Professional Documents

Culture Documents

Daily Report #3 (NEW FORMAT)

Uploaded by

Dave Patrick EscalaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Daily Report #3 (NEW FORMAT)

Uploaded by

Dave Patrick EscalaCopyright:

Available Formats

REVISION NO.

: 00

May 10, 2016

REVISION DATE:

DAILY JOURNAL

INCLUDE TASK ASSIGNMENTS OR MOVEMENTS, REFLECTION ON THE DAY S NEW LEARNING, ACCOMPLISHMENT, CHALLENGES FACED

AND HOW YOU RESPONDED, OBSERVATIONS AND RECOMMENDATIONS ON THE IMPROVEMENT OF SYSTEMS / OPERATION /

MANAGEMENT, ETC.

SCANNED COPIES OF THIS FORM SHALL BE SUBMITTED ON A WEEKLY BASIS THROUGH APPROVED LMS .

HARD COPIES OF THIS FORM SHOULD BE COMPILED AS PART OF THE STUDENT S PORTFOLIO.

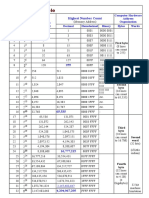

DATE AREA ASSIGNMENT Main Laboratory

June 12, 2019

TASK SHIFT/TIME 7:26 AM – 5:01 PM

Line 5 Orientation

Today I was reassigned to line 5 which handles the product Minute Maid Orange. I

was given an orientation on how the line was operated and how the unit processes have

their respective tasks. I learned the step by step process on how the product was formed

from filling the plastic bottles up to the packaging and storage. The supervisor has given me

the responsibility to determine if the net content of their product were in the right

specifications and determine the sugar amount in the orange juice. An hourly observation

was needed in order to secure the proper order of the operation. Every round of testing, 10

bottles of the same time manufactured was needed. The net contents were measured to

determine if the bottles are have the correct weight. Based on what I have observed inside

the laboratory, Minute Maid Orange has a higher amount of sugar than Sprite based on the

Brix outputted by the machine. In the packaging section, I was tasked to check whether the

correct bar code was printed in the set of product. I was also given with the information how

the temperature must vary and its importance in different sections of the unit processes.

TRAINEE S SIGNATURE

You might also like

- Daily Report #11 (NEW FORMAT)Document1 pageDaily Report #11 (NEW FORMAT)Dave Patrick EscalaNo ratings yet

- Daily Report #10 (NEW FORMAT)Document1 pageDaily Report #10 (NEW FORMAT)Dave Patrick EscalaNo ratings yet

- Daily Report #12 (NEW FORMAT)Document1 pageDaily Report #12 (NEW FORMAT)Dave Patrick EscalaNo ratings yet

- Daily Report #4 (NEW FORMAT)Document1 pageDaily Report #4 (NEW FORMAT)Dave Patrick EscalaNo ratings yet

- Daily Report #13 (NEW FORMAT)Document1 pageDaily Report #13 (NEW FORMAT)Dave Patrick EscalaNo ratings yet

- Daily Report #9 (NEW FORMAT)Document1 pageDaily Report #9 (NEW FORMAT)Dave Patrick EscalaNo ratings yet

- Form OVPAA 030G Practicum Daily Journal Fillable Blank44Document1 pageForm OVPAA 030G Practicum Daily Journal Fillable Blank44jianromeroNo ratings yet

- Narrative ReportDocument3 pagesNarrative ReportAlyssa Endso100% (2)

- Garlic Jim's Opening Closing ProceduresDocument13 pagesGarlic Jim's Opening Closing ProceduresRedondo Bruno100% (1)

- How To Write SOPDocument4 pagesHow To Write SOPJustice AkuboNo ratings yet

- Projects and Operations Management: From, Shri Hari Krishna K 151GCMD129 Section - C R.V. Institute of ManagementDocument6 pagesProjects and Operations Management: From, Shri Hari Krishna K 151GCMD129 Section - C R.V. Institute of ManagementHari KrishnaNo ratings yet

- Swa ProcedureDocument5 pagesSwa ProcedureVasilis IliopoulosNo ratings yet

- Final Paper - Spanish LatteDocument19 pagesFinal Paper - Spanish LatteSAAVEDRA , ANDREA COLUMBRESNo ratings yet

- Internship ReportDocument31 pagesInternship ReportYusuke AyameNo ratings yet

- Lean Management IndustryDocument29 pagesLean Management IndustrynikitaNo ratings yet

- SITHKOP005 Coordinate Cooking Operations: Assessment Tool 3 of 5: Practical Project Part A - Sous Chef RoleDocument59 pagesSITHKOP005 Coordinate Cooking Operations: Assessment Tool 3 of 5: Practical Project Part A - Sous Chef RoleJimmy Kapoor67% (3)

- Lean Management Paradigm Shif DR ArbainDocument84 pagesLean Management Paradigm Shif DR ArbainazlizawatiNo ratings yet

- De La Salle University - Dasmariñas: Improvement Proposal For Taza VerdeDocument14 pagesDe La Salle University - Dasmariñas: Improvement Proposal For Taza VerdeRizza IzonNo ratings yet

- CBLM Fbs NC II NewDocument121 pagesCBLM Fbs NC II NewRowena CabcaNo ratings yet

- Aquaporin InterviewDocument3 pagesAquaporin InterviewMichelle LiauNo ratings yet

- Learning Guide #3Document19 pagesLearning Guide #3andargie yigzawNo ratings yet

- Primera Entrega - Manufactura EsbeltaDocument20 pagesPrimera Entrega - Manufactura EsbeltaNatalia Roxana Heredia MejíaNo ratings yet

- Diagnóstico de Processos Produtivos de Uma Estação de Tratamento de Água No Norte Do Espírito SantoDocument16 pagesDiagnóstico de Processos Produtivos de Uma Estação de Tratamento de Água No Norte Do Espírito SantoMatheus Pires FerreiraNo ratings yet

- Group Work On TQM: 03 Assignment 01Document3 pagesGroup Work On TQM: 03 Assignment 01avinmanzanoNo ratings yet

- Using M & M To Understand SPCDocument11 pagesUsing M & M To Understand SPCJimmy Gilberto Davila VelezNo ratings yet

- Advance Inv MGM 250520 - RX - TGDocument18 pagesAdvance Inv MGM 250520 - RX - TGseanfaria100% (1)

- Artigo - DPPDocument16 pagesArtigo - DPPMatheus Pires FerreiraNo ratings yet

- 5S + Safety Finds A New Home at An Old Refinery: Company OverviewDocument28 pages5S + Safety Finds A New Home at An Old Refinery: Company OverviewFátima Macario MonzónNo ratings yet

- Operations ManagementDocument145 pagesOperations Managementsawantrahul1892% (12)

- Form OVPAA 030G Practicum Daily Journal Fillable 2 Fundamentals of Sustainable Supply ChainsDocument1 pageForm OVPAA 030G Practicum Daily Journal Fillable 2 Fundamentals of Sustainable Supply ChainsjianromeroNo ratings yet

- Continous Quality Improvement Made PossibleDocument21 pagesContinous Quality Improvement Made Possiblejohn488No ratings yet

- Impression To Be Disinfected (Including Material and Procedure)Document6 pagesImpression To Be Disinfected (Including Material and Procedure)Loredana Radu100% (2)

- Internship Report On Shakarganj Sugar Mill by SYED AHMAD MUSTAFADocument21 pagesInternship Report On Shakarganj Sugar Mill by SYED AHMAD MUSTAFAAhmad Mustafa100% (2)

- Form OVPAA 030G Practicum Daily Journal Fillable Dert PrepDocument1 pageForm OVPAA 030G Practicum Daily Journal Fillable Dert PrepjianromeroNo ratings yet

- Development of Problem-Solving Ability Problem Solving ProcessDocument8 pagesDevelopment of Problem-Solving Ability Problem Solving ProcessMeena KoushalNo ratings yet

- The Study of Pamas Eatery Website Reservation ServiceDocument30 pagesThe Study of Pamas Eatery Website Reservation ServiceMark Roel MartinezNo ratings yet

- Training and Supervision: Safe MethodDocument2 pagesTraining and Supervision: Safe MethodAlghubariNo ratings yet

- Product Owner Product Manager - Assignment - 2021Document2 pagesProduct Owner Product Manager - Assignment - 2021Tin TinNo ratings yet

- The Power of Business Process - Part 3Document10 pagesThe Power of Business Process - Part 3yara jindoNo ratings yet

- Internship ReportDocument39 pagesInternship Reportm bilal0% (1)

- SITHCCC005 Assessment 1 Short Answer (Xinlu Yu Elena)Document9 pagesSITHCCC005 Assessment 1 Short Answer (Xinlu Yu Elena)elena43% (7)

- Case Study 3Document6 pagesCase Study 3Jhesthony PaynoNo ratings yet

- Toyota - ProjectDocument101 pagesToyota - ProjectSanjay Shreesha33% (3)

- Ready Made FoodDocument34 pagesReady Made FoodEvogen GenesisNo ratings yet

- Improving Bakery Manufacturing PerformanceDocument9 pagesImproving Bakery Manufacturing PerformanceFlorentina Andre100% (3)

- 0117.16 Obe Learner Feedback Vers 3 11 Oct 23Document15 pages0117.16 Obe Learner Feedback Vers 3 11 Oct 23Christine IreshaNo ratings yet

- McDonald's Lean ToolsDocument10 pagesMcDonald's Lean Toolsomar salinasNo ratings yet

- REP0RTDocument38 pagesREP0RTfuzaaaaaNo ratings yet

- Pengelolaan Keluhan Dan Umpan Balik Keluhan SPO: Uptd Puskesmas Jaka SetiaDocument4 pagesPengelolaan Keluhan Dan Umpan Balik Keluhan SPO: Uptd Puskesmas Jaka SetianenengNo ratings yet

- Library of PD&T QMS Project HSE Moments: Presented By: On DateDocument8 pagesLibrary of PD&T QMS Project HSE Moments: Presented By: On DateSyahril Aizal AhmadNo ratings yet

- Developing Effective Standard Operating ProceduresDocument7 pagesDeveloping Effective Standard Operating ProceduresStewart MunesuNo ratings yet

- Dormworks 2Document70 pagesDormworks 2Mae D. SaliringNo ratings yet

- Welcom E: May 13thDocument14 pagesWelcom E: May 13thjames arlao100% (1)

- KhushbooDocument90 pagesKhushbooBhagyashree JoshiNo ratings yet

- EPGP-14C - Group 14 - QM Assignment 2 - Benevento FoodsDocument3 pagesEPGP-14C - Group 14 - QM Assignment 2 - Benevento FoodsAtul Agrawal100% (1)

- Resume Keith Morris 2018 - 4Document3 pagesResume Keith Morris 2018 - 4Denisse WeeNo ratings yet

- Sabar DairyDocument114 pagesSabar DairyChetakPatel100% (1)

- Кремовая Элегантная Фигуры Из Линий Здравоохранение Маркетинг Видео ПрезентацияDocument32 pagesКремовая Элегантная Фигуры Из Линий Здравоохранение Маркетинг Видео Презентацияazima.aitpembetovaNo ratings yet

- ASSESSMENT 1 SITHCCC001 Use Food Preparation EquipmentDocument13 pagesASSESSMENT 1 SITHCCC001 Use Food Preparation EquipmentHassam MughalNo ratings yet

- ReportDocument1 pageReportDave Patrick EscalaNo ratings yet

- Location 10 (Edited)Document15 pagesLocation 10 (Edited)Dave Patrick EscalaNo ratings yet

- GHVHJDocument13 pagesGHVHJDave Patrick EscalaNo ratings yet

- Location 12Document14 pagesLocation 12Dave Patrick EscalaNo ratings yet

- GRE Chemistry Test: Practice BookDocument56 pagesGRE Chemistry Test: Practice BookDave Patrick EscalaNo ratings yet

- Felicia Story Part1Document1 pageFelicia Story Part1Dave Patrick EscalaNo ratings yet

- Location 7 (Edited)Document17 pagesLocation 7 (Edited)Dave Patrick EscalaNo ratings yet

- Location 7 (Edited)Document17 pagesLocation 7 (Edited)Dave Patrick EscalaNo ratings yet

- Location 15Document15 pagesLocation 15Dave Patrick EscalaNo ratings yet

- Location 15Document15 pagesLocation 15Dave Patrick EscalaNo ratings yet

- Location 15Document15 pagesLocation 15Dave Patrick EscalaNo ratings yet

- Location 15Document15 pagesLocation 15Dave Patrick EscalaNo ratings yet

- Location 11Document15 pagesLocation 11Dave Patrick EscalaNo ratings yet

- GHVHJDocument13 pagesGHVHJDave Patrick EscalaNo ratings yet

- Location 12Document14 pagesLocation 12Dave Patrick EscalaNo ratings yet

- Daily Report #9 (NEW FORMAT)Document1 pageDaily Report #9 (NEW FORMAT)Dave Patrick EscalaNo ratings yet

- 1) - Discuss The Limitations of Memory Management S...Document3 pages1) - Discuss The Limitations of Memory Management S...MyounasNo ratings yet

- MATLAB in Model-Base Design For Slip Energy Recovery of Induction MotorDocument6 pagesMATLAB in Model-Base Design For Slip Energy Recovery of Induction Motorsanjay kumar yadavNo ratings yet

- Focus 4K Embedded NVRs-HEN64304Document4 pagesFocus 4K Embedded NVRs-HEN64304Mukesh BariaNo ratings yet

- Design of Analytical Model and Algorithm For Optimal Roadside Ap Placement in VanetsDocument11 pagesDesign of Analytical Model and Algorithm For Optimal Roadside Ap Placement in VanetsArash AziminejadNo ratings yet

- MIDPOINTDocument12 pagesMIDPOINTEvan Earl Santiago CasanayanNo ratings yet

- TMC411 - Goal SettingDocument26 pagesTMC411 - Goal SettingEmmanuel AkpanNo ratings yet

- YoDocument16 pagesYoCesar Arturo Quiñones GalarzaNo ratings yet

- Edge II Service Manual P21828-02A eDocument96 pagesEdge II Service Manual P21828-02A eHellen NogueiraNo ratings yet

- Asset-V1 HKUSTx+ELEC1200.1x+3T2015+type@asset+block@2.3 Representing Bit WaveformsDocument7 pagesAsset-V1 HKUSTx+ELEC1200.1x+3T2015+type@asset+block@2.3 Representing Bit WaveformsSATYAM MISHRANo ratings yet

- HP Deskjet Ink Advantage 2645 Technische Details b1b2db PDFDocument2 pagesHP Deskjet Ink Advantage 2645 Technische Details b1b2db PDFblackdot28No ratings yet

- Segmentation ADTDocument68 pagesSegmentation ADTSagar PatnaikNo ratings yet

- Signals and Systems: Lecture 6 - Fourier Series Representation of Periodic Signals Asst. Prof. Dr. Ertuğrul SAATÇIDocument18 pagesSignals and Systems: Lecture 6 - Fourier Series Representation of Periodic Signals Asst. Prof. Dr. Ertuğrul SAATÇIAlper KaracakayaNo ratings yet

- Basic Computer MaintenanceDocument11 pagesBasic Computer MaintenanceLinahtadiya LinahNo ratings yet

- Technical Service Manual: Code 4-131046 - Uk - 12/2013Document36 pagesTechnical Service Manual: Code 4-131046 - Uk - 12/2013Alberto Sanchez PamplonaNo ratings yet

- 2013 Excel Advanced ManualDocument188 pages2013 Excel Advanced ManualWasana Gayathree100% (3)

- HW 4a Solns PDFDocument7 pagesHW 4a Solns PDFAshwin ShreyasNo ratings yet

- Basic Operation of Network SystemsDocument65 pagesBasic Operation of Network SystemsMaria NgigiNo ratings yet

- Powers of 2 Table - Vaughn's SummariesDocument2 pagesPowers of 2 Table - Vaughn's SummariesAnonymous NEqv0Uy7KNo ratings yet

- 7 VK 61Document18 pages7 VK 61api-241473079No ratings yet

- Sep 2015 IG Investigation USISDocument29 pagesSep 2015 IG Investigation USISsenatortesterNo ratings yet

- EE2201 Measurement & InstrumentationDocument2 pagesEE2201 Measurement & InstrumentationveguruprasadNo ratings yet

- Account Usage and Recharge Statement From 29-Jan-2023 To 31-Jan-2023Document5 pagesAccount Usage and Recharge Statement From 29-Jan-2023 To 31-Jan-2023mazars advisoryNo ratings yet

- 090 - Nepal GEA - SOA ESB Design Guidelines v2.0Document52 pages090 - Nepal GEA - SOA ESB Design Guidelines v2.0rafahellcNo ratings yet

- MTech Syllabus (1-2)Document21 pagesMTech Syllabus (1-2)sunilswastikNo ratings yet

- Cusat Btech Ece S8 SyllabusDocument4 pagesCusat Btech Ece S8 SyllabusAmalNo ratings yet

- Evaluation of Online Tools: Dos and Don'ts: Unit 4Document28 pagesEvaluation of Online Tools: Dos and Don'ts: Unit 4DANNY PAUCARNo ratings yet

- I-PPT - I-Fundamentals-1-31-2020Document61 pagesI-PPT - I-Fundamentals-1-31-2020Kaye Cor0% (1)

- Red Hat System Administration I 1.7 Lab PDFDocument11 pagesRed Hat System Administration I 1.7 Lab PDFstefygrosuNo ratings yet

- Mathmatical Model of Control Systems PDFDocument36 pagesMathmatical Model of Control Systems PDFThomasVictor100% (1)

- CMW LTE UE UserManual V3-5-30 en 22Document940 pagesCMW LTE UE UserManual V3-5-30 en 22monel_24671100% (3)