Professional Documents

Culture Documents

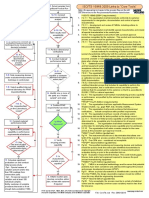

Detection Table - AIAG-VDA Process FMEA

Uploaded by

Raajha MunibathiranCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Detection Table - AIAG-VDA Process FMEA

Uploaded by

Raajha MunibathiranCopyright:

Available Formats

Detection Potential (D) for the validation of the Process Design

Ability to

D Detection Method Maturity Opportunity for Detection

Detect

No testing or inspection method has The failure mode is not or cannot be detected

10

been established or is known.

Very Low

9 It is Unlikely that testing or inspection The failure mode is not easily detected through random or sporadic

method will detect the failure mode audits

Human Inspection (visual, tactile, Audible), or use of manual gauging

8 Test or inspection method has not (attribute or variable) that should detect the failure mode or failure

been proven to be effective and cause.

reliable (ie, plant has little or no

Low

experience with method, gauge R&R Machine-based detection (automated or semi automated with

7 result marginal on comparable process notification by light, buzzer etc.), or use of a inspection equipment such

on its application, etc.) as a coordinate measuring machine that should detect failure mode or

failure cause

Test or inspection method has been Human Inspection (visual, tactile, Audible), or use of manual gauging

6 (attribute or variable) that will detect the failure mode or failure cause

proven to be effective and reliable (i.e.

plant has experience with method; (including product sample checks)

Moderate

gauge R&R results are acceptable on

Machine-base detection (semi automated with notification by light,

comparable process or this application

5 buzzer etc), or use of inspection equipment such as a coordinate

etc.)

measuring machine that will detect failure cause (including product

sample checks)

Machine-base automated detection method that will detect failure

mode downstream, prevent further processing or system will identify

4 the product as discrepant and allow it move forward in the process until

the designated reject unload area. Discrepant product will be controlled

System has been proven to be effective

by a robust system that will prevent outflow of the product from the

and reliable (i.e.; plant has experience

facility.

with method on identical process or

this application), gauge R&R results are

High acceptable, etc. Machine-based automated detection method that will detect failure

mode in-station, prevent further processing or system will identify the

3

product as discrepant and allow it move forward in the process until the

designated reject unload area. Discrepant product will be controlled by a

robust system that will prevent outflow of the product from the facility

Detection method has been proven to

Machine-based detection method that will detect the cause and prevent

2 be effective and reliable (ie; plant has

failure mode (discrepant part) from being produced.

experience with method, error-

proofing, verification etc.)

Failure mode cannot be physically produced as designed or processed, or detection methods proven to always

1 Very High

detect the failure mode and failure cause.

You might also like

- Occurrence Potential (O) rating criteria for process FMEADocument3 pagesOccurrence Potential (O) rating criteria for process FMEARaajha MunibathiranNo ratings yet

- Register Forum Home Page Post Attachment Files All Help Lost PasswordDocument3 pagesRegister Forum Home Page Post Attachment Files All Help Lost PasswordKirthivasanNo ratings yet

- ISO/TS 16949:2009 Awareness Training Programme OverviewDocument51 pagesISO/TS 16949:2009 Awareness Training Programme OverviewGanesan Sankaranarayanan88% (8)

- System QSB First Step Fast Response PDFDocument19 pagesSystem QSB First Step Fast Response PDFPrabagarane RamachandranNo ratings yet

- IATF Awareness TrainingDocument81 pagesIATF Awareness TrainingMR KonarengineeringNo ratings yet

- CQI 9 3rd Edition Errata SheetDocument2 pagesCQI 9 3rd Edition Errata SheetANONIMONo ratings yet

- 7 QC Tools: Q7T/PPT-1Document118 pages7 QC Tools: Q7T/PPT-1Amit Kumar SinghNo ratings yet

- Strategy Diagram ExamplesDocument8 pagesStrategy Diagram ExamplesmanuelNo ratings yet

- MSR-Columns hidden or deletedDocument2 pagesMSR-Columns hidden or deleted57641100% (1)

- Daimler Process Signoff DocumentDocument228 pagesDaimler Process Signoff DocumentWolf Villarin100% (1)

- Presentation Guidelines: Case Study - Zero Defect Drive by Laxmikant MishraDocument28 pagesPresentation Guidelines: Case Study - Zero Defect Drive by Laxmikant MishrapiyushNo ratings yet

- World Class Quality To Achieve Zero PPM 231111Document108 pagesWorld Class Quality To Achieve Zero PPM 231111Gyanesh_DBNo ratings yet

- FMEA Errata Sheet ENG AIAG VDA FMEA Handbook 202000602 PDFDocument10 pagesFMEA Errata Sheet ENG AIAG VDA FMEA Handbook 202000602 PDFBonny BonitoNo ratings yet

- AIAG-VDA PFMEA Template For Activity - (Delegate)Document38 pagesAIAG-VDA PFMEA Template For Activity - (Delegate)nadia_naaz90No ratings yet

- FMEA Latest Format 1st Edition 2019Document2 pagesFMEA Latest Format 1st Edition 2019jineshdmehtaNo ratings yet

- Special Processes: Molding System AssessmentDocument54 pagesSpecial Processes: Molding System AssessmentisolongNo ratings yet

- VCC Phased PPAP Requirements Handbook - V2Document14 pagesVCC Phased PPAP Requirements Handbook - V2medi38No ratings yet

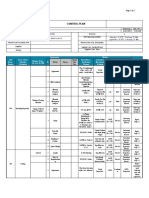

- CP20200804-A Model Control Plan - FoundationsDocument6 pagesCP20200804-A Model Control Plan - Foundationsmanno200No ratings yet

- TAFE Process Audit Check List - Revision 2Document16 pagesTAFE Process Audit Check List - Revision 2Vijay OfficialNo ratings yet

- Template Q-Offer v1 2Document25 pagesTemplate Q-Offer v1 2Krishna Mohan T.R100% (1)

- Core Tools PDFDocument1 pageCore Tools PDFsentrakerjaan100% (3)

- Severity Table - AIAG-VDA Process FMEADocument1 pageSeverity Table - AIAG-VDA Process FMEARaajha Munibathiran100% (2)

- Attribute MSA 4th EditionDocument4 pagesAttribute MSA 4th EditionSachin RamdurgNo ratings yet

- Tuv Rheinland Training Schedule 2017Document19 pagesTuv Rheinland Training Schedule 2017ramnathNo ratings yet

- QRQCDocument1 pageQRQCmoez50% (2)

- Nozzle E1 215-225 215-225 E2 220-230 220-230 E3 200-210 200-210 Hopper E4 175-185 175-185Document1 pageNozzle E1 215-225 215-225 E2 220-230 220-230 E3 200-210 200-210 Hopper E4 175-185 175-185KodhansNo ratings yet

- Attribute MSA TrainingDocument21 pagesAttribute MSA TrainingDisha ShahNo ratings yet

- Apqp Status LogDocument1 pageApqp Status Logsathyabalaraman67% (3)

- GP-12 Activity Checklist Ensures Quality FlatpacksDocument2 pagesGP-12 Activity Checklist Ensures Quality FlatpacksLam Nguyen100% (4)

- Machine capability investigation for measurable characteristicsDocument36 pagesMachine capability investigation for measurable characteristicsJosé María MorenoNo ratings yet

- Redesigning Enterprise Process For E-BusinessDocument211 pagesRedesigning Enterprise Process For E-BusinessMuarif AsdaNo ratings yet

- FMEA Methodology for Quality Improvement in Sheet Metal IndustryDocument5 pagesFMEA Methodology for Quality Improvement in Sheet Metal IndustryDanistergladwinNo ratings yet

- Report Example: Gage R&R Nested ANOVA ReportDocument4 pagesReport Example: Gage R&R Nested ANOVA Reportyuanita_mayasariNo ratings yet

- Training Module Aiag Cqi Licensed Training Partner Topqm Systems Overview enDocument3 pagesTraining Module Aiag Cqi Licensed Training Partner Topqm Systems Overview enjpaulNo ratings yet

- MSA & Destructive TestDocument4 pagesMSA & Destructive Testanon_902607157100% (1)

- GM 1927 36 Group A ElementsDocument129 pagesGM 1927 36 Group A ElementsVanessa GurrolaNo ratings yet

- Core Tools Forms V5dDocument119 pagesCore Tools Forms V5dIng. Alberto AguilarNo ratings yet

- 8D ReportDocument20 pages8D ReportSuryanarayana Tata100% (1)

- VDA QA Activity StatusDocument13 pagesVDA QA Activity StatusdysonNo ratings yet

- Specific Gravity in Rubber CompoundingDocument1 pageSpecific Gravity in Rubber CompoundingBharat ChatrathNo ratings yet

- NCR Supplier PPAP Training PresentationDocument166 pagesNCR Supplier PPAP Training PresentationAmitava Datta67% (3)

- VOLVO APQP-PPAP Deployment Supplier Information 挋嫌挋Document10 pagesVOLVO APQP-PPAP Deployment Supplier Information 挋嫌挋張永松No ratings yet

- IATF 16949 Webinar Slides 3.7.17 Final PDFDocument47 pagesIATF 16949 Webinar Slides 3.7.17 Final PDFwanphen kawnawanichNo ratings yet

- APQP and PPAP Workbook OverviewDocument25 pagesAPQP and PPAP Workbook OverviewisolongNo ratings yet

- The Practitioners Guide: 2019 Aiag-Vda FmeasDocument10 pagesThe Practitioners Guide: 2019 Aiag-Vda Fmeaskrishnan100% (3)

- VDA Flyer - 6 5 Product AuditDocument2 pagesVDA Flyer - 6 5 Product AuditEdwin Osogo100% (1)

- SPC SpreadsheetDocument8 pagesSPC Spreadsheetikesh mNo ratings yet

- Product Audit Report SummaryDocument44 pagesProduct Audit Report SummaryEnis SirbegovicNo ratings yet

- FMEA & Control PlanDocument78 pagesFMEA & Control Plansanqutbi75% (8)

- MSIL Operator Observance HandbookDocument41 pagesMSIL Operator Observance HandbookMohit SinghNo ratings yet

- Control PlanDocument1 pageControl PlanAmit PatelNo ratings yet

- Core Tools (APQP, PPAP, FMEA, MSA, SPC and Problem Solving)Document6 pagesCore Tools (APQP, PPAP, FMEA, MSA, SPC and Problem Solving)Rob Willestone100% (1)

- 01 - MsaDocument80 pages01 - MsaMohit SinghNo ratings yet

- PFMEA AIAG VDA Heading Hints PDFDocument1 pagePFMEA AIAG VDA Heading Hints PDFRamdas PaithankarNo ratings yet

- GM 1927-48 PPSR Form - SPPS 8219 Update 3Document8 pagesGM 1927-48 PPSR Form - SPPS 8219 Update 3Luis CisnerosNo ratings yet

- IMS Quality Manual MSSL 2018 LatestDocument46 pagesIMS Quality Manual MSSL 2018 LatestManjeet RanaNo ratings yet

- The New Seven Q.C. Tools TrainingDocument69 pagesThe New Seven Q.C. Tools TrainingPrakash KadirvelNo ratings yet

- Major 7 WastesDocument1 pageMajor 7 WastesRaajha MunibathiranNo ratings yet

- DOE - PresentationDocument59 pagesDOE - PresentationRaajha MunibathiranNo ratings yet

- 7 QC ToolsDocument13 pages7 QC ToolsWagner SouzaNo ratings yet

- Check Sheet HistogramDocument7 pagesCheck Sheet HistogramKhizzar IshaqueNo ratings yet

- X Bar & R Bar SampleDocument2 pagesX Bar & R Bar SampleRaajha MunibathiranNo ratings yet

- CMS Core Elements for Chemical ComplianceDocument33 pagesCMS Core Elements for Chemical ComplianceRaajha MunibathiranNo ratings yet

- FMEADocument24 pagesFMEARaajha MunibathiranNo ratings yet

- SPC FormatDocument2 pagesSPC FormatRaajha MunibathiranNo ratings yet

- MSDS-PELLASTOL 94 S - EnglishDocument13 pagesMSDS-PELLASTOL 94 S - EnglishRaajha MunibathiranNo ratings yet

- PPAPDocument53 pagesPPAPRaajha MunibathiranNo ratings yet

- MSA ExampleDocument4 pagesMSA ExampleRaajha MunibathiranNo ratings yet

- Corrective & Preventive Action Report (Capa) : Compliant. NoDocument1 pageCorrective & Preventive Action Report (Capa) : Compliant. NoRaajha Munibathiran100% (1)

- CMS Manual EngDocument43 pagesCMS Manual EngRaajha MunibathiranNo ratings yet

- HWM Validity ExpiredDocument1 pageHWM Validity ExpiredRaajha MunibathiranNo ratings yet

- Safety Data Sheet for RETINGAN MLFDocument10 pagesSafety Data Sheet for RETINGAN MLFRaajha MunibathiranNo ratings yet

- CMS Core Elements for Chemical ComplianceDocument33 pagesCMS Core Elements for Chemical ComplianceRaajha MunibathiranNo ratings yet

- Display of Information Related To Air, Water and Hazardous Waste GenerationDocument1 pageDisplay of Information Related To Air, Water and Hazardous Waste GenerationRaajha MunibathiranNo ratings yet

- Incident Investigation ReportDocument2 pagesIncident Investigation ReportRaajha MunibathiranNo ratings yet

- Incident Invetigation ProcedureDocument7 pagesIncident Invetigation ProcedureRaajha MunibathiranNo ratings yet

- Incident Invetigation ProcedureDocument7 pagesIncident Invetigation ProcedureRaajha MunibathiranNo ratings yet

- Techniques For ISO 9000 ImplementationDocument43 pagesTechniques For ISO 9000 ImplementationmasmulyoNo ratings yet

- Incident Investigation ReportDocument2 pagesIncident Investigation ReportRaajha MunibathiranNo ratings yet

- Seven QC Tools For Process Quality ImprovementDocument119 pagesSeven QC Tools For Process Quality ImprovementRaajha MunibathiranNo ratings yet

- SWOT Analysis Covid-19 ImpactDocument2 pagesSWOT Analysis Covid-19 ImpactRaajha MunibathiranNo ratings yet

- Non Conformence, & Corrective Action FormatDocument1 pageNon Conformence, & Corrective Action FormatRaajha MunibathiranNo ratings yet

- 8D Problem SolvingDocument14 pages8D Problem SolvingHiệp Hài HướcNo ratings yet

- Seven QC Tools for Process Quality ImprovementDocument65 pagesSeven QC Tools for Process Quality ImprovementRaajha MunibathiranNo ratings yet

- DPMO Sigma Table: Process Yield by Defects per MillionDocument1 pageDPMO Sigma Table: Process Yield by Defects per MillionRaajha MunibathiranNo ratings yet

- Risk Management Plan TemplateDocument2 pagesRisk Management Plan TemplateDimitris PapadopoulosNo ratings yet

- Gsrtc. 2 - 1 - 24Document1 pageGsrtc. 2 - 1 - 24Mitanshu BhavsarNo ratings yet

- LINNINS Et Al v. HAECO AMERICAS, LLC Et Al: Complaint Filed On 5/17/2016Document27 pagesLINNINS Et Al v. HAECO AMERICAS, LLC Et Al: Complaint Filed On 5/17/2016Jeff PetersNo ratings yet

- Manual de Generadores de Gas SolarDocument49 pagesManual de Generadores de Gas SolarJuvenal Segundo Chavez Acosta100% (7)

- Solving for angular velocity and velocities using analytical and IC methodsDocument16 pagesSolving for angular velocity and velocities using analytical and IC methodsAmalinaNo ratings yet

- Applying Lean Techniques in The Infrastructure Project: Jubail Industrial City, Suadi ArabiaDocument20 pagesApplying Lean Techniques in The Infrastructure Project: Jubail Industrial City, Suadi ArabiaYogesh SharmaNo ratings yet

- Catalytic Application of NanomaterialsDocument23 pagesCatalytic Application of NanomaterialsViji VijithaNo ratings yet

- Section A-A: PLUNGER, LGA, 7X7, G3Document1 pageSection A-A: PLUNGER, LGA, 7X7, G3Ericson. TatlongmariaNo ratings yet

- Lecture PLCDocument30 pagesLecture PLCProsenjit Chatterjee100% (1)

- Nikhil ResumeDocument2 pagesNikhil ResumeJaikumar KrishnaNo ratings yet

- Marketing Syllabus PDFDocument12 pagesMarketing Syllabus PDFSarika RikameNo ratings yet

- Valencia v. Sandiganbayan DIGESTDocument2 pagesValencia v. Sandiganbayan DIGESTkathrynmaydevezaNo ratings yet

- Roh Scenario Wolomin-V4Document4 pagesRoh Scenario Wolomin-V4Dennis-marius ThiemeNo ratings yet

- Police Personnel Management and RecordsDocument26 pagesPolice Personnel Management and RecordsLowie Jay Mier OrilloNo ratings yet

- NO Global Distribution NetworkDocument74 pagesNO Global Distribution NetworkSTEPHANY garcia bonillaNo ratings yet

- PPT 06Document15 pagesPPT 06Diaz Hesron Deo SimorangkirNo ratings yet

- Infotech JS2 Eclass Computer VirusDocument2 pagesInfotech JS2 Eclass Computer VirusMaria ElizabethNo ratings yet

- Markov Model Predicts AttritionDocument16 pagesMarkov Model Predicts AttritionWojood AlkhanNo ratings yet

- Order in Respect of Application Filed by Munjal M Jaykrishna Family Trust Under Regulation 11 of Takeover Regulations, 2011 For Acquisition of Shares in AksharChem (India) LimitedDocument10 pagesOrder in Respect of Application Filed by Munjal M Jaykrishna Family Trust Under Regulation 11 of Takeover Regulations, 2011 For Acquisition of Shares in AksharChem (India) LimitedShyam SunderNo ratings yet

- Direct and Inverse ProportionDocument4 pagesDirect and Inverse Proportionjoannng76No ratings yet

- Lecture 4Document10 pagesLecture 4unknownuser14.1947No ratings yet

- EVIDENCE DIGESTS RULE 129 sEC. 4 TO Rule 130 Section 41Document48 pagesEVIDENCE DIGESTS RULE 129 sEC. 4 TO Rule 130 Section 41Pat RañolaNo ratings yet

- Reputed Builders in VadodaraDocument10 pagesReputed Builders in Vadodararomy mattewNo ratings yet

- Lexmark MX32x, MX42x, MX52x, MX62x Series Disassembly of WEEE Manual v1.0 Sept-2019Document26 pagesLexmark MX32x, MX42x, MX52x, MX62x Series Disassembly of WEEE Manual v1.0 Sept-2019Fabio AntonioNo ratings yet

- Nc790 - Introduction To Systems Development l2 Sup QP 2009Document10 pagesNc790 - Introduction To Systems Development l2 Sup QP 2009isaachari100% (1)

- Mesalazine: Mesalazine (INN, BAN), Also Known As Mesalamine (USAN) or 5-Aminosalicylic AcidDocument4 pagesMesalazine: Mesalazine (INN, BAN), Also Known As Mesalamine (USAN) or 5-Aminosalicylic AcidAnkan PalNo ratings yet

- Exam 2 Guidelines 2019Document6 pagesExam 2 Guidelines 2019Sri VeludandiNo ratings yet

- C.J LetterDocument2 pagesC.J LetterIan WainainaNo ratings yet

- Differential RAID: Rethinking RAID For SSD ReliabilityDocument5 pagesDifferential RAID: Rethinking RAID For SSD ReliabilityRabiul SikderNo ratings yet

- String & Math FunctionsDocument38 pagesString & Math FunctionsThanu shreeNo ratings yet