Professional Documents

Culture Documents

Specification FOR Sprockets For Sugar Industry .: Indian Standard

Uploaded by

Shrinivas BartakkeOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Specification FOR Sprockets For Sugar Industry .: Indian Standard

Uploaded by

Shrinivas BartakkeCopyright:

Available Formats

UDC 621.85’051 : 5 : 664.

1 IS: 12199 - 1987

( Reaffirmed 1999 )

Indian Standard

SPECIFICATION FOR

SPROCKETS FOR SUGAR INDUSTRY

.

1. Scope - Specifies materials, dimensions and other requirements for sprockets for bagasse, carrier

cane carrier and feeder table chains used in sugar industry. This standard is applicable for sprocket

of head shaft, tail shaft and idler shaft.

2. Material

2.1 Any of the following materials may be used in the manufacture of sprockets.

2.1.1 Cast steel conforming to Grade 20-40 of IS :1030-1982 ’ Specification for carbon steel casting:

for general engineering purposes ( third revision )‘.

2.1.2 For fabricated steel sprockets, mild steel conforming to IS : 226-1975 ’ Specification fo

structural steel ( standard quality ) ( fifth revision ) ‘, may be used.

3. Terminology -The following definitions shall apply for the purpose of this standard.

3.1 Pitch Diameter - Diameter of the pitch circle that passes through the centres of the link pins as tht

chain is wrapped on the sprocket.

Chain pitch

Therefore, the pitch diameter =

Sin ( 180” + Number of teeth )

3.2 Bottom Diameter - Diameter of a circle tangent to the curve, called the seating curve, at the

bottom of the tooth gap. It is equivalent to the pitch diameter minus the diameter of the roller.

3.3 Outside Diameter - Diameter of the tips of teeth and is

= Chain pitch [ 06 + Cot ( 180” i Number of teeth) ]

I. Dimensions

1.1 The bore of the sprocket shall be to suit the diameter of the solid shaft on which the sprocket is

:o be fitted.

1.2 The sprocket may have 12, 14 or 16 teeth.

1.3 The tooth profile of the sprockets shall be to suit the dimensions of cane carrier chain as specified

n IS : 8465-1977 * Specification for cane carrier chains’ and bagasse carrier chains in accordance with

S : 8466-1977 ’ Specification for bagasse carrier chains’.

1.4 The sprockets shall be to suit 150 mm pitch chain having rollers of 75 mm diameter and 35 mm

ntidth.

1.5 The finished dimensions of the sprockets shall be as given in Table 1.

TABLE 1 DIMENSIONS FOR SPROCKETS

( All dimensions in millimetres. )

SI Chain Number Pitch Out,;de Bottim Skiw;ud Fkapke Bose Sprockets for Sprockets for

No. Pitch of Teeth Dia- . _ I I - Dia- Head Shaft Tail/Idler Shaft

meter meter, meter meter, ness meter ?----h--_- r---&----)

P 0 B S T D Shroud Boss Shroud Boss

Width, Width, Width, Width,

W G W G

(1) (2) (3) (4) (5) (6) (7) (8) (9) (10) (11) (12) (13)

i) 150 12 579’6 649’8 504’6 485 32’0 280 45 100 36 80

ii) 150 14 674’1 747’1 599.1 580 32’0 300 45 100 36 80

ii) 150 16 768’9 844’0 693.9 674 32’0 320 50 110 40 85

Adopted 28 October 1987 0 May 1988, BIS Gr 1

I I

BUREAU OF INDIAN STANDARDS

MANAK BHAVAN, a

BAHADUR SHAH ZAFAR MARG

NEW DELHI 110002

IS: 12198-1987

4.6 Outside diameter and the bottom diameter shall not vary by more than 2: mm and the flange

thickness and shroud width shall not vary by more than fl mm of the values given in Table 1.

5. Other Requirements

5.1 The sprockets-for head shafts shall be keyed to the shaft.

5.2 The sprockets for idler shafts shall be fitted with gun metal bush and shall be free to rotate on the

shaft.

5.3 In case of tail shaft, one sprocket shall be keyed and the other provided with gun metal bush.

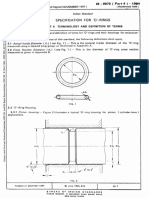

5.4 The sprockets shall have the central boss, The typical shape of the sprockets shall be as given in

Fig. 1.

DETAIL A

FIG. 1 SPROCKET FOR SUGAR INDUSTRY

6. Workmanship and Finish

6.1 The tooth profile ot the sprocket shall be machine cut by a hob milling or hobbing process.

6.2 Other surfaces of the flange and boss of the sprocket shall be machined after casting or fabrication.

as the case may be. There shall be no black spots on the flange faces and the bore of the boss after

machining.

6.3 The cast steel sprockets shall be free from blow holes, pits, burrs and other defects which are

deterimental to its use.

6.4 The fabricated steel sprockets shall be free from blow hole/sundercuts in welding.

6.5 There shall be no sharp edges in the sprockets.

7. Marking

7.1 The following particulars shall be marked on the sprockets:

a) Manufacturer’s name or recognized trade-mark, and

b) Number of teeth.

7.2 Sfandard Marking - Details available with the Bureau of Indian Standards.

8. Packing - As agreed to between the purchaser and the supplier.

9. Sampling for Lot Acceptance -As agreed to between the purchaser and the supplier.

2

Printed at Arcse Press, New Delhi, India

You might also like

- Suction Hose Couplings For Fire Fighting Purposes - SpecificationDocument9 pagesSuction Hose Couplings For Fire Fighting Purposes - SpecificationRakesh SiempuNo ratings yet

- Disclosure To Promote The Right To InformationDocument8 pagesDisclosure To Promote The Right To InformationindeceNo ratings yet

- Disclosure To Promote The Right To InformationDocument8 pagesDisclosure To Promote The Right To InformationBUDAPESNo ratings yet

- Is 7907 1 2004 PDFDocument30 pagesIs 7907 1 2004 PDFAnisVisuNo ratings yet

- Ford Worldwide Fastener Standard: Printed Copies Are UncontrolledDocument7 pagesFord Worldwide Fastener Standard: Printed Copies Are Uncontrolledferhat aydoganNo ratings yet

- Disclosure To Promote The Right To InformationDocument9 pagesDisclosure To Promote The Right To Informationharpreet singhNo ratings yet

- 723 Steel Countersunk Head Wire NailsDocument6 pages723 Steel Countersunk Head Wire NailszahoorNo ratings yet

- Belt Pulley Is.3142.1993 PDFDocument14 pagesBelt Pulley Is.3142.1993 PDFchidambaram kasiNo ratings yet

- Is 13517 1992 PDFDocument9 pagesIs 13517 1992 PDFIndira BanerjeeNo ratings yet

- M 269-96 (2008) (Turnbuckles and Shackles)Document25 pagesM 269-96 (2008) (Turnbuckles and Shackles)tran_lamNo ratings yet

- Gears-Cylindricalgears: (First Revision)Document3 pagesGears-Cylindricalgears: (First Revision)venothNo ratings yet

- Impervious Graphite Pipe and Threading: Standard Specification ForDocument3 pagesImpervious Graphite Pipe and Threading: Standard Specification ForLabeed ShamilNo ratings yet

- Astm C662Document3 pagesAstm C662정호철No ratings yet

- Steel Bars, Round and Square For Structural and General Engineering Purposes-DimensionsDocument6 pagesSteel Bars, Round and Square For Structural and General Engineering Purposes-DimensionsMADHUSHALININo ratings yet

- Comparison Sheet Final FFTG Laundry - BOQ - Eros Hotel 240519Document9 pagesComparison Sheet Final FFTG Laundry - BOQ - Eros Hotel 240519Raja KrsNo ratings yet

- Disclosure To Promote The Right To InformationDocument14 pagesDisclosure To Promote The Right To Informationkom1984No ratings yet

- Indian Stondurd Specification For Galvanized Steel Barbed Wire For Fencing (Third Revision)Document8 pagesIndian Stondurd Specification For Galvanized Steel Barbed Wire For Fencing (Third Revision)Muthusamy ArumugamNo ratings yet

- Is 7170 1989Document11 pagesIs 7170 1989Abhey DograNo ratings yet

- Is 15630 2005 PDFDocument11 pagesIs 15630 2005 PDFashishjawale7No ratings yet

- Is 1364 PDFDocument12 pagesIs 1364 PDFpRAVIN0% (1)

- CADENA EXCAVADORA HD UCFN10-008b - ARDocument4 pagesCADENA EXCAVADORA HD UCFN10-008b - ARGlcc WarezNo ratings yet

- Nyloc Nut Is 7002 PDFDocument11 pagesNyloc Nut Is 7002 PDFsanjibkrjana0% (1)

- Is.7887.1992-Mild Steel Wire Rods PDFDocument11 pagesIs.7887.1992-Mild Steel Wire Rods PDFashish19851No ratings yet

- Is 2830 - 2012Document13 pagesIs 2830 - 2012Arthanari VaidyanathanNo ratings yet

- Is 1691 1980 PDFDocument12 pagesIs 1691 1980 PDFRINJU VINNo ratings yet

- Hilti Drilling Screw DocumentDocument8 pagesHilti Drilling Screw DocumentGregory Alan Francisco IINo ratings yet

- IS 8856 1991 - Hexagon Weld Nuts PDFDocument12 pagesIS 8856 1991 - Hexagon Weld Nuts PDFDheeraj Chavan100% (1)

- WC - Is 12817Document10 pagesWC - Is 12817SanthoshKumarSharmaCHNo ratings yet

- Is.12262.1988 Steel Wire For Spring WashersDocument7 pagesIs.12262.1988 Steel Wire For Spring WashersPaviter SinghNo ratings yet

- C662-70 (2010) Standard Specification For Impervious Graphite Pipe and ThreadingDocument4 pagesC662-70 (2010) Standard Specification For Impervious Graphite Pipe and Threadingastewayb_964354182No ratings yet

- Materi Bimtek SOP PI Girder - PT WBPDocument69 pagesMateri Bimtek SOP PI Girder - PT WBPRiyanto Rivky100% (1)

- Concrete Construction Article PDF - The Impact of Metric Rebar ConversionDocument3 pagesConcrete Construction Article PDF - The Impact of Metric Rebar Conversionanthony santidadNo ratings yet

- Self Drilling Screws Fasteners Product Data 1673386Document8 pagesSelf Drilling Screws Fasteners Product Data 1673386Fabio Saraiva BoxNo ratings yet

- Hotrolledsteel "BE-Ai:I't Rri - Li) 1998" Parallelflangebeam Sections-DimensionsDocument7 pagesHotrolledsteel "BE-Ai:I't Rri - Li) 1998" Parallelflangebeam Sections-DimensionsKekeNo ratings yet

- Is 8023 1991Document10 pagesIs 8023 1991rohanmanimaniNo ratings yet

- ภาพถ่ายหน้าจอ 2567-01-06 เวลา 12.21.58Document122 pagesภาพถ่ายหน้าจอ 2567-01-06 เวลา 12.21.58จีรพจน์ ไทรทองคำNo ratings yet

- Is 3524 1 1982Document6 pagesIs 3524 1 1982suresh muthuramanNo ratings yet

- Is.12778.2004 0 PDFDocument20 pagesIs.12778.2004 0 PDFPhanindra AttadaNo ratings yet

- Static Shaft Pulleys With Internal BearingsDocument14 pagesStatic Shaft Pulleys With Internal Bearingsjonodo89100% (1)

- Nut Bolt 812Document31 pagesNut Bolt 812shashank shahNo ratings yet

- Plywood Tea-Chests-Specification: FifthDocument7 pagesPlywood Tea-Chests-Specification: Fifthrittu beheraNo ratings yet

- Corrugated Sheets: 10.1 General RemarksDocument12 pagesCorrugated Sheets: 10.1 General RemarksRannie IsonNo ratings yet

- CJ Generalrequirementsfor Vibratorsformassconcreting, ImmersiontypeDocument5 pagesCJ Generalrequirementsfor Vibratorsformassconcreting, ImmersiontypeRahul ChaudharyNo ratings yet

- 9975 4 PDFDocument4 pages9975 4 PDFSenthil Kumar GanesanNo ratings yet

- Impervious Graphite Pipe and Threading: Standard Specification ForDocument4 pagesImpervious Graphite Pipe and Threading: Standard Specification ForLabeed ShamilNo ratings yet

- 9975 4 PDFDocument4 pages9975 4 PDFSenthil Kumar GanesanNo ratings yet

- Diameter ( (See: Indian StandardDocument4 pagesDiameter ( (See: Indian StandardSenthil Kumar GanesanNo ratings yet

- Disclosure To Promote The Right To InformationDocument32 pagesDisclosure To Promote The Right To InformationByndy95No ratings yet

- 02 Jaulas de Agujas PDFDocument52 pages02 Jaulas de Agujas PDFRodrigo Schaider Dos SantosNo ratings yet

- Surface Vehicle Standard: InternationalDocument45 pagesSurface Vehicle Standard: InternationalshivendrakumarNo ratings yet

- Disclosure To Promote The Right To InformationDocument10 pagesDisclosure To Promote The Right To InformationGanesh DixitNo ratings yet

- Disclosure To Promote The Right To InformationDocument11 pagesDisclosure To Promote The Right To InformationAtendra SinghNo ratings yet

- IS 3803-2-1989 Steel Conversion of Elongation Values - Part-2 Austenitic SteelsDocument35 pagesIS 3803-2-1989 Steel Conversion of Elongation Values - Part-2 Austenitic SteelsAnwarul AfrojNo ratings yet

- Ti SPC Ohe Fasteners 0120 PDFDocument31 pagesTi SPC Ohe Fasteners 0120 PDFCounter RoverNo ratings yet

- Fasteners Part-3 Is.1369.1.1993Document9 pagesFasteners Part-3 Is.1369.1.1993Manish ThakurNo ratings yet

- Is 7452Document15 pagesIs 7452RishabhNo ratings yet

- IS-12101-Roller Type Hold BackDocument5 pagesIS-12101-Roller Type Hold BackShrinivas BartakkeNo ratings yet

- Is 3443 Crane RailsDocument18 pagesIs 3443 Crane RailsramyaNo ratings yet

- Figures of Speech PDFDocument24 pagesFigures of Speech PDFShrinivas BartakkeNo ratings yet

- Is 4000 High Strength Bolts in Steel Structures-Code of Prac.183134814Document15 pagesIs 4000 High Strength Bolts in Steel Structures-Code of Prac.183134814Narayan RoyNo ratings yet

- Figures of Speech PDFDocument24 pagesFigures of Speech PDFShrinivas BartakkeNo ratings yet

- Figures of Speech PDFDocument24 pagesFigures of Speech PDFShrinivas BartakkeNo ratings yet

- En Masse Conveyor Manual: Safety Installation Operation MaintenanceDocument38 pagesEn Masse Conveyor Manual: Safety Installation Operation MaintenanceShrinivas BartakkeNo ratings yet

- Is 808-1989 Steel TableDocument24 pagesIs 808-1989 Steel TableAtul Kumar Engineer86% (28)

- En Masse Conveyor Manual: Safety Installation Operation MaintenanceDocument38 pagesEn Masse Conveyor Manual: Safety Installation Operation MaintenanceShrinivas BartakkeNo ratings yet

- En Masse Conveyor Manual: Safety Installation Operation MaintenanceDocument38 pagesEn Masse Conveyor Manual: Safety Installation Operation MaintenanceShrinivas BartakkeNo ratings yet

- Thruster - Ed SibreDocument1 pageThruster - Ed SibreShrinivas BartakkeNo ratings yet

- Disc Brake Coupling - Bubenzer K - eDocument4 pagesDisc Brake Coupling - Bubenzer K - eShrinivas BartakkeNo ratings yet

- VOID-Textile LowResDocument24 pagesVOID-Textile LowResShrinivas BartakkeNo ratings yet

- Textile Conveyor BeltsDocument24 pagesTextile Conveyor BeltsShrinivas Bartakke100% (1)

- Conveyor BeltDocument5 pagesConveyor BeltrajeevkumarrajeevNo ratings yet

- Sparse ArrayDocument2 pagesSparse ArrayzulkoNo ratings yet

- 50 Hotelierstalk MinDocument16 pages50 Hotelierstalk MinPadma SanthoshNo ratings yet

- Sample Pilots ChecklistDocument2 pagesSample Pilots ChecklistKin kei MannNo ratings yet

- q2 Long Quiz 002 EntreDocument8 pagesq2 Long Quiz 002 EntreMonn Justine Sabido0% (1)

- 3.2.3 Practice - Taking The PSAT (Practice)Document5 pages3.2.3 Practice - Taking The PSAT (Practice)wrighemm200No ratings yet

- Case Chart Complete (Business Law)Document29 pagesCase Chart Complete (Business Law)LimShuLingNo ratings yet

- Organization of Brigada Eskwela Steering and Working CommitteesDocument2 pagesOrganization of Brigada Eskwela Steering and Working CommitteesCherry Lou RiofrirNo ratings yet

- Setup LogDocument221 pagesSetup LogCarlos MendezNo ratings yet

- Management and Entrepreneurship Important QuestionsDocument1 pageManagement and Entrepreneurship Important QuestionslambazNo ratings yet

- Paul S. Adler - Paul Du Gay - Glenn Morgan - Michael Reed (Eds.) - The Oxford Handbook of Sociology, Social Theory, and Organization Studies - Contemporary Currents-Oxford University Press, USA (2014)Document817 pagesPaul S. Adler - Paul Du Gay - Glenn Morgan - Michael Reed (Eds.) - The Oxford Handbook of Sociology, Social Theory, and Organization Studies - Contemporary Currents-Oxford University Press, USA (2014)Andreea Dobrita67% (3)

- RFBT - Law On Sales Cont. Week 11Document1 pageRFBT - Law On Sales Cont. Week 11Jennela VeraNo ratings yet

- Document 20Document3 pagesDocument 20api-586815209No ratings yet

- Notes On Mass and Energy Balances For Membranes 2007 PDFDocument83 pagesNotes On Mass and Energy Balances For Membranes 2007 PDFM TNo ratings yet

- Nxivm: 2nd Superseding IndictmentDocument32 pagesNxivm: 2nd Superseding IndictmentTony Ortega100% (2)

- 3.1-7 Printer Deployment - Copy (Full Permission)Document18 pages3.1-7 Printer Deployment - Copy (Full Permission)Hanzel NietesNo ratings yet

- Hi 3 Yt 318201Document3 pagesHi 3 Yt 318201partha khatuaNo ratings yet

- Manual MIB 303S-13/33Document58 pagesManual MIB 303S-13/33Daniel Machado100% (1)

- Indian Consumer - Goldman Sachs ReportDocument22 pagesIndian Consumer - Goldman Sachs Reporthvsboua100% (1)

- Millets: Future of Food & FarmingDocument16 pagesMillets: Future of Food & FarmingKIRAN100% (2)

- Oil Refinery OpsDocument3 pagesOil Refinery OpsPhiPhiNo ratings yet

- Median FilteringDocument30 pagesMedian FilteringK.R.RaguramNo ratings yet

- Wilo49608 Wilo Ge LeafletDocument46 pagesWilo49608 Wilo Ge LeafletJair Jimenez HerreraNo ratings yet

- PFMEA Reference Card PDFDocument2 pagesPFMEA Reference Card PDFRajesh Yadav100% (5)

- Dolby Atmos Specifications PDFDocument24 pagesDolby Atmos Specifications PDFVanya ValdovinosNo ratings yet

- FC2060Document10 pagesFC2060esnNo ratings yet

- Carpio V ValmonteDocument2 pagesCarpio V ValmonteErvin John Reyes100% (2)

- Basic Details: Government Eprocurement SystemDocument4 pagesBasic Details: Government Eprocurement SystemNhai VijayawadaNo ratings yet

- VKC Group of Companies Industry ProfileDocument5 pagesVKC Group of Companies Industry ProfilePavithraPramodNo ratings yet

- Deep Sea Electronics PLC: DSE103 MKII Speed Switch PC Configuration Suite LiteDocument14 pagesDeep Sea Electronics PLC: DSE103 MKII Speed Switch PC Configuration Suite LiteMostafa ShannaNo ratings yet

- The Financing Cycle Summary, Case Study, AssignmentsDocument18 pagesThe Financing Cycle Summary, Case Study, AssignmentsbernadetteNo ratings yet