0% found this document useful (0 votes)

190 views1 pageTest Certificate / Certificate of Conformity in Accordance With en 10204 3.1 Customer

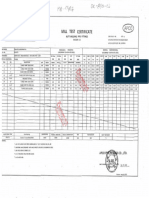

This certificate provides the results of tests on a mechanical seal housing part. It includes:

1) Chemical analysis showing the actual measured percentages of elements meet the minimum and maximum specifications.

2) Mechanical properties including yield stress, maximum stress, elongation and reduction of area meeting requirements.

3) Charpy impact test results exceeding minimum requirements at various temperatures.

4) Details on heat treatment and visual examination confirming conformance to standards.

5) Statement that the casting was inspected, tested and conforms to contract/purchase order requirements.

Uploaded by

Mehulkumar PatelCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

190 views1 pageTest Certificate / Certificate of Conformity in Accordance With en 10204 3.1 Customer

This certificate provides the results of tests on a mechanical seal housing part. It includes:

1) Chemical analysis showing the actual measured percentages of elements meet the minimum and maximum specifications.

2) Mechanical properties including yield stress, maximum stress, elongation and reduction of area meeting requirements.

3) Charpy impact test results exceeding minimum requirements at various temperatures.

4) Details on heat treatment and visual examination confirming conformance to standards.

5) Statement that the casting was inspected, tested and conforms to contract/purchase order requirements.

Uploaded by

Mehulkumar PatelCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd