Professional Documents

Culture Documents

09 Chapter 1

Uploaded by

Kaung Khant0 ratings0% found this document useful (0 votes)

15 views3 pagesOriginal Title

09 CHAPTER 1

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

15 views3 pages09 Chapter 1

Uploaded by

Kaung KhantCopyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 3

CHAPTER 1

INTRODUCTION

The differential is a very important part in a vehicle, as a component transfer,

the engine power is transmitted to the wheels. Engine power is transferred by a rear

propeller shaft to the wheel first changed direction by differential rotation are then

referred to rear axle shafts after that to the rear wheel. A differential is a device that

capable of transmitting torque and rotation through three shaft, almost always used in

one of two ways: in one way, it receives one input and provides two outputs this is

found in most automobiles and in the other way, it combines two input to create an

output that is the sum, differential, or average, of the input.

In automobiles and other wheeled vehicles, the differential allows each of the

driving road wheels to rotate at different speeds, while for most vehicles supplying

equal torque to each of them. A vehicle’s wheels rotate at different speeds, mainly

when turning corners. The differential is designed to drive a pair of wheels with equal

torque while allowing to rotate at different speeds. In vehicles without a differential,

such as karts, both driving wheels are forced to rotate at the same speed, usually on a

common axle driven by a simple chain-drive mechanism. When cornering, the inner

wheel needs to travel a shorter distance than the outer wheel, so with no differential,

the result in the inner wheel spinning and/or the outer wheel dragging, and this results

in difficult and unpredictable handling, damage to tires and roads, and strain on (or

possible failure of) the entire drive train.

On an FWD car or truck, the differential is normally an integral part of the

transaxle assembly located at the front of the vehicle. Transaxle design and operation

depends on whether the engine is mounted transversely or longitudinally. With a

transversely mounted engine, the crankshaft centerline and drive axle are on the same

plane. With a longitudinally mounted power plant, the differential must change the

power flow 90 degrees.

2

On RWD vehicles, the differential is located in the rear axle housing or

carrier. The drive shaft connects the transmission with the rear axle gearing. Four-

wheel-drive vehicles have differential on both their front and rear axles.

1.2. Aim and Objectives

The main aim of this thesis is to analyze design of the differential components.

The objectives of this thesis are:

1. To study the components of differential system and different types of

differential system

2. To study the working principle of differential system of a vehicle

3. To calculate the design of crown gear and drive pinion for differential unit

4. To calculate the design of spider gear and side gear for differential unit

5. To calculate the contact stress of bevel gear

6. To analyze the contact stress of bevel gear by using SolidWorks software

1.3. Scope of the Thesis

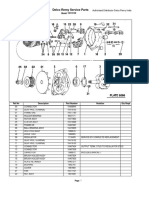

In this thesis, the differential unit and the related parts for differential system

are discussed. Design calculation of ring gear and pinion of differential unit for

Toyota Hilux (N-LN30-CDSY) are presented.

1.4. Implementation Program

The implementation program of this thesis is carried out by the following

procedures:

1. Studying types of differential system and their function for automobiles

2. Measuring the necessary components for differential system of Toyota

Hilux (N-LN30-CDSY)

3. Collecting the data from differential system of Toyota Hilux (N-LN30-

CDSY)

4. Calculating the design of the ring gear, pinion gear, spider gear and side

gear of differential system

5. Calculating the contact stress of the bevel gear by theoretically

6. Analyzing the contact stress of bevel gear with different face width and

different materials by using SolidWorks software

3

7. Comparing the theoretical result and simulation result of the bevel gear

1.5. Outline of the Thesis

In this thesis, five chapters can be found. Chapter one describes introduction to

differential system. Chapter two consists of literature reviews of the differential

system. Methodology and design theory of the differential unit is expressed in chapter

three. Chapter four describes design calculation of differential unit. Chapter five

includes the discussions, conclusions and recommendations.

You might also like

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- 3.board of ExaminerDocument2 pages3.board of ExaminerKaung KhantNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5795)

- ReferencesDocument6 pagesReferencesKaung KhantNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Literature ReviewDocument19 pagesLiterature ReviewKaung KhantNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Literature ReviewDocument34 pagesLiterature ReviewKaung KhantNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Design Calculation For GearboxDocument69 pagesDesign Calculation For GearboxKaung KhantNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Gold CoverDocument1 pageGold CoverKaung KhantNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Design Consideration of Transmisson SystemDocument39 pagesDesign Consideration of Transmisson SystemKaung KhantNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Design and Analysis of Five Speed Manual Gearbox (Oka-05 Jeep)Document1 pageDesign and Analysis of Five Speed Manual Gearbox (Oka-05 Jeep)Kaung KhantNo ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Discussions, Conclusion and RecommendationsDocument2 pagesDiscussions, Conclusion and RecommendationsKaung KhantNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Design Calculation of Gearbox: ST ND RD TH THDocument50 pagesDesign Calculation of Gearbox: ST ND RD TH THKaung KhantNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Kkna .Title Rev.01 PDFDocument10 pagesKkna .Title Rev.01 PDFKaung KhantNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Chapter 3Document14 pagesChapter 3Kaung KhantNo ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Sampel Mech - CalculationDocument36 pagesSampel Mech - CalculationMuhammad Farizan Praevia100% (1)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Alternator ManualDocument734 pagesAlternator ManualЕгор ГоряевNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Brosur SPX FlowDocument8 pagesBrosur SPX FlowAltino Mangiwa100% (1)

- X1Alluminio E02Document10 pagesX1Alluminio E02Dominic CioccarelliNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- PVT (Hydrocarbon Phase Behaviour)Document18 pagesPVT (Hydrocarbon Phase Behaviour)Oscar Mauricio TellezNo ratings yet

- ENGINEER'S Report For Generator Set of LaundryDocument3 pagesENGINEER'S Report For Generator Set of LaundryNathan Esteban79% (14)

- Energetic and Exergetic Analysis of A Multi-Stage Turbine, Coal-Fired 173 MW Power PlantDocument18 pagesEnergetic and Exergetic Analysis of A Multi-Stage Turbine, Coal-Fired 173 MW Power PlantDr-Aditya ChauhanNo ratings yet

- NGL PumpsDocument4 pagesNGL Pumpsamol patkiNo ratings yet

- Mark Scheme - Results Summer 2013: GCE Physics 6PH01 Paper 01R: Physics On The GoDocument18 pagesMark Scheme - Results Summer 2013: GCE Physics 6PH01 Paper 01R: Physics On The GoAli SajjadNo ratings yet

- F AdaptersDocument122 pagesF Adaptersxuanphuong2710No ratings yet

- Fire Sprinkler System GuideDocument2 pagesFire Sprinkler System GuideMike LojoNo ratings yet

- XDV Xtra Duty V BeltsDocument3 pagesXDV Xtra Duty V BeltsJohel ClNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Gate&Ies - Me Postal Course Book CollectionDocument3 pagesGate&Ies - Me Postal Course Book CollectionJaya Harshit50% (2)

- Lab 3 - Measuring Mass of EarthDocument7 pagesLab 3 - Measuring Mass of EarthJacob AltmillerNo ratings yet

- Delco Remy Service Parts: New Indo Trading Company Authorised Distributor Delco Remy IndiaDocument2 pagesDelco Remy Service Parts: New Indo Trading Company Authorised Distributor Delco Remy IndiaWilson AcostaNo ratings yet

- AGA3 1990 AlgorithmDocument3 pagesAGA3 1990 Algorithmyan2huaNo ratings yet

- Manual 6a32Document24 pagesManual 6a32Buho FielNo ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Catalog Bending TestDocument2 pagesCatalog Bending TestMarkusNo ratings yet

- V Belt Pulley Martin PDFDocument124 pagesV Belt Pulley Martin PDFmowgly92No ratings yet

- Translated Version of RalDocument31 pagesTranslated Version of RalsskamalakannanNo ratings yet

- PLB-0384-DAT-4830-ME-0005: ABB India LTDDocument3 pagesPLB-0384-DAT-4830-ME-0005: ABB India LTDAlex Labraña RojoNo ratings yet

- Cat Engine 3512bDocument9 pagesCat Engine 3512bPrasanna BhattacharyaNo ratings yet

- Outline Design Specification of Phase IV (March 2019) 01042019 PDFDocument164 pagesOutline Design Specification of Phase IV (March 2019) 01042019 PDFBilal A BarbhuiyaNo ratings yet

- Ha1005 PDFDocument18 pagesHa1005 PDFhidraulic50% (2)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- MCR Training ManualDocument71 pagesMCR Training ManualCluis Ke100% (1)

- Vent Master Cam C InjeccionDocument2 pagesVent Master Cam C InjeccionFreddy VeraNo ratings yet

- 1K 2K Service Manual 4th GenDocument305 pages1K 2K Service Manual 4th GenElectronica coetc100% (1)

- Technický Manuál RiminiDocument30 pagesTechnický Manuál Riminidoubleshot s.r.o.100% (1)

- 135MW CFBC Operation Manual 1 (20080306)Document148 pages135MW CFBC Operation Manual 1 (20080306)Amitabh Singh83% (6)

- Student Exploration: Air Track: Name: Akshat Date:12/15/20Document9 pagesStudent Exploration: Air Track: Name: Akshat Date:12/15/20Akshat Pant100% (8)