Professional Documents

Culture Documents

Astm e 202 - 05 PDF

Uploaded by

Julian Felipe Noguera CruzOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Astm e 202 - 05 PDF

Uploaded by

Julian Felipe Noguera CruzCopyright:

Available Formats

Designation: E 202 – 05

Standard Test Methods for

Analysis of Ethylene Glycols and Propylene Glycols1

This standard is issued under the fixed designation E 202; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope D 1209 Test Method for Color of Clear Liquids (Platinum-

1.1 These test methods cover the chemical and physical Cobalt Scale)

analysis of the commonly available grades of ethylene glycol, D 1613 Test Method for Acidity in Volatile Solvents and

diethylene glycol, triethylene glycol, propylene glycol, and Chemical Intermediates Used in Paint, Varnish, Lacquer,

dipropylene glycol. The key sections appear in the following and Related Products

order: D 4052 Test Method for Density and Relative Density of

Sections

Liquids by Digital Density Meter

D 5386 Test Method for Color of Liquids Using Tristimulus

Purity of Reagents 4 Colorimetry

Specific Gravity 6-8

Distillation Range 9-11

E 60 Practice for Photometric and Spectrophotometric

Acidity 12-14 Methods for Chemical Analysis of Metals

Water 15-17 E 180 Practice for Determining the Precision of ASTM

Iron 18-26

Color 27-29

Methods for Analysis and Testing of Industrial Chemicals

Gas Chromatographic Analysis 30-40 E 200 Practice for Preparation, Standardization, and Stor-

age of Standard and Reagent Solutions for Chemical

--````````,`,,,`,``,``,,,``,-`-`,,`,,`,`,,`---

1.2 Review the current appropriate Material Safety Data

Sheets (MSDS) for detailed information concerning toxicity, Analysis

first aid procedures, and safety precautions. E 203 Test Method for Water Using Karl Fischer Reagent

1.3 This standard does not purport to address all of the E 394 Test Method for Iron in Trace Quantities Using the

safety concerns, if any, associated with its use. It is the 1,10-Phenanthroline Method

responsibility of the user of this standard to establish appro- E 611 Test Methods for Low Concentrations of Diethylene

priate safety and health practices and determine the applica- Glycol in Ethylene Glycol by Gas Chromatography

bility of regulatory limitations prior to use. E 1064 Test Method for Water in Organic Liquids by

Coulometric Karl Fischer Titration

2. Referenced Documents E 1615 Test Method for Iron in Trace Quantities Using the

2.1 ASTM Standards: 2 FerroZine Method

D 891 Test Methods for Specific Gravity, Apparent, of E 2409 Test Method for Glycol Impurities in Mono-, Di-,

Liquid Industrial Chemicals Tri-, and Tetraethylene Glycol (Gas Chromatographic

D 1078 Test Method for Distillation Range of Volatile Method)

Organic Liquids 3. Significance and Use

D 1193 Specification for Reagent Water

3.1 These test methods measure certain chemical and physi-

cal properties of ethylene glycols and propylene glycols and

may be used to determine compliance with specification in

1

These test methods are under the jurisdiction of ASTM Committee E15 on which limits are established for these properties. For those tests

Industrial and Specialty Chemicals and are the direct responsibility of Subcommit-

tee E15.01 on General Standards. that use the procedure of another ASTM test method, that test

Current edition approved Oct. 1, 2005. Published November 2005. Originally method should be consulted for additional information on the

approved in 1962. Last previous edition approved in 2004 as E 202–04.

2

significance and use of that test.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

3.2 Alternative test methods and technology for several of

Standards volume information, refer to the standard’s Document Summary page on the methods can be found in the Appendix. The alternative test

the ASTM website. methods do not have precision data for the application of these

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

Copyright ASTM International 1

Copyright by ASTM Int'l (all rights reserved);

Provided by IHS under license with ASTM Licensee=Intertek Testing Services CB /5964714001

No reproduction or networking permitted without license from IHS Not for Resale, 10/14/2008 15:07:44 MDT

Reproduction authorized per License Agreement with Kathe Hooper (ASTMIHS Account); Mon Nov 14 10:31:53 EST 2005

E 202 – 05

methods in analyzing glycols. Use of these methods is optional been estimated to be 0.0000598 units at 48 df. The 95 % limit

and individuals using the alternative methods should assure for the difference between two such averages is 0.0002 unit.

themselves that the method is sufficiently precise. Precision 8.1.3 Reproducibility (Multilaboratory)—The standard de-

data presented is only for the original test methods listed. viation of results (each the average of duplicates), obtained by

analysts in different laboratories, has been estimated to be

4. Purity of Reagents 0.000191 unit at 5 dF. The 95 % limit for the difference

4.1 Purity of Reagents—Reagent grade chemicals shall be between two such averages is 0.0005 unit.

used in all tests. Unless otherwise indicated, it is intended that NOTE 1—These precision estimates are based on interlaboratory studies

all reagents shall conform to the specifications of the Commit- performed in 1962 and 1963 on six samples of the five glycols whose

tee on Analytical Reagents of the American Chemical Society, specific gravity values range from approximately 1.0233 to 1.1255. A total

where such specifications are available.3 Other grades may be of ten laboratories cooperated in the studies in which each analyst

used, provided it is first ascertained that the reagent is of performed duplicate determinations on each sample on each of two days.5

sufficiently high purity to permit its use without lessening the Practice E 180 was used in developing these precision estimates.

accuracy of the determination. 8.2 Bias—The bias of this test method has not been deter-

4.2 Unless otherwise indicated, references to water shall be mined due to the unavailability of suitable reference materials.

understood to mean reagent water conforming to Specification

D 1193, Type II or III. DISTILLATION RANGE

5. Quality Control 9. Procedure

5.1 It is recommended that a control chart for the concen- 9.1 Determine the distillation range of the sample in accor-

tration of the impurities in the glycol quality control sample be dance with Test Method D 1078. Use the conditions as speci-

established and maintained according to common guidelines.4 fied in Test Method D 1078, and the ASTM Solvents Distilla-

Measure the control sample each time a test sample(s) is tested. tion Thermometer shown in Table 1. (See Note 2 for certain

If the measured value exceeds the action limit of the control allowable exceptions in applying this test method to triethylene

chart, take appropriate action before proceeding with sample glycol.)

tests.

NOTE 2—In the distillation of triethylene glycol, it may not be possible

to collect the first drop of liquid within 15 min or to maintain the

SPECIFIC GRAVITY prescribed distillation rate of 4 to 5 mL/min with some sources of gas. In

this case, up to 30 min can be allowed to collect the first drop, and a

6. Procedure distillation rate of 2 to 3 mL/min is satisfactory. Alternatively, the flask

6.1 Determine the relative density of the sample at 20/20°C chamber may be covered with a suitable shield so that only the upper neck

using the pycnometer test method in accordance with Test and thermometer are exposed to room air to achieve the specified rates.

Methods D 891, except determine the water and sample 9.2 Use the following values of K in the equation for

--````````,`,,,`,``,``,,,``,-`-`,,`,,`,`,,`---

weights of the pycnometer at 20.0 6 0.1°C. barometric correction (Test Method D 1078):

Chemical K

7. Report

Ethylene glycol 0.045

7.1 Report the relative density at 20/20°C (in air) to the Diethylene glycol 0.050

nearest 0.0001 unit. Triethylene glycol 0.055

Propylene glycol 0.043

Dipropylene glycol 0.051

8. Precision and Bias

8.1 The following criteria should be used for judging the 10. Report

acceptability of results (see Note 1):

10.1 Report the corrected temperatures to the nearest 0.1°C

8.1.1 Repeatability (Single Analyst)—The standard devia-

at each volume required by the specification for the glycol

tion for a single determination has been estimated to be

being analyzed.

0.0000651 unit at 96 dF. The 95 % limit for the difference

between two such runs is 0.0002 unit.

8.1.2 Laboratory Precision (Within-Laboratory, Between-

Days)—The standard deviation of results (each the average of

5

duplicates), obtained by the same analyst on different days, has Details of the interlaboratory study are available as Research Report E15-0013

from ASTM Headquarters.

3

TABLE 1 Thermometers for Distillation Range

Reagent Chemicals, American Chemical Society Specifications, American

Chemical Society, Washington, DC. For suggestions on the testing of reagents not Thermometer Thermometer

Glycol

listed by the American Chemical Society, see Analar Standards for Laboratory Number Range

Chemicals, VWR International Ltd., Poole, Dorset, U.K., and the United States Ethylene glycol 104C 173 to 227°C

Pharmacopeia and National Formulary, U.S. Pharmacopeial Convention, Inc. Diethylene glycol 106C 223 to 277°C

(USPC), Rockville, MD. Triethylene glycol 107C 248 to 302°C

4

ASTM Manual on Presentation of Data and Control Chart Analysis, 7th Propylene glycol 104C 173 to 227°C

Edition, ASTM Manual Series MNL 7A (revision of Special Technical Publication Dipropylene glycol 106C 223 to 277°C

(STP) 15D).

Copyright ASTM International 2

Provided by IHS under license with ASTM Copyright by ASTM Int'l (all rights reserved); Licensee=Intertek Testing Services CB /5964714001

No reproduction or networking permitted without license from IHS Not for Resale, 10/14/2008 15:07:44 MDT

Reproduction authorized per License Agreement with Kathe Hooper (ASTMIHS Account); Mon Nov 14 10:31:53 EST 2005

E 202 – 05

11. Precision and Bias limit for the difference between two such runs is the value in

11.1 The following criteria should be used for judging the the table.

acceptability of results (Note 3): 11.1.2 Laboratory Precision (Within-Laboratory, Between-

11.1.1 Repeatability (Single Analyst)—The standard devia- Days)—The standard deviation of results (each the average of

tion for a single determination has been estimated to be the duplicates), obtained by the same analyst on different days, has

value in Table 2 at the indicated degrees of freedom. The 95 % been estimated to be the value in Table 2 at the indicated

degrees of freedom. The 95 % limit for the difference between

two such averages is the value in the table.

TABLE 2 Distillation Range Precision Values

11.1.3 Reproducibility (Multilaboratory)—The standard de-

Ethylene Glycol Diethylene Propylene

and and

viation of results (each the average of duplicates), obtained by

Distillation Range

Triethylene Dipropylene analysts in different laboratories, has been estimated to be the

0 to 5°C/qa 5 to 15°C Glycols Glycols value in Table 2 at the indicated degrees of freedom. The 95 %

Initial boiling point,° C: limit for the difference between two such averages is the value

Repeatability in the table.

Standard deviation 0.154 (54A) 0.154 (54) 0.218 (52) 0.148 (56)

95 % limit 0.4 0.4 0.6 0.4 NOTE 3—These precision estimates are based on interlaboratory studies

Laboratory Precision

performed in 1962 and 1963 on eleven samples of the five glycols whose

(Within Laboratory

Between Days)

distillation ranges varied from 1.4 to 9.7°C. A total of ten laboratories

Standard deviation 0.173 (27) 0.173 (27) 0.119 (23) 0.0901(28) cooperated in the studies in which each analyst performed duplicate

95 % limit 0.5 0.5 0.4 0.2 determinations on each sample on each of two days.5 Practice E 180 was

Reproducibility used in developing these precision estimates.

Standard deviation 0.414 (8) 0.414 (8) 0.489 (6) 0.190 (6)

95 % limit 1.2 1.2 1.4 0.5 11.2 Bias—The bias of this test method has not been

5 mL, °C: determined due to the unavailability of suitable reference

Repeatability

Standard deviation 0.118 (54) 0.118 (54) ... ...

materials.

95 % limit 0.3 0.3 ... ...

Laboratory Precision ACIDITY

(Within Laboratory

Between Days)

Standard deviation 0.147 (27) 0.147 (27) ... ... 12. Procedure

95 % limit 0.4 0.4 ... ...

Reproducibility 12.1 Determine the acidity of the sample in accordance with

Standard deviation 0.317 (8) 0.317 (8) ... ... Test Method D 1613.

95 % limit 0.9 0.9 ... ...

50 mL, °C:

Repeatability 13. Report

Standard deviation 0.0783 (54) 0.0783(54) 0.129 (52) 0.0892(56)

95 % limit 0.2 0.2 0.4 0.2

13.1 Report the acidity, expressed as mass percent of acetic

Laboratory Precision acid, to the nearest 0.0001 %.

(Within Laboratory

Between Days)

Standard deviation 0.0981 (27) 0.0981(27) 0.0961(26) 0.0505(28)

14. Precision and Bias

95 % limit 0.3 0.3 0.3 0.1 14.1 The following criteria should be used for judging the

Reproducibility

Standard deviation 0.279 (8) 0.279 (8) 0.201 (6) 0.133 (6) acceptability of results (see Note 4):

95 % limit 0.8 0.8 0.6 0.4 14.1.1 Repeatability (Single Analyst)—The standard devia-

95 mL, °C: tion for a single determination has been estimated to be

Repeatability

Standard deviation 0.0837 (54) 0.0837(54) ... ... 0.0000918 % absolute at 92 dF. The 95 % limit for the

95 % limit 0.2 0.2 ... ... difference between two such runs is 0.0003 % absolute.

Laboratory Precision 14.1.2 Laboratory Precision (Within-Laboratory, Between-

(Within Laboratory

Between Days) Days)—The standard deviation of results (each the average of

Standard deviation 0.126 (27) 0.126 (27) ... ... duplicates), obtained by the same analyst on different days, has

95 % limit 0.4 0.4 ... ... been estimated to be 0.000116 % absolute at 46 dF. The 95 %

Reproducibility

Standard deviation 0.336 (8) 0.336 (8) ... ... limit for the difference between two such averages is 0.0003 %

95 % limit 0.9 0.9 ... ... absolute.

Dry point C: 14.1.3 Reproducibility (Multilaboratory)—The standard de-

Repeatability

Standard deviation 0.0779 (14) 0.384 (36) 0.272 (46) 0.193 (56) viation of results (each the average of duplicates), obtained by

95 % limit 0.2 1.1 0.8 0.5 analysts in different laboratories, has been estimated to be

0.000279 % absolute at 5 df. The 95 % limit for the difference

Laboratory Precision

(Within Laboratory between two such averages is 0.0008 % absolute.

Between Days)

Standard deviation 0.122 (8) 0.640 (18) 0.103 (23) 0.250 (28) NOTE 4—These precision estimates are based on an interlaboratory

95 % limit 0.3 1.8 0.3 0.7 study performed in 1962 and 1963 on six samples of the five glycols

Reproducibility whose acidity values ranged from 0.0008 to 0.0044 %. A total of ten

Standard deviation 0.466 (7) 2.77 (8) 1.12 (5) 0.896 (6) laboratories cooperated in the studies in which each analyst performed

95 % limit 1.3 7.8 3.1 2.5 duplicate determinations on each of two days.5 Practice E 180 was used in

A

Degrees of freedom indicated by values within parentheses. developing these precision estimates.

--````````,`,,,`,``,``,,,``,-`-`,,`,,`,`,,`---

Copyright ASTM International 3

Copyright by ASTM Int'l (all rights reserved);

Provided by IHS under license with ASTM Licensee=Intertek Testing Services CB /5964714001

No reproduction or networking permitted without license from IHS Not for Resale, 10/14/2008 15:07:44 MDT

Reproduction authorized per License Agreement with Kathe Hooper (ASTMIHS Account); Mon Nov 14 10:31:53 EST 2005

E 202 – 05

14.2 Bias—The bias of this test method has not been interferences. Both test methods assume that the amount of

determined due to the unavailability of suitable reference color developed is proportional to the amount of iron in the test

materials. solution and that the calibration curve is linear over the

specified concentration range.

WATER

15. Procedure 20. Apparatus

15.1 Determine the water content of the sample using any 20.1 Spectrophotometer, capable of measuring light absorp-

suitable Karl Fischer reagent titration method. Test Method tion at approximately 510 nm.

E 203 is recommended. NOTE 6—A discussion of photometers and photometric practice is

given in Practice E 60.

16. Report

16.1 Report the water content to the nearest 0.01 % mass. 20.2 Absorption Cells, 5-cm light path.

17. Precision and Bias 21. Reagents

17.1 The following criteria should be used for judging the 21.1 Hydroxylamine Hydrochloride Solution (300 g/L)—

acceptability of results (see Note 5): Prepare fresh as needed. See the paragraph on hydroxylamine

17.1.1 Repeatability (Single Analyst)—The standard de- hydrochloride solution in the section on Nonstandardized

viation for a single determination has been estimated to be Reagent Solutions and Indicator Solutions in Practice E 200.

0.000370 % absolute at 92 dF. The 95 % limit for the difference 21.2 Iron, Standard Solution (1 mL = 0.005 mg Fe)—

between two such runs is 0.01 % absolute. Prepare the standard iron solution (1 mL = 0.01 mg Fe) in

17.1.2 Laboratory Precision (Within-Laboratory, Between- accordance with the paragraph on alternate method in the

Days)—The standard deviation of results (each the average of section on Standard Ion Solutions of Practice E 200. Accu-

duplicates), obtained by the same analyst on different days, has rately dilute the resulting solution (0.01 mg/mL) 1:1 for the

been estimated to be 0.00819 % absolute at 58 df. The 95 % 0.005-mg/mL solution required.

limit for the difference between two such averages is 0.02 % 21.3 Ortho-Phenanthroline Solution (3 g/L)—Dissolve 0.9

absolute. g of 1,10-phenanthroline monohydrate in 30 mL of iron-free

17.1.3 Reproducibility (Multilaboratory)—The standard de- ethanol (Note 7) and dilute to 300 mL with water.

viation of results (each the average of duplicates), obtained by 21.4 Ammonium Acetate-Acetic Acid Solution—Dissolve

analysts in different laboratories, has been estimated to be 100 g of ammonium acetate in about 600 mL of water, filter,

0.0187 % absolute at 9 df. The 95 % limit for the difference add 200 mL of glaciat acetic acid to the filtrate, and dilute to 1

between two such averages is 0.05 % absolute. L with water. See the paragraph on ammonium acetate-acetic

NOTE 5—These precision estimates are based on interlaboratory studies

acid solution in the section on Nonstandardized Reagent and

performed in 1962 and 1963 on seven samples of the five glycols whose Indicator Solutions in Practice E 200.

water values ranged from 0.02 to 0.31 %. A total of ten laboratories NOTE 7—Specially denatured alcohol conforming to Formula No. 30 of

cooperated in the studies in which each analyst performed duplicate the U.S. Bureau of Internal Revenue has been found satisfactory for this

determinations on each sample on each of two days. Each analyst purpose.

employed the form of the Karl Fischer reagent titration method commonly

used in the analyst’s laboratory. The 1962 study on three samples of 22. Preparation of Calibration Curve

--````````,`,,,`,``,``,,,``,-`-`,,`,,`,`,,`---

ethylene glycol by nine laboratories failed to show any significant

differences in precision attributable to differences in the methods used.5 22.1 Prepare a series of at least five standards by adding 1.0

Practice E 180 was used in developing these precision estimates. to 12.0 mL of standard iron solution (1 mL = 0.005 mg Fe)

from a buret to 100-mL glass-stoppered graduates so that the

17.2 Bias—The bias of this test method has not been

concentration range from 0.000 to 0.060 mg Fe is covered in

determined due to the unavailability of suitable reference

approximately equal increments. Make up to 80 mL with water.

materials.

Add 80 mL of water to another graduate as a blank. Add 5 mL

IRON of NH2OH·HCl solution, make up to the 100-mL mark with

ortho-phenanthroline solution and mix.

18. Summary of Test Method 22.2 Obtain the absorbance of each standard, corrected for

18.1 The sample is diluted with water and the iron deter- the blank, in accordance with 23.3. Prepare a calibration curve

mined photometrically at approximately 510 nm by the ortho- by plotting the absorbances of the standard iron solutions in

phenanthroline method without a preliminary ashing. The 5-cm cells against the milligrams of iron per 100 mL of

amounts and the concentrations of hydroxylamine hydrochlo- solution. This curve must be determined for each instrument

ride and ortho-phenanthroline solutions added has been in- and should be checked periodically.

creased over that given in conventional write-ups in order to

NOTE 8—Many spectrophotometers have the ability to calculate a

overcome the depression of the ferrous-ortho-phenanthroline

calibration graph automatically after measuring the calibration solutions

complex color by the large amount of glycol present. and subsequently to show the concentration of the component being

19. Significance and Use measured directly on a display. In such cases no manual calibration graphs

need to be constructed. It is, however, recommended to verify the

19.1 This test method is essentially identical to Test Method calculation procedure of the instrument and to establish the characteristics

E 394, which should be consulted for details on possible of the calibration graph according to suitable regression analysis software.

Copyright ASTM International 4

Provided by IHS under license with ASTM Copyright by ASTM Int'l (all rights reserved); Licensee=Intertek Testing Services CB /5964714001

No reproduction or networking permitted without license from IHS Not for Resale, 10/14/2008 15:07:44 MDT

Reproduction authorized per License Agreement with Kathe Hooper (ASTMIHS Account); Mon Nov 14 10:31:53 EST 2005

E 202 – 05

23. Procedure values ranged from 0.06 to 0.45 ppm. A total of ten laboratories

cooperated in the studies in which each analyst performed duplicate

23.1 For samples containing 0 to 0.5 ppm Fe, weigh about determinations on each sample on each of two days.5 Practice E 180 was

80 g of sample to the nearest 0.1 g into a 100-mL glass- used in developing these precision estimates.

stoppered graduate. For samples of larger iron content, use

26.2 Bias—The bias of this test method has not been

proportionally smaller samples. Dilute with water to 80 mL.

determined due to the unavailability of suitable reference

Add 80 mL of water to another graduate as a blank.

materials.

23.2 Add 5 mL of NH2OH·HCl solution to each graduate

and mix. Make up to the 100-mL mark with ortho- COLOR

phenanthroline solution and again mix. Check pH and if

necessary adjust the pH of the solution to between 3.0 and 4.0 27. Procedure

by the dropwise addition of the ammonium acetate-acetic acid

27.1 Determine the color of the sample in accordance with

solution.

Test Method D 1209.

23.3 Allow to stand for 5 min, fill a 5-cm absorption cell,

and measure the absorbance at approximately 510 nm, cor- 28. Report

rected for the blank (Note 9). From the calibration curve, read

28.1 Estimate and report the color to the nearest one

the milligrams of iron present.

platinum-cobalt unit.

NOTE 9—Although the ferrous-ortho-phenanthroline complex is re-

ported to have a maximum absorbance at approximately 510 nm, the 29. Precision and Bias

measurements on both the standard iron and sample solutions should be

made at or near the wavelength at which maximum absorbance is obtained

29.1 The following criteria should be used for judging the

with each individual instrument, as indicated by scanning in this region of acceptability of results (see Note 11):

the spectrum. This step will ensure that the measurements will be made 29.1.1 Repeatability (Single Analyst)—The standard devia-

with a maximum of sensitivity and will reduce wavelength calibration tion for a single determination has been estimated to be 0.0 unit

errors. at 40 dF. The 95 % limit for the difference between two such

runs is two units.

24. Calculation

29.1.2 Laboratory Precision (Within-Laboratory, Between-

24.1 Calculate the iron present, in parts per million, as Days)—The standard deviation of results (each the average of

follows: duplicates), obtained by the same analyst on different days, has

Iron, ppm 5 SD

W

S 3 1000 (1)

been estimated to be 0.64 unit at 46 dF. The 95 % limit for the

difference between two such averages is two units.

29.1.3 Reproducibility (Multilaboratory)—The standard de-

where: viation of results (each the average of duplicates), obtained by

W = iron found, mg, and analysts in different laboratories, has been estimated to be 2.47

S = sample used, g.

units at 9 df. The 95 % limit for the difference between two

25. Report such averages is seven units.

25.1 Report the iron content of the sample to the nearest NOTE 11—These precision estimates are based on interlaboratory

0.01 ppm. studies performed in 1962 and 1963 on a total of six samples of the five

glycols whose color ranged from 2 to 21 platinum-cobalt units. Because

the test results are based on visual comparison of the untreated sample

26. Precision and Bias with standards, duplicate determinations at low levels of color are almost

--````````,`,,,`,``,``,,,``,-`-`,,`,,`,`,,`---

26.1 The following criteria should be used for judging the always in perfect agreement. This was confirmed in the 1962 study of two

acceptability of results (see Note 10): samples of ethylene glycol with average colors of 2 and 21 platinum-

26.1.1 Repeatability (Single Analyst)—The standard devia- cobalt units. The standard deviation for duplicate determinations was

estimated to be 0.0 units at 40 dF. Therefore the stated 95 % limit in the

tion for a single determination has been estimated to be

repeatability statement is based on the reporting of results to the nearest 1

0.00744 ppm at 92 dF. The 95 % limit for the difference unit. The 1963 study omitted the duplicate determinations. A total of ten

between two such runs is 0.02 % ppm. laboratories cooperated in the studies in which each analyst performed

26.1.2 Laboratory Precision (Within-Laboratory, Between- duplicate determinations on each sample on each of two days.5 Practice

Days)—The standard deviation of results (each the average of E 180 was used in developing these precision estimates.

duplicates), obtained by the same analyst on different days, has 29.1.4 Bias—The bias of this test method has not been

been estimated to be 0.00971 at 45 dF. The 95 % limit for the determined due to the unavailability of suitable reference

difference between two such averages is 0.03 % ppm. materials.

26.1.3 Reproducibility (Multilaboratory)—The standard de-

viation of results (each the average of duplicates), obtained by GAS CHROMATOGRAPHIC ANALYSIS

analysts in different laboratories, has been estimated to be

0.0255 ppm absolute at 8 df. The 95 % limit for the difference 30. Scope

between two such averages is 0.07 ppm. 30.1 This gas chromatographic test method is intended for

NOTE 10—These precision estimates are based on interlaboratory the analysis of mixtures of ethylene, diethylene, and triethylene

studies performed in 1962 and 1963 on a total of seven samples of glycols or mixtures of propylene, dipropylene, and tripropylene

ethylene glycol, propylene glycol, and dipropylene glycol whose iron glycols in which one of the glycols is the principal component

Copyright ASTM International 5

Copyright by ASTM Int'l (all rights reserved);

Provided by IHS under license with ASTM Licensee=Intertek Testing Services CB /5964714001

No reproduction or networking permitted without license from IHS Not for Resale, 10/14/2008 15:07:44 MDT

Reproduction authorized per License Agreement with Kathe Hooper (ASTMIHS Account); Mon Nov 14 10:31:53 EST 2005

E 202 – 05

and the other two are present in concentrations of 0.1 to not 33.2 Microsyringe, 50-µL capacity.7

more than 1 %, each. Up to 1 % tetraethylene glycol in 33.3 Planimeter—The use of a planimeter to measure peak

triethylene glycol may be analyzed by this test method. The areas is recommended unless the recorder used with the

isomers of dipropylene and tripropylene glycol are not com- chromatograph is equipped with an integrator.

pletely resolved under the conditions used. Gas chromato- 33.4 Aluminum or Stainless Steel Tubing, 0.25 in. (6.35

graphic test methods for determining less than 0.1 % diethyl- mm) in outside diameter, with wall thickness of 0.032 in.

ene glycol in ethylene glycol are in accordance with Test (0.813 mm) for aluminum and 0.065 in. (1.65 mm) for stainless

Methods E 611. steel.

NOTE 12—A new gas chromatograhic method for glycols, Test Method 34. Reagents and Materials

E 2409, has been developed by Committee E15.

34.1 Polyethylene Glycol,8 20 000 molecular weight.

31. Summary of Test Method 34.2 Tetrafluoroethylene Polymer.9

31.1 The sample is injected into a gas chromatographic 34.3 Methylene Chloride (CH2Cl2).

column. The components are separated as they pass through 34.4 Helium (He).

the column with helium carrier gas, and their presence in the 34.5 Ethylene, Diethylene, Triethylene, Tetraethylene, Pro-

effluent is detected and recorded as a chromatogram. The pylene, Dipropylene, and Tripropylene Glycols— See Section

composition of the sample is determined by measuring the 36 for purity requirements.

areas under the peaks of the chromatogram. Two modes of

operating the gas chromatograph are described: linear pro- 35. Preparation of Chromatographic Column

grammed temperature and isothermal. Linear programmed 35.1 Dissolve 14 g of the polyethylene glycol in approxi-

temperature operation tends to give sharper peaks, and is, mately 200 mL of CH2Cl2 with gentle warming to aid solution.

therefore, preferred when it is desired to detect very low Add 186 g of tetrafluoroethylene polymer and sufficient CH2Cl

concentrations of impurities. 2 to form a slurry, and mix well, making certain that all

particles are wetted. Evaporate CH2Cl2 by heating gently over

32. Significance and Use a steam bath in a fume hood until the mixture is dry. Frequent

32.1 The concentrations of the components are obtained by stirring of the slurry during the drying operation is necessary to

a normalization technique, based on the assumption that all obtain a uniform coating. The use of a vacuum rotary evapo-

components are eluted under the conditions used. If all rator will greatly shorten the time required for drying.

components should not be eluted, the calculated concentrations 35.2 Screen the dried packing through a No. 30 mesh sieve

will be erroneously high, with the major components showing to remove lumps. Fill a 4-ft (122-cm) section of 1⁄4-in. (6-mm)

the most significant error on an absolute basis. Although water outside diameter aluminum or stainless-steel tubing with the

is detected under the conditions used, the best accuracy is screened packing (Note 13). Gently vibrate or tap the column

obtained by calculating the gas chromatographic results on a during the filling to ensure uniform packing, but exercise care

water-free basis and correcting these results for the water not to pack too tightly. Approximately 25 mL, or 15.1 g, of

content of the sample in accordance with Sections 15-17. packing is required to fill the aluminum tubing. Plug the ends

of the tubing with glass wool, and shape the tubing so it may

33. Apparatus be mounted conveniently in the oven of the chromatograph.

33.1 Gas Chromatographic Instruments, having the mini- NOTE 13—Chilling the packing in a refrigerator has been reported to

mal following characteristics.6 facilitate the handling of the packing during the filling of the tube.

33.1.1 Sample Injection Port, with heater characteristics

necessary for operations at 215 and 235°C. 35.3 Condition the column prior to use by placing the

33.1.2 Column Oven, capable of isothermal operation at 170 column in the chromatograph in accordance with 37.2, except

to 200°C, or linear programmed temperature operation be- heat the column to 225°C and maintain at that temperature for

tween 150 and 225°C at approximately 5°C/min. at least 4 h. Pass helium through the column at the specified

33.1.3 Detector of the conventional dual-pass thermal con- rate.

ductivity type, capable of operation at 270°C. 36. Calibration Factors

33.1.4 Recorder, 0 to 1-mV range, 1-s full-scale deflection

with a chart speed of approximately 1⁄2 in./min (12.7 mm/min) 36.1 In order to obtain the composition of the sample in

or other convenient speed that will produce a satisfactory terms of weight percent, the areas associated with each

chromatogram, and an attenuator switch to change the recorder

range as required. 7

Hamilton Microsyringe No. 705 has been found satisfactory and is available

33.1.5 Column, 4 ft (122 cm) long, 1⁄4 in. (6.35 mm) in

from supply houses.

outside diameter with a wall thickness of 0.032 in. (0.813 mm) 8

Carbowax polyethylene glycol compound 20M, which is available from supply

for aluminum or 0.065 in. (1.65 mm) for stainless steel houses, has been found satisfactory. Other polyethylene glycols having a molecular

construction; packed with 7 % polyethylene glycol on tet- weight of 20 000 may not perform in a satisfactory manner, and their stability and

ability to separate the glycols when used in column packing should be checked by

rafluoroethylene polymer. the use of standard mixtures.

9

Haloport F, available from Alltech Assoc., 2051 Waulkegen Rd., Deerfield, IL,

has been found satisfactory. Other fluorocarbons may be used if satisfactory

6

These parameters are summarized in Table 3 as typical values. See Note 15. performance is obtained.

--````````,`,,,`,``,``,,,``,-`-`,,`,,`,`,,`---

Copyright ASTM International 6

Copyright by ASTM Int'l (all rights reserved);

Provided by IHS under license with ASTM Licensee=Intertek Testing Services CB /5964714001

No reproduction or networking permitted without license from IHS Not for Resale, 10/14/2008 15:07:44 MDT

Reproduction authorized per License Agreement with Kathe Hooper (ASTMIHS Account); Mon Nov 14 10:31:53 EST 2005

E 202 – 05

component must be multiplied by an appropriate calibration factor for each minor component in the standard mixture in

factor. These factors are obtained from mixtures of known accordance with 38.1.2. Assume a calibration factor of unity

composition, and should be determined for each apparatus. The for the principal glycol in the standard mixture.

calibration factors may be obtained using standards prepared

from“hearts cuts” from the distillation of each of the glycols, or 37. Procedure

from commercial grades of each glycol as described in the 37.1 In analyzing the sample, either of two modes may be

following test methods. For highest accuracy, glycols obtained used in operating the gas chromatograph: linear programmed

from “hearts cuts” should be used. The calibration factors temperature or isothermal. Except for the column temperatures,

should be checked periodically or whenever there is evidence the procedure is the same for either mode, but other parameters

of a change in the column or instrument. will change depending on whether ethylene or propylene

36.2 Test Method A: glycols are being analyzed. The procedure using linear pro-

36.2.1 Purify the commercial grade of each glycol needed grammed temperature will be described first.

by careful fractional distillation in glass at reduced pressure, 37.2 Linear Programmed Temperature Operation:

discarding the first 30 % and retaining the next 30 % as the 37.2.1 Mount the column in the chromatograph, and adjust

“hearts cuts”. These fractions should be analyzed in accor- the operating conditions in accordance with the parameters

dance with 37.2 or 37.3 to be sure they are free from other given in Table 3 (Note 15). Allow sufficient time for the

homologues of the glycol. instrument to reach equilibrium as indicated by a stable base

36.2.2 Prepare a standard mixture of these glycols whose line on the chart at the maximum sensitivity setting to be used.

composition approximates that of the glycols to be analyzed. NOTE 15—The instrument parameters given in Table 3 may be consid-

The composition of this standard should be known to the ered to be typical values. For any specific instrument some adjustment of

nearest 0.01 %. Correct the composition for any water present column temperature, programming rate, helium flow rate, etc. will

as determined in accordance with 15.1, using the equation in probably be required to achieve retention times similar to those in Table

38.2.4. 4 and Table 5. The parameters should be adjusted so that the peaks

obtained are reasonably symmetrical, sharp, and exhibit satisfactory

36.2.3 Obtain at least two chromatograms of the standard resolution.

mixture in accordance with 37.2 or 37.3 and calculate the

average area percent for each of the glycols present in 37.2.2 Inject 10 µL of the sample into the chromatograph by

accordance with 38.2.1 (Note 14). Do not include any areas means of a microsyringe, and obtain a chromatogram of the

associated with air and water in calculating the area percent- sample using attenuation settings which allow for maximum

ages. Using the weight percent in the standard mixture and the peak heights for each peak without going off scale (Note 16).

average area percent, calculate the factor for each glycol in Approximate retention times for the glycols are given in Table

accordance with 38.1.1. 4 and Table 5. Typical chromatograms for diethylene glycol

and dipropylene glycol are shown in Fig. 1 and Fig. 2.

NOTE 14—The same mode of operation of the chromatograph must be

used in analyzing the standard mixture as will be used to analyze samples. NOTE 16—Direct “on-column” injection of the sample has been re-

Different calibration factors may be obtained for linear programmed ported to result in better-shaped peaks and to eliminate, or greatly reduce,

temperature and for isothermal operation. the buildup of carbon in the injection port. If this method of sample

injection is used, the temperature of the injection port should be the same

36.3 Test Method B: as that of the column.

36.3.1 For routine analyses, commercial grades of each 37.2.3 Repeat 37.2.2 to obtain a duplicate chromatogram.

glycol may be used if the gas chromatographic analysis in The area percent of each peak of the chromatograms should

accordance with 37.2 or 36.3 indicates that the other glycols

present do not exceed 1 area %, each. TABLE 3 Typical Instrument Parameters

36.3.2 Prepare a standard mixture of the glycols whose Instrument programmed temperature gas

composition approximates that of the glycol to be analyzed. chromatographA

The composition of the standard should be known to the Strip-chart recorder 0 to 1-mV range

Chart speed 1⁄2 in. (12.7 mm)/min

nearest 0.01 %. Correct the composition for any water present Column 4 ft of 1⁄4-in. (122 mm of 6-mm)

as determined in accordance with 15.1, using the equation in OD aluminum or stainless steel

38.2.4. If the concentrations of the minor components in the tubing packed with polyethylene

glycol11 on tetrafluoroethylene

glycols added to the principal component in the standard polymer12

mixture do not exceed 1 area %, the concentrations of these Column temperature

impurities in the mixture are insignificant at the concentration (a) Programmed 150 to 225°C at 5.6°C/min

temperature

levels included in the scope of this test method. operation

36.3.3 Obtain at least two chromatograms of the standard (b) Isothermal operation 170 or 200°C for ethylene

glycols (refer to 37.3.1)

mixture and of the principal glycol in accordance with 37.2 or 190°C for propylene glycols

37.3 and calculate the average area percent for each of the Carrier gas helium at 75 mL/min

glycols present in accordance with 38.2.1 (Note 14). Do not Detector current 190 mA

Injection port temperature 235°C for ethylene glycols

include any areas associated with air and water in calculating 215°C for propylene glycols

the area percentages. Using the weight percent for each glycol Detector block temperature 270°C

added to the principal glycol component and the average area Sample volume 10 µ

percents for each of these glycols, calculate the calibration A

See Note Note 15.

--````````,`,,,`,``,``,,,``,-`-`,,`,,`,`,,`---

Copyright ASTM International 7

Copyright by ASTM Int'l (all rights reserved);

Provided by IHS under license with ASTM Licensee=Intertek Testing Services CB /5964714001

No reproduction or networking permitted without license from IHS Not for Resale, 10/14/2008 15:07:44 MDT

Reproduction authorized per License Agreement with Kathe Hooper (ASTMIHS Account); Mon Nov 14 10:31:53 EST 2005

E 202 – 05

A

TABLE 4 Retention Time Data temperature if the sample contains more than approximately 1 % ethylene

Retention Time, min glycol in the presence of high concentrations of diethylene glycol.

Compound Programmed Isothermal Operation

Temperature 38. Calculation

Operation 170°C 200°C

38.1 Calibration Factors:

Air and water 0.4 0.3 0.3

Ethylene glycol 2.2 1.3 0.8

38.1.1 When “hearts cuts” of glycols are used to prepare the

Diethylene glycol 7.0 4.2 2.3 standard mixture, obtain the calibration factor for each glycol

Triethylene glycol 11.9 14.0 5.8 as follows:

Tetraethylene glycol 19.3 ... 16.3

A

Wi

Retention times vary with component concentration and from instrument to Fi 5 A (2)

instrument. Thus, the times listed, measured from the point of sample injection to %i

the peak maximum, are approximate.

where:

A Fi = calibration factor for component i,

TABLE 5 Retention Time Data

Wi = weight percent of component i in standard mixture,

Retention Time, min

and

Compound Programmed Isothermal A%i = average area percent of component i in standard

Temperature Operation at

Operation 190°C

mixture.

Air and water 0.5 0.3

38.1.2 When commercial grades of glycols are used to

Propylene-glycol 4.0 1.3 prepare the standard mixture, obtain the calibration factor for

Dipropylene glycol, 3 unresolved 8.1 3.3 each glycol present in minor concentration as follows:

isomers 9.3 3.9

10.3 4.8 Bi

Tripropylene glycolB 12.4 7.9 Fi 5 A 2 A (3)

si bi

A

Retention times vary with component concentrations and from instrument to

instrument. Thus, the times listed, measured from the point of sample injection to where:

the peak maximum, are approximate.

B

Fi = calibration factor for component i,

Several isomers are usually indicated by the shape of the peak, but they are not

sufficiently resolved to list separate retention times.

Bi = weight percent of minor component i added to

principal glycol in preparing the standard mixture,

Asi = average area percent of minor component i in stan-

dard mixture, and

agree within approximately 0.1 area % for duplicate chromato- Abi = average area percent of minor component i in prin-

grams. If they do not agree this closely, obtain replicate cipal component.

chromatograms until agreement is achieved.

38.2 Sample Composition:

NOTE 17—Generally, three chromatograms may be required to obtain 38.2.1 Calculate the area percentage of each component as

agreement. The first injection of the sample seems to condition the follows:

column.

NOTE 18—Frequent, rigorous cleaning of the injection port with hot AiTi 3 100

A%i 5 (4)

water and acetone may be required to avoid a buildup of carbonaceous ~A 1T1! 1 ~A2T2! 1 ~A 3T3! 1 ~A4T4!

material in the injection port which will cause erroneous answers.

Frequent septum changes help prevent extraneous peaks. where:

A% i =

area percent for glycol i,

37.2.4 Draw base lines under each glycol peak and measure Ai =

area for glycol i,

the area of each peak with a planimeter, unless the recorder is Ti =

recorder attenuation for area of glycol i,

equipped with an integrator. A1, A2, A3, A4 =

areas for mono, di, tri, and tetraalkyl

37.3 Isothermal Operation: glycols, respectively, and

37.3.1 Follow the procedure in accordance with 37.2, ex- T1, T2, T3, T4 = recorder attenuation for areas for mono,

cept use a constant column temperature of 170 °C for the di, tri, and tetraalkyl glycols, respec-

analysis of mixtures of ethylene, diethylene, and triethylene tively.

glycols. A temperature of 200°C is used for mixtures contain- 38.2.2 Calculate the corrected area of each glycol as fol-

ing tetraethylene glycol (Note 15 and Note 19). Approximate lows:

retention times for the glycols are given in Table 4 and Table

Aci 5 A %i 3 Fi (5)

5. Typical chromatograms for a sample of ethylene and of

diethylene glycol at temperatures of 170 and 200°C respec- where:

tively, are shown in Fig. 3 and Fig. 4. A typical chromatogram Ac i = corrected area for glycol i,

of dipropylene glycol is shown in Fig. 5. A%i = area percent for glycol i, and

NOTE 19—The higher temperature is used to obtain a reasonably short

Fi = factor for glycol i.

retention time for tetraethylene glycol. Complete resolution of the 38.2.3 Calculate the weight percent of each glycol on an

ethylene and diethylene glycol peaks may not be achieved at this higher anhydrous basis as follows:

--````````,`,,,`,``,``,,,``,-`-`,,`,,`,`,,`---

Copyright ASTM International 8

Copyright by ASTM Int'l (all rights reserved);

Provided by IHS under license with ASTM Licensee=Intertek Testing Services CB /5964714001

No reproduction or networking permitted without license from IHS Not for Resale, 10/14/2008 15:07:44 MDT

Reproduction authorized per License Agreement with Kathe Hooper (ASTMIHS Account); Mon Nov 14 10:31:53 EST 2005

E 202 – 05

--````````,`,,,`,``,``,,,``,-`-`,,`,,`,`,,`---

FIG. 1 Chromatogram of Diethylene Glycol Linear Programmed Temperature Operation (Recorder Attenuation in Parentheses)

FIG. 2 Chromatogram of Dipropylene Glycol Linear Programmed Temperature Operation (Recorder Attenuation in Parentheses)

Aci 38.2.4 Correct the weight percent of each glycol for the

C i 5 A 1 A 1 A 1 A 3 100 (6)

c1 c2 c3 c4 water content of the sample as follows:

where: Ci~100 2 D!

Gi 5 100 (7)

Ci = weight percent of glycol i, ex-

pressed on an anhydrous basis,

Aci = corrected area for glycol i, and

Ac1, Ac2, Ac3, Ac4 = corrected areas for mono, di, tri,

and tetraalkyl glycols, respectively.

Copyright ASTM International 9

Copyright by ASTM Int'l (all rights reserved);

Provided by IHS under license with ASTM Licensee=Intertek Testing Services CB /5964714001

No reproduction or networking permitted without license from IHS Not for Resale, 10/14/2008 15:07:44 MDT

Reproduction authorized per License Agreement with Kathe Hooper (ASTMIHS Account); Mon Nov 14 10:31:53 EST 2005

E 202 – 05

FIG. 3 Chromatogram of Ethylene Glycol Isothermal Operation at 170°C (Recorder Attenuation in Parentheses)

FIG. 4 Chromatogram of Diethylene Glycol Isothermal Operation at 200°C (Recorder Attenuation in Parentheses)

where: 39. Report

Gi = weight percent of glycol i, corrected for water content 39.1 Report the weight percent of each component to the

of sample, nearest 0.01 %.

Ci = weight percent of glycol i, expressed on an anhydrous

basis, and 40. Precision and Bias

D = weight percent of water in the sample as determined

40.1 The following criteria should be used for judging the

by Karl Fischer Reagent.

acceptability of results (see Note 20):

--````````,`,,,`,``,``,,,``,-`-`,,`,,`,`,,`---

Copyright ASTM International 10

Copyright by ASTM Int'l (all rights reserved);

Provided by IHS under license with ASTM Licensee=Intertek Testing Services CB /5964714001

No reproduction or networking permitted without license from IHS Not for Resale, 10/14/2008 15:07:44 MDT

Reproduction authorized per License Agreement with Kathe Hooper (ASTMIHS Account); Mon Nov 14 10:31:53 EST 2005

E 202 – 05

--````````,`,,,`,``,``,,,``,-`-`,,`,,`,`,,`---

FIG. 5 Chromatogram of Dipropylene Glycol Isothermal Operation at 190°C (Recorder Attenuation in Parentheses)

40.1.1 Repeatability (Single Analyst)—The standard devia- models of instruments.10 The calibration factors for converting area to

tion for a single determination has been estimated to be the weight percent were obtained using standard samples which, unknown to

value in Table 6 at the indicated degrees of freedom. The 95 % the participants, had the same composition as the test samples.10

The precision estimates for the propylene glycol samples are based on

limit for the difference between two such runs is the value in a 1966 interlaboratory study in which four samples of the glycols were

the table. analyzed. The concentrations of the minor components ranged from 0.25

40.1.2 Laboratory Precision (Within-Laboratory, Between- to 0.79 weight %. Nine laboratories cooperated in the study in which each

Days)—The standard deviation of results (each the average of analyst performed duplicate determinations by each mode of instrument

duplicates), obtained by the same analyst on different days, has operation on each of two days, using eight different makes or models of

been estimated to be the value in Table 6 at the indicated instruments.10 The calibration factors for converting area to weight

percent were obtained using samples of known composition prepared by

degrees of freedom. The 95 % limit for the difference between

each analyst.10 Practice E 180 was used in developing these precision

two such averages is the value in the table. estimates.

40.1.3 Reproducibility (Multilaboratory)—The standard de-

viation of results (each the average of duplicates), obtained by 40.2 Bias—The bias of this test method has not been

analysts in different laboratories, has been estimated to be the determined due to the unavailability of suitable reference

value in Table 6 at the indicated degrees of freedom. The 95 % materials.

limit for the difference between two such averages is the value 41. Keywords

in the table.

41.1 acidity; color; distillation range; ethylene glycols; gas

NOTE 20—The precision estimates for the ethylene glycols are based on chromatography; iron; propylene glycols; specific gravity;

a 1964–1965 interlaboratory study in which three samples of the glycols water

were analyzed. The concentrations of the minor glycol components ranged

from 0.48 to 1.00 weight %. Seven laboratories cooperated in the study in

which each analyst performed duplicate determinations by each mode of 10

Details of the interlaboratory study are available from ASTM Headquarters.

instrument operation on each of two days, using seven different makes or Request RR: E15-0028.

Copyright ASTM International 11

Copyright by ASTM Int'l (all rights reserved);

Provided by IHS under license with ASTM Licensee=Intertek Testing Services CB /5964714001

No reproduction or networking permitted without license from IHS Not for Resale, 10/14/2008 15:07:44 MDT

Reproduction authorized per License Agreement with Kathe Hooper (ASTMIHS Account); Mon Nov 14 10:31:53 EST 2005

E 202 – 05

TABLE 6 Gas Chromatographic Precision Values

Ethylene Glycols Propylene Glycols

Standard Deviation, Major Minor Major Minor

absolute % Compo- Compo- Compo- Compo-

nentA nentB nentA nentB

Programmed

Tempera-

ture, Weight %:

Repeatability

Standard 0.0477 0.0272 0.0224 0.0172

deviation (42C) (12) (64) (92)

95 % limit 0.13 0.076 0.063 0.048

Laboratory

Precision

(Within-

Laboratory

Between-

Days)

Standard 0.0700 0.0363 0.0366 0.0260

deviation (21) (56) (32) (46)

95 % limit 0.20 0.10 0.10 0.073

Reproducibility

Standard 0.1024 (6) 0.0527 (6) 0.0615 (7) 0.0499 (7)

deviation

95 % limit 0.29 0.15 0.17 0.14

Isothermal

Temperature,

Weight %

Repeatability

Standard 0.0516 0.0277 0.0265 0.0197

deviation (42) (112) (70) (94)

95 % limit 0.14 0.078 0.074 0.055

Laboratory

Precision

(Within-

Laboratory

Between-

Days)

Standard 0.0498 0.0282 0.0515 0.0494

deviation (21) (56) (35) (47)

95 % limit 0.14 0.079 0.14 0.14

Reproducibility

Standard 0.1033 (6) 0.0528 (6) 0.0633 (8) 0.0536 (7)

deviation

95 % limit 0.29 0.15 0.18 0.15

A

Concentration range from 97 to 100 %.

B

Concentration range of less than 1 %.

C

Degrees of freedom indicated by values within parentheses.

APPENDIX

X1.

TABLE X1.1 X1.1 Scope—Listed in Table X1.1 are alternative test

Analysis

Listed Test

Alternative Test Method

methods and technology for several of the test methods. The

Method

alternative test methods do not have precision data for the

Relative Density D 891 D 4052 application of these methods in analyzing glycols. Use of these

Distillation Range D 1078 none

Acidity D 1613 Potentiometric titration as methods is optional and individuals using the alternative

an option to visual methods should assure themselves that the method is suffi-

endpoint titration

Water E 203 E 1064

ciently precise. Precision data presented is only for the original

Iron E 394 E 1615 test methods listed.

Color D 1209 D 5386

Gas Chromatographic E 611 E 2409

Analysis

--````````,`,,,`,``,``,,,``,-`-`,,`,,`,`,,`---

Copyright ASTM International 12

Copyright by ASTM Int'l (all rights reserved);

Provided by IHS under license with ASTM Licensee=Intertek Testing Services CB /5964714001

No reproduction or networking permitted without license from IHS Not for Resale, 10/14/2008 15:07:44 MDT

Reproduction authorized per License Agreement with Kathe Hooper (ASTMIHS Account); Mon Nov 14 10:31:53 EST 2005

E 202 – 05

ASTM International takes no position respecting the validity of any patent rights asserted in connection with any item mentioned

in this standard. Users of this standard are expressly advised that determination of the validity of any such patent rights, and the risk

of infringement of such rights, are entirely their own responsibility.

This standard is subject to revision at any time by the responsible technical committee and must be reviewed every five years and

if not revised, either reapproved or withdrawn. Your comments are invited either for revision of this standard or for additional standards

and should be addressed to ASTM International Headquarters. Your comments will receive careful consideration at a meeting of the

responsible technical committee, which you may attend. If you feel that your comments have not received a fair hearing you should

make your views known to the ASTM Committee on Standards, at the address shown below.

This standard is copyrighted by ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959,

United States. Individual reprints (single or multiple copies) of this standard may be obtained by contacting ASTM at the above

address or at 610-832-9585 (phone), 610-832-9555 (fax), or service@astm.org (e-mail); or through the ASTM website

(www.astm.org).

--````````,`,,,`,``,``,,,``,-`-`,,`,,`,`,,`---

Copyright ASTM International 13

Provided by IHS under license with ASTM Copyright by ASTM Int'l (all rights reserved); Licensee=Intertek Testing Services CB /5964714001

No reproduction or networking permitted without license from IHS Not for Resale, 10/14/2008 15:07:44 MDT

Reproduction authorized per License Agreement with Kathe Hooper (ASTMIHS Account); Mon Nov 14 10:31:53 EST 2005

You might also like

- Astm D2074-2007Document2 pagesAstm D2074-2007Hasan Zeki BayrakNo ratings yet

- Astm D2180-1989 (2008)Document2 pagesAstm D2180-1989 (2008)WMJNo ratings yet

- Fatty Acid EthanolamideDocument9 pagesFatty Acid Ethanolamidegaurav chauhanNo ratings yet

- TestsDocument10 pagesTestsmehwish05No ratings yet

- Anyonik Surfactant Tayini PDFDocument5 pagesAnyonik Surfactant Tayini PDFSami KocahanNo ratings yet

- Volatile Matter in Green Petroleum Coke Quartz Crucible ProcedureDocument4 pagesVolatile Matter in Green Petroleum Coke Quartz Crucible ProcedureAli VarmazyarNo ratings yet

- Chlorine in Aromatics by Monochromatic Wavelength Dispersive X-Ray Fluorescence SpectrometryDocument7 pagesChlorine in Aromatics by Monochromatic Wavelength Dispersive X-Ray Fluorescence SpectrometryAlberto PavanNo ratings yet

- Genamin Quats Presentation - Essential Ingredients, IncDocument31 pagesGenamin Quats Presentation - Essential Ingredients, IncMaximiliano MackeviciusNo ratings yet

- Is Iso 1066 1975Document9 pagesIs Iso 1066 1975Clausius ClapeyronNo ratings yet

- Pidicryl 120V pigment dispersing agent technical data sheetDocument1 pagePidicryl 120V pigment dispersing agent technical data sheethai nguyenNo ratings yet

- Fed STD 791DDocument460 pagesFed STD 791DAliNo ratings yet

- ASTM D2281-10 Standard Test Method For Evaluation of Wetting Agents by Skein TestDocument3 pagesASTM D2281-10 Standard Test Method For Evaluation of Wetting Agents by Skein TestDerek Vaughn100% (1)

- E 1405 - 98 R99 - Rte0mdutotDocument3 pagesE 1405 - 98 R99 - Rte0mdutotdelta lab sangliNo ratings yet

- Astm D 2008 - 12Document7 pagesAstm D 2008 - 12alexander guerraNo ratings yet

- Molecular Weight DeterminationsDocument14 pagesMolecular Weight DeterminationsEdwin Kamalha0% (1)

- Methods of Test For Petroleum and Its Products: Indian StandardDocument28 pagesMethods of Test For Petroleum and Its Products: Indian StandardNivedhitha JananiNo ratings yet

- Astm e 301-88 Standard Test Method For Total Acidity of Organic AcidsDocument3 pagesAstm e 301-88 Standard Test Method For Total Acidity of Organic AcidsGianinaRoncalChávezNo ratings yet

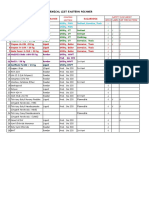

- Chemical List Eastern PolymerDocument1 pageChemical List Eastern PolymerIan MardiansyahNo ratings yet

- Redicote E-7000: Versatile Emulsifier: Provides Both AniDocument1 pageRedicote E-7000: Versatile Emulsifier: Provides Both AniRabin Bera0% (1)

- Basf Aditivo PinturasDocument34 pagesBasf Aditivo Pinturasv0% (1)

- D 1881Document4 pagesD 1881seterisparigusNo ratings yet

- Total Iodine Value of Drying Oils and Their Derivatives: Standard Test Method ForDocument3 pagesTotal Iodine Value of Drying Oils and Their Derivatives: Standard Test Method ForAl7amdlellahNo ratings yet

- Synthesis and Applications of Polystyrene-Blockpoly (N-Vinyl-2-Pyrrolidone) CopolymersDocument10 pagesSynthesis and Applications of Polystyrene-Blockpoly (N-Vinyl-2-Pyrrolidone) CopolymersBruna Guedes AlvarengaNo ratings yet

- Hydrosulphite DeterminationDocument3 pagesHydrosulphite Determination950 911100% (1)

- Astm C871Document6 pagesAstm C871DilaFirizqinaNo ratings yet

- TDS Polartech 7600Document1 pageTDS Polartech 7600Ngũ Viên Gia Các100% (1)

- Acidity-Alkalinity of Halogenated Organic Solvents and Their AdmixturesDocument3 pagesAcidity-Alkalinity of Halogenated Organic Solvents and Their AdmixturesShaker QaidiNo ratings yet

- D 3465 - 00 Monomero Por CGDocument3 pagesD 3465 - 00 Monomero Por CGsbiasotoNo ratings yet

- TDS Alcomer 216Document2 pagesTDS Alcomer 216PrototypeNo ratings yet

- Astm D3306Document5 pagesAstm D3306mfelwazieryNo ratings yet

- Shieldex Coil - C 303Document2 pagesShieldex Coil - C 303nanoNo ratings yet

- Total Sulfur in The Analysis Sample of Refuse-Derived Fuel: Standard Test Methods ForDocument4 pagesTotal Sulfur in The Analysis Sample of Refuse-Derived Fuel: Standard Test Methods FornerissaloveNo ratings yet

- Dapro DF 7010 MSDSDocument8 pagesDapro DF 7010 MSDSdipen roy100% (1)

- Hydroxyl Value of Fatty Oils and Acids: Standard Test Method ForDocument3 pagesHydroxyl Value of Fatty Oils and Acids: Standard Test Method ForAl7amdlellah100% (1)

- Measurement of Hindered Phenolic Antioxidant Content in HL Turbine Oils by Linear Sweep VoltammetryDocument6 pagesMeasurement of Hindered Phenolic Antioxidant Content in HL Turbine Oils by Linear Sweep VoltammetryMohanadNo ratings yet

- D1617 - 07 (2012) Standard Test Method For Ester Value of Solvents and Thinners PDFDocument3 pagesD1617 - 07 (2012) Standard Test Method For Ester Value of Solvents and Thinners PDFJacques BlueqNo ratings yet

- Norma Tension Superficial D1331Document4 pagesNorma Tension Superficial D1331cristiangggNo ratings yet

- Astm D 3341Document4 pagesAstm D 3341Manuel GuzmanNo ratings yet

- Chapter 1 A Textbook On PetroChemicals by DRBKB Rao - pdf.1HNzZJN17qx0ZFwZPM2M5DBfDGSksWBtDocument49 pagesChapter 1 A Textbook On PetroChemicals by DRBKB Rao - pdf.1HNzZJN17qx0ZFwZPM2M5DBfDGSksWBtKuldeepsingh ChandelNo ratings yet

- ASTMDocument10 pagesASTMtenNo ratings yet

- D 6646 - 03 - Rdy2ndyDocument8 pagesD 6646 - 03 - Rdy2ndyLoanNo ratings yet

- Acid Value and Amine Value of Fatty Quaternary Ammonium ChloridesDocument3 pagesAcid Value and Amine Value of Fatty Quaternary Ammonium ChloridesShaker Qaidi100% (1)

- PH Meter ManualDocument1 pagePH Meter ManualManasNo ratings yet

- Astm D1208 - 1 (En)Document3 pagesAstm D1208 - 1 (En)rezokaNo ratings yet

- Astm E2680 16 PDF DownloadDocument4 pagesAstm E2680 16 PDF DownloadAnonymous kd6WjmxTIFNo ratings yet

- Sitren Airvoid 320 en Oi 0218Document1 pageSitren Airvoid 320 en Oi 0218JuanCamiloLemaZambranoNo ratings yet

- Corrosion Inhibitor BS 6580: Data SheetDocument4 pagesCorrosion Inhibitor BS 6580: Data SheetNicko RizqienggalNo ratings yet

- SGS Raporu - PDF - 1Document17 pagesSGS Raporu - PDF - 1Jacek StanislawskiNo ratings yet

- Moisture Volatile OilDocument2 pagesMoisture Volatile OilRobert GilmoreNo ratings yet

- Polyolefin Monofilaments: Standard Specification ForDocument9 pagesPolyolefin Monofilaments: Standard Specification Forgoodcharacter1No ratings yet

- The Preparation of Substitute Ocean Water: Standard Practice ForDocument3 pagesThe Preparation of Substitute Ocean Water: Standard Practice ForAbid HussainNo ratings yet

- ASTM-D974 - No. de Acido Por ColorDocument7 pagesASTM-D974 - No. de Acido Por ColorIvan Pulido100% (2)

- IS 6932 Part 11-1983Document7 pagesIS 6932 Part 11-1983Vijay Reddy MullapudiNo ratings yet

- MT 23 Miscibility With Hydrocarbon Oil: Miscellaneous Techniques and ImpuritiesDocument6 pagesMT 23 Miscibility With Hydrocarbon Oil: Miscellaneous Techniques and ImpuritiesFelipe Navarrete0% (1)

- Wanhua Wannate 8018: Parameters SpecificationsDocument13 pagesWanhua Wannate 8018: Parameters SpecificationsRakesh SharmaNo ratings yet

- Polyester PolyolsDocument5 pagesPolyester PolyolsWSERNo ratings yet

- Analysis of Ethylene Glycols and Propylene Glycols: Standard Test Methods ForDocument13 pagesAnalysis of Ethylene Glycols and Propylene Glycols: Standard Test Methods ForSergeyVorobyov100% (1)

- Analysis of Ethylene Glycols and Propylene Glycols: Standard Test Methods ForDocument13 pagesAnalysis of Ethylene Glycols and Propylene Glycols: Standard Test Methods ForJuan MancipeNo ratings yet

- 198681704-ASTM-D-E202 Metodo Te Pureza de Glicol PDFDocument12 pages198681704-ASTM-D-E202 Metodo Te Pureza de Glicol PDFNicola MargarelliNo ratings yet

- Analysis of Ethylene Glycols and Propylene Glycols: Standard Test Methods ForDocument14 pagesAnalysis of Ethylene Glycols and Propylene Glycols: Standard Test Methods FormanojballaNo ratings yet

- Astm D 976 - 06Document4 pagesAstm D 976 - 06Julian Felipe Noguera CruzNo ratings yet

- Kinematic Viscosity of Transparent and Opaque Liquids (And Calculation of Dynamic Viscosity)Document10 pagesKinematic Viscosity of Transparent and Opaque Liquids (And Calculation of Dynamic Viscosity)Justin DiravirajNo ratings yet

- Kinematic Viscosity of Transparent and Opaque Liquids (And Calculation of Dynamic Viscosity)Document13 pagesKinematic Viscosity of Transparent and Opaque Liquids (And Calculation of Dynamic Viscosity)Julian Felipe Noguera CruzNo ratings yet

- Water in Crude Oils by Potentiometric Karl Fischer TitrationDocument7 pagesWater in Crude Oils by Potentiometric Karl Fischer TitrationJulian Felipe Noguera CruzNo ratings yet

- Pour Point of Petroleum Products: Standard Test Method ForDocument10 pagesPour Point of Petroleum Products: Standard Test Method ForJulian Felipe Noguera CruzNo ratings yet

- D1298 05 PDFDocument6 pagesD1298 05 PDFJulian Felipe Noguera CruzNo ratings yet

- Glass Capillary Kinematic Viscometers: Standard Specifications and Operating Instructions ForDocument24 pagesGlass Capillary Kinematic Viscometers: Standard Specifications and Operating Instructions ForJulian Felipe Noguera CruzNo ratings yet

- ASTM D 891 - 95 (Reapproved 2004)Document4 pagesASTM D 891 - 95 (Reapproved 2004)Julian Felipe Noguera CruzNo ratings yet

- Salts in Crude Oil (Electrometric Method) : Standard Test Method ForDocument6 pagesSalts in Crude Oil (Electrometric Method) : Standard Test Method ForJulian Felipe Noguera CruzNo ratings yet

- Astm D445 2012 PDFDocument13 pagesAstm D445 2012 PDFJulian Felipe Noguera CruzNo ratings yet

- Astm D 445 - 06 PDFDocument10 pagesAstm D 445 - 06 PDFJulian Felipe Noguera CruzNo ratings yet

- D1298 PDFDocument6 pagesD1298 PDFQoryk QodryNo ratings yet

- Astm D 323 - 06 PDFDocument10 pagesAstm D 323 - 06 PDFJulian Felipe Noguera CruzNo ratings yet

- Kinematic Viscosity of Transparent and Opaque Liquids (And Calculation of Dynamic Viscosity)Document10 pagesKinematic Viscosity of Transparent and Opaque Liquids (And Calculation of Dynamic Viscosity)Justin DiravirajNo ratings yet

- Salts in Crude Oil (Electrometric Method) : Standard Test Method ForDocument6 pagesSalts in Crude Oil (Electrometric Method) : Standard Test Method ForJulian Felipe Noguera CruzNo ratings yet

- Astm D 130 - 04 PDFDocument9 pagesAstm D 130 - 04 PDFJulian Felipe Noguera CruzNo ratings yet

- Astm D 93 - 07 PDFDocument16 pagesAstm D 93 - 07 PDFJulian Felipe Noguera CruzNo ratings yet

- Glass Capillary Kinematic Viscometers: Standard Specifications and Operating Instructions ForDocument24 pagesGlass Capillary Kinematic Viscometers: Standard Specifications and Operating Instructions ForJulian Felipe Noguera CruzNo ratings yet

- Water in Crude Oils by Potentiometric Karl Fischer TitrationDocument7 pagesWater in Crude Oils by Potentiometric Karl Fischer TitrationJulian Felipe Noguera CruzNo ratings yet

- ASTM D 86 - 07b PDFDocument27 pagesASTM D 86 - 07b PDFJulian Felipe Noguera Cruz100% (1)

- ASTM D 4377 - 00 (Reapproved 2006) PDFDocument7 pagesASTM D 4377 - 00 (Reapproved 2006) PDFJulian Felipe Noguera CruzNo ratings yet

- Glass Capillary Kinematic Viscometers: Standard Specifications and Operating Instructions ForDocument24 pagesGlass Capillary Kinematic Viscometers: Standard Specifications and Operating Instructions ForJulian Felipe Noguera CruzNo ratings yet

- D1298 PDFDocument6 pagesD1298 PDFQoryk QodryNo ratings yet

- Astm D 4294 - 08 PDFDocument8 pagesAstm D 4294 - 08 PDFJulian Felipe Noguera CruzNo ratings yet

- Kinematic Viscosity of Transparent and Opaque Liquids (And Calculation of Dynamic Viscosity)Document10 pagesKinematic Viscosity of Transparent and Opaque Liquids (And Calculation of Dynamic Viscosity)Justin DiravirajNo ratings yet

- Pour Point of Petroleum Products: Standard Test Method ForDocument10 pagesPour Point of Petroleum Products: Standard Test Method ForJulian Felipe Noguera CruzNo ratings yet

- Astm D 4294 - 08 PDFDocument8 pagesAstm D 4294 - 08 PDFJulian Felipe Noguera CruzNo ratings yet

- Astm D 3230 - 08 PDFDocument6 pagesAstm D 3230 - 08 PDFJulian Felipe Noguera Cruz100% (2)

- Kinematic Viscosity of Transparent and Opaque Liquids (And Calculation of Dynamic Viscosity)Document13 pagesKinematic Viscosity of Transparent and Opaque Liquids (And Calculation of Dynamic Viscosity)Julian Felipe Noguera CruzNo ratings yet

- DEE20023 Chapter 4 JUNCTION FIELD EFFECT TRANSISTOR SESI II 20222023Document51 pagesDEE20023 Chapter 4 JUNCTION FIELD EFFECT TRANSISTOR SESI II 20222023Muhd ZarifNo ratings yet

- Pengaruh Pembebasan Tanah Terhadap Keterlambatan Proyek Pembangunan Jalan Tol Cinere - Jagorawi Seksi II BDocument8 pagesPengaruh Pembebasan Tanah Terhadap Keterlambatan Proyek Pembangunan Jalan Tol Cinere - Jagorawi Seksi II BAgsartika YuniNo ratings yet

- Thermal controller for semiconductor switching devicesDocument15 pagesThermal controller for semiconductor switching devicesAnonymous G1iPoNOKNo ratings yet

- FDSC Supporting Innovation in Health and Social Care Personal and Professional Development, Level 4, 20 Credits Assessment BriefDocument14 pagesFDSC Supporting Innovation in Health and Social Care Personal and Professional Development, Level 4, 20 Credits Assessment BriefleeleelauraNo ratings yet

- Labomed Prima DNT SeriesDocument5 pagesLabomed Prima DNT SeriesCarlos EstradaNo ratings yet

- Foreign Worker Appraisal Form (Updated)Document8 pagesForeign Worker Appraisal Form (Updated)Muhamad HasifNo ratings yet

- Cell TheoryDocument31 pagesCell TheoryMarc Ian Young100% (1)

- COT Math 2 Q3 W2Document25 pagesCOT Math 2 Q3 W2Reginelie PadogNo ratings yet

- Second Conditional WorksheetDocument2 pagesSecond Conditional WorksheetEmanAbdel-HaqNo ratings yet

- The Standard Penetration Test - Its Application and Interpretation - Stroud-1989Document21 pagesThe Standard Penetration Test - Its Application and Interpretation - Stroud-1989Rajeev Kusugal67% (3)

- 5 - Organization ChartDocument2 pages5 - Organization ChartYass AhmedNo ratings yet

- Drilling Soal TBI 2Document6 pagesDrilling Soal TBI 2jendeuk kimNo ratings yet

- Cancer - 2005 - Van Gogh - The Efficacy of Voice Therapy in Patients After Treatment For Early Glottic CarcinomaDocument11 pagesCancer - 2005 - Van Gogh - The Efficacy of Voice Therapy in Patients After Treatment For Early Glottic CarcinomaNathalia Dos ReisNo ratings yet

- Eddo 2020Document65 pagesEddo 2020temesgenNo ratings yet

- Understanding Social WorkDocument7 pagesUnderstanding Social WorkIsis Angelica FarinasNo ratings yet

- ERDAS IMAGINE 2011 USER MANUALDocument73 pagesERDAS IMAGINE 2011 USER MANUALNø Wømen Nø CryNo ratings yet

- Pile FoundationDocument38 pagesPile FoundationChowdhury PriodeepNo ratings yet

- Mobilgear SHC XMP Series Performance ProfileDocument2 pagesMobilgear SHC XMP Series Performance ProfileosamaelnahrawyNo ratings yet

- 2022 Charge Transfer Observed in Light Activated Catalyst ParticlesDocument2 pages2022 Charge Transfer Observed in Light Activated Catalyst ParticlesTien TruongNo ratings yet

- DLP # 5Document3 pagesDLP # 5MAILENE YAPNo ratings yet

- NEOM-NDS-SPC-015 - 01.00 - Neutral Earthing Resistor (NER) SpecificationDocument15 pagesNEOM-NDS-SPC-015 - 01.00 - Neutral Earthing Resistor (NER) Specificationcawoc96196No ratings yet

- MDSReport 1072712729Document3 pagesMDSReport 1072712729Muhammad RamadhonNo ratings yet

- Biocorrosion: H.A. Videla and L.K. Herrera BDocument26 pagesBiocorrosion: H.A. Videla and L.K. Herrera Bcanmert kocaNo ratings yet

- How To Ask For Help in An EmailDocument3 pagesHow To Ask For Help in An Emailapi-435123349No ratings yet

- Dwnload Full Sociology in Modules 3rd Edition Schaefer Test Bank PDFDocument35 pagesDwnload Full Sociology in Modules 3rd Edition Schaefer Test Bank PDFphillipsantosdod5is100% (10)

- David Nguyen - StatementDocument2 pagesDavid Nguyen - StatementDavidNo ratings yet

- Testy Dlja Podg K Egje Po Angl Jaz Macmillan Exam Skills KN Uchitelja 2015 64cDocument66 pagesTesty Dlja Podg K Egje Po Angl Jaz Macmillan Exam Skills KN Uchitelja 2015 64cDaria StryapshinaNo ratings yet

- Mathematics 2 DLL Quarter 2 Week 6Document7 pagesMathematics 2 DLL Quarter 2 Week 6Ana Mae SaysonNo ratings yet

- CAPF AC 2009-19 History Questions Analysis: Credits: Team Study FundaDocument44 pagesCAPF AC 2009-19 History Questions Analysis: Credits: Team Study FundaAbhilash GaurNo ratings yet

- Kyoto Protocol UPSC NotesDocument3 pagesKyoto Protocol UPSC NotesSanchit RanaNo ratings yet