14 in.) wings more than doubled the Based on the proposed parameters, injector draft ranges

draft of a 5 cm (2 in.) point in a silt loam soil. from 200 N/tool/cm (114 lbf/tool/in.) in a coarse textured

Reported draft for a conventional, narrow subsoiler soil to 450 N/tool/cm (257 lbf/tool/in.) in a fine-textured

shank varies widely, ranging from 90 to 675 N/tool/cm soil (table 1).

(51 to 385 lbf/tool/in.) (Wolf et al., 1981; Wildman et al.,

1978). Based on a comparison of reported draft across soil MOLDBOARD PLOWS

textural groups, subsoiler draft in medium and coarse Moldboard plow draft data (per cross-section of tilled

textured soils is estimated as 70% and 45%, respectively, of soil) is well documented for several soil textural groups

that for fine-textured soils (Bowers, 1989; Cooper, 1971; ranging from sand to clay loam (ASAE, 1994a). Draft is

Godwin et al., 1985; Khalilian et al., 1988; Mielke et al., described as a positive linear function of depth and

1994; Reeder et al., 1992; Shinners, 1989; Smith and quadratic with respect to speed. The ASAE data note that

Williford, 1988; Smith, 1989; Spoor and Godwin, 1978; soil moisture and specific gravity affect plow draft, but the

Trouse and Reaves, 1980; Wildman et al., 1978; Williams relationship is not quantified. A model to estimate

et al., 1979; Wolf et al., 1981). Draft is linearly related to moldboard plow draft utilizing soil moisture and strength

depth and quadratic with respect to speed (table 1). At was proposed by Eradat-Oskoui and Witney (1982) and

6.4 km/h (4 mph), the proposed draft ranges from about tested by Eradat-Oskoui et al. (1982). In their model, draft

135 to 300 N/tool/cm (77 to 171 lbf/tool/in.), similar to was calculated as a function of soil cone index, soil

current ASAE data which ranges from about 150 to moisture, soil specific weight, depth and width of tillage,

315 N/tool/cm (86 to 180 lbf/tool/in.). Draft for a plow speed, and plow tail angle. The proposed model

subsoiler with 30 cm (12 in.) winged points is estimated as predicted draft better than previous models for their

30% greater than that for a narrow point (Spoor and conditions. Since detailed soil information is generally not

Godwin, 1978). known, a simpler model is proposed for general use.

VOL. ll(6):773-783 775

Table 1. Draft parameters and an expected range in drafts estimated by the model parameters for tillage and seeding implements

Machine Machine Soil

Parameters, SI Parameters, English Parameters

SI English Range

Implement Units A B C Units A B C Fl F2 F3 ±%

MAJOR TILLAGE TOOLS

Subsoiler/manure injector

Narrow point N/tool/cm 226 — 1.81 lbf/tool/in. 129 — 2.71 1.0 0.70 0.45 50

30 cm winged point N/tool/cm 294 — 2.35 lbf/tool/in. 167 — 3.52 1.0 0.70 0.45 50

Moldboard plow N/cm2 6.5 — 0.051 lbf/in.2 9.4 — 0.191 1.0 0.70 0.45 40

Chisel plow

5 cm straight point N/tool/cm 91 5.39 — lbf/tool/in. 52 4.94 — 1.0 0.85 0.65 50

7.5 cm shovel/35 cm sweep N/tool/cm 107 6.34 — lbf/tool/in. 61 5.81 — 1.0 0.85 0.65 50

10 cm twisted shovel N/tool/cm 123 7.29 — lbf/tool/in. 70 6.68 — 1.0 0.85 0.65 50

Sweep plow

Primary tillage N/cm 2 3.9 0.19 — lbf/in.2 5.7 0.44 — 1.0 0.85 0.65 45

Secondary tillage N/cm 2 3.1 0.15 — lbf/in.2 4.5 0.35 — 1.0 0.85 0.65 35

Disk harrow, tandem

Primary tillage N/cm 2 3.09 0.16 — lbf/in.2 4.5 0.37 ^- 1.0 0.88 0.78 50

Secondary tillage N/cm 2 2.16 0.11 — lbf/in.2 3.1 0.26 — 1.0 0.88 0.78 30

Disk harrow, offset

Primary tillage N/cm 2 3.64 0.19 — lbf/in.2 5.3 0.44 — 1.0 0.88 0.78 50

Secondary tillage N/cm 2 2.54 0.13 — lbf/in.2 3.7 0.30 — 1.0 0.88 0.78 30

Disk gang, single

Primary tillage N/cm 2 1.24 0.06 — lbf/in.2 1.8 0.14 — 1.0 0.88 0.78 25

Secondary tillage N/cm 2 0.9 0.04 — lbf/in.2 1.2 0.09 — 1.0 0.88 0.78 20

Coulters

Smooth or ripple N/tool/cm 55 2.73 — lbf/tool/in. 31 2.50 — 1.0 0.88 0.78 25

Bubble or flute N/tool/cm 66 3.28 — lbf/tool/in. 37 3.00 — 1.0 0.88 0.78 25

Field cultivator

Primary tillage N/tool/cm 46.0 2.77 — lbf/tool/in. 26.0 2.54 — 1.0 0.85 0.65 30

Secondary tillage N/tool/cm 32.0 1.94 — lbf/tool/in. 19.0 1.78 — 1.0 0.85 0.65 25

Row crop cultivator

S-tine N/row/cm 140 7.00 — lbf/row/in. 80.0 6.41 — 1.0 0.85 0.65 15

C-shank N/row/cm 260 13.00 — lbf/row/in. 148 11.91 — 1.0 0.85 0.65 15

No-till N/row/cm 435 21.75 — lbf/row/in. 248 19.92 — 1.0 0.85 0.65 20

Rod weeder N/m/cm 210 10.70 — lbf/ft/in. 37.0 3.02 — 1.0 0.85 0.65 25

Disk-bedder N/row/cm 185 9.50 — lbf/row/in. 106 8.70 — 1.0 0.88 0.78 40

MINOR TILLAGE TOOLS

Rotary hoe N/m 600 — — lbf/ft 41 — — 1.0 1.0 1.0 30

Coil tine harrow N/m 250 — — lbf/ft 17 — — 1.0 1.0 1.0 20

Spike tooth harrow N/m 600 — — lbf/ft 40 — — 1.0 1.0 1.0 30

Spring tooth harrow N/m 2000 — — lbf/ft 135 — — 1.0 1.0 1.0 35

Roller packer N/m 600 — — lbf/ft 40 — — 1.0 1.0 1.0 50

Roller harrow N/m 2600 — — lbf/ft 180 — — 1.0 1.0 1.0 50

Land plane N/m 8000 — — lbf/ft 550 — — 1.0 1.0 1.0 45

SEEDING IMPLEMENTS

Row crop planter, prepared seedbed

Mounted-seeding only N/row 500 — — lbf/row 110 — — 1.0 1.0 1.0 25

Drawn-seeding only N/row 900 — — lbf/row 200 — — 1.0 1.0 1.0 25

Drawn-seed, fert. and herb. N/row 1550 — — lbf/row 350 — — 1.0 1.0 1.0 25

Row crop planter, no-till

Seed, fert. and herb.,

1 fluted coulter/row N/row 1820 — — lbf/row 410 — — 1.0 0.96 0.92 25

Row crop planter, zone-till

Seed, fert. and herb. N/row 3400 — — lbf/row 765 — — 1.0 0.94 0.82 35

Grain drill w/press wheels

< 2.4 m drill width N/row 400 — — lbf/row 90 — — 1.0 1.0 1.0 25

2.4-3.7 m drill width N/row 300 — — lbf/row 67 — — 1.0 1.0 1.0 25

> 3.7 m drill width N/row 200 — — lbf/row 25 — — 1.0 1.0 1.0 25

Grain drill, no-till

1 fluted coulter/row N/row 720 — — lbf/row 160 — — 1.0 0.92 0.79 35

Hoe drill

Primary tillage N/m 6100 — — lbf/ft 420 — — 1.0 1.0 1.0 50

Secondary tillage N/m 2900 — — lbf/ft 200 — — 1.0 1.0 1.0 50

Pneumatic drill N/m 3700 — — lbf/ft 250 — — 1.0 1.0 1.0 50

Bowers (1989) reported a wide range in draft both within 10% of measured values for clay and loam soils.

between and within soil textural groups. Differences within Summers et al. (1986) evaluated the effects of speed and

a textural group were presumably due to varying soil depth on moldboard plow draft in clay loam and silt loam

moisture and strength. Frisby and Summers (1979) found soils in Oklahoma and reported that measured data were

that predicted draft based on the ASAE data was high but closely estimated by the ASAE data. The draft data

776 APPLIED ENGINEERING IN AGRICULTURE

reported by Summers et al. (1986) confirmed the linear The proposed parameters for chisel plow draft (table 1)

increase of draft with depth and the quadratic relationship are based on a comparison of reported values across soil

with speed described by ASAE. textural groups (Bowers, 1989; Frisby and Summers, 1979;

Since most reported plow draft data are in reasonable Hendrick, 1980; Hunt, 1977; Reid, 1978, 1983; Self et al.,

agreement with the current ASAE data (Bowers, 1985; 1983; Stephens et al., 1981; Summers et al., 1986; Zwilling

Bowers, 1989; Chaplin et al., 1986; Frisby and Summers, and Hummel, 1988; Bashford et al., 1991). Draft is

1979; Nichols et al., 1958; Reaves and Schafer, 1975; Reid, generally found to be a linear function of both depth and

1978, 1983; Self et al., 1983; Stephens et al., 1981; speed (Summers et al., 1986; Kydd et al., 1984; Gregory

Summers et al., 1986; Wilkins and Rasmussen, 1993; and M'Hedhbi, 1988), but draft has also been reported to

Williams et al., 1979; Zwilling and Hummel, 1988), the be a quadratic function of depth (Grisso et al., 1994). Draft

proposed parameters (table 1) are based on the current parameters (A and B) for medium textured soils were

ASAE data. Draft is linear with respect to depth, quadratic established based on data reported by Summers et al.

with speed (ASAE, 1994a; Summers et al., 1986) and (1986) for silt loam soil. Through comparisons across data

adjusted for soil texture. Draft for medium and coarse sets, drafts in medium and coarse textured soils were set at

textured soils is estimated as 70% and 45%, respectively, of 85% and 65%, respectively, of the draft in fine-textured

that for fine-textured soils. Bowers (1989) reported that soil. Bowers (1989) reported that the ASAE data tended to

moldboard plow draft in the sandy loam soils of overestimate draft for chisel plows in the medium and

North Carolina tended to be underestimated by the ASAE coarse textured soils of North Carolina. Chisel plow draft

data. Based on the proposed parameters, estimated draft for based on the proposed parameters is lower than that

coarse textured soils is somewhat higher than that specified specified in the current ASAE data for these soils.

by ASAE for sand and sandy loam soils.

FIELD CULTIVATORS

CHISEL PLOWS Field cultivators are similar in design to chisel plows,

Compared to a moldboard plow, a chisel plow has a but they are operated at shallower tillage depths. Draft data

greater field capacity, requires less power, creates no back for field cultivators is published by ASAE (1994a) to be the

or dead furrows and it can be managed to leave significant same as that for a chisel plow. Draft is reported to be a

amounts of crop residue on the soil surface. The rough linear function of speed and quadratic with depth (ASAE,

surface from a fall chisel-plowed field traps snow and 1994a; Grisso etal., 1994).

moisture and helps protect the soil from wind and water The proposed parameters for field cultivator draft

erosion. (table 1) were based on a summary of reported draft data

Draft data for chisel plows are specified by ASAE with (Dumas and Renoll, 1982; Frisby and Summers, 1979;

draft described as a linear function of speed and a quadratic Stephens et al., 1981; Kydd et al., 1984; Zwilling and

function with respect to depth (ASAE, 1994a). This current Hummel, 1988). Like the chisel plow, draft was determined

ASAE data for chisel plows is not consistent with other to increase linearly with speed and depth. From the data of

implement data reported across soil textural groups. Unlike Kydd et al. (1984), draft during secondary tillage was

the moldboard plow and disk harrow, draft is higher for estimated as 70% of that required for primary tillage. Few

medium than fine-textured soils. data are available comparing draft across soil textural

Chisel plow point selection affects soil shatter, soil groups. Similar to chisel plows, drafts for medium and

inversion, residue cover after tillage (Dickey et al., 1992) coarse textured soils were estimated as 85% and 65%,

and draft (Gregory and M'Hedhbi, 1988). Straight, 5 cm respectively, of the draft in a fine-textured soil. Field

(2 in.) points shatter less soil and bury less residue than cultivator draft based on the proposed parameters tends to

7.5 cm (3 in.) or 10 cm (4 in.) twisted shovels. Wide be lower during secondary tillage (30 to 50 N/tool/cm,

sweeps are sometimes used to undercut weeds and loosen 17 to 29 lbf/tool/in.) and higher during primary tillage

soil without burying surface residue. Bashford et al. (1991) (45 to 70 N/tool/cm, 26 to 40 lbf/tool/in.) than that

reported draft for chisel sweeps similar to points for spring specified by the current ASAE data (45 to 55 N/tool/cm,

tillage on a soft sand or on a fall-tilled clay soil, but draft 26 to 31 lbf/tool/in.). The proposed data are in close

was higher for points than sweeps on a stubble-covered agreement with draft reported by Grisso et al. (1994) for

clay soil. Gregory and M'Hedhbi (1988) reported that typical tillage depths.

chisel plow draft should vary with the cross-sectional area

of the furrow formed during tillage. The cross-sectional SWEEP PLOWS

area formed by a chisel point is trapezoidal (Willatt and Sweep plows are typically run at depths of 7.5 to 10 cm

Willis, 1965; Koohestani and Gregory, 1985) with the (3 to 4 in.) and are used to loosen soil and undercut weeds

bottom width approximated by the width of the chisel while leaving the soil surface undisturbed. The design of

point. Based on the cross-sectional area described by sweep plows indicates that the draft should follow a similar

Koohestani and Gregory (1985) and a 30° angle of crescent functional form as chisel plows and other chisel-type tools.

failure, chisel draft with a 10 cm (4 in.) point is about 15% The current ASAE data does not include draft for sweep

greater and a 5 cm (2 in.) point 15% less than that of a plows.

7.5 cm (3 in.) point (table 1). The proposed draft Summers et al. (1986) measured speed-draft

parameters for chisel plows with straight, 5 cm (2 in.) relationships of sweep plows in clay loam and silt loam

points and 10 cm (4 in.) twisted shovels were estimated by soils in Oklahoma. Kydd et al. (1984) reported draft data

multiplying the draft for 7.5 cm (3 in.) shovels by 0.85 and for sweep plows (blade cultivators) in both primary and

1.15, respectively. secondary tillage conditions. Draft was reported to be

VOL. ll(6):773-783 777

linear with respect to speed (Mielke et al., 1989; Because tandem and offset disk designs are becoming

Summers et al., 1986; Kydd et al., 1984) and depth more similar in mass, the large difference in draft between

(Summers et al., 1986; Kydd et al., 1984). Comparisons of the two disk harrow types assumed in the past is no longer

sweep plow draft data across soil textural groups were not justified. Summers et al. (1986) reported greater draft for

found. The proposed sweep plow parameters were based an offset compared to a tandem disk, but direct

upon a composite of reported data (Summers et al., 1986; comparisons were difficult due to greatly different soil

Kydd et al., 1984). Similar to chisel plows, field cultivators conditions. A composite of values reported for silt loam

and other chisel-type tools, draft in medium and coarse soils (Bowers, 1989; Frisby and Summers, 1979; Self et al.,

textured soils was estimated to be 85% and 6 5 % , 1983) indicates that tandem disk draft is about 90% of that

respectively, of that in a fine-textured soil (table 1). Based for an offset disk. Bowers (1989) reported tandem disk

on sweep plow draft data reported by Kydd et al. (1984), draft to be about 69% and 89%, respectively, of that for an

draft during secondary tillage was estimated as 70% of that offset disk on fine sandy loam and sandy loam soils, and

required for primary tillage. Bashford et al. (1991) reported tandem disk draft to be

about 60% of that for an offset disk in a soft sand. For the

DISK HARROWS proposed parameters, draft of a tandem disk was set at 85%

Disk harrows and combination tillage tools using disk of that required for an offset disk at the same depth.

gangs are among the most commonly used tillage Disk draft is typically greater during primary than

implements. Disk harrows are used for primary tillage, secondary tillage. Sometimes draft is perceived to be

seedbed preparation, weed control and incorporation of greater during secondary tillage due to increased operating

manure, fertilizers, and herbicides. In the past, tandem disk depth and reduced tractive efficiency in tilled soil. Draft for

harrows typically had less mass per unit width, smaller a tandem disk during secondary tillage was about 38% of

diameter blades, and a narrower blade spacing than offset that for primary tillage in a loamy fine sand (Self et al.,

disk harrows. Tandem disks were generally used for 1983), 73% in a loamy sand, 73% in a fine sandy loam,

secondary or light primary tillage while offset disks were 76% in a sandy loam and 56% in a loam (Bowers, 1989).

used for heavy primary tillage. In recent years, large Offset disk draft for secondary tillage was about 63% of

tandem disk harrows similar to offset disks in mass, blade primary tillage draft in a clay loam (Reid, 1978), 58% in a

size, blade spacing, blade shape, and primary tillage sandy clay loam and 93% in a sandy loam (Reid et al.,

capabilities have become common (Krishnan et al., 1988). 1983). In the proposed parameters, draft during secondary

Many factors affect disk harrow draft including gang tillage was assumed to be 70% of that required for primary

angle, mass per blade, blade type and spacing, operating tillage for all soils.

depth, and travel speed (Gill et al., 1981, 1982; Since ASAE data for disk harrow draft do not consider

Schafer et al., 1991; Sommer et al., 1983). Draft data for depth, a direct comparison with the proposed data is

disk harrows is reported by ASAE (1994a) with draft difficult. The proposed data estimate a narrower range of

expressed as a function of implement mass, independent of draft at a given depth than the current data. In a medium

speed and working depth. Drafts in medium and coarse- textured soil, however, the proposed data are similar to

textured soils is estimated to be about 80% and 53%, ASAE data [55 kg (121 lbf)/blade] for a silt loam soil at

respectively, of the draft in a fine-textured soil. Bowers depths of 14 cm (5.5 in.) and 20 cm (8 in.), respectively, for

(1989) reported that the ASAE data for disk harrow draft primary and secondary tillage with a tandem disk harrow at

tended to underestimate measured draft for tandem disk 8.9 km/h (5.5 mph). The proposed draft for an offset disk

harrows in the medium and coarse textured soils of is similar to ASAE data [105 kg (231 lbf)/blade] at a depth

North Carolina. More recent studies report disk harrow of 18 cm (7 in.) during primary tillage and a depth of

draft as a positive linear function of speed and depth (Kydd 23 cm (9 in.) during secondary tillage.

et al., 1984; Summers et al., 1986), but primary tillage draft

has also been reported to be a quadratic function of speed SINGLE DISK GANGS

(Krishnan et al., 1988) and depth (Grisso et al., 1994). Single disk gangs are frequently used on combination

Since most newer tandem and offset disks can limit tillage tools for both primary and secondary tillage. Draft

depth of tillage with transport wheels, draft data based on data for single disk gangs are currently not specified in the

depth of tillage is preferred to draft estimates based on ASAE data. Hunt (1977) reported that draft for a single

mass. A convenient measure of disk draft is projected disk gang was about 50% of that for a light tandem (double

specific draft (PSD). Projected specific draft is the machine gang) disk harrow. The gang angle is typically less for a

draft divided by the rectangular area defined by the cutting single disk gang (8° to 12°) than a tandem disk harrow

width and the depth of disk penetration (Sommer et al., (18° to 22°). Reducing the gang angle tends to reduce both

1983). The proposed parameters for primary tillage with a depth of operation and draft per unit depth (Sommer et al.,

tandem disk harrow in fine-textured soils were based on 1983). Based on draft-gang angle relationships described

data presented by Summers et al. (1986) and a comparison by Sommer et al. (1983), reducing the gang angle from

of reported draft data across soil textural groups (Bowers, 20° to 10° reduces draft by 25 to 30%. Considering the

1989; Frisby and Summers, 1979; Kydd et al., 1984; Reid, draft reduction for a single gang and the reduced gang

1978; Reid et al., 1983; Self et al., 1983; Stephens et al., angle, draft (PSD) for a single disk gang was estimated as

1981; Williams et al., 1979; Zwilling and Hummel, 1988). 40% of that for a tandem disk under similar conditions

Drafts for medium and coarse textured soils were estimated (table 1).

as 88% and 78%, respectively, of the draft for a fine-

textured soil.

778 APPLIED ENGINEERING IN AGRICULTURE

COULTERS weeds between the crop rows. Some use cut-away disks to

Most no-till planters and drills and many tillage remove weeds adjacent to the row.

implements use coulters to cut surface residue and in some Row crop cultivator draft (per unit of width) is

cases to till a narrow band of soil. Draft data for coulters estimated as a linear function of depth (ASAE, 1994a).

are currently not specified by ASAE. Coulter draft is Hunt (1977) reported a range of values similar to that

influenced by factors such as coulter design, amount and reported by ASAE. Frisby and Summers (1979) reported

type of surface residue, operating depth, operating speed, cultivator draft in clay, loam, and sandy soils. Stephens

and soil condition. et al. (1981) reported draft for row cultivators with three to

Based on soil bin tests in sandy loam and clay loam five sweeps or five S-tine shanks per row in a sandy-loam

soils, coulter draft and vertical forces are lowest for thin soil. No draft data for no-till cultivators were found.

coulters with small wedge slopes (Tice and Hendrick, The proposed parameters for S-tine and C-shank

1992). Choi and Erbach (1986) noted that a 46 cm (18 in.) cultivators (table 1) were based on a synopsis of the

coulter had better residue cutting characteristics than a reported draft data (ASAE, 1994a; Hunt, 1977; Frisby and

41 cm (16 in.) coulter, but residue cutting was more Summers, 1979; Stephens et al., 1981). The parameters for

affected by soil strength than coulter shape. Draft and no-till cultivators (table 1) was estimated from the

vertical forces increased with coulter depth and diameter proposed sweep plow data assuming a 56 cm (22 in.)

(Choi and Erbach, 1986; Kushwaha et al., 1986), increased sweep plus added draft for three coulters to approximate

with soil strength (Choi and Erbach, 1986) and increased the draft of one cutting coulter and two cut-away disks per

with the presence of crop residue on the soil surface row. Draft for all row cultivators was assumed to be a

(Kushwaha et al., 1986). Coulter shape did not linear function of both speed and depth. Similar to the

significantly affect draft or vertical forces, but forces chisel plow, field cultivator and sweep plow, draft in

tended to be higher for fluted than notched, ripple, or medium and coarse textured soils was assumed to be 85%

smooth coulters (Choi and Erbach, 1986). Bowers (1985) and 65%, respectively, of the draft in a fine-textured soil.

cited work by Trouse and Reaves (1980) for various types Based on the proposed parameters, draft for the S-tine

of coulters in clay loam, silt loam, and sandy loam soils cultivator is at the low end and the C-shank cultivator with

where smooth coulter draft was lower (15 to 40%) than that sweeps is at the high end of the range currently specified

of fluted and bubble coulters. by ASAE.

Coulter draft in the range of 45 to 50 N/cm (26 to

29 lbf/in.) of depth for a 46 cm (18 in.) diameter rippled ROTARY HOES

coulter was reported by Choi and Erbach (1986) based on Rotary hoes are designed to dislodge small weeds and

soil bin tests in a silty-clay-loam soil with cornstalk loosen crusted soil early in the growing season

residue. In soil bin tests in a clay loam soil with straw (Springman et al., 1989). Rotary hoes work best at

residue, Kushwaha et al. (1986) measured draft in the relatively high speeds in tilled fields with light to moderate

range of 35 to 40 N/cm (20 to 23 lbf/in.) of depth for a residue cover. Rotary hoe draft is reported to be linear with

smooth coulter, 46 cm (18 in.) in diameter. In general, draft respect to speed (ASAE, 1994a). Rotary hoe draft reported

reported by Trouse and Reaves (1980) tended to be higher by Stephens et al. (1981) was within the range in expected

than that reported by Choi and Erbach (1986) or Kushwaha draft per unit width (400 to 900 N/m, 30 to 60 lbf/ft)

et al. (1986), ranging from about 60 N/cm (34 lbf/in.) for a reported by Hunt (1977). Based on a composite of reported

smooth coulter in a sandy loam to 125 N/cm (71 lbf/in.) draft, the proposed draft data for a rotary hoe is 600 N/m

for a bubble coulter in clay loam soil. (41 lbf/ft), independent of travel speed. A simple

The proposed draft parameters for smooth and ripple relationship that is independent of tillage depth and speed

coulters (table 1) were established from a composite of the is consistent with the parameters reported for other minor

reported data (Choi and Erbach, 1986; Kushwaha et al., tillage tools (table 1).

1986; Trouse and Reaves, 1980). Coulter draft was

assumed to be a linear function of both depth and speed ROD WEEDERS

with a 20% increase for fluted and bubble coulters. Similar Rod weeders use a rotating round or square rod

to disk harrows, draft in medium and coarse textured soils traveling below the soil surface to undercut weeds, leaving

was 88% and 78%, respectively, of the draft in fine- them lying on the soil surface. Expected draft was specified

textured soils. by ASAE (1994a) and Hunt (1977) to be in the range of

500 to 1,830 N/m (35 to 125 lbf/ft). Kydd et al. (1988)

Row CROP CULTIVATORS reported draft data for rod weeders under typical Canadian

Row crop cultivators are designed for a wide range of prairie conditions at 8 km/h (4.9 mph) ranging from 900 to

soil and residue conditions. S-tine shanks stir and loosen 1,650 N/m (62 to 113 lbf/ft) at 2.5 to 7.5 cm (1 to 3 in.)

soil over a wide area. They are suitable for tilled fields with depth, respectively. Draft was a linear function of speed.

light or moderate residue (Springman et al., 1989). The proposed parameters for rod weeder draft in medium

C-shanks slice and lift the soil, cutting weeds and pushing textured soil were based on Kydd et al. (1988). Similar to

soil aside and thus are more suitable for harder soils and sweep plows and row crop cultivators, draft for medium

heavier crop residue. Conservation tillage (no-till) and coarse textured soils were set at 85% and 65%,

cultivators are heavy duty cultivators most suitable for hard respectively, of the draft in fine-textured soils. These

soils and heavy residue (Springman et al., 1989; Grisso and parameters provided drafts within a range similar to that

Schuler, 1992). Most no-till cultivators use a cutting coulter previously published by ASAE. When cultivator shanks are

and a single 41 to 61 cm (16 to 24 in.) sweep to undercut added to aid penetration of the cutting rod, cultivator shank

VOL. ll(6):773-783 779

draft must be calculated separately and added to the rod correct depth, cover the seed, and firm the soil around the

draft to obtain total draft. seed. Planting conditions in a conservation tillage system

are not as uniform as in a conventionally tilled field with a

MINOR TILLAGE TOOLS prepared seedbed, so some soil treatment at planting is

Minor tillage tools include harrows, packers, and some required. Most no-till planters use one or more coulters to

specialty tillage implements. Few draft data are reported cut the residue and prepare a narrow band of soil.

for many of these implements. ASAE data for the spike Removing or incorporating the residue from the soil

tooth harrow (440 to 730 N/m, 30 to 50 lbf/ft) is similar to surface allows faster soil warm-up and easier placement of

that reported by PAMI (1986); 400 N/m (27 lbf/ft) at fertilizer.

6.6 km/h (4 mph) and 760 N/m (52 lbf/ft) at 9.8 km/h Row crop planter draft per row is published in the

(6 mph). Hunt (1977) reported a range in draft from 300 to current ASAE data (1994a). These data are based upon a

900 N/m (21 to 62 lbf/ft). The proposed draft parameter of prepared seedbed in a loam soil and include rolling

600 N/m (40 lbf/ft) and an estimate of the expected resistance. There appears to be little difference in draft

variation (±30%) provides drafts similar to the reported across soil textural groups when planting in a firm,

data (Hunt, 1977; PAMI, 1986; ASAE, 1994a). prepared seedbed (Frisby and Summers, 1979).

Coil-tine (round wire tooth) harrows are used to level Dickey et al. (1994) reported that the residue from the

seedbeds in a wide range of crop residue conditions. These previous crop influenced planter draft more than the tillage

harrows are also common attachments to no-till grain drills practice used. Bowers (1989) reported draft in a loamy

in the midwest. Coil-tine harrow draft is not included in the sand for seeding units to be similar to that reported by

current ASAE Standards (1994a). The proposed draft Stephens et al. (1981) in a silt loam soil. When planting

parameter of 250 N/m (17 lbf/ft) was derived from draft with seed, fertilizer, and herbicide application, planter draft

data reported by PAMI (1988) for a harrow-packer tends to be higher and more variable. Draft measurements

(table 1). ranging from about 1200 to 1800 N (270 to 400 lbf)/row

Spring tooth harrows have long been used to smooth are common with no consistent trends across soil textural

and level seedbeds prior to planting. Spring tooth harrow groups (Bowers, 1989; Matthews et al., 1981; Reid et al.,

draft ranging from 1460 to 2190 N/m (100 to 150 lbf/ft) is 1983; Stephens et al., 1981). A lower draft of 500 to

specified by ASAE (1994a). A wider range in draft of 1000 1000 N (112 to 224 lbf)/row is reported for some soils

to 4400 N/m (69 to 300 lbf/ft) was reported by Hunt (Bowers, 1989).

(1977). Draft for a spring tooth harrow was expected to be Rolling resistance of transport and press wheels is a

similar to that of a field cultivator during secondary tillage. large portion of row planter draft. Row planter draft only

Based on the proposed field cultivator draft data (table 1), increased about 10% when planting at a depth of 7.5 cm

spring tooth harrow draft was estimated as 1350 N/m (3 in.) compared to 2.5 cm (1 in.) in a prepared seedbed of

(94 lbf/ft) at a depth of 5 cm (2 in.) and 2650 N/m silt loam soil (Stephens et al., 1981) indicating little

(180 lbf/ft) at 10 cm (4 in.). A typical draft parameter of contribution to draft from seeding depth. Bowers (1989)

2000 N/m (135 lbf/ft) with a variation of ± 3 5 % is indicated 15 to 20% lower draft in an untilled fine sandy

proposed (table 1). loam soil compared to the same planter in a prepared

Roller packers are seedbed tillage tools used to break seedbed, possibly due to lower rolling resistance on firm

soil clods and firm soil prior to seeding. Hunt (1977) and soil.

ASAE (1994a) reported roller packer drafts of 300 to Since planter draft in a prepared seedbed does not

900 N/m (21 to 62 lbf/ft). The proposed draft parameter of appear to be greatly affected by soil texture or planting

600 N/m (40 lbf/ft) was based on this data. Roller harrows depth, row planter draft in a prepared seedbed was

combine the leveling action of spring tooth harrows with estimated as 500 N (112 lbf)/row for a mounted planter

the soil firming of roller packers. Roller harrow draft data with seed units only, 900 N (200 lbf)/row for a drawn

was not included in the current ASAE Standards. The planter with only seeding units and 1550 N (350 lbf)/row

proposed roller-harrow draft parameter of 2600 N/m with seed, fertilizer, and herbicide units (table 1). No-till

(180 lbf/ft) was set by combining the proposed roller planter draft was estimated as 1325 N (300 lbf)/row for

packer and spring tooth harrow parameters (table 1). seed, fertilizer, and herbicide units plus the estimated draft

Disk bedders are used to build elevated seedbeds for of one fluted coulter (320 to 470 N/row, 72 to

cotton and many vegetable crops. Disk bedder draft was 106 lbf/row). Draft for zone-till planters was estimated as

not included in the current ASAE Standards. The proposed the same draft (1325 N/row, 300 lbf/row) plus the draft of

disk-bedder draft was based on Reid (1978) and adjusted three fluted coulters per row (1440 to 2100 N/row, 324 to

for soil texture similar to disk harrows. Land plane draft of 472 lbf/row).

4400 to 11 600 N/m (300 to 800 lbf/ft) was reported by The proposed row planter draft parameter for a mounted

both Hunt (1977) and ASAE (1994a). Based on this planter with seed units only is at the lower end of the range

reported data, an expected draft parameter of 8000 N/m listed in the current ASAE standards. Draft for a drawn

(550 lbf/ft) ±45% is proposed. planter with seed units only is somewhat higher than the

upper end of the range listed by ASAE. The proposed data

for row planters applying seed, fertilizer, and herbicide is

SEEDING EQUIPMENT in the mid-range of that listed currently by ASAE.

Row CROP PLANTERS

Row crop planters are used for seed placement for a GRAIN DRILLS

wide range of crops. The major functions of a row crop Draft for conventional grain drills is specified in the

planter are to open a seed furrow, place the seed at the current ASAE data (1994a). The draft includes rolling

780 APPLIED ENGINEERING IN AGRICULTURE

resistance, and is independent of seeding depth and speed. ASAE in revising the Machinery Management Standards,

Kydd et al. (1984) observed little difference in draft with EP496 and D497.

furrow openers raised or lowered, so draft was assumed to

be largely a function of transport and press wheel rolling

resistance. Grain drill draft does not appear to be affected REFERENCES

by soil texture when seeding in a prepared seedbed (Frisby Ahmed, M. H. and R. J. Godwin. 1983. The influence of wing

and Summers, 1979). Mungai (1991) reported conservation position on subsoiler penetration and soil disturbance.

tillage drill draft to be about 80% of that in a J. Agric. Eng. Res. 28(5):489-492.

conventionally tilled seedbed on loam soil and 75% on a ASAE Standards, 41st Ed. 1994a. D497. Agricultural machinery

sandy loam, presumably due to a lower rolling resistance management data. St. Joseph, Mich.: ASAE.

on firmer soil. . 1994b. S414. Terminology and definitions for

agricultural tillage implements. St. Joseph, Mich.: ASAE.

Since grain drill draft is not greatly affected by soil . 1994c. S477. Terminology for soil-engaging

texture or seeding depth, a range of draft values based on components for conservation-tillage planters, drills and

drill width is proposed. Published data (Frisby and seeders. St. Joseph, Mich.: ASAE.

Summers, 1979; Mungai, 1991; Stephens et al., 1981; . 1994d. EP291. Terminology and definitions for soil

Kydd et al., 1984) indicate that draft for a conventional tillage and soil-tool relationships. St. Joseph, Mich.: ASAE.

disk drill in a tilled, firm seedbed ranges from 200 N Bashford, L. L., D. V. Byerly and R. D. Grisso. 1991. Draft and

(45 lbf)/row for a wide drill (>3.66 m, 12 ft) to 400 N energy requirements of agricultural implements in semi-arid

(90 Ibf)/row for a narrow (2.44 m, 8 ft) drill. Since rolling regions of Morocco. Agric. Mech. in Asia, Africa and Latin

resistance is not as dominant in firm, no-till conditions, Am. 22(3):79-82.

draft for no-till drills was estimated as 250 N (56 lbf)/row Bowers Jr., C. G. 1985. Southeastern tillage energy data and

recommended reporting. Transactions of the ASAE 28(3):731 -

plus the coulter draft of 320 to 470 (72 to 106 lbf) N/row.

737.

The proposed drill draft parameters are within the range . 1989. Tillage draft and energy requirements for 12

currently reported by ASAE. southeastern soil series. Transactions of the ASAE 32(5): 1492-

1502.

HOE DRILLS AND PNEUMATIC SEEDERS Chaplin, J., M. Lueders and D. Rugg. 1986. A study of

Hoe drills are used for seeding into prepared and compaction and crop yields in loamy sand soil after seven

untilled seedbeds. Several opener and press wheel designs years of reduced tillage. Transactions of the ASAE 29(2):389-

are in use. Most use spring trip shanks and boot openers 392.

Choi, C. and D. C. Erbach. 1986. Cornstalk residue shearing by

and rubber or steel press wheels to firm the seed furrow.

rolling coulters. Transactions of the ASAE 29(6): 1530-1535.

Hoe drill draft is not currently included in the ASAE Cooper, A. W. 1971. Effects of tillage on soil compaction. In

Standards (ASAE, 1994a). Stephens et al. (1981) reported Compaction of Agricultural Soil, Chapter 7. Organized by

hoe drill draft of 1500 N/m (103 lbf/ft) in a tilled seedbed. K. K. Barnes, W. M. Carleton, H. M. Taylor, R. I.

Kydd et al. (1984) reported draft for hoe drills in tilled Throckmorton and G. E. Vanden Berg. St. Joseph, Mich.:

seedbeds to range from 1300 to 4200 N/m (90 to ASAE.

290 lbf/ft) of width. One drill was used in both tilled and Dickey, E. C , P. Jasa, D. P. Shelton and J. C. Siemens. 1992.

untilled seedbeds. Draft increased from 2500 N/m Conservation tillage systems. In Conservation Tillage Systems

(170 lbf/ft) in a tilled seedbed to 6100 N/m (420 lbf/ft) in and Management-Crop Residue Management with No-till,

untilled conditions. The proposed hoe drill parameters Ridge-till, Mulch-till, 89-92. Ames: MidWest Plan Service,

(table 1) are based on Kydd et al. (1984). Iowa State Univ.

Dickey, E. C, P. J. Jasa and R. D. Grisso. 1994. Long term tillage

Pneumatic seeders utilize a grain/fertilizer tank attached effects on grain yield and soil properties in a soybean/grain

to or towed behind a specially designed cultivator. sorghum rotation. J. Prod. Agric. 7(4):465-470.

Pneumatic seeder draft was not included in the current Dumas, W. T. and E. Renoll. 1982. Energy and machinery

ASAE Standards (1994a). The proposed draft parameter of management for cotton production systems. ASAE Paper No.

3700 N/m (250 lbf/ft) (table 1) was based on draft 82-1054. St. Joseph, Mich.: ASAE.

reported by Kydd et al. (1984). Their data represented an Eradat-Oskoui, K. and B. D. Witney. 1982. The determination of

average value for nine seeders used over a range of field plough draught - Part I. Prediction from soil and

conditions. meteorological data with cone index as the soil strength

parameter. J. Terramechanics 19(2):97-106.

Eradat-Oskoui, K., D. H. Rackham and B. D. Witney. 1982. The

determination of plough draught - Part II. The measurement

CONCLUSION and prediction of plough draught for two mouldboard shapes

A general model with machine- and soil-specific in three soil series. 7. Terramechanics 19(3): 153-164.

parameters is proposed to estimate the draft of tillage and Frisby, J. C. and J. D. Summers. 1979. Energy-related data for

seeding implements under general conditions. Machine selected implements. Transactions of the ASAE 22(5): 1010-

draft is estimated as a function of soil texture, implement 1011.

width, depth, and speed of operation for most major Garner, T. H. and D. Wolf. 1981. Tillage energy versus hardpan

operations. Equation 1 and the parameters listed in table 1 configuration and tillage depth. ASAE Paper No. 81-1572.

can be used to estimate typical drafts for a wide variety of St. Joseph, Mich.: ASAE.

Garner, T. H., W. R. Reynolds, H. L. Musen, G. E. Miles, J. W.

tillage and seeding implements. The draft relationships for

Davis, D. Wolf and U. M. Peiper. 1987. Energy requirement

tillage and seeding equipment are provided for use in for subsoiling coastal plain soils. Transactions of the ASAE

machinery management programs. They are developed for 30(2):343-349.

consideration by the Machinery Management committee of

VOL. ll(6):773-783 781

Gill, W. R., C. AReaves and A. C. Bailey. 1981. The influence of Nichols, M. L. and C. A. Reaves. 1958. Soil reaction: To

harrow disk curvature on forces. Transaction of the ASAE subsoiling equipment. Agricultural Engineering 39(6): 336-

24(3):579-583. 339.

Gill, W. R., A. C. Bailey and C. A. Reaves. 1982. Harrow disk Owen, G. T. 1988. Soil disturbance associated with deep

curvature - Influence on soil penetration. Transactions of the subsoiling on compact soils. Canadian Agric. Eng. 30(1):33-

ASAE 25(5): 1173-1180. 37.

Godwin, R. J., E. McKyes, S. Negi, G. V. Eades, J. R. Ogilvie and . 1989. Subsoiling forces and tool speed in compact

C. Lovegrove. 1976. Engineering design criteria for slurry soils. Canadian Agricultural Engineering 31(l):15-20.

injectors. In Proc. 8th Annual Waste Mgmt. Conf., 657-671. PAMI. 1986. Evaluation Report 471. Humboldt, Saskatchewan,

Rochester, N.Y.: Cornell Univ. Canada: Prairie Agricultural Machinery Inst.

Godwin, R. J., N. L. Warner and J. E. Hall. 1985. Soil injection of . 1988. Evaluation Report 572. Lethbridge, Alberta,

liquid wastes. In Agricultural Waste Utilization and Canada: Prairie Agricultural Machinery Inst.

Management, Proc. Fifth Int. Symp. Agric. Wastes, 63-72. Reaves, C. A. and R. L. Schafer. 1975. Force versus width of cut

St. Joseph, Mich.: ASAE. for moldboard bottoms. Transactions of the ASAE 18(5):852-

Gregory, J. M. and K. M'Hedhbi. 1988. Draft prediction for chisel 858.

plows. ASAE Paper No. 88-1616. St. Joseph, Mich.: ASAE. Reeder, R., R. Wood and C. Finck. 1992. Five subsoiler designs

Grisso, R. D. and R. T. Schuler. 1992. Crop cultivators. In and their effects on soil and crop yields. ASAE Paper No.

Conservation Tillage Systems and Management-Crop Residue 92-1594. St. Joseph, Mich.: ASAE.

Management with No-till, Ridge-till, Mulch-till, 109-110. Reid, J. T. 1978. A comparison of the energy input of some tillage

Ames: MidWest Plan Service, Iowa State Univ. tools. ASAE Paper No. 78-1039. St. Joseph, Mich.: ASAE.

Grisso, R. D., M. Yasin and M. F. Kocher. 1994. Tillage Reid, J. T., L. M. Carter and R. L. Clark. 1983. Draft

implement forces operating in silty clay loam. ASAE Paper measurements with a three-point dynamometer. ASAE Paper

94-1532. St. Joseph, Mich.: ASAE. No. 83-1036. St. Joseph, Mich.: ASAE.

Hann, M. J., N. L. Warner and R. J. Godwin. 1987. Slurry injector Rotz, C. A. and J. R. Black. 1985. Machinery requirements and

design and operational practices for minimizing soil surface cost comparisons across tillage systems. In A Systems

disturbance and crop damage. ASAE Paper No. 87-1610. Approach to Conservation Tillage, 171-190, ed. F. M. DTtri.

St. Joseph, Mich.: ASAE. Chelsea, Mich.: Lewis Publishers Inc.

Hendrick, J. G. 1980. A powered rotary chisel. Transactions of the Rotz, C. A. and H. A. Muhtar. 1992. Rotary power requirements

ASAE 23(6): 1349-1352. for harvesting and handling equipment. Applied Engineering

Horsfield, B. 1974. Power needs for liquid manure applications. in Agriculture 8(6):751-757.

Prairie Farmer 146(9). Scarborough, J. N., E. C. Dickey and D. H. Vanderholm. 1978.

Hunt, D. 1977. Farm Power and Machinery Management, 7th Ed. Sizing of liquid manure tank wagons and the economic

Ames, Iowa: Iowa State Univ. Press. evaluation of liquid manure injection. Transactions of the

Khalilian, A., T. H. Garner, H. L. Musen, R. T. Dodd and S. A. AS4£ 21(6): 1181-1184.

Hale. 1988. Energy for conservation tillage in coastal plain Schafer, R. L., C. E. Johnson, M. L. Chapman and W. R. Gill.

soils. Transactions of the ASAE 31 (5): 1333-1337. 1991. Disk spacing model for optimizing gang performance.

Koohestani, M. and J. M. Gregory. 1985. Measurement of tillage Transactions of the ASAE 34(3):711-717.

parameters that affect residue cover. ASAE Paper No. Schmitt, M. A. and R. G. Hoeft. 1986. Manure injection - Can

85-2045. St. Joseph, Mich.: ASAE. sometimes injure corn crop. Crops and Soils 38(8): 19-22.

Krishnan, P., L. J. Kemble, T. H. Williams and N. E. Collins. Self, K. P., A. Khalilian, D. G. Batchelder, P. D. Bloome and

1988. Draft requirements of disk harrows. ASAE Paper No. G. Riethmuller. 1983. Draft and power requirements of tillage

88-1504. St. Joseph, Mich.: ASAE. implements in Oklahoma soils. ASAE Paper No. 83-1038.

Kushwaha, R. L., A. S. Vaishnav and G. C. Zoerb. 1986. Soil bin St. Joseph, Mich.: ASAE.

evaluation of disc coulters under no-till crop residue Shinners, K. J. 1989. Costs and benefits of subsoil tillage in a

conditions. Transactions of the ASAE 29(l):40-44. Wisconsin soil. ASAE Paper No. 89-1507. St. Joseph, Mich.:

Kydd, H. D., G. E. Frehlich and A. R. Boyden. 1984. Tillage ASAE.

power requirements in western Canada. ASAE Paper No. Siemens, J. C , E. C. Dickey, P. J. Jasa, D. P. Shelton and V. L.

84-1027. St. Joseph, Mich.: ASAE. Hofman. 1992. Representative tillage implement descriptions.

Lague, C. 1991. Design of a semi-liquid dairy cattle manure In Conservation Tillage Systems and Management-Crop

spreader/injector. Applied Engineering in Agriculture Residue Management with No-till, Ridge-till, Mulch-till, 116-

7(6): 655-660. 121. Ames: MidWest Plan Service, Iowa State Univ.

Matthews, E. J., P. S. Shackleford and J. T. Walker. 1981. Low Smith, L. A. 1989. Power requirements for implements used on

energy cotton production systems. ASAE Paper No. 81-1573. cotton and soybean production systems. ASAE Paper No.

St. Joseph, Mich.: ASAE. 89-1507. St. Joseph, Mich.: ASAE.

Mielke, L. N., L. L. Bashford and A. J. Jones. 1989. Sweep plow Smith, L. A. and J. R. Williford. 1988. Power requirements of

modification with shanks for subsurface tillage. Transactions conventional, triplex and parabolic subsoilers. Transactions of

of the ASAE 32(6): 2046-2050. the ASAE 31(6):1685-1688.

Mielke, L. N., R. D. Grisso, L. L. Bashford and A. M. Parkhurst. Sommer, M. S., S. H. Chen and J. F. Bierl. 1983. Disk blade

1994. Bi-level subsoiler performance using tandem shanks. performance. ASAE Paper No. 83-1537. St. Joseph, Mich.:

Applied Engineering in Agriculture 10(3):345-349. ASAE.

Mungai, G. S. N. 1991. Evaluation of energy requirements for Spoor, G. and R. J. Godwin. 1978. An experimental investigation

conservation tillage systems in Michigan. Unpub. M.S. thesis, into the deep loosening of soil by rigid tines. J. Agric. Eng.

Agricultural Engineering Dept., Michigan State Univ., Res. 23(3):243-258.

East Lansing. Springman, R., D. Buhler, R. Schuler, D. Mueller and J. Doll.

Negi, S., E. McKeyes, R. J. Godwin and J. R. Ogilvie. 1978. 1989. Row crop cultivators for conservation tillage systems.

Design and performance of a liquid manure injector. Bulletin A3483. Madison, Wis.: Cooperative Extension

Transactions of the ASAE 21(5):963-966. Service, Univ. of Wisconsin.

Nichols, M. L., I. E Reed and C. A. Reaves. 1958. Soil Reaction: Stephens, L. E., A. D. Spencer, V. G. Floyd and W. W Brixius.

To Plow Share Design. Agricultural Engineering 39(6):340- 1981. Energy requirements for tillage and planting. ASAE

343. Paper No. 81-1512. St. Joseph, Mich.: ASAE.

782 APPLIED ENGINEERING IN AGRICULTURE

Summers, J. D., A. Khalilian and D. G. Batchelder. 1986. Draft Willatt, S. T. and A. H. Willis. 1965. A study of the trough formed

relationships for primary tillage in Oklahoma soils. by the passage of tines through soil. J. Agric. Eng. Res. 10:1 -4.

Transactions oftheASAE 29(l):37-39. Williams, T. H., N. E. Collins and L. J. Kemble. 1979. Yield and

Tice, E. M. and J. G. Hendrick. 1992. Disc coulter operating energy requirements for in-row chiseling. ASAE Paper No.

characteristics. Transactions of the ASAE 35(1):3-10. 79-1021. St. Joseph, Mich.: ASAE.

Trouse Jr., A. C. and C. A. Reaves. 1980. Reducing energy inputs Wolf, D., T. H. Garner and J. W. Davis. 1981. Tillage mechanical

into no-tillage systems. In Proc. Third Annual Southeastern energy input and soil crop response. Transactions oftheASAE

No-Tillage Conf, 188-195. Williston: Univ. of Florida. 24(6): 1412-1425.

White, R. G. 1977. Matching tractor horsepower and farm Upadhyaya, S. K., T. H. Williams, L. J. Kemble and N. E. Collins.

implement size. Bull. E-1152. East Lansing: Cooperative 1984. Energy requirements for chiseling in coastal plain soils.

Extension Service, Michigan State Univ. Transactions of the ASAE 27(6): 1643-1649.

Wildman, W. E., C. A. Reaves and W. R. Gill. 1978. Effect of slip Zwilling, E. L. and J. W. Hummel. 1988. Draft and energy

plow design on draft forces and soil loosening. Transactions of requirements for midwest tillage operations. ASAE Paper No.

the ASAE 2l(3):422-426. 88-1615. St. Joseph, Mich.: ASAE.

Wilkins, D. E. and R E. Rasmussen. 1993. Long-term residue

management effects on tillage draft. ASAE Paper No. 93-1111.

St. Joseph, Mich.: ASAE.

VOL. ll(6):773-783 783

You might also like

- CartoMobile iPhone/iPad App: Optimize Ground Survey Data Collection for Airborne LIDAR Accuracy AssessmentFrom EverandCartoMobile iPhone/iPad App: Optimize Ground Survey Data Collection for Airborne LIDAR Accuracy AssessmentNo ratings yet

- Draft Force Inputs For Primary and Secondary Tillage Implements in A Clay Loam Soil - 2013 - Askari, KhalifahamzehghasemDocument6 pagesDraft Force Inputs For Primary and Secondary Tillage Implements in A Clay Loam Soil - 2013 - Askari, KhalifahamzehghasemVijay ChavanNo ratings yet

- Draught Prediction of Agricultural ImplementsDocument10 pagesDraught Prediction of Agricultural ImplementsRahma IelmahNo ratings yet

- Manjeet PreM Et Al 1Document8 pagesManjeet PreM Et Al 1Prem Ranjan MehtaNo ratings yet

- 216605-Article Text-533466-1-10-20211026Document7 pages216605-Article Text-533466-1-10-20211026Alex AdamsNo ratings yet

- Development of Decision Support Software For Matching Tractor-Implement System Used On Iranian FarmsDocument13 pagesDevelopment of Decision Support Software For Matching Tractor-Implement System Used On Iranian FarmsAJER JOURNALNo ratings yet

- Soil Dynamics in TillageDocument14 pagesSoil Dynamics in Tillagerevange2112No ratings yet

- 1 s2.0 S0022489817302239 MainDocument12 pages1 s2.0 S0022489817302239 MainendryasNo ratings yet

- This Is A Sample Cover Image For This Issue. The Actual Cover Is Not Yet Available at This Time.Document10 pagesThis Is A Sample Cover Image For This Issue. The Actual Cover Is Not Yet Available at This Time.luis zamoranoNo ratings yet

- Rectangular Zone Delineation Using ILPDocument9 pagesRectangular Zone Delineation Using ILPYenifer Rodriguez CorreaNo ratings yet

- Estimating Field Machinery Cost: A Whole Farm Approach: James G. Robb, John A. Smith, and Daryl E. EllisDocument5 pagesEstimating Field Machinery Cost: A Whole Farm Approach: James G. Robb, John A. Smith, and Daryl E. EllisJulus VODOUNNOUNo ratings yet

- Soil & Tillage Research: Jafar Habibi Asl, Surendra SinghDocument7 pagesSoil & Tillage Research: Jafar Habibi Asl, Surendra Singhdiegomanuel123No ratings yet

- The Influence of Implements and Operational Parameters on Draught and Soil DisturbanceDocument14 pagesThe Influence of Implements and Operational Parameters on Draught and Soil DisturbancevodounnouNo ratings yet

- Plow Moldboard or Disc PlowDocument7 pagesPlow Moldboard or Disc PlowAdewaleNo ratings yet

- Effect of Disc and Tilt Angles of Disc PDocument12 pagesEffect of Disc and Tilt Angles of Disc PMuhammad DennyNo ratings yet

- Draft Force Prediction For A High-Speed Disc Implement Using Discrete Element ModellingDocument9 pagesDraft Force Prediction For A High-Speed Disc Implement Using Discrete Element ModellingAlex AdamsNo ratings yet

- Estimating Field Capacity PDFDocument4 pagesEstimating Field Capacity PDFMatthester100% (1)

- PdfviewerDocument12 pagesPdfviewerdo aNo ratings yet

- An Excel Spreadsheet To Estimate Performance ParamDocument10 pagesAn Excel Spreadsheet To Estimate Performance Paramsina giahkarNo ratings yet

- Finite Element Modeling of Soil Sinkage by Multiple LoadingDocument8 pagesFinite Element Modeling of Soil Sinkage by Multiple LoadinglfbNo ratings yet

- Draught and Soil Disturbance of Model TiDocument18 pagesDraught and Soil Disturbance of Model TivodounnouNo ratings yet

- 7 Ijasraug20197Document8 pages7 Ijasraug20197TJPRC PublicationsNo ratings yet

- Aerial Fertilization of Oil PalmDocument5 pagesAerial Fertilization of Oil PalmAiigaa AiirenNo ratings yet

- A Program For Predicting Performance of Agricultural Machinery in Visual BasicDocument10 pagesA Program For Predicting Performance of Agricultural Machinery in Visual BasicTANKO BAKONo ratings yet

- Use of An Instrumented Disc Coulter For Mapping SoilDocument14 pagesUse of An Instrumented Disc Coulter For Mapping Soilshafie.meNo ratings yet

- TRACTOR1 Alsuhaibani 2015Document5 pagesTRACTOR1 Alsuhaibani 2015Siti ZahrohNo ratings yet

- Simulação Numérica e Testes de Campo de Plantadeira de Plantio Mínimo Com Palha (Shi Yinyan 2019)Document9 pagesSimulação Numérica e Testes de Campo de Plantadeira de Plantio Mínimo Com Palha (Shi Yinyan 2019)Julio Crystyano HessNo ratings yet

- Agriculture and Natural ResourcesDocument5 pagesAgriculture and Natural ResourcesRidwan JarwantoNo ratings yet

- Tutorial CorelDRAW-X8Document10 pagesTutorial CorelDRAW-X8Ajay BhargavaNo ratings yet

- IJASR - Field and Economic Studies of Tractor Operated Manure SpreadeDocument10 pagesIJASR - Field and Economic Studies of Tractor Operated Manure SpreadeTJPRC PublicationsNo ratings yet

- Traction Tractor PerformanceDocument48 pagesTraction Tractor PerformanceSubhasis Mishra67% (3)

- Effect of Ballast and Tire Inflation Pressure On Wheel SlipDocument5 pagesEffect of Ballast and Tire Inflation Pressure On Wheel SlipRavi VhtakarNo ratings yet

- Route Planning For Agricultural Tasks A General Approach For Fleets ofDocument17 pagesRoute Planning For Agricultural Tasks A General Approach For Fleets ofAnonymous 3LGI6CENo ratings yet

- Trans Asae 361Document11 pagesTrans Asae 361ይቴ ስንሻዉNo ratings yet

- Development of A Unique, Mobile, Single Wheel Traction Testing MachineDocument4 pagesDevelopment of A Unique, Mobile, Single Wheel Traction Testing MachineUjjal DeyNo ratings yet

- T.K. Maheshwari and Uday Veer Singh2Document8 pagesT.K. Maheshwari and Uday Veer Singh2biswaNo ratings yet

- Measurement of Tillage Forces and Soil D PDFDocument23 pagesMeasurement of Tillage Forces and Soil D PDFvodounnouNo ratings yet

- Herrick Jones 2002 PenetrometerDocument6 pagesHerrick Jones 2002 PenetrometercaritoleddaNo ratings yet

- Soil and TillageDocument5 pagesSoil and TillageThunder HeadNo ratings yet

- Design and Development of Manually Operated ReaperDocument8 pagesDesign and Development of Manually Operated ReaperIOSRjournalNo ratings yet

- Tool Kit For Scaling Agroforestry Interventions 1684037548Document12 pagesTool Kit For Scaling Agroforestry Interventions 1684037548varun batraNo ratings yet

- MJAE - Volume 32 - Issue 1 - Pages 19-40Document22 pagesMJAE - Volume 32 - Issue 1 - Pages 19-40Amine LaribiNo ratings yet

- EEAE2022_Veleva_HristovaDocument5 pagesEEAE2022_Veleva_Hristovaгл.ас. Галя ХристоваNo ratings yet

- Design Construction and Testing of An inDocument11 pagesDesign Construction and Testing of An invodounnouNo ratings yet

- An Empirical Model For Tractive Performance of Rubber-TracksDocument17 pagesAn Empirical Model For Tractive Performance of Rubber-TracksJatin DarveNo ratings yet

- Development-of-a-dynamic-simulation-model-of-a-towed_2018_Journal-of-TerrameDocument11 pagesDevelopment-of-a-dynamic-simulation-model-of-a-towed_2018_Journal-of-TerrameOrfeas AvraamNo ratings yet

- Artigo CEC 2018 The Use of Metaheuristics To Optimizing Routes in Agricultural Fields, Forster, KatoDocument8 pagesArtigo CEC 2018 The Use of Metaheuristics To Optimizing Routes in Agricultural Fields, Forster, KatoAlfred JuniorNo ratings yet

- Precision farming introduction: technologies and benefitsDocument13 pagesPrecision farming introduction: technologies and benefitsprogram distanNo ratings yet

- Self-propelled paddy transplanter evaluationDocument3 pagesSelf-propelled paddy transplanter evaluationha2012ma2013No ratings yet

- Herrick Jones 2002 PenetrometerDocument5 pagesHerrick Jones 2002 Penetrometerme-elormNo ratings yet

- NRSC 18 - Flyer - UIM2014 - US2 - Genesys PDFDocument19 pagesNRSC 18 - Flyer - UIM2014 - US2 - Genesys PDFAshoka VanjareNo ratings yet

- Ijasr - Performance Evaluation of Tractor Operated PDFDocument10 pagesIjasr - Performance Evaluation of Tractor Operated PDFAnonymous dbnms1yNo ratings yet

- Testing of CultivatorDocument33 pagesTesting of CultivatorEr. Narendra Kumar YadavNo ratings yet

- Applications of Laser in Agriculture A CDocument6 pagesApplications of Laser in Agriculture A CSurahmanNo ratings yet

- Analysis of Steel Track Undercarriage Wear Based On Geographic LocationDocument9 pagesAnalysis of Steel Track Undercarriage Wear Based On Geographic LocationCharlNo ratings yet

- Plant Power ShredderDocument27 pagesPlant Power ShredderDanica Joyce DayritNo ratings yet

- DalalClayton METHODSLANDEVALUATION 1993Document31 pagesDalalClayton METHODSLANDEVALUATION 1993da0297956No ratings yet

- Development of Rotary Weeder Blades by Finite Element MethodDocument5 pagesDevelopment of Rotary Weeder Blades by Finite Element MethodijsretNo ratings yet

- Agriculture: A Mathematical Model of The Plane-Parallel Movement of An Asymmetric Machine-and-Tractor AggregateDocument15 pagesAgriculture: A Mathematical Model of The Plane-Parallel Movement of An Asymmetric Machine-and-Tractor AggregatevodounnouNo ratings yet

- Call For Proposals ICT-enabled Mechanisation in Africa: Reference: Annex C - Declaration by The ApplicantDocument2 pagesCall For Proposals ICT-enabled Mechanisation in Africa: Reference: Annex C - Declaration by The ApplicantvodounnouNo ratings yet

- Standardized Tractor Performance Testing: Research UpdateDocument6 pagesStandardized Tractor Performance Testing: Research UpdateCarlo_FilippinNo ratings yet

- Project Number Event Title Event Type Event Date Location (City) Location (Country)Document60 pagesProject Number Event Title Event Type Event Date Location (City) Location (Country)vodounnouNo ratings yet

- Sample Preliminary Acceptance LetterDocument1 pageSample Preliminary Acceptance LettervodounnouNo ratings yet

- Project Profile On Soyabean Oil PDFDocument9 pagesProject Profile On Soyabean Oil PDFsumitNo ratings yet

- American Society of Plant Biologists (ASPB) The Plant CellDocument6 pagesAmerican Society of Plant Biologists (ASPB) The Plant CellvodounnouNo ratings yet

- Feasibility of Soya Based Food ProductsDocument5 pagesFeasibility of Soya Based Food Productsgsakir77No ratings yet

- Module L Carbon FootprintDocument13 pagesModule L Carbon FootprintvodounnouNo ratings yet

- Impacts of Conservation Agriculture On Soil Structure and Hydraulic Properties of Malawian Agricultural SystemsDocument8 pagesImpacts of Conservation Agriculture On Soil Structure and Hydraulic Properties of Malawian Agricultural SystemsvodounnouNo ratings yet

- Steps in Qualitative Data AnalysisDocument9 pagesSteps in Qualitative Data AnalysisvodounnouNo ratings yet

- Musa - Khapayi@nmmu - Ac.za Phillip - Celliers2@nmmu - Ac.zaDocument17 pagesMusa - Khapayi@nmmu - Ac.za Phillip - Celliers2@nmmu - Ac.zavodounnouNo ratings yet

- 0-306-48163-4 - 7 Hydromorphic SoilsDocument2 pages0-306-48163-4 - 7 Hydromorphic SoilsJulus Hyacinthe VodounnouNo ratings yet

- Size SeparationDocument53 pagesSize SeparationvodounnouNo ratings yet

- Technik Plus Conservation Agriculture in AfricaDocument9 pagesTechnik Plus Conservation Agriculture in AfricavodounnouNo ratings yet

- Numerical analysis of conical and cylindrical axial cyclone separatorsDocument9 pagesNumerical analysis of conical and cylindrical axial cyclone separatorsvodounnouNo ratings yet

- Series Forestry: Elec Jour OFP Agric UniveDocument8 pagesSeries Forestry: Elec Jour OFP Agric UnivevodounnouNo ratings yet

- Design Construction and Testing of An inDocument11 pagesDesign Construction and Testing of An invodounnouNo ratings yet

- Impact of Ploughing On Soil Seed Bank DyDocument9 pagesImpact of Ploughing On Soil Seed Bank DyvodounnouNo ratings yet

- Soil & Tillage Research: SciencedirectDocument8 pagesSoil & Tillage Research: SciencedirectvodounnouNo ratings yet

- Draught Force Requirements of A Disc Plo PDFDocument17 pagesDraught Force Requirements of A Disc Plo PDFvodounnouNo ratings yet

- Traction Prediction Using Soil Parameter PDFDocument16 pagesTraction Prediction Using Soil Parameter PDFvodounnouNo ratings yet

- Performance Evaluation of Rotavator BaseDocument9 pagesPerformance Evaluation of Rotavator BasevodounnouNo ratings yet