Professional Documents

Culture Documents

Plow Moldboard or Disc Plow

Uploaded by

AdewaleCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Plow Moldboard or Disc Plow

Uploaded by

AdewaleCopyright:

Available Formats

See discussions, stats, and author profiles for this publication at: https://www.researchgate.

net/publication/286314859

Comparison of the energy requirements of an experimental plow, a moldboard

plow and a disk plow

Article in Philippine Agricultural Scientist · June 2007

CITATIONS READS

13 3,078

3 authors, including:

Ahmet Çelik

Ataturk University

45 PUBLICATIONS 650 CITATIONS

SEE PROFILE

Some of the authors of this publication are also working on these related projects:

conservation agriculture View project

hasan kaan View project

All content following this page was uploaded by Ahmet Çelik on 23 January 2016.

The user has requested enhancement of the downloaded file.

Comparison of Energy

THE PHILIPPINE Requirements of an SCIENTIST

AGRICULTURAL Experimental Plow ISSNA.0031-7454

Celik et al.

Vol. 90 No. 2, 173-178

June2007

Research Note

Comparison of the Energy Requirements of an Experimental Plow, a Moldboard

Plow and a Disk Plow

Ahmet Celik*, Mustafa Gokalp Boydas and Nihat Turgut

Ataturk University, Faculty of Agriculture, Department of Agricultural Machinery, 25240 – Erzurum, Turkey.

*Author for correspondence; phone: +90 442 231 2552; fax: +90 442 236 09 58; e-mail: ahcelik@atauni.edu.tr

Field experiments were conducted on a wheat stubble field to compare specific draft and energy

uses of three different plows with three bottoms: an experimental plow (EP), a disk plow (DP) and

a moldboard plow (MP). Plow draft, forward speed and fuel consumption measurements were

made with a test tractor equipped with fuel transducer, three hitch point transducers, ground

speed radar and data logger. The experiments were carried out at a constant depth (20 cm) and

at three tractor forward speeds (4.5, 5.4 and 6.3 km h-1).

The results indicated that the specific draft, drawbar power and fuel consumption were

affected significantly by plows and speeds. Lowest draft and drawbar power were obtained for

the moldboard plow (5.73 kN, 8.39 kW). Lowest specific draft and fuel consumption were obtained

for the experimental plow (2.30 N cm-2, 14.96 L ha-1). Highest draft, specific draft, drawbar power

and fuel consumption were obtained for the disk plow (9.59 kN, 4.15 N cm-2, 14.43 kW and 17.31

L ha-1, respectively). Draft, power and fuel consumption increased with increasing forward speeds.

Overall energy efficiency of all plows ranged from 10–20%. The experimental plow was found to

have the highest field efficiency.

Key Words: disk plow, draft, fuel consumption, moldboard plow, soil tillage

optimize the overall performance in different working

INTRODUCTION conditions (Shrestha et al. 2001).

Draft and power requirements are important parameters

In agricultural practice, primary tillage is considered the for measuring and evaluating performance of tillage

largest power and time-consuming operation, which is implements and therefore are considered to be essential

generally based on the use of the moldboard plow when attempting to correctly match a tillage implement to a

(Shrestha et al. 2001; Bowers 1989). The moldboard plow is tractor (Grisso et al. 1996; Al-Janobi and Al-Suhaibani 1998).

the most common tillage implement in the world, ranging Much research has been done to measure draft and energy

from the simplest type for animal traction, up to the highly requirements of plows under various conditions. In some

advanced, large plows for tractors. This type of plow is not studies, mathematical models have been developed to

completely proper for every field condition, desired tillage predict plow draft (Arvidson et al. 2004; Grisso et al. 1996;

quality and low fuel requirements. The disk plow was Taniguchi et al. 1999; Perfect et al. 1997; Bowers 1989).

developed as an alternative to be used in soil conditions The drawbar energy requirement is dependent on

where the moldboard plow would not work well such as tillage depth, forward speed, soil conditions and implement

heavy and sticky soils, excessively dry soils, soils too hard geometry (Upadhyaya et al. 1984). The effects of speed on

to penetrate and in very loose or stony soils. draft depend on the soil and implement type. It has widely

Many studies have been conducted to optimize the been reported that the draft forces on implements increase

performance of plows in numerous different ways, primarily significantly with speed and the relationship varies from

using a trial and error method under specific operating linear to quadratic (Grisso et al. 1996; Kheiralla et al. 2004).

conditions. Optimizing a plow for every soil condition in Results showed that the draft of moldboard and disc plows

this manner is a time-consuming and difficult task as there increased by the square of speed while the increase of

may be any number of different field conditions. To design draft of many other tillage implements was linearly related

an energy efficient plow for different operating conditions, to speed (Kushwaha and Linke 1996).

it is necessary to consider the interactive effects of plows, The objectives of this study were to design an

soil types and operational parameters. A rigorous study is effective plow as a combination of both a moldboard and

needed to describe the interaction of these factors and to

The Philippine Agricultural Scientist Vol. 90 No. 2 (June 2007) 173

Comparison of Energy Requirements of an Experimental Plow A. Celik et al.

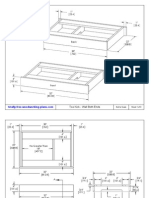

disk plow to produce better soil conditions and minimize which forms the main body of plow (Fig. 1). The disk, which

energy requirements; and compare an experimental plow was assembled on a bearing as it is on a disk plow and

with a moldboard plow and a disk plow with respect to placed on the body of the experimental plow, was 5 cm

draft, power, fuel requirements and field capacity at different high from ground level. The edge of the disk followed the

tractor forward speeds. edge of the moldboard breast on a line as if it were an

extension of its surface.

MATERIALS AND METHODS

Plow Draft and Fuel Consumption Measurements

Experimental Setup During tilling, the draft force, fuel consumption and forward

The experiment was performed in a wheat stubble field at speed of the plows were measured. The draft force was

the Ataturk University, Faculty of Agriculture Farm. Stubble measured by using draft pins, connected with the top and

length was approximately 15 cm. The soil texture of the lower links of three point linkage. 68 kN capacity draft pins

experimental field was classified by Akgul (1987) as silty sensed the horizontal component of the link forces as

loam (26.8% clay, 52.2% silt and 21.0% sand). Average soil voltage. The three draft pins were calibrated prior to the

moisture content, bulk density and cone index of the

experiments by using a specially built calibration rig. All

experimental field were 8.85 % d.b., 1.19 Mg m-3 and 2.32

MPa, respectively. Tillage operations and soil sampling draft recordings were started after the tractor ran in one of

were carried out in October 2004. three forward speeds and finished at the end of each plot.

The experimental design was a complete randomized The recorded length was changed from 30–35 m and the

block design with three replications. Treatments were three frequency of readings was 10 per second. The measured

different types of plows – a moldboard plow (MP), a disk draft data were recorded on a notebook computer and later

plow (DP) and an experimental plow (EP; Zade Baharat- evaluated.

Bakliyat- Tohumculuk, Kayseri, Turkey) – and three tractor Tractor forward speed was measured by a DJRVS II

forward speeds: 4.5, 5.4 and 6.3 km h-1. Tractor forward type radar unit mounted on the left side of the tractor.

speeds were achieved by selecting appropriate gears and Three different forward speeds were achieved by selecting

by adjusting engine throttle at engine speeds (1700–1900 appropriate gears and by adjusting engine throttle at engine

rpm). The adjusted tillage depth was 20 cm. The size of the speeds (1700–1900 rpm). Fuel consumption was measured

plots was 4 m × 50 m. A Ford 5000 S Model tractor (49.4 kW by a flow meter (0.001 L accuracy), which was located in

2100 min-1) was used to pull plows (Anon. 1972). the fuel line between the fuel filter and the injection pump

of the tractor. During tillage, starting and finishing values

Plow Configuration of the flow meter were recorded. Fuel consumption of a

Three different fully mounted types of plows with three pass was determined by the subtracting starting values

bottoms were used in this experiment to evaluate their from the finishing ones.

energy requirement over different tractor forward speeds. Tillage draft and fuel consumption data taken during

Dimensions and other properties of the moldboard plow the field tests were then processed to determine the

(MP), disk plow (DP) and experimental plow (EP) are given average and standard deviation of draft, forward speed,

in Table 1. The experimental plow had been designed as a tillage depth, fuel consumption and effective working

combination of both a moldboard and a disk plows. width.

The experimental plow consisted of three main parts:

a share, a piece of moldboard breast and a concave disk,

Table 1. General specifications of plows.

Specifications Experimental Disk Plow Moldboard

Plow Plow

Number of bottom 3 3 3

Total height (mm) 1250 1160 1190

Total length (mm) 2220 2200 1850

Total width (mm) 1050 1200 1040

Down suction (mm) 25 - 25

Side suction (mm) 5 - 15

Share form pointed - pointed

0

Tilt angle ( ) 0 18 -

0

Disk angle ( ) 28 50 -

Disk diameter (mm) 550 660 -

Total working width (mm) 915 990 820

174 The Philippine Agricultural Scientist Vol. 90 No. 2 (June 2007)

Comparison of Energy Requirements of an Experimental Plow A. Celik et al.

V f * w * fe

Fc =

c

where

Fc = Effective field capacity (ha h-1)

Vf = Forward speed (km h-1)

w = Effective working width (m)

fe = Field efficiency (%)

c = Constant (10)

Field efficiency is described as the ratio of the time when

the plows are tilling at an optimum forward speed and

performing over its full width of action to the total time

spent in the field (Hunt 1983). During tilling, effective

working time, turning time and working width were

recorded, and then field efficiency was calculated according

to the above definition.

RESULTS AND DISCUSSION

The average of the measured effective working width,

working depth, forward speed and field capacity for all

treatments is shown in Table 2. To compare the performance

of the selected plows, an analysis of variance was performed

on these values. The effective working depth of the plows

changed between 21.98–24.10 cm. Working depth was

generally close to the set depth, 20 cm, for the moldboard

plow and was more than the set depth for the experimental

Fig. 1. Front (a) and top (b) views of the experimental plow plow.

The effective working width of the plows changed

The average values of all the data obtained were used between 0.97–1.1 m. The widest working width was obtained

in the statistical analyses. The significance of differences with the experimental plow and the narrowest was obtained

among means was determined using Duncan’s multiple with the moldboard plow. The effect of forward speed on

range test. The level of probability value was set at 0.05 for the effective working width was not statistically important.

all comparisons. As a result of effective working width, the effective field

The effective field capacity of the plow was determined capacity of plows was statistically significant (P<0.05). The

in ha h-1 by using the following equation (Hunt 1983; highest effective field capacity was obtained with the

Srivastava et al. 1993): experimental plow and the lowest one was obtained with

the moldboard plow (Table 2).

Table 2. Average of effective working depth, working width, field capacity and forward

speed.

Working Working Field Forward

Factors Depth Width Capacity Speed

-1 -1

(cm) (m) (ha h ) (km h )

MP 21.98 a 0.97 a 0.43 a 5.26 a

Plows DP 22.82 a 1.02 ab 0.46 ab 5.29 a

EP 24.10 b 1.10 b 0.49 b 5.29 a

Forward 4.5 22.35 a 1.00 a 0.38 a 4.43 a

speeds 5.4 23.05 ab 1.06 a 0.47 b 5.26 b

-1

(km h ) 6.3 23.49 b 1.03 a 0.54 c 6.12 c

Values followed by the same letter within the same column are not significantly different according to Duncan’s

multiple range tests.

The Philippine Agricultural Scientist Vol. 90 No. 2 (June 2007) 175

Comparison of Energy Requirements of an Experimental Plow A. Celik et al.

The average forward speeds were approximately 1.5– plow. Fuel consumption per hour increased with increasing

3% lower than the set values. The effect of plows on forward speed, but fuel consumption per hectare decreased

changing of the set forward speed was not significant. with increasing forward speed (Table 4).

Average speed for the moldboard plow was 5.26 km h-1 and The result obtained for the experimental plow was

was 5.29 km h-1 for the disk and experimental plow. approximately the same as that for the moldboard plow.

A summary of the variance analyses performed on the The experimental plow had the smallest specific draft and

draft and power data for the various plows and forward energy use for soil tilling. This may be attributed to the

speeds is shown in Table 3. The moldboard plow, disk plow geometry and other specification of the plow bottom, which

and experimental plow revealed significant differences for consisted of a share, a moldboard and a disk.

draft and power (P < 0.01). The overall energy efficiency (OEE) includes the load

The draft, drawbar power, specific drawbar power and matching of the tractor and implement, the draft efficiency

specific energy were statistically significant (P < 0.05) for and the engine/power train operating conditions. Overall

plows. Lowest specific draft, drawbar power, unit drawbar energy efficiency values presented in Table 4 for plows

power and specific energy were obtained for the were calculated by the equation given below (Bowers 1985).

experimental plow, and the highest was for the disk plow.

The average specific energy of the experimental plow and (3.6MJkW −1 h −1 ) * PDB

OEE =

the moldboard plow were 18.18 and 19.44 kW h ha-1, (38.7 MJL−1 ) * FC * C

respectively, approximately 37–41% less than that of the where

disk plow (Table 3). OEE = overall energy efficiency (%)

The mean fuel consumption of the moldboard plow, PDB = drawbar power (kW)

disk plow and experimental plow were 15.89 L ha-1, 17.31 L 38.7 = heating value of the diesel fuel (MJ L-1)

ha-1 and 14.96 L ha-1, respectively. The fuel consumption FC = fuel consumption rates required (L ha-1)

of the disk plow was 16% higher than that of the C = theoretical field capacity (ha h-1)

experimental plow and 9% higher than that of the moldboard

Table 3. Average draft, specific draft, drawbar power, specific drawbar power and specific

energy.

Draft Specific Drawbar Specific Specific

Factors (kN) Draft Power Drawbar Power Energy

-2 -1 -1

(N cm ) (kW) (kW m ) (kW h ha )

MP 5.73 a 2.71 a 8.39 a 8.70 a 19.44 a

Plows 31.03 b

DP 9.59 b 4.15 b 14.43 b 14.19 b

EP 6.08 a 2.30 a 9.07 a 8.32 a 18.18 a

Forward 4.5 5.99 a 2.74 a 7.38 a 7.51 a 19.94 a

speeds 22.83 ab

-1 5.4 7.25 b 3.04 a 10.63 b 10.24 b

(km h )

6.3 8.16 b 3.37 a 13.88 c 13.45 c 25.87 b

Values followed by the same letter within the same column are not significantly different according to Duncan’s

multiple range tests.

Table 4. Average fuel consumption and overall energy efficiency.

Fuel Fuel Overall

Factors Consumption Consumption Energy

-1 -1

(L h ) (L ha ) Efficiency (%)

MP 8.01 a 15.89 ab 11

Plows 17

DP 9.18 c 17.31 b

EP 8.61 b 14.96 a 12

Forward 4.5 7.54 a 17.14 a 11

speeds 13

-1 5.4 8.48 b 15.54 a

(km h )

6.3 9.77 c 15.49 a 15

Values followed by the same letter within the same column are not significantly different according to

Duncan’s multiple range tests.

176 The Philippine Agricultural Scientist Vol. 90 No. 2 (June 2007)

Comparison of Energy Requirements of an Experimental Plow A. Celik et al.

The normal range for OEE is 10–20%, and this can be improved by considering the obtained results and their

used as a quick check for the validity of fuel consumption effects on the soil. If the experimental plow can provide the

measurements. A tractor-implement combination having an best effect on soil properties then its energy efficiency will

overall energy efficiency below 10% indicates poor load be more significant.

matching and/or low tractive efficiency, while a value above

20% indicates a good load match and/or high tractive ACKNOWLEDGMENTS

efficiency (Bowers 1985). Table 4 shows that the overall

energy efficiencies of the plows for various forward speed

combinations were between 10% and 20%. The authors are grateful to Zade Baharat-Bakliyat-

Based on the results of this experiment, the Tohumculuk, Kayseri, Turkey for the supply and the use

experimental plow was the most energy efficient plow in of the experimental plow, Mr. Matt Lawrence from the

terms of draft, drawbar power, fuel consumption per hectare Agricultural and Biological Engineering of the

and specific energy, followed by the moldboard plow and Pennsylvania State University for the technical review and

disk plow. valuable suggestions.

Plow share and concave disk may be the main reasons

why the experimental plow was the most energy efficient. REFERENCES CITED

Plow shares could cut and penetrate into the soil easily ABU-HAMDEH NH, REEDER RC. 2003. A nonlinear 3D

and disks could turn over the soil with their concave finite element analysis of the soil forces acting on a

surface. For disc plows the disc angle ranges between 400 disk plow. Soil & Tillage Res 74:115-124.

and 450 and the tilt angle of the disc ranges between 15– AKGÜL M. 1987. A research on the occurrence of plow

250 (O’Dogherty et al. 1996). For the experimental plow, the pan on the soil of Ataturk University, Faculty of

disk angle was reduced to 280 and the tilt angle was reduced Agriculture’s Farm. [Masteral Thesis]. Erzurum:

to 00. Along with reduced tilt and disk angles, smaller disk Ataturk University Institute of Natural and Applied

size and shallower disk concavity reduced vertical and Sciences. (Available at the AU Library). 45 p.

horizontal pressure areas on the disk surface (O’Dogherty AL-JANOBI AA, AL-SUHAIBANI SA. 1998. Draft of

et al. 1996). These may be the main reasons for the lower primary tillage implements in sandy loam soil. Appl

energy requirements of the experimental plow. Eng Agric 14 (4): 343-348.

The effects of the experimental plow on soil physical ANONYMOUS. 1972. Agricultural Engineers Yearbook of

conditions, such as mixing, breaking, producing straight Standards. St. Joseph, MI , U.S.A.: American Society

furrow, producing smooth tillage bottom and covering plant of Agricultural Engineers.

residue, were not part of this particular investigation, but ARVIDSSON J, KELLER J, GUSTAFSSON K. 2004.

should be studied in the future to be sure if the experimental Specific draft for moldboard plow, chisel plow and

plow can improve soil conditions at lower energy disc harrow at different water contents. Soil & Tillage

consumption. Res 79: 221–231.

BOWERS Jr. CG. 1985. Southeastern tillage energy data

CONCLUSION and recommended reporting. Trans ASAE 28 (3): 731-

Summaries of power and energy requirements have been 737.

reported for the moldboard plow, the disk plow and the BOWERS Jr CG. 1989. Tillage draft and energy

experimental plow. The experimental plow was the most measurements for twelve southeastern soil series.

energy efficient implement in terms of draft, drawbar power, Trans ASAE 32 (5): 1492–1502.

fuel consumption per hectare and specific energy, followed GRISSO RD, YASIN M, KOCHER MF. 1996. Tillage

by the moldboard plow and disk plow. The specific draft implement forces operating in silty clay loam. Trans

was generally the highest for the disk plow and the lowest ASAE 39(6): 1977-1982.

for the experimental plows. The differences can probably HUNT D. 1983. Farm Power and Machinery Management.

be explained by differences in the plow’s geometry and the 8th ed. Iowa, U.S.A.: The Iowa State University Press.

tilt angle of disk plow (Abu-Hamdeh and Reeder 2003). KHEIRALLA AF, YAHYA A, ZOHADIE M, IHSAK W.

Increasing forward speed increased specific draft, power 2004. Modelling of power and energy equirements

and fuel consumption as expected. for tillage implements operating in Serdang sandy

The results also showed that the experimental plow is clay loam, Malaysia. Soil & Tillage Res 78: 21-34.

the best for energy efficiency in soil tillage and should be KUSHWAHA RL, LINKE C. 1996. Draft-speed relationship

of simple tillage tools at high operating speeds. Soil

& Tillage Res 39: 61-73.

The Philippine Agricultural Scientist Vol. 90 No. 2 (June 2007) 177

Comparison of Energy Requirements of an Experimental Plow A. Celik et al.

O’DOGHERTY MJ, GODWIN RJ, HANN MJ, Al-Ghazal SRIVASTAVA AK, GOERING CE, ROHRBACH RP. 1993.

AA. 1996. A geometrical analysis of inclined and Engineering Principles of Agricultural Machines.

tilted spherical plough discs. J Agric Eng Res 63: ASAE Textbook No. 6, 2950 Niles Road, St. Joseph,

205 -218. Michigan 49085-9659, U.S.A.

PERFECT E, MCLAUGHLIN NB, KAY BD. 1997. Energy TANIGUCHI T, MAKANGA JT, OHTOMO K,

requirements for conventional tillage following KISHIMOTO T. 1999. Draft and soil manipulation by

different crop rotations. Trans ASAE 40(1): 45-49. a moldboard plow under different forward speed and

SHRESTHA DS, SINGH G, GEBRESENBET G. 2001. body attachments. Trans ASAE 42(6): 1517-1521.

Optimizing design parameters of a moldboard plow. UPADHYAYA SK, WILLIAMS TH, KEMBLE LJ, COLLINS

J Agric Eng Res 78 (4): 377-389. NE. 1984. Energy requirement for chiseling in coastal

plain soils. Trans ASAE 27 (6): 1643-1649.

178 The Philippine Agricultural Scientist Vol. 90 No. 2 (June 2007)

View publication stats

You might also like

- Fluid Mixing II: A Symposium Organised by the Yorkshire Branch and the Fluid Mixing Processes Subject Group of the Institution of Chemical Engineers and Held at Bradford University, 3-5 April 1984From EverandFluid Mixing II: A Symposium Organised by the Yorkshire Branch and the Fluid Mixing Processes Subject Group of the Institution of Chemical Engineers and Held at Bradford University, 3-5 April 1984No ratings yet

- Draft Force Inputs For Primary and Secondary Tillage Implements in A Clay Loam Soil - 2013 - Askari, KhalifahamzehghasemDocument6 pagesDraft Force Inputs For Primary and Secondary Tillage Implements in A Clay Loam Soil - 2013 - Askari, KhalifahamzehghasemVijay ChavanNo ratings yet

- 216605-Article Text-533466-1-10-20211026Document7 pages216605-Article Text-533466-1-10-20211026Alex AdamsNo ratings yet

- Development of An Equipment For Measuring Pressure-Sinkage Behaviour of A Heavy Clay SoilDocument10 pagesDevelopment of An Equipment For Measuring Pressure-Sinkage Behaviour of A Heavy Clay SoilPeter AjewoleNo ratings yet

- Analysis of Tractor Transmission Pm2805Document8 pagesAnalysis of Tractor Transmission Pm2805Sunilkumar ReddyNo ratings yet

- Draught Prediction of Agricultural ImplementsDocument10 pagesDraught Prediction of Agricultural ImplementsRahma IelmahNo ratings yet

- Soil Dynamics in TillageDocument14 pagesSoil Dynamics in Tillagerevange2112No ratings yet

- Design and Analysis of Disc Plough For Agricultural IndustryDocument12 pagesDesign and Analysis of Disc Plough For Agricultural Industryሐይማኖቴ ህያዉ ናትNo ratings yet

- Manjeet PreM Et Al 1Document8 pagesManjeet PreM Et Al 1Prem Ranjan MehtaNo ratings yet

- Effect of Disc and Tilt Angles of Disc PDocument12 pagesEffect of Disc and Tilt Angles of Disc PMuhammad DennyNo ratings yet

- Effects of Different Tire Configurations On Tractor Performance (#138475) - 119900Document8 pagesEffects of Different Tire Configurations On Tractor Performance (#138475) - 119900Caio GiarettaNo ratings yet

- Soil & Tillage Research: Jafar Habibi Asl, Surendra SinghDocument7 pagesSoil & Tillage Research: Jafar Habibi Asl, Surendra Singhdiegomanuel123No ratings yet

- Development of A Unique, Mobile, Single Wheel Traction Testing MachineDocument4 pagesDevelopment of A Unique, Mobile, Single Wheel Traction Testing MachineUjjal DeyNo ratings yet

- Effect of Ballast and Tire Inflation Pressure On Wheel SlipDocument5 pagesEffect of Ballast and Tire Inflation Pressure On Wheel SlipRavi VhtakarNo ratings yet

- Finite element analysis of subsoiler and paraplow tinesDocument7 pagesFinite element analysis of subsoiler and paraplow tinesLiv CBNo ratings yet

- Development and Evaluation of A Prototype Manual Precision Rice Planter For Smallholder Farmers in North-Eastern NigeriaDocument8 pagesDevelopment and Evaluation of A Prototype Manual Precision Rice Planter For Smallholder Farmers in North-Eastern NigeriaOyeniyi Samuel KehindeNo ratings yet

- Articol Buletin UPBDocument12 pagesArticol Buletin UPBMihai MatacheNo ratings yet

- Draught and Soil Disturbance of Model TiDocument18 pagesDraught and Soil Disturbance of Model TivodounnouNo ratings yet

- Computer Simulations To Maximise Fuel Efficiency and Work Performance of Agricultural Tractors in Rotovating and Ploughing OperationsDocument11 pagesComputer Simulations To Maximise Fuel Efficiency and Work Performance of Agricultural Tractors in Rotovating and Ploughing OperationsKhairulNo ratings yet

- 1 s2.0 S0022489817302239 MainDocument12 pages1 s2.0 S0022489817302239 MainendryasNo ratings yet

- 7 Ijasraug20197Document8 pages7 Ijasraug20197TJPRC PublicationsNo ratings yet

- 03 - Review of LiteratureDocument10 pages03 - Review of LiteratureAbhi BarathNo ratings yet

- Ijasr - Performance Evaluation of Tractor Operated PDFDocument10 pagesIjasr - Performance Evaluation of Tractor Operated PDFAnonymous dbnms1yNo ratings yet

- Calculo Draft - AhmadiDocument6 pagesCalculo Draft - AhmadiferNo ratings yet

- Draught Requirements of Enamel Coated Animal Drawn Mouldboard PloughDocument7 pagesDraught Requirements of Enamel Coated Animal Drawn Mouldboard PloughSHOLANKE EZEKIEL SHOWUNMINo ratings yet

- Development of A Portable Pneumatic Grain Broadcasting Unit: Ahmad, M. CDocument8 pagesDevelopment of A Portable Pneumatic Grain Broadcasting Unit: Ahmad, M. CMariana VictoriaNo ratings yet

- Experimental Validation of Computational Uid Dynamics Modeling For Narrow Tillage Tool DraftDocument7 pagesExperimental Validation of Computational Uid Dynamics Modeling For Narrow Tillage Tool DraftistimatNo ratings yet

- Traktori Drugi SeminarskiDocument16 pagesTraktori Drugi SeminarskiStefanPericNo ratings yet

- IJASR - Field and Economic Studies of Tractor Operated Manure SpreadeDocument10 pagesIJASR - Field and Economic Studies of Tractor Operated Manure SpreadeTJPRC PublicationsNo ratings yet

- Development A Feeding Mechanism of Chopper For Chopping Sugarcane BagasseDocument19 pagesDevelopment A Feeding Mechanism of Chopper For Chopping Sugarcane BagassedansihNo ratings yet

- Journal of Terramechanics 1972 Vol. 9 No. 1 pp. 65-72 AbstractsDocument1 pageJournal of Terramechanics 1972 Vol. 9 No. 1 pp. 65-72 Abstractsjuan carlosNo ratings yet

- Comparison of Energy of Tillage System in Wheat PRDocument6 pagesComparison of Energy of Tillage System in Wheat PRFedhii CaaliiNo ratings yet

- EEAE2022_Veleva_HristovaDocument5 pagesEEAE2022_Veleva_Hristovaгл.ас. Галя ХристоваNo ratings yet

- T.K. Maheshwari and Uday Veer Singh2Document8 pagesT.K. Maheshwari and Uday Veer Singh2biswaNo ratings yet

- Afriani 2019 IOP Conf. Ser. Earth Environ. Sci. 245 012039Document7 pagesAfriani 2019 IOP Conf. Ser. Earth Environ. Sci. 245 012039Angel VargasNo ratings yet

- Ama 44 (3) 2013Document7 pagesAma 44 (3) 2013Associate Professor Dr. Said Elshahat AbdallahNo ratings yet

- Bertonha 9 9 2015 812 818Document8 pagesBertonha 9 9 2015 812 818Vandyck Mensah EmmanuelNo ratings yet

- Performance of Sprinkler Irrigation Systems at DifferentDocument7 pagesPerformance of Sprinkler Irrigation Systems at DifferentKarem Meza CapchaNo ratings yet

- Agan PressuremeterDocument8 pagesAgan PressuremeterVeenoyNo ratings yet

- Parameters Affecting Tractor Fuel Consumption During Primary Tillage Operation in Uyo, Akwa Ibom State, NigeriaDocument6 pagesParameters Affecting Tractor Fuel Consumption During Primary Tillage Operation in Uyo, Akwa Ibom State, NigeriaMamta AgarwalNo ratings yet

- A Review On Problem Identification in Tyne For 5-Tyne Duck Foot CultivatorDocument6 pagesA Review On Problem Identification in Tyne For 5-Tyne Duck Foot CultivatorIJRASETPublicationsNo ratings yet

- Calculation of The Power Requirement For Soil Cutting by Rotary Tool BladeDocument8 pagesCalculation of The Power Requirement For Soil Cutting by Rotary Tool BladeVIJAY MOURYANo ratings yet

- New Model Predicts Particle Size from Impact CrushingDocument4 pagesNew Model Predicts Particle Size from Impact CrushingKallol MahalanabisNo ratings yet

- Laterite Soil Shear Strength Characteristics From The Use of The Standard Proctor and Compression MachineDocument13 pagesLaterite Soil Shear Strength Characteristics From The Use of The Standard Proctor and Compression MachineAZOJETENo ratings yet

- Measurement of Strains Induced On A Three-Bottom MoldboardDocument33 pagesMeasurement of Strains Induced On A Three-Bottom MoldboardJohn Paulo PeridoNo ratings yet

- Weeder pdf33Document8 pagesWeeder pdf33Anonymous 1MgSpwNo ratings yet

- Vibration Effects On The Performance of A Single-Shank SubsoilerDocument12 pagesVibration Effects On The Performance of A Single-Shank SubsoilerمحمدکعبیNo ratings yet

- Mini Excavator Design and AnalysisDocument9 pagesMini Excavator Design and AnalysisInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Suitability Assessment of Soils For Pavement Subgrade Using Gyratory Compaction and Bearing Capacity TestingDocument5 pagesSuitability Assessment of Soils For Pavement Subgrade Using Gyratory Compaction and Bearing Capacity Testingyoseph dejeneNo ratings yet

- Cyclic Loading On Foundation To Evaluate The Coefficient of Elastic Uniform Compression of SandDocument8 pagesCyclic Loading On Foundation To Evaluate The Coefficient of Elastic Uniform Compression of SandMehedi HasanNo ratings yet

- Influence of Tillage Depth, Penetration Angle and Forward Speed OnDocument6 pagesInfluence of Tillage Depth, Penetration Angle and Forward Speed OnBF DalmagroNo ratings yet

- Design and Evaluation of Crushing Hammer Mill: January 2019Document25 pagesDesign and Evaluation of Crushing Hammer Mill: January 2019ppd9890No ratings yet

- Prediction of Fuel Consumption of MiningDocument8 pagesPrediction of Fuel Consumption of MiningRonaldNo ratings yet

- Turbo Generator Foundation Design Using Sap2000Document9 pagesTurbo Generator Foundation Design Using Sap2000Syed Rizwan SaleemNo ratings yet

- Calculation of Optimum Soil Conditioning in EPB Tunneling (Case Study: Ahwaz Metro Project, Line 1)Document13 pagesCalculation of Optimum Soil Conditioning in EPB Tunneling (Case Study: Ahwaz Metro Project, Line 1)ahmed lotfyNo ratings yet

- A Three-Point Hitch Dynamometer For Load MeasuremeDocument7 pagesA Three-Point Hitch Dynamometer For Load MeasuremeCaio GiarettaNo ratings yet

- Draft Relationships For Tillage and SeedDocument11 pagesDraft Relationships For Tillage and SeedvodounnouNo ratings yet

- Plant Power ShredderDocument27 pagesPlant Power ShredderDanica Joyce DayritNo ratings yet

- A2 PDFDocument16 pagesA2 PDFMirza SakibNo ratings yet

- Tillage Pattern For Fuel EcomoniDocument4 pagesTillage Pattern For Fuel EcomoniMunnaf M AbdulNo ratings yet

- A Review and Critique of Academic Lab Safety ResearchDocument9 pagesA Review and Critique of Academic Lab Safety ResearchAdewaleNo ratings yet

- Lightweight Mouldboard PlowsDocument12 pagesLightweight Mouldboard PlowsAdewaleNo ratings yet

- Ruling On Using Eggs or Sperm From Someone Other Than The Spouses in Artificial InseminationDocument1 pageRuling On Using Eggs or Sperm From Someone Other Than The Spouses in Artificial InseminationAdewaleNo ratings yet

- Plowing With MoldboardDocument14 pagesPlowing With MoldboardAdewaleNo ratings yet

- Agronomy 06 00030Document12 pagesAgronomy 06 00030AdewaleNo ratings yet

- Handbook of Research MethodologyDocument28 pagesHandbook of Research Methodologyaggarwalakanksha0% (1)

- Particle Agglomeration of Acid-Modified Tapioca Starches: Characterization and Use As Direct Compression Fillers in TabletsDocument16 pagesParticle Agglomeration of Acid-Modified Tapioca Starches: Characterization and Use As Direct Compression Fillers in TabletsAdewaleNo ratings yet

- 6 3 The Iodine Clock Reaction LabDocument3 pages6 3 The Iodine Clock Reaction LabAdewaleNo ratings yet

- Current Research in Green and Sustainable Chemistry: Luna Jena, Dhani Soren, Pratap Kumar Deheri, Puspalata PattojoshiDocument5 pagesCurrent Research in Green and Sustainable Chemistry: Luna Jena, Dhani Soren, Pratap Kumar Deheri, Puspalata PattojoshiAdewaleNo ratings yet

- Catalyst From BaggasemainDocument14 pagesCatalyst From BaggasemainAdewaleNo ratings yet

- Ruling On A Muslim Entering A Church: The QuestionDocument4 pagesRuling On A Muslim Entering A Church: The QuestionAdewaleNo ratings yet

- 6 3 The Iodine Clock Reaction Student Lab SheetDocument3 pages6 3 The Iodine Clock Reaction Student Lab SheetAdewaleNo ratings yet

- 6 3 The Iodine Clock Reaction Lab AnswersDocument4 pages6 3 The Iodine Clock Reaction Lab AnswersAdewaleNo ratings yet

- Lesson 3 Overview - FSC 432 - Petroleum RefiningDocument1 pageLesson 3 Overview - FSC 432 - Petroleum RefiningAdewaleNo ratings yet

- EPA AP42 Section 5 - Petroleum RefiningDocument16 pagesEPA AP42 Section 5 - Petroleum RefiningStephen BoyleNo ratings yet

- Engineering Chemistry PDFDocument39 pagesEngineering Chemistry PDFYash NaiwarNo ratings yet

- Rada 2018Document10 pagesRada 2018AdewaleNo ratings yet

- Corrosion and Management in Oil and GasDocument11 pagesCorrosion and Management in Oil and GasAdewaleNo ratings yet

- XRD 2Document2 pagesXRD 2AdewaleNo ratings yet

- The Determination of Iron (II) by Redox Titration: Experiment 15Document1 pageThe Determination of Iron (II) by Redox Titration: Experiment 15AdewaleNo ratings yet

- Prostration For ForgetfulnessDocument16 pagesProstration For ForgetfulnessAdewaleNo ratings yet

- 03 - Toe Kick Wall Both EndsDocument3 pages03 - Toe Kick Wall Both Endsrocky21stNo ratings yet

- BS EN 10106:1996 Standard for Cold Rolled Non-Oriented Electrical Steel Sheet and StripDocument18 pagesBS EN 10106:1996 Standard for Cold Rolled Non-Oriented Electrical Steel Sheet and Stripurias90No ratings yet

- Lecture 13 Yield CriterionDocument10 pagesLecture 13 Yield CriterionManoj MallickNo ratings yet

- HistorianRetrieval PDFDocument233 pagesHistorianRetrieval PDFynnaNo ratings yet

- Final 2010Document8 pagesFinal 2010Hakkı ÇelimliNo ratings yet

- Master: The New Polypropylene Sewer Pipe SystemDocument6 pagesMaster: The New Polypropylene Sewer Pipe SystemFaraj MohamedNo ratings yet

- JM IND AluminumCorrugatedSheets DSDocument2 pagesJM IND AluminumCorrugatedSheets DSGia Minh Tieu TuNo ratings yet

- Jetking Rajajinagar MinDocument7 pagesJetking Rajajinagar MinNeha ShekarNo ratings yet

- Page 29 PDFDocument1 pagePage 29 PDFJuan Ponce ManríquezNo ratings yet

- V-30i H.D.H Machine Instruction ManualDocument54 pagesV-30i H.D.H Machine Instruction ManualsunhuynhNo ratings yet

- Production Report November 2021Document9 pagesProduction Report November 2021nasir ahmedNo ratings yet

- Summative Test New NormalDocument1 pageSummative Test New NormalElron KarlNo ratings yet

- GP1850 Service Manual - FurunoDocument24 pagesGP1850 Service Manual - FurunoCarlos Proaño100% (1)

- OEVDocument2 pagesOEVVikash Khaliyav YadavNo ratings yet

- Government of Chhattisgarh: Ublic Orks EpartmentDocument19 pagesGovernment of Chhattisgarh: Ublic Orks EpartmentLucky ChopraNo ratings yet

- Ancillary Products: DualproofDocument24 pagesAncillary Products: DualproofNightly OwlNo ratings yet

- Wall Roof ThimblesDocument3 pagesWall Roof Thimblessiyavash seifNo ratings yet

- Characteristics OF SEWAGEDocument10 pagesCharacteristics OF SEWAGEBalanlan PenalesNo ratings yet

- 01 - Different Types of Metal Joining ProcessesDocument44 pages01 - Different Types of Metal Joining ProcessesMetwally NaserNo ratings yet

- Aplications of Engine RoomDocument10 pagesAplications of Engine Roomady.sabauNo ratings yet

- GeoxdrawDocument12 pagesGeoxdrawWelsinsin Kevin SinNo ratings yet

- VIEWIT: Computation of Seen Areas, Slope, and Aspect For Land-Use PlanningDocument67 pagesVIEWIT: Computation of Seen Areas, Slope, and Aspect For Land-Use PlanningPACIFIC SOUTHWEST RESEARCH STATION REPORTNo ratings yet

- Literature Review Concrete BlockDocument8 pagesLiterature Review Concrete Blockc5r0xg9z100% (1)

- Fallout76 Config FileDocument4 pagesFallout76 Config FilesalianheinrichNo ratings yet

- Sheet Metal Tools PDFDocument13 pagesSheet Metal Tools PDFANDERSON LIMA DA SILVANo ratings yet

- COD orders for stainless steel water bottlesDocument588 pagesCOD orders for stainless steel water bottlessattar khanNo ratings yet

- Model ICB 100-800 HP Boilers: Performance DataDocument4 pagesModel ICB 100-800 HP Boilers: Performance DatasebaversaNo ratings yet

- Computaion IntelligentDocument624 pagesComputaion IntelligentThaiHuynhNgocNo ratings yet

- Css - Divide - Content - Area Into Two Columns - Stack OverflowDocument5 pagesCss - Divide - Content - Area Into Two Columns - Stack OverflowjunkyardNo ratings yet

- Request For Quotation - Pile WorksDocument2 pagesRequest For Quotation - Pile WorksOsama MZNo ratings yet

- Antifog Disc InsulatorDocument35 pagesAntifog Disc InsulatorJayant Kumar DasNo ratings yet