Professional Documents

Culture Documents

Indirect-Fired Heater: Prevent Hydrate Formation, Reduce Viscosity, and Break Down Emulsions

Uploaded by

Chams Eddine Chehidi0 ratings0% found this document useful (0 votes)

47 views1 pageIndirect fired heater

Original Title

indirect-fired-heater-ps (1)

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentIndirect fired heater

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

47 views1 pageIndirect-Fired Heater: Prevent Hydrate Formation, Reduce Viscosity, and Break Down Emulsions

Uploaded by

Chams Eddine ChehidiIndirect fired heater

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

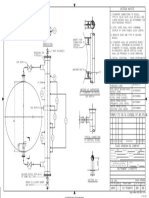

Indirect-Fired Heater

Prevent hydrate formation, reduce viscosity, and break down emulsions

Applications The skid-mounted indirect-fired diesel heater

■■ Operations requiring the heating is used for raising the temperature of well

of well effluents effluents to prevent hydrate formation,

reduce viscosity, and break down emulsions.

Benefits

■■ Improved efficiency through hydrate This unit consists of a vessel for water bath

formation prevention, viscosity at atmospheric pressure, a 4-in [102-mm] split

reduction, and emulsion break down coil with intermediate choke, and an adjust-

able choke with a 1.5-in [38-mm] seat and

Features

solid-stem tip. A manifold is equipped with

■■ Vessel for water bath

three 3.125-in [79-mm] gate valves rated to

at atmospheric pressure

5,000-psi [34-MPa] working pressure. Indirect-fired heater.

■■ Split coil with intermediate choke

The heater also includes a diesel shutdown

■■ Adjustable choke with a 1.5-in seat

valve actuated by a pilot-light stoppage

and a solid-stem tip

and temperature controller, a flame arrestor

■■ Three 3.125-in gate valves rated on the burner air inlet, and a spark arrestor

to 5,000-psi working pressure on the chimney exhaust.

■■ Diesel shutdown valve controlled

by pilot-light stoppage and

temperature controller Specifications

Model IHT-BAG

■■ Flame arrestor on burner air inlet

Service H2S

■■ Spark arrestor on chimney exhaust

Fluid class DD

Working temperature, degF [degC] 32 to 200 [0 to 93]

Working pressure (coil), psi [MPa] 5,000 [34] upstream and downstream from the choke

Heating capacity, MMBtu/h [J/h] 2 [2,120]

Diesel consumption, galUS/h [L/h] 29 [110]

Effluent inlet connection 3-in Fig 1002 Female

Effluent outlet connection 3-in Fig 1002 Male

Diesel inlet connection 1⁄4-in NPT

Electrical supply 400 V AC at 60 Hz, 10 A

Footprint, ft × ft [m × m] 19.4 × 7.4 [5.90 × 2.25]

Height, ft [m] 13.1 [4.0] with chimney

Weight, lbm [kg] 33,069 [15,000]

Certifications

Design Type Approval/Design Verification Review

Manufacturing Certificate of Conformity

Documentation Quality File and Load Test

Applicable codes ANSI B31.3, API-6A (PSL-2), API-12K, H2S (NACE MR0175)

Optional accessories Set of D58 choke beans, part number P582643

*Mark of Schlumberger

Other company, product, and service names

www.slb.com/BeCertain

are the properties of their respective owners.

Copyright © 2011 Schlumberger. All rights reserved. 10-TS-0032

You might also like

- Cisco Itp in Eservglobal In: Sigtran and Itp TrainingDocument263 pagesCisco Itp in Eservglobal In: Sigtran and Itp TrainingbayoubgoorNo ratings yet

- Flare Technical Specification PDFDocument15 pagesFlare Technical Specification PDFJabel Oil Services Technical DPT100% (1)

- Chemical Process Retrofitting and Revamping: Techniques and ApplicationsFrom EverandChemical Process Retrofitting and Revamping: Techniques and ApplicationsGade Pandu RangaiahNo ratings yet

- DC 950045 001Document1 pageDC 950045 001Abu Anas M.SalaheldinNo ratings yet

- HKJFTCC 1 DKK 1B M GPT 99 05654 PDFDocument18 pagesHKJFTCC 1 DKK 1B M GPT 99 05654 PDFIBIKUNLENo ratings yet

- Saes-J-002 - 2012Document32 pagesSaes-J-002 - 2012NSJAa100% (1)

- Flare System Data SheetDocument5 pagesFlare System Data SheetrutujaNo ratings yet

- 2012 FlaretechreportDocument275 pages2012 Flaretechreportalberto esau reyes cruzNo ratings yet

- Protect Your Power Plant With Continuous Security.: SPPA-T3000 R8.2Document8 pagesProtect Your Power Plant With Continuous Security.: SPPA-T3000 R8.2Melchor VasquezNo ratings yet

- Sabp Z 060Document27 pagesSabp Z 060Hassan MokhtarNo ratings yet

- Fan Basics and Selection CriteriaDocument6 pagesFan Basics and Selection CriteriaSangamesh WaranNo ratings yet

- Free Instrumentation Excel Spreadsheet tools Hydrostatic Level Calculator and Orifice plate flow error calculator - Field Instrumentation - Industrial Automation, PLC Programming, scada & Pid Control System.pdfDocument2 pagesFree Instrumentation Excel Spreadsheet tools Hydrostatic Level Calculator and Orifice plate flow error calculator - Field Instrumentation - Industrial Automation, PLC Programming, scada & Pid Control System.pdfMeshackMukaka100% (1)

- 123, SPECS-GAS-123, Mini QGM Floating Gas Trap, Rev 2Document2 pages123, SPECS-GAS-123, Mini QGM Floating Gas Trap, Rev 2fahrain2012No ratings yet

- NTF-DS-CV-001 Data Sheet Control Valve Rev.BDocument4 pagesNTF-DS-CV-001 Data Sheet Control Valve Rev.BRicardo NapitupuluNo ratings yet

- Sabp P 002 PDFDocument15 pagesSabp P 002 PDFAnonymous evKjt4OeENo ratings yet

- Managing Obsolete Technologies - Strategies and PracticesDocument30 pagesManaging Obsolete Technologies - Strategies and PracticescarakooloNo ratings yet

- Saes T 481 PDFDocument9 pagesSaes T 481 PDFQa QcNo ratings yet

- TMR Vs QMR TMR Vs QMR TMR vs. QMR TMR vs. QMRDocument15 pagesTMR Vs QMR TMR Vs QMR TMR vs. QMR TMR vs. QMRdijoz85No ratings yet

- Saes J 505Document16 pagesSaes J 505aaaNo ratings yet

- Saep 303Document59 pagesSaep 303Demac SaudNo ratings yet

- Saep 135Document46 pagesSaep 135Demac SaudNo ratings yet

- Saes Z 004Document40 pagesSaes Z 004nadeem100% (1)

- Det Tronics Eqp Safety System Software s3 GraphicsDocument327 pagesDet Tronics Eqp Safety System Software s3 GraphicsNestor German Pissoni100% (1)

- Saes J 902Document32 pagesSaes J 902Mudabbir HussainNo ratings yet

- Sabp Z 017Document72 pagesSabp Z 017Salvatore MasalaNo ratings yet

- Siemens Ihm Pxm50.e A6v11211557 enDocument71 pagesSiemens Ihm Pxm50.e A6v11211557 enMatheus PraseresNo ratings yet

- 34 Samss 617Document9 pages34 Samss 617Rodolfo Garcia HernandezNo ratings yet

- 60a11 ReadingDocument19 pages60a11 Readingishu vohraNo ratings yet

- RLP Topd HDD e 1800 0046 H1 R2Document10 pagesRLP Topd HDD e 1800 0046 H1 R2fedemochileroNo ratings yet

- B0750as RDocument474 pagesB0750as RCamiloNo ratings yet

- Saes B 061Document19 pagesSaes B 061Ahmed Nasralla HefnawyNo ratings yet

- Materials System SpecificationDocument6 pagesMaterials System SpecificationEagle SpiritNo ratings yet

- Dse PN MetricDocument29 pagesDse PN MetricSuman DeyNo ratings yet

- Nioec-Sp-00-50 Criteria For Process and MechanicsDocument37 pagesNioec-Sp-00-50 Criteria For Process and MechanicsCalNo ratings yet

- Sae 44Document26 pagesSae 44Anonymous 4IpmN7OnNo ratings yet

- SAES-Z-002 Regulated Vendors List For Process Automation SystemsDocument14 pagesSAES-Z-002 Regulated Vendors List For Process Automation SystemsZubair RaoofNo ratings yet

- CPU945 6ES5998-3UF21 06 e OCR PDFDocument673 pagesCPU945 6ES5998-3UF21 06 e OCR PDFfabyanoNo ratings yet

- C84-01-ICS-IsT-04 Communication Signal List (Modbus List) REV.2Document8 pagesC84-01-ICS-IsT-04 Communication Signal List (Modbus List) REV.2wqs_19No ratings yet

- Instrument Installation: NIOEC-SP-70-02Document23 pagesInstrument Installation: NIOEC-SP-70-02Mohammad AminiNo ratings yet

- Engineering Standard: IPS-E-IN-160Document96 pagesEngineering Standard: IPS-E-IN-160Anonymous nz5jy6No ratings yet

- Fdocuments - in - Shell Dep ListDocument25 pagesFdocuments - in - Shell Dep Listdeyanshu7No ratings yet

- 015-FH-1002 (Rev.1) PDFDocument8 pages015-FH-1002 (Rev.1) PDFarjun PV RaoNo ratings yet

- Sabp Z 064Document33 pagesSabp Z 064Hassan MokhtarNo ratings yet

- ValSpeQ 4.16.2 Release NoteDocument3 pagesValSpeQ 4.16.2 Release NoteEDUARDONo ratings yet

- Engineering Encyclopedia: Heat Exchanger Concepts, BasicDocument22 pagesEngineering Encyclopedia: Heat Exchanger Concepts, Basicdineshnandhu007No ratings yet

- Emergency ShutdownDocument77 pagesEmergency ShutdownNazim MirzaNo ratings yet

- Saes J 002Document25 pagesSaes J 002Dinesh BoopalanNo ratings yet

- Engineered Temperature CP003R - Eng-TempDocument16 pagesEngineered Temperature CP003R - Eng-TemppeccNo ratings yet

- Best Practice: Load Management For Energy Efficiency: Heat Transfer EquipmentDocument75 pagesBest Practice: Load Management For Energy Efficiency: Heat Transfer Equipmentsethu1091No ratings yet

- 34 Samss 118 PDFDocument9 pages34 Samss 118 PDFCherukunnon JubuNo ratings yet

- May 12Document33 pagesMay 12dillipsh123No ratings yet

- 305.icm-Ou-11.07 Programmable Logic ControllerDocument28 pages305.icm-Ou-11.07 Programmable Logic ControllerTpNo ratings yet

- Saes S 040Document22 pagesSaes S 040Mohammed YousufNo ratings yet

- Saes y 301Document10 pagesSaes y 301kartik_harwani4387No ratings yet

- Valves and Regulators - Turndown RatioDocument3 pagesValves and Regulators - Turndown RatioklashincoviskyNo ratings yet

- 2501-General Instructions For Thermal DesignDocument12 pages2501-General Instructions For Thermal DesignfarooqkhanerNo ratings yet

- ISO 12213-3 Part 1 - Introduction and GuidelinesDocument8 pagesISO 12213-3 Part 1 - Introduction and GuidelinesserefbingolNo ratings yet

- SP-2061 - Technical Authority SystemDocument22 pagesSP-2061 - Technical Authority Systemarjunprasannan7No ratings yet

- 61a1 ReadingDocument7 pages61a1 Readingishu vohraNo ratings yet

- R2 00 MGS2800HV (50Hz 10kV)Document4 pagesR2 00 MGS2800HV (50Hz 10kV)luat1983No ratings yet

- Guide On Multiple RegressionDocument29 pagesGuide On Multiple RegressionLucyl MendozaNo ratings yet

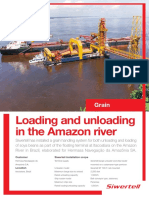

- Casesheet 086 Siwertell Hermasa Brazil Grain Unloader TerminalDocument2 pagesCasesheet 086 Siwertell Hermasa Brazil Grain Unloader TerminalersNo ratings yet

- CERES News Digest - Week 11, Vol.4, March 31-April 4Document6 pagesCERES News Digest - Week 11, Vol.4, March 31-April 4Center for Eurasian, Russian and East European StudiesNo ratings yet

- Berger Paints - Ar-19-20 PDFDocument302 pagesBerger Paints - Ar-19-20 PDFSahil Garg100% (1)

- Midterm Quiz 01 - Adjusting Entries From Accrual To Provision For Uncollectible AccountsDocument3 pagesMidterm Quiz 01 - Adjusting Entries From Accrual To Provision For Uncollectible AccountsGarp Barroca100% (1)

- Galanz - Galaxy 7-9-12K - SPLIT PDFDocument42 pagesGalanz - Galaxy 7-9-12K - SPLIT PDFUbaldo BritoNo ratings yet

- PraxiarDocument8 pagesPraxiara_roy003No ratings yet

- Solar Power Plant in Iit HyderabadDocument9 pagesSolar Power Plant in Iit HyderabadHimanshu VermaNo ratings yet

- DenmarkDocument4 pagesDenmarkFalcon KingdomNo ratings yet

- Aug 2020 Builders Line Tamil MonthlyDocument48 pagesAug 2020 Builders Line Tamil MonthlyBuildersLineMonthlyNo ratings yet

- BSDC CCOE DRAWING FOR 2x6 KL R-1Document1 pageBSDC CCOE DRAWING FOR 2x6 KL R-1best viedosNo ratings yet

- Che 342 Practice Set I IDocument4 pagesChe 342 Practice Set I IDan McNo ratings yet

- T53 L 13 Turboshaft EngineDocument2 pagesT53 L 13 Turboshaft EngineEagle1968No ratings yet

- Grant Miller Resume-ColliersDocument3 pagesGrant Miller Resume-ColliersDeven GriffinNo ratings yet

- ASTM G165-99 (R2005) Standard Practice For Determining Rail-To-Earth ResistanceDocument5 pagesASTM G165-99 (R2005) Standard Practice For Determining Rail-To-Earth Resistance曾乙申100% (1)

- Steinway Case - CH 03Document5 pagesSteinway Case - CH 03Twēéty TuiñkleNo ratings yet

- Evaluation of Performance of Container Terminals T PDFDocument10 pagesEvaluation of Performance of Container Terminals T PDFjohnNo ratings yet

- q2 Long Quiz 002 EntreDocument8 pagesq2 Long Quiz 002 EntreMonn Justine Sabido0% (1)

- Farmers' Satisfaction With The Paddy Procurement Practices of The National Food Authority in The Province of Palawan, PhilippinesDocument13 pagesFarmers' Satisfaction With The Paddy Procurement Practices of The National Food Authority in The Province of Palawan, PhilippinesPsychology and Education: A Multidisciplinary JournalNo ratings yet

- Efecto de Superdesintegrantes en La Disolución de Drogas CatiónicasDocument6 pagesEfecto de Superdesintegrantes en La Disolución de Drogas CatiónicascbcalderonNo ratings yet

- Text That Girl Cheat Sheet NewDocument25 pagesText That Girl Cheat Sheet NewfhgfghgfhNo ratings yet

- MC 33199Document12 pagesMC 33199Abbode HoraniNo ratings yet

- Business Mathematics and Statistics: Fundamentals ofDocument468 pagesBusiness Mathematics and Statistics: Fundamentals ofSamirNo ratings yet

- Autoclave 2Document52 pagesAutoclave 2SILVANA ELIZABETH ROMO ALBUJANo ratings yet

- LaMOT Rupture DiscsDocument20 pagesLaMOT Rupture Discshlrich99No ratings yet

- MIami Beach City Attorney's DenialDocument7 pagesMIami Beach City Attorney's DenialDavid Arthur WaltersNo ratings yet

- International Business EnvironmentDocument5 pagesInternational Business EnvironmentrahulNo ratings yet

- Sparse ArrayDocument2 pagesSparse ArrayzulkoNo ratings yet

- BP Azspu Driver Fatigue & Tiredness Management ProcedureDocument11 pagesBP Azspu Driver Fatigue & Tiredness Management ProcedureEl Khan100% (1)

- Personal Information: Witec Smaranda 11, A3 Bis, Blvd. Chisinau, Bucharest, Romania 0040722597553Document6 pagesPersonal Information: Witec Smaranda 11, A3 Bis, Blvd. Chisinau, Bucharest, Romania 0040722597553MirelaRoșcaNo ratings yet