Professional Documents

Culture Documents

Hvacprocedure 6

Uploaded by

hemantOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Hvacprocedure 6

Uploaded by

hemantCopyright:

Available Formats

Supports should be installed per manufacturer's specifications or per UMC requirements;

Supports for flexible ducts should be spaced at no more than 4 foot intervals;

Flexible ducts should be supported by strapping having a minimum width of 1_ inches at all

contact points with the duct;

Supports should not constrict the inner liner of the duct;

Flexible ducts should have maximum of _ inch sag per foot between supports;

Flexible ducts may rest on ceiling joists or truss supports as long as they lie flat and are supported

at no more that 4 foot intervals.

Boots

After mechanically attaching the register boot to floor, wall, or ceiling, all openings between the

boot and floor, wall, or ceiling should be sealed with caulk or mastic.

Seal Air Handler

Openings greater than 1/16 inch should be sealed with mastic and mesh, or butyl adhesive tape;

Openings less than 1/16 inch should be sealed with mastic or UL 181A listed tape;

Unsealed access doors should be sealed with UL 181A listed tape.

CHECK REFRIGERANT CHARGE

For systems with fixed metering devices use evaporator superheat method:

- indoor coil airflow must be greater than 350 cfm/ton;

- refrigerant system evacuation must be complete (all non-condensables must be removed from

the system;

- in hot, dry climates be cautious to be within range of superheat charging chart or use a different

method.

For systems with thermostatic expansion valves use the subcooling method.

CHECK COMBUSTION PERFORMANCE

Check each chamber for correct flame;

Check for proper drafting.

TEST SYSTEM PERFORMANCE

The following are testing requirements and procedures that must be followed to ensure that the HVAC

system has been properly installed. The tests are designed to determine whether:

1. Room-by-room air flows are correct;

2. Total supply is as designed;

3. Total return = total supply;

4. Ducts, plenum, and air handler are tight;

5. Static pressure is correct.

Test the system to ensure that it performs properly, by (1) verifying HVAC equipment sizes

installed are those specified, (2) measuring duct leakage, and measuring either (3a) fan flow or (3b)

supply and return flows and plenum static pressures:

1. Air conditioner sensible capacity must be no more than 15% greater than the calculated sensible

load; fan flow must be greater than 350 cfm/ton; check that the correct size air handler is

installed.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Electrical Definnitions-2 PDFDocument1 pageElectrical Definnitions-2 PDFhemantNo ratings yet

- Electrical Definnitions-3Document1 pageElectrical Definnitions-3hemantNo ratings yet

- Electrical Definnitions-1Document1 pageElectrical Definnitions-1hemantNo ratings yet

- Hvacprocedure 7Document1 pageHvacprocedure 7hemantNo ratings yet

- Hvacprocedure 5Document1 pageHvacprocedure 5hemantNo ratings yet

- Hvacprocedure 4Document1 pageHvacprocedure 4hemantNo ratings yet

- Hvacprocedure 3Document1 pageHvacprocedure 3hemantNo ratings yet

- HVAC Engineer Interview 70 Question Answers (Mechanical Engineer) PDFDocument11 pagesHVAC Engineer Interview 70 Question Answers (Mechanical Engineer) PDFChahbi Ramzi100% (1)

- Distance Between Two Pipes (Insulated Pipes)Document3 pagesDistance Between Two Pipes (Insulated Pipes)hemantNo ratings yet

- Hvacprocedure 2 PDFDocument1 pageHvacprocedure 2 PDFhemantNo ratings yet

- HVAC FormulasDocument7 pagesHVAC FormulasAshok Kumar S100% (4)

- Procedures For Hvac System Design and InstallationDocument1 pageProcedures For Hvac System Design and InstallationhemantNo ratings yet

- R/U Value Calculations Heat Gain CalculationsDocument1 pageR/U Value Calculations Heat Gain CalculationshemantNo ratings yet

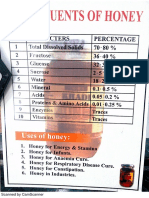

- Honey ConstituentsDocument2 pagesHoney ConstituentshemantNo ratings yet

- Pipe Size CalculaterDocument4 pagesPipe Size Calculaterhemant100% (1)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)