Professional Documents

Culture Documents

Basic Meat Processing Procedures

Uploaded by

Abhinav Gupta100%(1)100% found this document useful (1 vote)

21 views2 pagesOriginal Title

Basic meat processing procedures

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

100%(1)100% found this document useful (1 vote)

21 views2 pagesBasic Meat Processing Procedures

Uploaded by

Abhinav GuptaCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

Dept.

of Livestock Products Technology

BVSc 3rd year

Dr. Rawat

BASIC MEAT PROCESSING PROCEDURES

Processing refers to any treatment including salting which brings about a substantial change in

chemical and physical state of meat

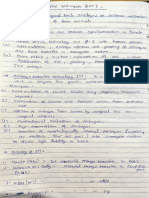

Basic processing procedures

1. Comminution- All processed meats can be classified as either non comminuted or

comminuted products. Non- comminuted meat products are made from intact cuts of meat

such as ham and bacon. These are usually cured, smoked or cooked. Comminuted meat

refers to subdivision of meat into meat pieces or particles. Size reduction helps in uniform

distribution of seasoning and eliminates toughness of meat from older animals and also

saves fuel cost for cooking. Example of comminuted meat products are sausage and meat

patties. Meat mincer is used for coarse grinding and bowl chopper is used for fine grinding

to make meat emulsions.

(Difference between and examples of comminuted and non-comminuted meat products)

imp

2. Emulsification- Mixture of two immiscible liquids where one liquid is dispersed in another

liquid is known as emulsion. Emulsion has continuous and dispersed phase. Meat emulsion

contains a dispersed phase of solid or liquid fat droplets and continuous phase of water

containing salts and proteins. Meat emulsion is an oil-in-water type of emulsion.

Solubilized myofibrillar proteins act as emulsifiers which stabilizes the emulsion. Fat

droplets are usually larger than 50µm. For preparation of emulsions, lean meat is first

chopped with salt to extract salt soluble proteins and then fat and other ingredients are

added.

3. Meat extension- Non-meat food incorporated in meat products are known as meat

extenders. They are of 3 types-

• Fillers- They are used to reduce the cost of formulation. Eg. rice, pea, corn, potato,

etc. They have high carbohydrate content.

• Binders- They act as binding agent to hold the shape of the product together. Eg.

skim milk powder, sodium caseinate, dried whey, etc.

• Extenders- Meat extenders are non-meat substance with high protein content. It is

used to reduce cost of meat product processing. Eg- soy protein, pulses, etc.

(difference between the 3)

4. Preblending- It refers to mixing of a part or all the curing ingredients with ground meat in

a specified proportion. This process helps in better extraction of proteins.

5. Hot Processing- It refers to processing of carcass as soon as possible after slaughter in pre

rigor state. It is a common practice in India.

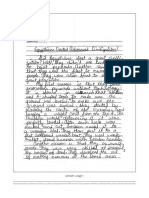

6. Cooking- Meat and meat products are cooked by any 3 of the following methods-

• Dry heat cooking- It is used for relatively tender cuts of meat. It involves broiling,

roasting or frying.

• Moist heat cooking- It is used for relatively tough cuts of meat. Eg. pressure

cooking, stewing, simmering, etc. Simmering involves cooking meat in hot water

at 70°C.

• Microwave cooking- Microwaves are high frequency, non-ionising

electromagnenic waves generated by magnetron vacuum tube within the oven.

They penetrate the food from all directions causing water, fat and sugar molecules

to vibrate at a high speed. The vibration produces tremendous friction, which lead

s to heat production which cooks the food. The spread of heat throughout the 3D

space in food is called volume heating. Heat transfers from the food then into the

container and environment as opposed to conventional cooking.

You might also like

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Abattoir Design and Construction PDFDocument4 pagesAbattoir Design and Construction PDFAbhinav Gupta100% (2)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- New Doc 2020-09-25 17.47.26Document2 pagesNew Doc 2020-09-25 17.47.26Abhinav GuptaNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- COD (Cystic Ovarian Degenration) PDFDocument6 pagesCOD (Cystic Ovarian Degenration) PDFAbhinav GuptaNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Assisted reproductive techniques for genetic improvement in female animalsDocument5 pagesAssisted reproductive techniques for genetic improvement in female animalsAbhinav GuptaNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Classification of Low Risk and High Risk Materials Generated in An Abattoir and Its Hygenic DisposalDocument6 pagesClassification of Low Risk and High Risk Materials Generated in An Abattoir and Its Hygenic DisposalAbhinav GuptaNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Sulphonamides: Broad Spectrum Antibacterial AgentsDocument11 pagesSulphonamides: Broad Spectrum Antibacterial AgentsAbhinav GuptaNo ratings yet

- Diagnosis and treatment of metal poisoningDocument11 pagesDiagnosis and treatment of metal poisoningAbhinav GuptaNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Fluorine Toxicity, Common Salt and Urea PoisoningDocument21 pagesFluorine Toxicity, Common Salt and Urea PoisoningAbhinav GuptaNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Egg Notes LPT 3rd Yr BVSCDocument7 pagesEgg Notes LPT 3rd Yr BVSCAbhinav GuptaNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Histamine and Antihistamines. NotesDocument5 pagesHistamine and Antihistamines. NotesSubha2000100% (1)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Agrochemicals Toxicity PDFDocument14 pagesAgrochemicals Toxicity PDFAbhinav GuptaNo ratings yet

- Pharmacology - 2. Unit 01. New - HighlightedDocument4 pagesPharmacology - 2. Unit 01. New - HighlightedManish ShankarpureNo ratings yet

- Arawali Veterinary College: Department of Livestock Production TechnologyDocument19 pagesArawali Veterinary College: Department of Livestock Production TechnologyAbhinav GuptaNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Nitrite and Chlorate Toxicity in RuminantsDocument11 pagesNitrite and Chlorate Toxicity in RuminantsAbhinav GuptaNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- LPT Assignment For 2nd Internal AssessmentDocument4 pagesLPT Assignment For 2nd Internal AssessmentAbhinav GuptaNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Milk Hygiene Practice in IndiaDocument4 pagesMilk Hygiene Practice in IndiaAbhinav GuptaNo ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Milk Hygiene Practice in IndiaDocument4 pagesMilk Hygiene Practice in IndiaAbhinav GuptaNo ratings yet

- Agrochemicals Toxicity PDFDocument14 pagesAgrochemicals Toxicity PDFAbhinav GuptaNo ratings yet

- Table Poultry AMIDocument2 pagesTable Poultry AMIAbhinav GuptaNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Milk PropertiesDocument18 pagesMilk PropertiesAbhinav GuptaNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Animal Husbandry PaperDocument6 pagesAnimal Husbandry PaperAbhinav GuptaNo ratings yet

- Maximum Residue Levels For Common AnthelminticsDocument2 pagesMaximum Residue Levels For Common AnthelminticsAbhinav GuptaNo ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- Speciation of MeatDocument21 pagesSpeciation of MeatAbhinav GuptaNo ratings yet

- New Microsoft Office Word DocumentDocument45 pagesNew Microsoft Office Word DocumentAbhinav GuptaNo ratings yet

- Classification of Low Risk and High Risk Materials Generated in An Abattoir and Its Hygenic DisposalDocument6 pagesClassification of Low Risk and High Risk Materials Generated in An Abattoir and Its Hygenic DisposalAbhinav GuptaNo ratings yet

- Milk Processing 10000 LPDDocument29 pagesMilk Processing 10000 LPDLATHWALBRONo ratings yet

- Horse Vs Cattle Meat, Sheep Vs Goat MeatDocument4 pagesHorse Vs Cattle Meat, Sheep Vs Goat MeatAbhinav GuptaNo ratings yet

- Role of VetDocument4 pagesRole of VetAbhinav GuptaNo ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Milk Hygiene Practice in IndiaDocument4 pagesMilk Hygiene Practice in IndiaAbhinav GuptaNo ratings yet

- Foreign AidDocument4 pagesForeign AidJesse JhangraNo ratings yet

- What Is MotivationDocument6 pagesWhat Is MotivationJohn Paul De GuzmanNo ratings yet

- Surrealismo TriplevDocument13 pagesSurrealismo TriplevVictor LunaNo ratings yet

- Lesson Plans by Noman Niaz MaharDocument3 pagesLesson Plans by Noman Niaz MaharNoman Niaz 13No ratings yet

- Fishblade RPGDocument1 pageFishblade RPGthe_doom_dudeNo ratings yet

- Warren BuffetDocument11 pagesWarren BuffetSopakirite Kuruye-AleleNo ratings yet

- Lesson 5 Classifications of CommunicationDocument48 pagesLesson 5 Classifications of CommunicationRovenick SinggaNo ratings yet

- Contrastive Study of English and Romanian Legal TerminologyDocument39 pagesContrastive Study of English and Romanian Legal TerminologyVictorNo ratings yet

- Fasader I TraDocument56 pagesFasader I TraChristina HanssonNo ratings yet

- Arts, Sciences& Technology University in Lebanon: Clinical Booking WebsiteDocument25 pagesArts, Sciences& Technology University in Lebanon: Clinical Booking WebsiteTony SawmaNo ratings yet

- SriRaghavendra StotraDocument15 pagesSriRaghavendra StotravedanthiNo ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- SCM Software Selection and EvaluationDocument3 pagesSCM Software Selection and EvaluationBhuwneshwar PandayNo ratings yet

- Literature 1 Study GuideDocument7 pagesLiterature 1 Study GuideEs EsNo ratings yet

- 1967 Painting Israeli VallejoDocument1 page1967 Painting Israeli VallejoMiloš CiniburkNo ratings yet

- USD - DPF Cleaning Machine - POSEYDON1000 - PolDocument8 pagesUSD - DPF Cleaning Machine - POSEYDON1000 - PolAbaidi RabieNo ratings yet

- OsteoporosisDocument57 pagesOsteoporosisViviViviNo ratings yet

- KluberDocument20 pagesKluberJako MishyNo ratings yet

- Bruce MoenDocument4 pagesBruce MoenGeorge Stefanakos100% (5)

- Afro Asian LiteratureDocument62 pagesAfro Asian LiteratureNicsyumulNo ratings yet

- 7) Set 3 Bi PT3 (Answer) PDFDocument4 pages7) Set 3 Bi PT3 (Answer) PDFTing ShiangNo ratings yet

- g6 Sws ArgDocument5 pagesg6 Sws Argapi-202727113No ratings yet

- Pathways Rw1 2e U7 TestDocument9 pagesPathways Rw1 2e U7 TestGrace Ann AbanteNo ratings yet

- Coleção Bernoulli Ensino Médio 2020 - 100% BNCC by Bernoulli Sistema de Ensino - IssuuDocument1 pageColeção Bernoulli Ensino Médio 2020 - 100% BNCC by Bernoulli Sistema de Ensino - IssuuVitor OliveiraNo ratings yet

- Sec 4 RA 6713 & Sec 3 RA 3019 OutlineDocument4 pagesSec 4 RA 6713 & Sec 3 RA 3019 OutlineAivan Charles TorresNo ratings yet

- Titanium Plates and Screws For Open Wedge HtoDocument6 pagesTitanium Plates and Screws For Open Wedge HtoDaniel Quijada LucarioNo ratings yet

- Duttaphrynus Melanostictus,: Errata VersionDocument11 pagesDuttaphrynus Melanostictus,: Errata Versionutama 3002No ratings yet

- Unilever BD Recruitment and Selection ProcessDocument34 pagesUnilever BD Recruitment and Selection Processacidreign100% (1)

- 100 Answers To Common English QuestionsDocument9 pages100 Answers To Common English Questionsflemus_1No ratings yet

- Json Cache 1Document5 pagesJson Cache 1Emmanuel AmoahNo ratings yet

- Kepler's ProblemDocument21 pagesKepler's ProblemGustavo MiasatoNo ratings yet

- Surprise-Inside Cakes: Amazing Cakes for Every Occasion—with a Little Something Extra InsideFrom EverandSurprise-Inside Cakes: Amazing Cakes for Every Occasion—with a Little Something Extra InsideRating: 4 out of 5 stars4/5 (6)

- Not That Fancy: Simple Lessons on Living, Loving, Eating, and Dusting Off Your BootsFrom EverandNot That Fancy: Simple Lessons on Living, Loving, Eating, and Dusting Off Your BootsNo ratings yet

- The Obesity Code: Unlocking the Secrets of Weight LossFrom EverandThe Obesity Code: Unlocking the Secrets of Weight LossRating: 5 out of 5 stars5/5 (4)

- Body Love Every Day: Choose Your Life-Changing 21-Day Path to Food FreedomFrom EverandBody Love Every Day: Choose Your Life-Changing 21-Day Path to Food FreedomRating: 4 out of 5 stars4/5 (1)

- Waiter Rant: Thanks for the Tip—Confessions of a Cynical WaiterFrom EverandWaiter Rant: Thanks for the Tip—Confessions of a Cynical WaiterRating: 3.5 out of 5 stars3.5/5 (487)

- Saved By Soup: More Than 100 Delicious Low-Fat Soups To Eat And Enjoy Every DayFrom EverandSaved By Soup: More Than 100 Delicious Low-Fat Soups To Eat And Enjoy Every DayRating: 4 out of 5 stars4/5 (10)