Professional Documents

Culture Documents

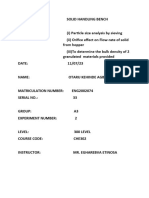

Lab No2 CMT

Uploaded by

SofiaJabadanEspulgarOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Lab No2 CMT

Uploaded by

SofiaJabadanEspulgarCopyright:

Available Formats

I.

Title: REDUCING FIELD SAMPLES TO TESTING SIZES

II. Objective: The correct method of obtaining sample for laboratory use and for mechanical

analysis is an important aspect of Material Testing. The purpose of this exercise is to obtain a

representative sample for testing

III. Materials

a. Fine Aggregates

- consist of natural sand or crushed stone with most particles passing through a 3/8-inch

sieve

b. Coarse Aggregates

- any particles greater than 0.19 inch, but generally range between 3/8 and 1.5 inches in

diameter

IV. Apparatus and Method of Testing

a. Apparatus (with definition or use)

1. Spade

- a tool with a blade for digging, esp. one with a long handle

2. Trowel

- A small hand tool with a short handle and a flat, usually pointed blade used for

spreading, shaping, and smoothing plaster, cement, mortar or dirt

3. Galvanized Iron Pan

- have tapered sides and designed for sample handling, storage, and processing

tasks in the laboratory

4. 1”- standard sieve

- devices used to separate particles of 1” size of aggregates

b. Step by Step procedure

1. From a stock pile of aggregates, take a representative sample of sand and gravel. Place

the materials in the containers separately.

2. Wash it thoroughly with water so that it will be free from silt and clay.

3. Set the samples to air dry condition.

4. Pass the sample in the 1 in. sieve and disregard the sample which is more than 1 in. in

diameter.

5. Make a conical mound, flatten it with trowel, and divide into four parts. Take the

opposite division for mechanical analysis of aggregates.

6. In case a sample divider is available, pour the sample into the divider and retain the

sample poured on the one side. The sample will be used then for sieve analysis,

colorimetric test, and for the preparation of concrete specimen.

V. Data and Results

a. Final Weight of Fine Aggregate (after washing and drying):

Weight = 10.1kg

Final Weight of Coarse Aggregate (after washing and drying):

Weight =10kg

b. Observation/s

- Each aggregate has its own physical properties which partially depends on

how, where and when was the aggregate is stored or keep before it is used. In

the laboratory experiment, sample contains some silt and clay that have been

observed during the washing of the aggregates, which we can conclude that the

before the bagging of aggregates it is stored in an open area.

VI. Discussion (Report)

1. Illustrate the “method of quartering” as a method of reducing field samples to testing

sizes.

2. Significance of these two methods.

Samples from the field need to be reduced to appropriate sizes for testing. It is

necessary to reduce while minimizing the chance of variability during handling or

transporting. In some cases, a few particles on a given sieve or mesh might affect a

gradation which is enough to alter an interpretation of the field sample and

subsequently the entire material's compliance with specifications. The appropriate

field sample reduction method is mainly dependent on the nominal maximum size of

the aggregate, the amount of free moisture in the sample, and the equipment

available.

VII. Review of Related Literature

VIII. Appendices:

1. References

Portland Cement Association (n.d). Aggregates. Retrieved from

https://www.cement.org/cement-concrete-applications/concrete-materials/aggregates

Trowel (n.d). Retrieved from https://www.urbandictionary.com/define.php?

term=Trowel

Spade (n.d). Retrieved from

https://dictionary.cambridge.org/us/dictionary/english/spade

Galvanized Pans – Tapered Sides (n.d). Retrieved from

https://myerstest.com/product/galvanized-pans-tapered/

Gatenby. A., (2018) Sieve Testing

. Retrieved from https://cdn2.hubspot.net/hub/75757/file-15588822-

pdf/docs/sieve_std_cert_cal.pdf

Reducing Field Samples of Soil and Aggregate to Testing Size

(2018). Retrieved from https://www.codot.gov/business/designsupport/materials-

and-geotechnical/manuals/2019-fmm/cps/CP-30s/%2810%29%20CP%2032-19

2. Journal (review of related literature)

The splitting or quartering method is used at the procedures for reducing samples so that

the reduced sample meets the minimum sample size for testing, has minimum segregation,

and is representative of the original sample. The said method is mainly used in both

construction field and in the laboratory for the sake of knowing whether the field samples

have some impurities that can greatly affect the finished project of the construction.

3. Printed ASTM/AASHTO Manual

a. ASTM D 702

b. AASHTO Designation T 2-74

4. Photographs

You might also like

- Lab No2 CMTDocument7 pagesLab No2 CMTSofiaJabadanEspulgarNo ratings yet

- Sample PreparationDocument6 pagesSample PreparationSara MohamedNo ratings yet

- Me136p Exp5 Sieve Analysis of AggregatesDocument9 pagesMe136p Exp5 Sieve Analysis of AggregatesJohn Henry SalvadoNo ratings yet

- ACTIVITY 3 - Preparation of Undisturbed Soil Sample For TestingDocument5 pagesACTIVITY 3 - Preparation of Undisturbed Soil Sample For TestingNiko ChavezNo ratings yet

- Cem Train-21 SamplingDocument7 pagesCem Train-21 SamplingmohamedredaNo ratings yet

- Kenny's Solid Bench FileDocument24 pagesKenny's Solid Bench Fileotaken6No ratings yet

- Sample CollectionDocument12 pagesSample CollectionLucho DomNo ratings yet

- Module6: Sampling: TopicsDocument47 pagesModule6: Sampling: TopicsRAMEES MAJEEDNo ratings yet

- Lab Manual With 20 ExpDocument68 pagesLab Manual With 20 ExpGiridhari ChandrabansiNo ratings yet

- Laboratory Manual: Name: Roll No.: Semester: Academic YearDocument58 pagesLaboratory Manual: Name: Roll No.: Semester: Academic YearDipankar NathNo ratings yet

- College of Engineering Civil Engineering Program: Self-Instructional Manual (SIM) For Self-Directed Learning (SDL)Document5 pagesCollege of Engineering Civil Engineering Program: Self-Instructional Manual (SIM) For Self-Directed Learning (SDL)REX IAN BONGALESNo ratings yet

- GEOTECH - ACTIVITY 3 - Preparation of Undisturbed Soil Sample For TestingDocument6 pagesGEOTECH - ACTIVITY 3 - Preparation of Undisturbed Soil Sample For TestingJoan Cabug-osNo ratings yet

- Sampling Soils and Contaminated Media With Hand-Operated Bucket AugersDocument4 pagesSampling Soils and Contaminated Media With Hand-Operated Bucket Augerscassandraclaremail100% (1)

- Inspection of The Testing Laboratory Expirement #: 1Document40 pagesInspection of The Testing Laboratory Expirement #: 1Ali EspinosaNo ratings yet

- Mapua University: Experiment No. 4BDocument9 pagesMapua University: Experiment No. 4BGeojanni PangibitanNo ratings yet

- Argillaceous Swellingxocks - Methods For Laboratory TestingDocument16 pagesArgillaceous Swellingxocks - Methods For Laboratory Testingvenkatraman20No ratings yet

- Mackintoch Probe TestDocument20 pagesMackintoch Probe TestMuhammad Yusoff Zakaria50% (2)

- Di Pa FinalllllllllDocument62 pagesDi Pa FinallllllllllouryNo ratings yet

- Testing Swelling Rocks 1999Document16 pagesTesting Swelling Rocks 1999Alejandro425No ratings yet

- Lab Report - Copy EditedDocument24 pagesLab Report - Copy EditedSaksham ShekhawatNo ratings yet

- Hydraulics Probset1 AlmineDocument6 pagesHydraulics Probset1 AlmineRhodison EsmundoNo ratings yet

- Sabita Manual 37 tmh5 April 2021 1 15 84Document70 pagesSabita Manual 37 tmh5 April 2021 1 15 84recruitrldNo ratings yet

- Laboratory Test and Preparation of Report Use of EquipmentDocument16 pagesLaboratory Test and Preparation of Report Use of EquipmentEncik ComotNo ratings yet

- Mapua University: Experiment No. 3ADocument10 pagesMapua University: Experiment No. 3AGeojanni PangibitanNo ratings yet

- Lap Report GeoDocument23 pagesLap Report GeoAnonymous 2FDTST37uNo ratings yet

- Soil Sampling GuideDocument8 pagesSoil Sampling Guidesagus000100% (1)

- Scan-Cm 41 - PfiDocument3 pagesScan-Cm 41 - PfiFrederico Manfio dos SantosNo ratings yet

- Wet Preparation of Disturbed Soil SamplesDocument8 pagesWet Preparation of Disturbed Soil SamplesMae CostalesNo ratings yet

- Screenshot 2022-10-17 at 18.52.41Document41 pagesScreenshot 2022-10-17 at 18.52.41Rod VincentNo ratings yet

- Sampling of Aggregates - IS2430Document14 pagesSampling of Aggregates - IS2430nsureshbabuNo ratings yet

- Dry Preparation of Disturbed SoilDocument2 pagesDry Preparation of Disturbed SoilJenny Ann ValderramaNo ratings yet

- Standard Methods of Sampling Stone, Gravel, Sand and Paving Mixtures For Use As Highway MaterialsDocument7 pagesStandard Methods of Sampling Stone, Gravel, Sand and Paving Mixtures For Use As Highway MaterialsWissem TaktakNo ratings yet

- Ore SamplingDocument8 pagesOre SamplingSunilNo ratings yet

- D6610-Standard Practice For Manually Sampling Coal From Surfaces of A StockpileDocument3 pagesD6610-Standard Practice For Manually Sampling Coal From Surfaces of A StockpileAya100% (1)

- Term Papers (Final Requirement) : Student NameDocument35 pagesTerm Papers (Final Requirement) : Student NameJerome YangaNo ratings yet

- Presentationgroupageoteknik 150320092112 Conversion Gate01Document89 pagesPresentationgroupageoteknik 150320092112 Conversion Gate01Paradise BirdNo ratings yet

- D2980-04 (2010) Standard Test Method For Volume Weights, Water-Holding Capacity, and Air Capacity of Water-Saturated Peat MaterialsDocument3 pagesD2980-04 (2010) Standard Test Method For Volume Weights, Water-Holding Capacity, and Air Capacity of Water-Saturated Peat MaterialsMohammed AliNo ratings yet

- Paper No.: 12 Paper Title: Food Packaging Technology Module - 31: Quality Evaluation of Packaging MaterialsDocument8 pagesPaper No.: 12 Paper Title: Food Packaging Technology Module - 31: Quality Evaluation of Packaging MaterialsSaleh Saeed AgbaryNo ratings yet

- Laboratory Exercise No. 1 AggregatesDocument11 pagesLaboratory Exercise No. 1 AggregatesHaha HahahahNo ratings yet

- Sampling Method: Caharian, John Carlo Dayanan, Vynce Viktor Hingco, VincentDocument6 pagesSampling Method: Caharian, John Carlo Dayanan, Vynce Viktor Hingco, Vincentvince coNo ratings yet

- Chapter 3Document9 pagesChapter 3አስጠኚ TUBENo ratings yet

- Sample Preparation and Assaying: G E. G, E V. P, W E. H, JDocument11 pagesSample Preparation and Assaying: G E. G, E V. P, W E. H, JAg Badia PatoNo ratings yet

- Field Collection of Soil Samples For Subsequent Lead DeterminationDocument3 pagesField Collection of Soil Samples For Subsequent Lead DeterminationAhmad Zubair RasulyNo ratings yet

- Particle Size Distribution Sieve Analysis Lab ReportDocument2 pagesParticle Size Distribution Sieve Analysis Lab ReportSANI SULEIMAN0% (1)

- Particle Size Distribution Sieve Analysis Lab ReportDocument2 pagesParticle Size Distribution Sieve Analysis Lab ReportSANI SULEIMANNo ratings yet

- Article of SandDocument6 pagesArticle of Sandmanish kumar yadavNo ratings yet

- ProcedureDocument5 pagesProcedureAli M. ChehadehNo ratings yet

- Lab Manual of Concrete Technology: Chetan S. PatilDocument76 pagesLab Manual of Concrete Technology: Chetan S. PatilashoknrNo ratings yet

- Lap Report GeoDocument23 pagesLap Report GeoAnonymous 2FDTST37uNo ratings yet

- JIS M 8109-1996 Method For Sampling and Method of Determination of Moisture Content of Garnierite Nickel OreDocument30 pagesJIS M 8109-1996 Method For Sampling and Method of Determination of Moisture Content of Garnierite Nickel OreAnjani Prastika100% (6)

- PQT ProcedureDocument7 pagesPQT ProcedureCak Nhass100% (2)

- Laboratory Test and Preparation of Report Use of EquipmentDocument16 pagesLaboratory Test and Preparation of Report Use of Equipmentlsatchithananthan100% (1)

- Field Tests For Const'n Materials (Final)Document13 pagesField Tests For Const'n Materials (Final)Irish サルタン タムビスNo ratings yet

- Lab Manual: Material Handling LaboratoryDocument25 pagesLab Manual: Material Handling LaboratoryMeyakorberNo ratings yet

- Simple Method For Measuring Soil Sand Content by Nylon Mesh SievingDocument6 pagesSimple Method For Measuring Soil Sand Content by Nylon Mesh Sievingsriramgopal.anne8356No ratings yet

- Field Test and SamplingDocument25 pagesField Test and SamplingPUBGXML GAMINGNo ratings yet

- 006 RC Drilling Induction PDFDocument29 pages006 RC Drilling Induction PDFhassan bachu100% (1)

- Precipitated Silica-Surface Area by Multipoint BET Nitrogen AdsorptionDocument3 pagesPrecipitated Silica-Surface Area by Multipoint BET Nitrogen Adsorptiondavid dawoudNo ratings yet

- Constitutive Modeling of Soils and RocksFrom EverandConstitutive Modeling of Soils and RocksPierre-Yves HicherRating: 5 out of 5 stars5/5 (1)

- Wilcon Brochures PDFDocument31 pagesWilcon Brochures PDFSofiaJabadanEspulgarNo ratings yet

- Capitol Steel Corporation - Rebar PricelistDocument1 pageCapitol Steel Corporation - Rebar PricelistSofiaJabadanEspulgarNo ratings yet

- Pricelist WoodDocument35 pagesPricelist WoodSofiaJabadanEspulgarNo ratings yet

- Door - Wilcon Depot IncDocument3 pagesDoor - Wilcon Depot IncSofiaJabadanEspulgarNo ratings yet

- Capitol Steel Corporation - Rebar PricelistDocument1 pageCapitol Steel Corporation - Rebar PricelistSofiaJabadanEspulgarNo ratings yet

- Wood PricelistDocument7 pagesWood PricelistSofiaJabadanEspulgarNo ratings yet

- Ceramics - Wilcon Depot IncDocument15 pagesCeramics - Wilcon Depot IncSofiaJabadanEspulgarNo ratings yet

- Steel Bars, Alloy, Standard GradesDocument4 pagesSteel Bars, Alloy, Standard GradesSofiaJabadanEspulgarNo ratings yet

- Seamless Ferritic Alloy-Steel Pipe For High-Temperature ServiceDocument8 pagesSeamless Ferritic Alloy-Steel Pipe For High-Temperature ServiceSofiaJabadanEspulgarNo ratings yet

- Pressure Vessel Plates, Alloy Steel, 9 Percent Nickel, Double-Normalized and TemperedDocument3 pagesPressure Vessel Plates, Alloy Steel, 9 Percent Nickel, Double-Normalized and TemperedSofiaJabadanEspulgarNo ratings yet

- Stainless Steel Bars and Shapes': Standard Specification ForDocument7 pagesStainless Steel Bars and Shapes': Standard Specification ForSofiaJabadanEspulgarNo ratings yet

- Pressure Vessel Plates, Alloy Steel, Manganese-Molybdenum and Manganese-Molybdenum-NickelDocument2 pagesPressure Vessel Plates, Alloy Steel, Manganese-Molybdenum and Manganese-Molybdenum-NickelSofiaJabadanEspulgarNo ratings yet

- ASTM-A307: Licensed by Information Handling Services Licensed by Information Handling ServicesDocument7 pagesASTM-A307: Licensed by Information Handling Services Licensed by Information Handling ServicesSofiaJabadanEspulgarNo ratings yet