Professional Documents

Culture Documents

Bamboo Rayon

Uploaded by

Heiner SigüenzaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Bamboo Rayon

Uploaded by

Heiner SigüenzaCopyright:

Available Formats

®

BAMBOO AND RAYON

Bamboo Becomes Rayon process, including sodium hydroxide and sulfuric acid. Because of

these environmental issues, Patagonia does not use rayon fabric

Bamboo is the fastest-growing woody plant in the world, capable

or bamboo fabric made by the viscose process.

of growing up to four feet a day. Most of it is grown organically

(though very little is certified organic), and in most locations

requires no irrigation or fertilizers. There are some concerns Alternatives to Rayon

about its use focused on depleting natural bamboo habitat (for Patagonia’s material developers have been investigating bamboo

pandas) and clearing forests for bamboo plantations. But for the since 2003, but since almost all available bamboo fabric is made

most part, the growing of bamboo can be considered sustainable. using the viscose process, we do not use bamboo fabric in our

product line. We are aware of some linen-type bamboo fabric

Bamboo stalks contain bast fibers that can be processed into a

that is processed as bast fiber, but currently we are not using it

relatively stiff and rough fabric like flax (linen) or hemp. However,

because we have hemp fabrics that perform well in this type of

most bamboo fabric in the market has a smooth, silky hand that

application. The appeal of bamboo fabric is usually the drape and

feels similar to rayon – because that’s essentially what it is. Rayon

the hand that is a product of the viscose-type chemical processing.

is a regenerated cellulose fiber, which means that a natural raw

We have searched for an alternative fabric with these attributes,

material is converted through a chemical process into a fiber that

but with less harm to the environment. The best we have found

falls into a category between naturals and synthetics. The source

is called Tencel®, a branded name of lyocell fiber. Tencel is also

of cellulose can be wood, paper, cotton fiber or, in this case,

a regenerated cellulose fiber, but processed with a non toxic

bamboo.

spinning solvent in a closed-loop system.

The Problem with the Viscose Rayon Process The raw material is wood pulp harvested from eucalyptus

tree farms, and the pulp is certified by the Forest Stewardship

There is more than one way to make rayon. The most common

Council® (FSC). It is possible to use bamboo, or other sources

way – and the one widely used for bamboo – is called the viscose

of cellulose, but eucalyptus yields the best quality fiber with the

process. In this process, cellulose material (such as bamboo) is

least amount of waste. Therefore we think this process is the best

dissolved in a strong solvent to make a thick, viscous solution

available option.

that is forced through a spinneret into a quenching solution

where strands solidify into fiber. This is sometimes called We do have to ensure that the processing of Tencel and lyocell

hydrolysis alkalization or solution spinning because the fiber is fibers does not utilize any of the harmful chemicals sometimes

“spun” in a chemical solution. The solvent used for this process used to treat the fibrillation of these fibers. Some factories

is carbon disulfide, a toxic chemical that is a known human use a formaldehyde treatment to avoid pilling and fuzz, but

reproductive hazard. It can endanger factory workers and pollute other formaldehyde-free treatments are available and are

the environment via air emissions and wastewater. The recovery environmentally preferred.

of this solvent in most viscose factories is around 50%, which

means that the other half goes into the environment. Other

potentially hazardous chemicals are also used in the viscose

page 1 ©2012 Patagonia, Inc

You might also like

- Textile MoodboardDocument2 pagesTextile MoodboardFaten effaNo ratings yet

- Comparitive Study of Fabrics Produced From Bamboo and ModalDocument24 pagesComparitive Study of Fabrics Produced From Bamboo and Modalshashank drNo ratings yet

- Lyocell Fiber: Lenzing Fibers Inc. CelluloseDocument5 pagesLyocell Fiber: Lenzing Fibers Inc. CelluloseGrosu Marian CatalinNo ratings yet

- Organic Fabrics Info Booklet - CompressedDocument12 pagesOrganic Fabrics Info Booklet - CompressedMarianaGranadoNo ratings yet

- Modal Rayon Lyocell Rayon: Cuproamonium Rayon Acetate RayonDocument18 pagesModal Rayon Lyocell Rayon: Cuproamonium Rayon Acetate RayonHrs Shihab100% (1)

- Bamboo FiberDocument14 pagesBamboo FiberHikmatkhan NooraniNo ratings yet

- Paper & Paper MakingDocument47 pagesPaper & Paper MakingEllyzsha PenialberNo ratings yet

- Classification of FibresDocument9 pagesClassification of Fibres01917473787No ratings yet

- Classification of Man-Made Fibers and Their CodesDocument2 pagesClassification of Man-Made Fibers and Their CodesNazmul-HassanNo ratings yet

- Application of Contemporary Fibers in Apparel - LyocellDocument5 pagesApplication of Contemporary Fibers in Apparel - LyocellVasant Kothari100% (1)

- FibresDocument5 pagesFibresu92445622No ratings yet

- Preparation of Rayon ThreadDocument20 pagesPreparation of Rayon ThreadAkshaya SuruthiNo ratings yet

- Sustainable FabricsDocument48 pagesSustainable FabricsBright Mariya100% (1)

- Bamboo Fabric Products and UsesDocument7 pagesBamboo Fabric Products and UsesDorin VladNo ratings yet

- BambooDocument2 pagesBambootkr163No ratings yet

- Bamboo FabricDocument12 pagesBamboo FabricSweta Saha100% (1)

- Application of Contemporary Fibres in Apparels - Hibiscus FIBREDocument3 pagesApplication of Contemporary Fibres in Apparels - Hibiscus FIBREVasant KothariNo ratings yet

- Properties of Bamboo, PLA and SPF FibresDocument2 pagesProperties of Bamboo, PLA and SPF FibresDorin VladNo ratings yet

- Bamboo FibreDocument8 pagesBamboo FibreChaitali ChandraNo ratings yet

- Introduction To YarnDocument18 pagesIntroduction To YarnAbhradeep BhattacharjeeNo ratings yet

- Presentation On: Semi Synthetic or Regenerated FiberDocument8 pagesPresentation On: Semi Synthetic or Regenerated Fibersazzad alaminNo ratings yet

- Fibres PPT 1Document19 pagesFibres PPT 1rajesh duaNo ratings yet

- Fabric Science - Eco - Friendly TextilesDocument50 pagesFabric Science - Eco - Friendly TextilesAkankshya SahooNo ratings yet

- Natural FabricsDocument20 pagesNatural FabricsSantosh BishtNo ratings yet

- Not All Natural Fibers Are Created Equal: The Truth About Viscose RayonDocument4 pagesNot All Natural Fibers Are Created Equal: The Truth About Viscose RayonDanish NawazNo ratings yet

- Fiber CraftDocument37 pagesFiber CraftTagaBukidDotNet100% (1)

- Classification of Man-Made Fibers and Their CodesDocument2 pagesClassification of Man-Made Fibers and Their CodesFalgon IslamNo ratings yet

- Chemistry Project Class 11 A3Document41 pagesChemistry Project Class 11 A3ERROR ???No ratings yet

- Summer Project Bamboo FibreDocument12 pagesSummer Project Bamboo FibreShantanuGupta100% (1)

- RafaDocument8 pagesRafaMD.MAHABUB ALOM REFAETNo ratings yet

- Topic 1:: Types of Textile Fibers - List of Textile Fibers by Its SourcesDocument9 pagesTopic 1:: Types of Textile Fibers - List of Textile Fibers by Its SourcesKAWSER RAFINo ratings yet

- LYOCELLDocument5 pagesLYOCELLKingson_786100% (1)

- Fibres There Are Many Fibres Which Can Be Considered As Eco-Friendly 1. HempDocument3 pagesFibres There Are Many Fibres Which Can Be Considered As Eco-Friendly 1. HempSudhir JainNo ratings yet

- Bamboo Home TextilesDocument14 pagesBamboo Home TextilesPallavi JainNo ratings yet

- What Are Natural FibersDocument2 pagesWhat Are Natural FibersCathy BiasettiNo ratings yet

- Hardy HempDocument1 pageHardy HempMady IsanNo ratings yet

- Rayon ProductionDocument51 pagesRayon Productiontigerkiller75% (12)

- Journal of Textile Science & EngineeringDocument6 pagesJournal of Textile Science & Engineeringirc.indusNo ratings yet

- Lyocell Fibre DocumentDocument4 pagesLyocell Fibre DocumentHossain RsfaNo ratings yet

- Semi&Fully SyntheticDocument6 pagesSemi&Fully SyntheticArresh NadeanNo ratings yet

- Textile Fundamentals: Project On Fibre ClassificationDocument7 pagesTextile Fundamentals: Project On Fibre ClassificationAnubhav kashyapNo ratings yet

- Bamboo FiberDocument16 pagesBamboo FiberHikmatkhan NooraniNo ratings yet

- Sustainable Building Materials: Sheep WoolDocument32 pagesSustainable Building Materials: Sheep WoolshrutiNo ratings yet

- Rohit Raj - FS Assignment 2-Converted-CompressedDocument38 pagesRohit Raj - FS Assignment 2-Converted-CompressedRohit RajNo ratings yet

- Coco PeatDocument3 pagesCoco PeatLennoux BNo ratings yet

- Textile Fibers: Created By: Mrs. Christine Holt FACS Educator Westlake High SchoolDocument49 pagesTextile Fibers: Created By: Mrs. Christine Holt FACS Educator Westlake High SchoolAnonymous 51N3PEzjNo ratings yet

- Wet Processing of Bamboo FabricsDocument3 pagesWet Processing of Bamboo FabricsviendetmayNo ratings yet

- Investigatory Project Chemistry - 1Document27 pagesInvestigatory Project Chemistry - 1Jayesh ModiNo ratings yet

- Textile Fibres ClassificationDocument43 pagesTextile Fibres ClassificationPalani RajanNo ratings yet

- FKM 1Document13 pagesFKM 1itee0510No ratings yet

- Chemistry Class 8 CH - 3 Synthetic Fibres and Plastics: FibreDocument3 pagesChemistry Class 8 CH - 3 Synthetic Fibres and Plastics: FibreJayesh ParmarNo ratings yet

- Organic Bamboo FiberDocument14 pagesOrganic Bamboo FiberNaimul HasanNo ratings yet

- Preparation of Cuprammonium Biodegradable Rayon Fibers From Different Papers With Schweitzers Solution.Document4 pagesPreparation of Cuprammonium Biodegradable Rayon Fibers From Different Papers With Schweitzers Solution.Mukund PrasadNo ratings yet

- Fabric Science Assignment 1 On "Hemp" & "Bamboo" Cohesiveness PropertyDocument10 pagesFabric Science Assignment 1 On "Hemp" & "Bamboo" Cohesiveness PropertyaadishNo ratings yet

- Tensile Strength of FibersDocument27 pagesTensile Strength of FibersKaushik DwivediNo ratings yet

- Rayon Presentation UpdatedDocument3 pagesRayon Presentation UpdatedsaleemNo ratings yet

- Bamboo Fibres in Textile PDFDocument20 pagesBamboo Fibres in Textile PDFJeffery PattonNo ratings yet

- MMCF Certified FabricsDocument2 pagesMMCF Certified FabricsvictoriawildmanNo ratings yet

- AttributesDocument1 pageAttributeshepheifangNo ratings yet

- A 1Document1 pageA 1Heiner SigüenzaNo ratings yet

- Dynamic Analysis and DesignDocument20 pagesDynamic Analysis and DesignHeiner SigüenzaNo ratings yet

- Bamboo RayonDocument1 pageBamboo RayonHeiner SigüenzaNo ratings yet

- BAMBOO Durability TestDocument11 pagesBAMBOO Durability TestFebio DalantaNo ratings yet

- BAMBOO Durability TestDocument11 pagesBAMBOO Durability TestFebio DalantaNo ratings yet

- Framework For Assessing BambooDocument42 pagesFramework For Assessing BambooHeiner SigüenzaNo ratings yet

- Manual Revit ArchitectureDocument1,714 pagesManual Revit ArchitectureRichard FigueroaNo ratings yet

- Manual de Compresora de SuelosDocument19 pagesManual de Compresora de SuelosHeiner SigüenzaNo ratings yet

- Mine Developmen-WPS OfficeDocument7 pagesMine Developmen-WPS OfficePeter Ayuba AkpaNo ratings yet

- L-8 Collapsible SoilsDocument27 pagesL-8 Collapsible SoilsAshebirNo ratings yet

- Stabilization of Expansive Soil With Rice Husk Ash PDFDocument10 pagesStabilization of Expansive Soil With Rice Husk Ash PDFKiarith LópezNo ratings yet

- Natural Attenuation in Vadose Zone Natures Gift To Mine ClousureDocument14 pagesNatural Attenuation in Vadose Zone Natures Gift To Mine ClousureVictor Manuel Yañez ZapataNo ratings yet

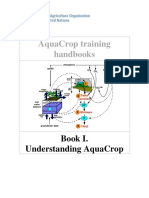

- Aquacrop Training Handbooks: Book I. Understanding AquacropDocument59 pagesAquacrop Training Handbooks: Book I. Understanding Aquacropqputu100% (1)

- Atterberg Limits of SoilDocument22 pagesAtterberg Limits of SoilDanao ErickNo ratings yet

- Summary of The Liquefaction Site 1998Document20 pagesSummary of The Liquefaction Site 1998williamvargasmongeNo ratings yet

- Rocks and MineralsDocument6 pagesRocks and Mineralsapi-235019933No ratings yet

- Chapter 2 Soil ClassificationDocument22 pagesChapter 2 Soil Classificationanon_917763370No ratings yet

- Rbcsoils ScienceDocument17 pagesRbcsoils ScienceRayge HarbskyNo ratings yet

- Chapter 2 (New) - Soil As A ResourceDocument20 pagesChapter 2 (New) - Soil As A ResourceReizell DalawangbayanNo ratings yet

- Is An Aquifer An Underground River?: Click HereDocument3 pagesIs An Aquifer An Underground River?: Click HereLasandu WanniarachchiNo ratings yet

- 1 Sc-Plastic LimitDocument14 pages1 Sc-Plastic LimitNurul AmshahieraNo ratings yet

- Basic Soil Properties From CPT in Bangkok Clay For Highway DesignDocument8 pagesBasic Soil Properties From CPT in Bangkok Clay For Highway DesigntangkokhongNo ratings yet

- Project Muhammad SahabiDocument56 pagesProject Muhammad SahabiAbdullahi MuhammadNo ratings yet

- Structure of Regolith SimulantDocument7 pagesStructure of Regolith SimulantBrianNo ratings yet

- DBT 203 Metal Extractive Technology: Topic 1: Extracting Metal From OresDocument24 pagesDBT 203 Metal Extractive Technology: Topic 1: Extracting Metal From OresSollehah SuhaimiNo ratings yet

- Pengaruh Tinggi Muka Air Tanah Terhadap PH, Eh, Fe, Al, MN Dan P Terlarut Pada Tanaman Nanas Klon Gp3 Di UltisolDocument8 pagesPengaruh Tinggi Muka Air Tanah Terhadap PH, Eh, Fe, Al, MN Dan P Terlarut Pada Tanaman Nanas Klon Gp3 Di UltisolLanggengWaskithoArcherNo ratings yet

- Annex 1 - Titration Method For Determining Salt Iodate and Iodide ContentDocument35 pagesAnnex 1 - Titration Method For Determining Salt Iodate and Iodide Contentr0466No ratings yet

- Soil ErosionDocument2 pagesSoil ErosionGürkan YıldırımNo ratings yet

- Basic Soil Plant Water RelationsDocument4 pagesBasic Soil Plant Water Relationskayle navajaNo ratings yet

- Bamboo AgroforestryDocument26 pagesBamboo AgroforestrySri AgustinNo ratings yet

- Soil and Nutrient Losses in Erosion Gullies at Different Degrees of RestorationDocument10 pagesSoil and Nutrient Losses in Erosion Gullies at Different Degrees of RestorationpNo ratings yet

- Hot Pepper: Land PreparationDocument4 pagesHot Pepper: Land PreparationAmber ThompsonNo ratings yet

- Manual Guidelines Mine Haul Road Design Haul Trucks Roads Planning Alignment Sections Surface Construction EconomicsDocument95 pagesManual Guidelines Mine Haul Road Design Haul Trucks Roads Planning Alignment Sections Surface Construction EconomicsKRUSHNA CHANDRA GUJIRINo ratings yet

- NPK Questionnaire 15 - AppendixDocument7 pagesNPK Questionnaire 15 - AppendixSX100% (1)

- A Laboratory Investigation Into Effect of Water Content On The CBR of A Subgrade SoilDocument8 pagesA Laboratory Investigation Into Effect of Water Content On The CBR of A Subgrade SoilAlberto AmparánNo ratings yet

- Module 2 (Rocks)Document8 pagesModule 2 (Rocks)JamesBuensalidoDellavaNo ratings yet

- Well Fact Sheet: Well Owner ResponsibilitiesDocument2 pagesWell Fact Sheet: Well Owner ResponsibilitiesHill County Conservation DistrictNo ratings yet

- List of Copper OreDocument11 pagesList of Copper Orenasir.hdip8468No ratings yet