Professional Documents

Culture Documents

Adhesive Wear: Muttaqin Naeiman Bin Mazlan (A174390)

Uploaded by

Muttaqin NaeimanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Adhesive Wear: Muttaqin Naeiman Bin Mazlan (A174390)

Uploaded by

Muttaqin NaeimanCopyright:

Available Formats

MUTTAQIN NAEIMAN BIN MAZLAN (A174390)

ADHESIVE WEAR

Adhesive wear is a phenomenon which occurs when two metals rub together with

sufficient force to cause the removal of material from the less wear-resistant surface. This wear is

dependent on physical and chemical factors such as material properties, presence of corrosive

atmosphere or chemicals, as well as the dynamics such as the velocity and applied load.

This phenomenon is considered corrosion by means of mechanical action rather than

chemical reactions. ASTM G77 provides specifications and testing procedures for adhesive wear

testing. Adhesive wear is also known as sliding wear or scuffing wear.

HOW IT WORKS

When two metal surfaces come into contact with each other, they initially touch only at a

few rough points. Friction and wear originate at these points. When a compressive load is

applied, these rough points are plastically deformed and finally welded together because of the

high pressure that is created. As sliding continues, these bonds are broken, producing cavities on

one surface and depressions on the second surface. Abrasive particles detach and rub against the

surface, contributing to wear

HOW TO PREVENT

The most suitable method to reduce the abrasive wear is by using low coefficient of friction of

tool steel. This requires a good tool surface finish, preferably with the grinding and polishing

performed parallel with the direction of tooling movement. Other solutions include lubricants or

surface coatings.

You might also like

- Wear Mitigation by The Use of Surface CoatingsDocument10 pagesWear Mitigation by The Use of Surface CoatingsRodrigo Jechéla BarriosNo ratings yet

- Adhesion Wear and AbrasiveDocument28 pagesAdhesion Wear and AbrasiveSanjay Shelar100% (1)

- Dickson and Benson 560 Assignment TwoDocument7 pagesDickson and Benson 560 Assignment TwoDICKSON SIMUTAMINo ratings yet

- Industrial Tribology WearDocument23 pagesIndustrial Tribology WearAtif HashmiNo ratings yet

- 2 ND Proposal With RamiDocument9 pages2 ND Proposal With Ramiyunus_mohammed1641No ratings yet

- Module 3Document27 pagesModule 3Aditya ranjan BubunNo ratings yet

- What Is Wear? 1.1 DefinitionDocument18 pagesWhat Is Wear? 1.1 DefinitionSHYAM SUNDARNo ratings yet

- 15 - Chapter 7 PDFDocument24 pages15 - Chapter 7 PDFpavan_1988No ratings yet

- Basic Wear Modes in Lubricated SystemDocument8 pagesBasic Wear Modes in Lubricated SystemTino_No ratings yet

- Fundamental Theory of DamagesDocument30 pagesFundamental Theory of DamagesMisge ChekoleNo ratings yet

- Basic Wear ModesDocument6 pagesBasic Wear ModesolguinrfNo ratings yet

- A Critical Review On Different Types of Wear of MaterialsDocument7 pagesA Critical Review On Different Types of Wear of MaterialsIAEME PublicationNo ratings yet

- Wear Analysis of Hard Faced Agricultural Equipment - Doc FFDocument15 pagesWear Analysis of Hard Faced Agricultural Equipment - Doc FFSunil BasavarajuNo ratings yet

- Wear of Impact Socket - A ReviewDocument4 pagesWear of Impact Socket - A Reviewlaukik_rautNo ratings yet

- Hardfacing To Increase Wear ResistanceDocument6 pagesHardfacing To Increase Wear ResistanceanruloNo ratings yet

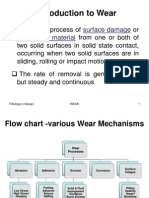

- Introduction To Wear: Surface Damage Removal of MaterialDocument33 pagesIntroduction To Wear: Surface Damage Removal of MaterialSelvamuthu KumaranNo ratings yet

- Hydrodynamic Bearings BestDocument21 pagesHydrodynamic Bearings BestJoker DanNo ratings yet

- Module 3Document22 pagesModule 3sandhrarosechackochan.b20me1136No ratings yet

- Chapter#2 Assignment#3Document5 pagesChapter#2 Assignment#3Tilahun WorkuNo ratings yet

- Chapter Two Fundamentals of The Theory of DamagesDocument33 pagesChapter Two Fundamentals of The Theory of DamagesMuket Agmas0% (1)

- GallingDocument6 pagesGallinghrh_pogcNo ratings yet

- Basics of Wear IiwDocument7 pagesBasics of Wear IiwSomnath ChakravartyNo ratings yet

- Tribological Properties and Applications of AluminaDocument27 pagesTribological Properties and Applications of Aluminalamia97No ratings yet

- Environmentally Assisted Cracking and Fatigue CorrosionDocument4 pagesEnvironmentally Assisted Cracking and Fatigue CorrosionBrian WereNo ratings yet

- A Wear and Surface DamageDocument3 pagesA Wear and Surface Damageemad sabriNo ratings yet

- Wear Introduction of WearDocument22 pagesWear Introduction of WearVinit ShrivastavaNo ratings yet

- FrettingDocument2 pagesFrettingsolidwormNo ratings yet

- Rear (Driven) Bicycle Sprockets. New, Left, Shows No Wear. Right, Used, Shows Obvious Wear From Being Driven ClockwiseDocument7 pagesRear (Driven) Bicycle Sprockets. New, Left, Shows No Wear. Right, Used, Shows Obvious Wear From Being Driven Clockwiseumar_hazrad8219No ratings yet

- Chap 2Document49 pagesChap 2goitomNo ratings yet

- 01 Dujv UE Presentation 2018 PDFDocument69 pages01 Dujv UE Presentation 2018 PDFelias attalahNo ratings yet

- Friction of MetalsDocument20 pagesFriction of MetalssequitoNo ratings yet

- Presentation 1Document43 pagesPresentation 1TgemunuNo ratings yet

- Interactive Mechanism and Friction Modelling of Transient Tribological Phenomena in Metal Forming Processes: A ReviewDocument21 pagesInteractive Mechanism and Friction Modelling of Transient Tribological Phenomena in Metal Forming Processes: A ReviewvinothkumarNo ratings yet

- Modes of FractureDocument10 pagesModes of FractureAHMED DIABNo ratings yet

- Chapter-3 Damage MechanismsDocument16 pagesChapter-3 Damage Mechanismssafeer ahmadNo ratings yet

- Tribology in Design: AssignmentDocument9 pagesTribology in Design: AssignmentSathish SathiNo ratings yet

- Brief Discussion On Tribology: Department of Orthopaedics Kasturba Medical CollegeDocument7 pagesBrief Discussion On Tribology: Department of Orthopaedics Kasturba Medical CollegechinmayghaisasNo ratings yet

- Mechanisms of Wear in TribologyDocument4 pagesMechanisms of Wear in TribologyVishwanath HokraniNo ratings yet

- Liquid-Metal Embrittlement 2Document2 pagesLiquid-Metal Embrittlement 2skluxNo ratings yet

- Corrosion-Surface DamageDocument29 pagesCorrosion-Surface DamageGcwalisile DlaminiNo ratings yet

- 02 - Wear (Desgaste) - 02Document36 pages02 - Wear (Desgaste) - 02Fabian Luna BernalNo ratings yet

- TRIBOLOGY AssignmentDocument20 pagesTRIBOLOGY Assignmentmunish0875No ratings yet

- Module 5 WearDocument23 pagesModule 5 WearrohanNo ratings yet

- Metallic Wear: Deeptesh SinghDocument51 pagesMetallic Wear: Deeptesh Singhadityanarang147No ratings yet

- STLE - Basic of WearDocument17 pagesSTLE - Basic of WearGerson NevesNo ratings yet

- Engineering Tribology: Prof. Dr. Tamer S. MahmoudDocument44 pagesEngineering Tribology: Prof. Dr. Tamer S. MahmoudbassemNo ratings yet

- Module 3: Wear: Fig. 3.1 (A) : Zero Wear of Helical GearDocument30 pagesModule 3: Wear: Fig. 3.1 (A) : Zero Wear of Helical GearMohammad Ishfaq BhatNo ratings yet

- 07-Mechanical Aspects of CorrosionDocument22 pages07-Mechanical Aspects of CorrosionYonas GereNo ratings yet

- Coconut Ash FinalDocument47 pagesCoconut Ash FinalMusic LoverNo ratings yet

- Recognizing and Dealing With General Anodizing ProblemsDocument9 pagesRecognizing and Dealing With General Anodizing ProblemsalipeyNo ratings yet

- Materials 12 01862 PDFDocument15 pagesMaterials 12 01862 PDFLULZNo ratings yet

- Surface EngineringDocument23 pagesSurface EngineringPoorna SravanNo ratings yet

- Efecto de Las Cargas en El Agrietamiento Por Corrosión Bajo TensiónDocument6 pagesEfecto de Las Cargas en El Agrietamiento Por Corrosión Bajo TensióngamalielNo ratings yet

- Wear and Corrosion Behaviour of Friction Stir Welded Aluminium Alloys-An OverviewDocument16 pagesWear and Corrosion Behaviour of Friction Stir Welded Aluminium Alloys-An OverviewTJPRC PublicationsNo ratings yet

- Factors Affecting WearDocument23 pagesFactors Affecting WearhashimtkmceNo ratings yet

- Lubricated SlidingDocument14 pagesLubricated Slidings s s sNo ratings yet