Professional Documents

Culture Documents

Gan Thermal Analysis For High-Performance Systems

Uploaded by

ahsoopkOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Gan Thermal Analysis For High-Performance Systems

Uploaded by

ahsoopkCopyright:

Available Formats

www.qorvo.

com

GaN Thermal Analysis for High-Performance Systems

Dylan Murdock, Mechanical Engineer - Advanced Packaging, Infrastructure & Defense Products, Qorvo

Mark C. Woods, Mechanical Engineer - Advanced Packaging, Infrastructure & Defense Products, Qorvo

Abstract

This paper addresses Qorvo’s integrated approach to thermal design that leverages

modeling, empirical measurements (including micro-Raman thermography), and finite

element analysis (FEA) for high performance microwave GaN HEMT devices and

MMICs. This methodology is highly effective and has been empirically validated. By

properly addressing FEA boundary condition assumptions and the limitations of infrared

microscopy, resulting model calculations are more accurate at both the product and end

application level than traditional methods based on lower power density technology.

Introduction

The need for higher and higher output power amplifiers from system requirements has

resulted in successive solid state technology improvements. As the technology has

moved toward higher capabilities, the applications that drive the technology have moved

even further. Power requirements of 10's of Watts from just a few years ago have moved

upward to 50 Watts and higher. Gallium Nitride on Silicon Carbide (GaN-on-SiC) has

emerged as a superior device technology which boasts high power density, typically

greater than 5W/mm gate periphery, high drain operating voltage, typically 20V to 48V,

and comparable gain and drain efficiency when compared to traditional Gallium Arsenide

(GaAs) pseudomorphic high electron mobility transistor (pHEMT) technology. The

requirement to get more power into a smaller circuit area has resulted in the

development of GaN power amplifier products that provide thermal challenges at both

the product and system level.

In order to fully appreciate the thermal implications of GaN technology, a multi-prong

approach involving die-level electrical modeling, empirical measurements, and finite

element analysis has been developed. This paper will discuss this approach to GaN

thermal analysis in four sections:

Thermal modeling and empirical measurements, including micro-Raman

measurements;

Thermal analysis, including finite element analysis (FEA), the uses and limitations of

infrared microscopy, and a secondary verification using RF testing;

Die-attach methods, including accounting for contact resistance when comparing

epoxy to solder, and die-attach performance as a factor in device operating

temperature; and

Improved packaging options from Qorvo, including GaN on Copper, and GaN in Plastic

I. THERMAL MODELING AND EMPIRICAL MEASUREMENTS

To construct the baseline thermal model for a given process, an electrical simulation of

the GaN device using non-linear models for the field effect transistors is used to obtain

estimates of heat generation which allow for an initial prediction of thermal performance.

The device is then physically fabricated and tested.

Figure 1: GaN thermal model

White Paper: GaN Thermal Analysis for High-Performance Systems

page 2 of 15

Empirical thermal data is collected with both electrical measurements and micro-Raman

measurements. Raman thermography is a non-invasive optical technique, based on

Raman scattering spectroscopy, that enables temperature measurements with sub-

micron spatial and nanosecond time resolution.1 It probes the temperature-induced

phonon shift in a material, with respect to a reference phonon frequency measured at

ambient temperature.2 Additional details on experimental setups and applications of

micro-Raman thermography are described in [1,2].

Raman thermography has been established as an important high fidelity regimen for

physically small geometries. It offers proven, accurate and repeatable improvement in

spatial resolution down to 0.5μm as well as micron scale depth resolution for true 3D

thermography. As will be discussed below, Raman thermography improves upon the

underestimation of device peak temperature due to lateral spatial averaging associated

with conventional infrared (IR) thermography measurements.

A combination of measurement methods, including micro-Raman and electrical, should

be used in conjunction with thermal simulations, in order to gain accurate information on

the thermal properties of GaN devices.

Using the measured data as the empirical baseline, an FEA model is constructed, which

then becomes the baseline for modeling and predicting thermal performance. There are

typically multiple iterations between the micro-Raman measurements and the FEA in

order to build models that provide good correlation over different geometries and

materials stack-ups.

Finite element simulations are used to determine the power and environmental

conditions required to run devices at specific elevated temperatures in order to properly

accelerate and measure the life of the device. This measured life data is used for

construction of a device reliability Arrhenius plot. Today's GaN transistors include gate

lengths measuring down to 0.15μm in size and lower, meaning that there is still some

area averaging that occurs with micro-Raman thermography. With this methodology

White Paper: GaN Thermal Analysis for High-Performance Systems

page 3 of 15

these averages are reflected in both the thermal model and device reliability Arrhenius

plots. This process enables a tightly-coupled mean time to failure (MTTF) curve and

product level thermal analysis that accurately predicts product life.

II. THERMAL ANALYSIS

Once the baseline thermal model development is complete, FEA is then employed to

accurately predict channel temperature and thermal resistances at the product level. The

FEA begins with a die-level simulation, proceeds to the package level, and continues all

the way to system level, where it examines the packaged product within the next higher

assembly.

When modeling and measuring heat generation and removal, it is critical to select proper

boundary conditions and to understand the impact of those assumptions. Commonly,

unrealistic or improper assumptions are made on temperature and heat removal

boundary conditions. The unrealistic predictions and measurements that result often

lead to product designs that appear to work well on a datasheet, but will fail in

application.

Uses and limitations of infrared

Infrared microscopes are widely-used for determining fault location by searching for hot

spots in semiconductor devices. However the application of IR for thermal

characterization is limited due to spatial resolution incompatibility. IR microscopes

cannot resolve a spot size as small as the active area of a GaN transistor. Therefore, IR

measurement necessarily averages-in colder, non-active areas with the active area that

needs to be measured. In other words, when an IR measurement is taken of an area

that is only 0.25µm wide, for example, the resultant temperature reading can be 20-30oC

cooler than the peak temperature of the active area. An example IR image of a discrete

GaN transistor is shown in Fig 2.

White Paper: GaN Thermal Analysis for High-Performance Systems

page 4 of 15

A typical IR microscope collects light in the Mid Wave Infrared (MWIR) spectrum. The

theoretical spatial resolution limits of MWIR measurement can be calculated using

Rayleigh’s resolution criteria:

D = distance between resolvable targets

λ = wavelength (3-5µm for MWIR)

N.A. = numerical aperture (cannot exceed 1)

Figure 2: IR image of a typical GaN FET cell

White Paper: GaN Thermal Analysis for High-Performance Systems

page 5 of 15

To demonstrate the impact of IR resolution limits when measuring GaN devices, a half

symmetry finite element model of a GaN device was constructed. The model assumes

bilateral symmetry about the y-axis. This simulation places the device on a .040” thick

copper-tungsten base with AuSn die-attach. A boundary condition of 85oC has been

applied at the base of the CuW.

A volumetric heat load typical of GaN devices has been applied beneath the channel;

the resulting 3D temperature field is shown in the contour plot of Figure 2(a) and the

corresponding surface temperature is shown in Figure 2(b).

The peak temperature recorded in the simulation is 204oC at the midpoint of the GaN

channel (x = 0 for this half-model). This condition occurs below the surface of the

substrate and cannot be imaged by infrared thermography. Table 1 lists the maximum

and average temperatures for the surface regions as would be recorded by IR

measurement. These surface regions are identified in Figures 3(a) through 3(d).

Table 1: FEA Temperature Estimates

Pixel

Alignment

Measured Body or Size (µm x to Hot True Max Surface Temp. as

o o

Area µm) Spot Temp., C Measured with IR, C

Simulated GaN

Device - - 204.3 -

Surface region #1 2.5 x 2.5 centered - 195.9

Surface region #2 2.5 x 2.5 offset - 189.1

Surface region #3 5.0 x 5.0 centered - 188.3

Surface region #4 5.0 x 5.0 offset - 183.0

In this ideal example, the application of infrared thermography to image a 2.5µm x 2.5µm

area, a representative IR resolution limit, of the surface above the channel results in a

measurement which underestimates the peak channel temperature by 8-15oC. The

range of offset is caused by an inability to precisely align the center of one pixel on top of

White Paper: GaN Thermal Analysis for High-Performance Systems

page 6 of 15

the hottest section of a channel. Figures 3(b) and 3(d) show the impact of having the

pixel alignment such that the channel lies at the boundary of the area imaged by the

pixel. In this case, the average surface temperature of a 2.5µm x 2.5µm area

underestimates maximum channel temperature by more than 15oC. Using a 5µm x 5µm

area pushes the error to 21oC.

Figure 2(b):Temperature field in the ~2micron thick GaN layer above the SiC substrate

Figure 2(c): Surface temperature above the gate

White Paper: GaN Thermal Analysis for High-Performance Systems

page 7 of 15

Fig 3(a) Surface Region #1: Width = 2.5 microns (centered over hottest part of channel)

Fig 3(b) Surface Region #2: Width = 2.5 microns (offset in both x and y)

White Paper: GaN Thermal Analysis for High-Performance Systems

page 8 of 15

Fig 3(c) Surface Region #3: Width = 5 microns (centered over hottest part of channel)

Fig 3(d) Surface Region #4: Width = 5 microns (offset in both x and y)

In the case of GaN thermal analysis, sub-micron processes are used to make the

transistors, with hotspots that are significantly smaller than 0.5μm, and IR microscopy is

only capable of resolving—in complete detail—something that is on an order of

magnitude larger.

Additionally, IR thermography only measures the surface temperature of the transistor,

whereas the peak temperature actually occurs below the surface, in the gallium nitride

epitaxy. This reduction in measured temperature is exaggerated during pulsed operation

White Paper: GaN Thermal Analysis for High-Performance Systems

page 9 of 15

where the thermal time constant of the semiconductor material above the heat source

dampens the measured temperature range.

Finally, emissivity (ε) on the surface of a die varies significantly. The common solution is

to paint the die matte black to achieve a near ε = 1, but a true and consistent blackbody

cannot be created.

Table 2: Effects of Emissivity Variation

Measured Body or Size (µm x True Max Surface Temp. as

o o

Area µm) Emissivity Temp., C Measured with IR, C

Simulated GaN

Device - - 204.3 -

Surface Area 2.5 x 2.5 1.0 - 189.1

Surface Area 2.5 x 2.5 0.9 - 170.2

The effects of emissivity are included in this extension of the previous example. Here it is

seen that IR thermography underestimates peak GaN channel temperatures by as much

as 34oC assuming an ideally small measurement area.

Another challenge this creates is that paint imparts a dielectric load on the die, which

can be difficult to predict and is typically inconsistent. This changes RF performance and

as a result, accuracy and repeatability suffer.

Secondary verification - RF testing

A secondary verification approach involves assembling a part and testing it in a condition

where the channel temperature is expected to be 200°C, for example. If the RF

performance has shifted, that can be correlated with temperature sensitivity to power

output.

By taking multiple approaches to thermal analysis, and importantly, keeping in mind the

importance of proper FEA boundary condition assumptions and limitations of infrared

microscopy, model outputs are more accurate and reliable on datasheets, as well as in

application.

White Paper: GaN Thermal Analysis for High-Performance Systems

page 10 of 15

III. DIE-ATTACH METHODS

Accounting for contact resistance when comparing epoxy to solder

When comparing conductive epoxy to solder, contact resistance is often neglected, and

it is assumed that the thermal conductivity of an epoxy joint is equal to what is

represented on the epoxy datasheet. A preferred approach is to empirically benchmark

solder performance and then determine the actual epoxy performance relative to solder

which allows for more accurate simulations and tradeoff studies. This exposes contact

resistance as a significant contributor to epoxy joint thermal impedance. If, instead, a

datasheet value is used in a model without contact resistance, it leads to an overly

optimistic calculation of thermal resistance.

Die-attach performance as a factor in device operating temperature

One of the challenges of thermal modeling is finding an accurate estimate for die-attach

thermal performance, which is a very important factor in device operating temperatures.

Vendors of die-attach solders/epoxies often only list the bulk thermal conductivity (k) of

their product. This is only one component of the overall die-attach thermal

impedance. Bondline thickness, interfacial resistances, voiding, and filler characteristics

all contribute to the overall thermal resistance, and these are to a large extent dependent

on dispensing and curing processes. In addition, die-attach integrity and performance

are impacted by material properties and surface characteristics of the two items being

bonded. Experimentation is usually required to know with reasonable certainty how a

die-attach solution will perform.

The graphic below illustrates the relationship between bondline thickness, bulk thermal

conductivity, and total die-attach thermal resistance.

White Paper: GaN Thermal Analysis for High-Performance Systems

page 11 of 15

Figure 4: Illustration of die-attach thermal resistance / impedance

Below is a chart that illustrates the importance of accurate die-attach performance data.

Here a GaN power amplifier die has been modeled in a typical QFN package. The

maximum channel temperature has been plotted against the die-attach thermal

impedance (RD/A”).

As the RD/A” approaches zero (i.e., die-attach performance improves), the maximum

channel temperature (TCH) decreases, approaching a limit which is set by the conductive

thermal resistance of the die and the QFN base. The left vertical dashed line denotes

RD/A” as calculated solely from the measured bondline thickness (L) and the vendor-

supplied value for bulk thermal conductivity (k). The right vertical dashed line is RD/A” as

measured in the laboratory.

For this particular die/package combination, TCH is underestimated by 40oC when

interfacial resistances are not taken into account.

White Paper: GaN Thermal Analysis for High-Performance Systems

page 12 of 15

Operation for the die in this model is such that PDISS = 23 Watts. If the total package

thermal resistance Rθ is calculated, ignoring interfacial resistances yields an incorrect

value of:

Rθ = (TCH – TBASE)/ PDISS = (180oC – 100oC)/23W = 3.5oC/W

whereas the actual package thermal resistance is more accurately represented by:

Rθ = (TCH – TBASE)/ PDISS = (220oC – 100oC)/23W = 5.2oC/W

GaN Die in QFN - 23W CW Power Dissipation

Bottom surface of QFN is held fixed at 100 oC

270

260

250

240

Max Channel Temperature (oC)

230

220

210

200

190

180

170

160 Less than

150

theoretical

Actual measured RD/A" (includes

limit at the

140 epoxy conduction resistance plus

measured

RD/A"= L/k based on the die-to-epoxy and epoxy-to-

130 bondline

vendor-supplied bulk package interfacial resistances)

120 thickness thermal conductivity

(L)

110 value (k)

100

0.00 0.01 0.01 0.02 0.02 0.03 0.03 0.04 0.04 0.05 0.05

Die-Attach Thermal Impedance R" (C-cm2/W)

Figure 5: Illustration of the importance of accurate die-attach performance data

IV. IMPROVED PACKAGING OPTIONS FROM QORVO

Qorvo has been an industry-leader in meeting the demand for GaN technology worldwide, with

extensive research and development programs and numerous GaN-based standard

White Paper: GaN Thermal Analysis for High-Performance Systems

page 13 of 15

product releases. As GaN technology has developed, and its power potential realized,

existing semiconductor packaging technology has proven incapable of effectively

supporting high power GaN products. In response, Qorvo has developed improved

packaging options that provide a complete product solution for the ever-widening array

of military and commercial GaN applications. Included in Qorvo’s new GaN package

options for high-performance systems are GaN on Copper and GaN in Plastic which are

available through a number of products to be launched in 2014.

GaN on Copper

There is a growing demand for the ability to have a high-reliability, high-power, large chip

size in a copper package. Qorvo has developed a copper flange-type package with

leads (commonly called a module) that can handle very high power and also be scaled

easily to accommodate small, large, or multiple die and components. The copper flange

is thermally superior to low CTE industry standards such as CuW and CuMo, while

simultaneously increasing system level reliability and allowing for solder attach to a high

CTE heat sink.

GaN in Plastic

Qorvo also offers GaN in Plastic options—air cavity plastic or over-molded plastic. These

packages are very small in size and low cost, but they still maintain good power handling

capabilities. Plastic packages are CTE-matched to PCBs, so system level reliability is

excellent. The small package sizes and excellent RF performance make them ideal

replacements for costly flanged or metal-backed module components.

SUMMARY

In summary, a combination of thermal measurement methods, including micro-Raman

and electrical is highly accurate and should be used in conjunction with thermal

simulations, in order to gain accurate information on the thermal performance of GaN

devices. Using this integrated approach enables a tightly-coupled MTTF plot and product

level thermal simulation.

White Paper: GaN Thermal Analysis for High-Performance Systems

page 14 of 15

Additional important considerations include advanced package options for high-

performance systems, accounting for contact resistance when comparing epoxy to

solder, and die-attach performance as a factor in device operating temperature.

References

1

N. Killat and M. Kuball, University of Bristol, H.H. Wills Physics Laboratory; T.-M.

Chou, U. Chowdhury, and J. Jimenez, Qorvo, Inc. Temperature Assessment of

AlGaN/GaN HEMTs: A Comparative study by Raman, Electrical and IR

Thermography

2

J. Pomeroy, M. Bernardoni, M. Kuball, H.H. Wills Physics Laboratory, University

of Bristol; D.C. Dumka, D.M. Fanning, Qorvo, Inc. Low Thermal Resistance GaN-

on-Diamond Transistors Characterized by 3-D Raman Thermography Mapping

3

S. Kiefer, M. Nair, P. Sanders, J. Steele, M. Sutton, R. Thoma, S. Wilson,

Motorola Digital DNA Laboratories; G. Albright, C. Li, J. McDonald, Quantum

Focus Inc. Infrared Microthermography for Integrated Circuit Fault Location;

Sensitivity and Limitations

White Paper: GaN Thermal Analysis for High-Performance Systems

page 15 of 15

You might also like

- SRF HRF SSR DanjouxDocument12 pagesSRF HRF SSR Danjouxalexander100% (1)

- GSMA - The Mobile Economy 2020 PDFDocument62 pagesGSMA - The Mobile Economy 2020 PDFtobeca100% (1)

- Jlpea 08 00023 PDFDocument20 pagesJlpea 08 00023 PDFKarim BNo ratings yet

- IR Sensor Calibration - Extreme Uniformity Is Not BoringDocument8 pagesIR Sensor Calibration - Extreme Uniformity Is Not BoringrajannplNo ratings yet

- Use of Infra-Red Thermography For Automotive Climate Control AnalysisDocument5 pagesUse of Infra-Red Thermography For Automotive Climate Control AnalysissinasayedanaNo ratings yet

- Shutter LessDocument8 pagesShutter LessMahgul khanNo ratings yet

- Infrared Thermography Princeton University Gas DynamicsDocument20 pagesInfrared Thermography Princeton University Gas DynamicsDs HarrisNo ratings yet

- SSE - Efecto Tamaño de La Fuente - TG26-Version-2-December-2017Document6 pagesSSE - Efecto Tamaño de La Fuente - TG26-Version-2-December-2017RONALD ALFONSO PACHECO TORRESNo ratings yet

- Temperature Compensation of Total Power RadiometersDocument6 pagesTemperature Compensation of Total Power RadiometersJoh IgnacioNo ratings yet

- 5679 Gidon PaperDocument2 pages5679 Gidon PaperKrlos_25No ratings yet

- Ciarp2011 Submission 85Document8 pagesCiarp2011 Submission 85Daniela BonillaNo ratings yet

- Design of MEMS Temperature Sensor For High Voltage SwitchgearDocument6 pagesDesign of MEMS Temperature Sensor For High Voltage SwitchgearNguyen ngoc thongNo ratings yet

- Thermal Resistance Calculation of AlGaN-GaN DevicesDocument10 pagesThermal Resistance Calculation of AlGaN-GaN DevicesАндрей ВольхинNo ratings yet

- Manual Espectrómetro GRMDocument33 pagesManual Espectrómetro GRMjorgeNo ratings yet

- Machine Learning Based Automatic Defect Detection in Non Stationary Thermal Wave ImagingDocument7 pagesMachine Learning Based Automatic Defect Detection in Non Stationary Thermal Wave ImagingENG AIK LIMNo ratings yet

- Seminar ReportDocument18 pagesSeminar ReportAmbarish100% (1)

- RF-Power MeasurementTechniques PDFDocument3 pagesRF-Power MeasurementTechniques PDFJose Jullian100% (1)

- Therm 2.0 Building Component Model For Steady State Two Dimensonal Heat TransferDocument5 pagesTherm 2.0 Building Component Model For Steady State Two Dimensonal Heat TransferhalilkutluNo ratings yet

- Hot Spot Temperature Analysis of Transformer Using FEM On COMSOLDocument7 pagesHot Spot Temperature Analysis of Transformer Using FEM On COMSOLEditor IJTSRDNo ratings yet

- Imeko TC10 2016 052Document6 pagesImeko TC10 2016 052Matt HillocksNo ratings yet

- Weld TestDocument5 pagesWeld Testkoib789No ratings yet

- Development of Low-Cost Thermal Camera For Examine Human Body TemperatureDocument7 pagesDevelopment of Low-Cost Thermal Camera For Examine Human Body TemperatureJoko NugrohoNo ratings yet

- Spatial Resolution Impacts Temperature ReadingsDocument9 pagesSpatial Resolution Impacts Temperature Readingslbk50No ratings yet

- Liebmann - Testing Temperature Uniformity On A Flat-Plate Infrared CalibratorDocument6 pagesLiebmann - Testing Temperature Uniformity On A Flat-Plate Infrared CalibratorCristian MendezNo ratings yet

- 2010 190 Tarin AppnoteDocument4 pages2010 190 Tarin AppnoteGreatLukeNo ratings yet

- EUSPEN2018 Metrologie WavefrontInterferometerDocument1 pageEUSPEN2018 Metrologie WavefrontInterferometerJOBERTNo ratings yet

- Application of Infrared Thermography for Damage Detection in Structural ConcreteDocument16 pagesApplication of Infrared Thermography for Damage Detection in Structural ConcreteAnithaNo ratings yet

- Heat Transfer in High-Voltage Surge ArrestersDocument4 pagesHeat Transfer in High-Voltage Surge Arresterscik_sya87No ratings yet

- Heat Sink Cooling AnalysisDocument6 pagesHeat Sink Cooling AnalysisHarryNo ratings yet

- 41 Stauffer2001Document11 pages41 Stauffer2001CamiloNo ratings yet

- AThermal Simulation Model For Laser-Assisted MillingDocument10 pagesAThermal Simulation Model For Laser-Assisted MillingEng M G ElkhateebNo ratings yet

- Fluke EtfDocument8 pagesFluke Etfjoseggs7192No ratings yet

- Highly Sensitive FBG Based Sensor For Temperature Measurement Operating in Optical FiberDocument10 pagesHighly Sensitive FBG Based Sensor For Temperature Measurement Operating in Optical FiberARIFFIN BIN ZULKIFLINo ratings yet

- Dynamic Line Ratings Based on Weather MeasurementsDocument10 pagesDynamic Line Ratings Based on Weather MeasurementsNataGB100% (1)

- Infrared Thermography A Versatile TechnologyDocument7 pagesInfrared Thermography A Versatile TechnologyJintotholath JjNo ratings yet

- Lfa 457 Thermal TesterDocument12 pagesLfa 457 Thermal TesterlbnxxxxNo ratings yet

- Thermal Conductivity Measurements On Challenging Samples by The 3 Omega MethodDocument6 pagesThermal Conductivity Measurements On Challenging Samples by The 3 Omega MethodTriều Huỳnh NhậtNo ratings yet

- Thermal Rating Monitoring of The TNBDocument7 pagesThermal Rating Monitoring of The TNBBogdan VicolNo ratings yet

- Certamente ImportanteDocument10 pagesCertamente ImportanteLucas SantosNo ratings yet

- Seasat-Radiometric Calibration Algorithm DevelopmentDocument9 pagesSeasat-Radiometric Calibration Algorithm DevelopmentJoh IgnacioNo ratings yet

- Formsat 5Document6 pagesFormsat 5gramuiitmNo ratings yet

- Emissivity Measurement and Temperature Correction Accuracy ConsiderationsDocument9 pagesEmissivity Measurement and Temperature Correction Accuracy ConsiderationsGiustNo ratings yet

- Hardness Is EvrithingDocument30 pagesHardness Is EvrithingUoVT ManufacturingNo ratings yet

- How Furnace Model Predictive Control Forecasts Transitions To Enhance Strip Quality and ProductivityDocument12 pagesHow Furnace Model Predictive Control Forecasts Transitions To Enhance Strip Quality and ProductivityJJNo ratings yet

- Ref14 CurrentReuse CGLnaDocument8 pagesRef14 CurrentReuse CGLnaRajendra ChikkanagoudaNo ratings yet

- An Atmospheric Correction Parameter Calculator For A Single Themal BandDocument3 pagesAn Atmospheric Correction Parameter Calculator For A Single Themal BandLiliana Maria Plata SarmientoNo ratings yet

- Measuring Rake Face Temperatures Using Coated Cutting ToolsDocument13 pagesMeasuring Rake Face Temperatures Using Coated Cutting ToolsArnav SharmaNo ratings yet

- Smoothing Effect of The Thermal Interface Material On The Temperature Distribution in A Stepwise Varying Width Microchannel Cooling DeviceDocument11 pagesSmoothing Effect of The Thermal Interface Material On The Temperature Distribution in A Stepwise Varying Width Microchannel Cooling DeviceMohamednjahi OmriNo ratings yet

- Darwish 2005Document8 pagesDarwish 2005Michel CresseauxNo ratings yet

- Emissivity and AccuracyDocument9 pagesEmissivity and Accuracyalexander100% (1)

- Wallscheid 2017Document8 pagesWallscheid 2017Sooraj KrishnanNo ratings yet

- KippZonen Brochure Pyrgeometers V1101Document4 pagesKippZonen Brochure Pyrgeometers V1101Justin T FrancisNo ratings yet

- Dynamic Overhead Line Loading Using Cooperative Smart Sensor NetworksDocument8 pagesDynamic Overhead Line Loading Using Cooperative Smart Sensor NetworkscarlosticozNo ratings yet

- A Fast Settling Slew Rate Enhancement Technique For Operational AmplifiersDocument4 pagesA Fast Settling Slew Rate Enhancement Technique For Operational AmplifiersShubham SharmaNo ratings yet

- Current Ratings of Power Semiconductors and Thermal DesignDocument9 pagesCurrent Ratings of Power Semiconductors and Thermal DesignIuro NascimentoNo ratings yet

- 399icrre 111 PDFDocument6 pages399icrre 111 PDFDave ChaudhuryNo ratings yet

- Generic Gas Turbine Combustor: Description of The CombustorDocument7 pagesGeneric Gas Turbine Combustor: Description of The CombustorStanley BoswellNo ratings yet

- Fire ManualDocument30 pagesFire ManualMarian DragosNo ratings yet

- Arduino Measurements in Science: Advanced Techniques and Data ProjectsFrom EverandArduino Measurements in Science: Advanced Techniques and Data ProjectsNo ratings yet

- Gallium Nitride-enabled High Frequency and High Efficiency Power ConversionFrom EverandGallium Nitride-enabled High Frequency and High Efficiency Power ConversionGaudenzio MeneghessoNo ratings yet

- Why Do We Need Inverse of A MatrixDocument9 pagesWhy Do We Need Inverse of A MatrixahsoopkNo ratings yet

- How to Write a Strong Methodology SectionDocument10 pagesHow to Write a Strong Methodology SectionahsoopkNo ratings yet

- Reactive Jamming in Wireless NetworksDocument7 pagesReactive Jamming in Wireless NetworksahsoopkNo ratings yet

- Lecture On Antenna MatchDocument25 pagesLecture On Antenna MatchahsoopkNo ratings yet

- Matrices - Why Multiply A Matrix With Its Transpose - Mathematics Stack ExchangeDocument6 pagesMatrices - Why Multiply A Matrix With Its Transpose - Mathematics Stack ExchangeahsoopkNo ratings yet

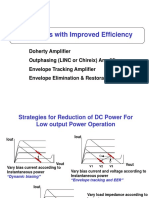

- Strategies for Improving Power Amplifier Efficiency in Wireless SystemsDocument31 pagesStrategies for Improving Power Amplifier Efficiency in Wireless SystemsahsoopkNo ratings yet

- ELG4152L305Document33 pagesELG4152L305Rahul GalaNo ratings yet

- State Variable ModelsDocument3 pagesState Variable ModelsahsoopkNo ratings yet

- Avionics PA Design With Cree's CGHV27030S Amplifier: Eric BonelliDocument51 pagesAvionics PA Design With Cree's CGHV27030S Amplifier: Eric BonelliahsoopkNo ratings yet

- MAG and MSGDocument2 pagesMAG and MSGahsoopkNo ratings yet

- Strategies for Improving Power Amplifier Efficiency in Wireless SystemsDocument31 pagesStrategies for Improving Power Amplifier Efficiency in Wireless SystemsahsoopkNo ratings yet

- PA Design Thesis - Very GoodDocument81 pagesPA Design Thesis - Very GoodahsoopkNo ratings yet

- Mathematical Model of Class e Amplifier Based On The Harmonic Balance MethodDocument5 pagesMathematical Model of Class e Amplifier Based On The Harmonic Balance MethodahsoopkNo ratings yet

- Equiv Circuit ModelDocument11 pagesEquiv Circuit ModelahsoopkNo ratings yet

- Prod AppNotesDocument11 pagesProd AppNotesahsoopk100% (1)

- Mixers 2Document20 pagesMixers 2Nelson BernardoNo ratings yet

- The Directional CouplerDocument11 pagesThe Directional CouplerahsoopkNo ratings yet

- Mixer Basic PrimeDocument12 pagesMixer Basic PrimeDurbha RaviNo ratings yet

- Wilkinson Power CombinerDocument106 pagesWilkinson Power Combinerahsoopk100% (1)

- Design of Adaptive Highly Efficient GaN Power AmplifierDocument11 pagesDesign of Adaptive Highly Efficient GaN Power AmplifierahsoopkNo ratings yet

- PIC Based DDS For Audio / LFDocument10 pagesPIC Based DDS For Audio / LFahsoopk100% (2)

- Mplab IDE TutorialDocument12 pagesMplab IDE Tutorialahsoopk100% (1)

- Errata: The Schottky Diode Mixer (AN 995)Document9 pagesErrata: The Schottky Diode Mixer (AN 995)ahsoopk100% (1)

- Microwave Office Training: Tuning, Optimization, and Yield AnalysisDocument59 pagesMicrowave Office Training: Tuning, Optimization, and Yield AnalysisahsoopkNo ratings yet

- TQP3M9007Document9 pagesTQP3M9007ahsoopkNo ratings yet

- Microstrip, Stripline, and CPW DesignDocument40 pagesMicrostrip, Stripline, and CPW DesignNameNo ratings yet

- Direct Digital Synthesis: Application Note #5 Impact On Function Generator DesignDocument5 pagesDirect Digital Synthesis: Application Note #5 Impact On Function Generator Designvinay_2211No ratings yet

- Appendix 09Document3 pagesAppendix 09ahsoopkNo ratings yet

- Digsilent Powerfactory: Technical Reference DocumentationDocument11 pagesDigsilent Powerfactory: Technical Reference DocumentationVladimirCoelloNo ratings yet

- GRE Math Practice Test 17Document22 pagesGRE Math Practice Test 17Malik Shahzad100% (2)

- Printable Resume For Mechanical EngineerDocument5 pagesPrintable Resume For Mechanical EngineerSachin PintoNo ratings yet

- ReliaSoft 2020 Installation and LicensingDocument11 pagesReliaSoft 2020 Installation and LicensingSergio CastilloNo ratings yet

- Az-220 Dumps Microsoft Azure Iot Developer: 100% Valid and Newest Version Az-220 Questions & Answers Shared by CertleaderDocument13 pagesAz-220 Dumps Microsoft Azure Iot Developer: 100% Valid and Newest Version Az-220 Questions & Answers Shared by CertleaderIamSajid Jatoi0% (1)

- Automatizare KNX Homeserver Gira enDocument24 pagesAutomatizare KNX Homeserver Gira enCristian CorneliuNo ratings yet

- Final Summer Training ReportDocument24 pagesFinal Summer Training ReportHarish NaiduNo ratings yet

- LabPlanningManual 02 enDocument12 pagesLabPlanningManual 02 enJulio AlceramNo ratings yet

- OFM 2012 Administration ODocument262 pagesOFM 2012 Administration OKarla Paola Rojas Gudiño100% (1)

- Characteristics of ComputersDocument2 pagesCharacteristics of ComputersBilas Joseph33% (3)

- Strut and Tie Model Deep Beam DesignDocument10 pagesStrut and Tie Model Deep Beam DesignAzhar PLNo ratings yet

- Shruti Assignment 2Document25 pagesShruti Assignment 2Shruti SuryawanshiNo ratings yet

- Top devices and drivers in Windows system reportDocument8 pagesTop devices and drivers in Windows system reportQ Sang PangerandzNo ratings yet

- Modern-Day Narcissus The Selfie Obsession - Sabotage TimesDocument3 pagesModern-Day Narcissus The Selfie Obsession - Sabotage Timesapi-317264340No ratings yet

- Press Release and Result 13 17 Dated 15-03-2022Document2 pagesPress Release and Result 13 17 Dated 15-03-2022sameer bakshiNo ratings yet

- DBT416 Amigo ReportDocument32 pagesDBT416 Amigo ReportArjareeNo ratings yet

- Tutorial 2Document3 pagesTutorial 2Stephen KokNo ratings yet

- Ajibm 2018092915061190Document16 pagesAjibm 2018092915061190josinonNo ratings yet

- User's Manual of Haiwell H and N Series MPUDocument1 pageUser's Manual of Haiwell H and N Series MPUMuhammad Anowar KabirNo ratings yet

- GEE S1 GRD Script ShahriarRahmanDocument2 pagesGEE S1 GRD Script ShahriarRahmanWilliam CarvalhoNo ratings yet

- Manual of Fish Sclerochronology-Ifremer PDFDocument466 pagesManual of Fish Sclerochronology-Ifremer PDFDaniela Mariana RosioruNo ratings yet

- Screw TechDocument34 pagesScrew TechJaime Munoz100% (1)

- List of Companies in Bangalore LocationDocument13 pagesList of Companies in Bangalore LocationKaisar HassanNo ratings yet

- 988H DIGNOSTIC Techdoc Print PageDocument5 pages988H DIGNOSTIC Techdoc Print Pagerao abdul bariNo ratings yet

- Resume PaanDocument2 pagesResume PaanMUHAMMAD FARHANNo ratings yet

- Web Technology Paper MidsDocument5 pagesWeb Technology Paper MidsAbdullah Bin Rauf100% (1)

- India Edition OM Best Practice Guidelines 1Document132 pagesIndia Edition OM Best Practice Guidelines 1Abhishek P100% (3)

- Relevance Feedback in Content Based Image Retrieval: A ReviewDocument7 pagesRelevance Feedback in Content Based Image Retrieval: A ReviewDinh ThanhNo ratings yet

- Emerging Technologies: An SEO-Optimized GuideDocument22 pagesEmerging Technologies: An SEO-Optimized GuideES BirnurNo ratings yet

- Proceedings of the 6th International Conference on Nuclear Option in Countries with Small and Medium Electricity GridsDocument4 pagesProceedings of the 6th International Conference on Nuclear Option in Countries with Small and Medium Electricity GridsChirag PoladiaNo ratings yet