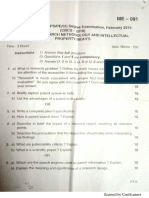

Professional Documents

Culture Documents

Chapter 4 Illu PDF

Chapter 4 Illu PDF

Uploaded by

Sindhu V M0 ratings0% found this document useful (0 votes)

13 views26 pagesOriginal Title

chapter 4 illu.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

13 views26 pagesChapter 4 Illu PDF

Chapter 4 Illu PDF

Uploaded by

Sindhu V MCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 26

4p) 1820 ston®.hersied_stisceinereal act Kal

A Giefiacs Weadle. CA tre lesteradd bey Corrente 1

7

4p 19255 t2gni@e

14 possible sto. reeagre Currebpt pie Gn Ga wite

mm purge 0D. _dowelneed ber st

elecire naaghet: i

ye:

ce OD elecric Current bat could ibe

7

I: |

wected on golvanoreetéSi = -

athe “hist axernpt Of mats ba apenas

mas _peade try warren clelq— rule int

120-1842 Klumeroue dupe apenas

4in 1260.- &clison as planted ol poles Sree ea

bigh siear piezance coven filament —UOCE ene OCC tap larop—

| ke plerammaAinated bid heus ipcand: > saiiaiinnesiiad

‘

| acters atk mento pai slenizerBeey

aubough €cliaon cidn’t Towent port incarcies

cent lorp. be did invent. “the. | pindt_pracsical a

sncanclescent Larmp— & power _Systern?. that Usos.

Suitable pes _nouttip ple. _ dtéiri bution! pve lange—

aneag* “th: 1B comeciemciol Gppit.casion—O5-

gincan.des.cengteimp_tisas_ap—lhe—pisacns P+

Colne eia- fous duparmog. wene. tome Ob

284 1280 | & ppesiated 11 taro Op tb.

>

Colvin bia.

i a !

AA

Larmp saturces i oe

wg “corns geno _

i tous proscar ge ES SUFE FROITE

£0015 MSC barge —$— c

Bx 7-fluroscent, larop,, Bk haere y VeRSe

Lp Sediucn Vapour Larp- Lip Sedliars Vapour

dover. ke

¥

a a

P| = SupraRT WIRES

S[EAD- 1d WIRES.

aU

“IE wige EyTTON

i STEACO pee. —

lise ll

usnsT La fA Se ne a1 _DEFLe CIOR

fet Wis fuse

Bote

i Ft Ge cande scent lampt

beaticg “a_crirt or lament “to_-bigh =tenop— _tabich

causes the tsire to! inGandesc!

pee (glow).

he frramleserca jn ubire Mesut

: Of tk &_snesisiay

Wine i

oz.

| Enctasare Fouts) = [08-03-2016 -

- = |

the dintb are glo enveloped 12 Used

Antatt® & hishe cae i

rope Of 2512 oa> less cone pacts lara pRB,

Wbich ame designate 4 dype B ae

|____ Batisg_onecige " apcignatet O¢Ceeicdti, be __

Shape a of the eoclosive. : z _

—c_-2 Cane ca 3 Decor

= Straight 6 > Standard _

P > Plar [tr embuldt Hemitne - line type —

Pweg —

Joua apim 10 S10} MpUODTUNS>

maskex Ane eae 1

acid prekod Tee se a A wizie [

bowl (osy Sinrer” dou. —~y

. |

. ‘i

= 7 mas : _ a

i i ‘ i i 1 fel t|

| as wb gues Visible light increase: sai

ti ad GUS Op

= ¢ 34le -teroP ss

| seeap! cours 4 ere —untboua tbe. Uipe. btming|

| inn shoot _&% —Stacti ation 'e picfent shus increas

-tne ctisadvantage _?, rk. J@s Conduct

heace_auiaagy—froraHee _prlanert eh iCb FeducerL

overall Do rop. 2 btCLency L

c jgeneraild Lager, i2 Achaans age for LL

oe I z i. aa ‘on. LET

x pechoia,tie: a= : =e

ahere Ore 3 Ptibod2 Ob Conshucsy used

dandesd range: Saditechdtéerdk kemien

EleCkrical Conneci on:

: the base” prcavicte

impene cago tyes ob Hnses

o> cere type oe

b> Seren rit ening Contacts

cy SKiared sere :

d> Bipost

- € pre focus ~ —

4) ise 7

Arscancta cent_1risp hava _em_auenage Cpe

$p21_ tooobors 609 Gbove_5 reabib jos typical]

a ee 4

dead

t C ond. at Lge ances ane

| pes: i192 aoe SoeeeGeee, Hee

| __larop— -U}e ts a fonction 9 many fectora

| 2netreling kllarncht _Conpiguration _£:_ Suppastt,— F

b fi Qa —op_of -Cyclis § _uaattages. 7 __

a ,

: i

4

a %

[ thi receioD 26 stecilar to —those,

hig_expre Fi i

. Lenser Cherent of 2 giNem nacserias| iy

[ prec0eeg ete >

Under saved Condition

i

iat

exp ‘the pea unit _aaeo_is arst hen |

did ome Rarneter B.

it

re e ay 7 7 tei y

se Lumen ‘otp & tidy & lad fa

32 Abid

Cla Ge iE

ais 4

1A

Lilede =

oe Qeienes —anetpilt 221 propetitional tog |

a) tt bee, bere 1 aac _tongtha, |)

324 wo Ch) + dey

[6 2'.200 Cha) :

had

fy 2 2b |

e pare Pa eee ae

[pe

[dps _o-0cs }

o fs *

eo

= (tate 2ely |

| ell gp! incandescent _tomp_has—a filament of _el=n-

liz in s1egduivedt to Cory Bru Ce

£2 Ace tength

Oyuiben_lame of; Steotlan ype tn natietss— attest

pe Buse & i eo) candle pommer |

date i at

3 F

L> lovcrn 1

|

4 G22 £ See a

idiengity Peat ;

ti>2 _ God’ Leole i|

ai ee

(Lbs ett | B

|

sine — ian

Power intake y' iV -

fr a] taanp (32)

= = a

pa ies leet

ee .

j (ney aR i a

bts

I :

Lo dys 0+3968 dy

dae ossaee (0-008) 21-484 x10°% Cm

ag it db 2 'Or CONIA Cory.

C=toro w= lb tan 8

t =

Io £08 1S

i aaa

[eens | + —_____

Surface argo, 4 2 Tr*

: mx Cr 3t6)* |

& §-44m? |

iiieineeedaal

wrbile Cer rent Apernaches in th pif-ty ise —___

ts Ele, eco then Tow.

4 without Adevice:to Lint the Current the

Cleckinde& touid burn up within A naalter Of

Second SHiemapimtl yaut_gatenrst_clischionge Sosenity

| eauime ia Seale Sot

| -

R39 esitchamiy functions.

oy inate Hye Curtemt $$$,

2)__pmovicieR a Stating Vottage Kick

{O3) provide — power foctom Casi mecsion

Burning positi

J GaSsQous cischarge lamp are usally

Sensitive Ap burning -pasition. 44 “the fampg

JaMe oem. ed tin _a_position_ctbes than injende”

se, Suen Otrtect targe-- he. Calatya—cl. [es Cars ___

lamp2 “ane *s

mi). 4% pouct be chernicatiy st

At mist “Sup xe. eva poma:tion Siipamm ebpicitet

oA). St toist be ay.

Electroluminescence:-

Electroluminescence (EL) is an optical phenomenon and electrical

phenomenon in which a material emits light in response to the passage of

an electric current or to a strong electric field. This is distinct from black

body light emission resulting from heat (incandescence), a chemical reaction

(chemi-luminescence), sound (sono-luminescence), or other mechanical action

(mechano-luminescence).

Mechanism

|

; | !

i /

ree inrenen

Spectrum of a blue/green electroluminescent light source for a clock

radio (similar to the one seen in the above image). Peak wavelength is at

492 nm and the FWHM spectral bandwidth is quite wide at about 85 nm.

Electroluminescence is the result of radiative

recombination of electrons & holes in a material, usually a semiconductor. The

excited electrons release their energy as photons - light.

Prior to recombination, electrons and holes may be separated either

by doping the material to form a p-n junction (in semiconductor

electroluminescent devices such as light-emitting diodes) or through excitation

by impact of high-energy electrons accelerated by a strong electric field (as

with the phosphors in electroluminescent displays).

It has been recently shown that as a solar cell improves its light-to-

electricity efficiency (improved open-circuit voltage), it will also improve its

electricity-to-light (EL) efficiency.

Electroluminescent devices are fabricated using either organic or

inorganic electroluminescent materials. The active materials are generally

semiconductors of wide enough bandwidth to allow exit of the light.

The most typical inorganic thin-film EL (TFEL) is ZnS:Mn with yellow-orange

emission.

Examples of the range of EL material include:

+ Powdered zinc sulfide doped with copper (producing greenish light)

or silver (producing bright blue light)

+ Thin-film zinc sulfide doped with manganese (producing orange-red color)

+ Naturally blue diamond, which includes a trace of boron that acts as a

dopant.

+ Semiconductors containing Group Ill and Group V elements, such as indium

phosphide (InP), gallium arsenide (GaAs), and gallium nitride (GaN) (Light-

emitting diodes.)

¢ Certain organic semiconductors, such as [Ru(bpy)3]**(PFe")2, where bpy is

2,2'-bipyridine

Practical implementations

The most common electroluminescent (EL) devices are composed of

either powder (primarily used in lighting applications) or thin films (for

information displays.)

LEC

Light-emitting capacitor, or LEC, is a term used since at least 1961 to

describe electroluminescent panels. General Electric has patents dating to 1938

on flat electroluminescent panels that are still made as night lights and

backlights for instrument panel displays. Electroluminescent panels are

a capacitor where the dielectric between the outside plates is a phosphor that

gives off photons when the capacitor is charged. By making one of the contacts

transparent, the large area exposed emits light.

Electroluminescent automotive instrument panel backlighting, with each

gauge pointer also an individual light source, entered production on 1960

Pree’. 8 ‘

Chrysler and Imperial passenger cars, and was continued successfully on

several Chrysler vehicles through 1967.

Night lamps

Sylvania Lighting Division in Salem and Danvers, MA, produced and

marketed an EL night lamp (right), under the trade name Panelescent at

roughly the same time that the Chrysler instrument panels entered production.

These lamps have proven extremely reliable, with some samples known to be

still functional after nearly 50 years of continuous operation. Later in the

1960s, Sylvania's Electronic Systems Division in Needham, MA developed and

manufactured several instruments for the Apollo Lunar Lander and Command

Module using electroluminescent display panels manufactured by the

Electronic Tube Division of Sylvania at Emporium, PA. Raytheon, Sudbury, MA,

manufactured the Apollo guidance computer, which used a Sylvania

electroluminescent display panel as part of its display-keyboard interface

(DSKY).

Backlight

aero

A Casio digital LCD watch with an electroluminescent backlight.

Powder phosphor-based electroluminescent panels are frequently used

as backlights for liquid crystal displays. They readily provide gentle, even

illumination for the entire display while consuming relatively little electric

power. This makes them convenient for battery-operated devices such as

pagers, wristwatches, and computer-controlled thermostats, and their gentle

green-cyan glow is common in the technological world. They require relatively

high voltage (between 60 and 600 volts). For battery-operated devices, this

voltage must be generated by a converter circuit within the device. This

converter often makes an audible whine or siren sound while the backlight is

activated. For line-voltage-operated devices, it may be supplied directly from

the power line. Electroluminescent nightlights operate in this fashion.

Brightness per unit area increases with increased voltage and frequency.

Thin film phosphor electroluminescence was first commercialized during

the 1980s by Sharp Corporation in Japan, Finlux (Oy Lohja Ab) in Finland,

and Planar Systems in the US. In these devices, bright, long-life light emission is

achieved in thin film yellow-emitting manganese-doped zinc sulfide material.

Displays using this technology were manufactured for medical and vehicle

applications where ruggedness and wide viewing angles were crucial, and

liquid crystal displays were not well developed. In 1992, Timex introduced

its Indiglo EL display on some watches.

Recently, blue-, red-, and green-emitting thin film electroluminescent

materials that offer the potential for long life and full color electroluminescent

displays have been developed.

In either case, the EL material must be enclosed between two electrodes

and at least one electrode must be transparent to allow escape of the

produced light. Glass coated with indium tin oxide is commonly used as the

front (transparent) electrode while the back electrode is coated with reflective

metal. Additionally, other transparent conducting materials, such as carbon

nanotube coatings or PEDOT can be used as the front electrode.

The display applications are primarily passive (je., voltages are driven

from edge of the display cf. driven from a transistor on the display). Similar to

LCD trends, there have also been Active Matrix EL (AMEL) displays

demonstrated, where circuitry is added to prolong voltages at each pixel. The

solid-state nature of TFEL allows for a very rugged and high-resolution display

fabricated even on silicon substrates. AMEL displays of 1280x1024 at over 1000

lines per inch (Ipi) have been demonstrated by a consortium including Planar

Systems.

Fhe world's first electroluminescent billboard campaign, Canada, Winter 2005

Electroluminescent technologies have low power consumption compared

to competing lighting technologies, such as neon or fluorescent lamps. This,

together with the thinness of the material, has made EL technology valuable to

the advertising industry. Relevant advertising applications include

electroluminescent billboards and signs. EL manufacturers are able to control

precisely which areas of an electroluminescent sheet illuminate, and when.

This has given advertisers the ability to create more dynamic advertising that is

still compatible with traditional advertising spaces.

An EL film is a so-called Lambertian radiator: unlike with neon lamps,

filament lamps, or LEDs, the brightness of the surface appears the same from

all angles of view; electroluminescent light is not directional and therefore hard

to compare with (thermal) light sources measured in lumens or lux. The light

emitted from the surface is perfectly homogeneous and is well-perceived by

the eye. EL film produces single-frequency (monochromatic) light that has a

very narrow bandwidth, is absolutely uniform and visible from a great distance.

Bk

1966 Dodge Charger instrument panel with electroluminescent

lighting. Chrysler first introduced cars with EL panel lighting in its 1960 model

year.

In principle, EL lamps can be made in any color, However, the commonly

used greenish color closely matches the peak sensitivity of human vision,

producing the greatest apparent light output for the least electrical power

input. Unlike neon and fluorescent lamps, EL lamps are not negative

resistance devices so no extra circuitry is needed to regulate the amount of

current flowing through them. A new technology now being used is based on

multispectral phosphors that emit light from 600 to 400nm depending on the

drive frequency; this is similar to the colour changing effect seen with aqua EL

sheet but on a larger scale.

Electroluminescent lighting is now used as an application for public safety

identification involving alphanumeric characters on the roof of vehicles for

clear visibility from an aerial perspective.

Electroluminescent lighting, especially electroluminescent wire (EL wire),

has also made its way into clothing as many designers have brought this

technology to the entertainment and night life industry.

Engineers have developed an electroluminescent "skin" that can stretch

more than six times its original size while still emitting light. This hyper-elastic

light-emitting capacitor (HLEC) can endure more than twice the strain of

previously tested stretchable displays. It consists of layers of transparent

hydrogel electrodes sandwiching an insulating elastomer sheet. The elastomer

changes luminance and capacitance when stretched, rolled and otherwise

deformed. In addition to its ability to emit light under a strain of greater than

480% its original size, the group's HLEC was shown to be capable of being

integrated into a soft robotic system. Three six-layer HLEC panels were bound

together to form a crawling soft robot, with the top four layers making up the

light-up skin and the bottom two the pneumatic actuators. The discovery could

lead to significant advances in health care, transportation, electronic

communication and other areas.

Construction and Working Principle of LCD Display

What is an LCD (Liquid Crystal Display)?

A liquid crystal display or LCD draws its definition from its name itself. It is

a combination of two states of matter, the solid and the liquid. LCD uses a liquid

crystal to produce a visible image. Liquid crystal displays are super-thin

technology display screens that are generally used in laptop computer screens,

‘TVs, cell phones and portable video games. LCD’s technologies allow displays to

be much thinner when compared to a cathode ray tube (CRT) technology.

Liquid crystal display is composed of several layers which include two

polarized panel filters and electrodes. LCD technology is used for displaying the

image in a notebook or some other electronic devices like mini computers. Light

;

ig projected from a lens on a layer of liquid crystal. This combination of colored

light with the grayscale image of the crystal (formed as electric current flows

through the crystal) forms the colored image. This image is then displayed on

the screen.

An LCD

‘An LCD is either made up of an active matrix display grid or a passive display

grid. Most of the Smartphone’s with LCD technology uses active matrix display,

but some of the older displays still make use of the passive display grid designs.

Most of the electronic devices mainly depend on liquid crystal display

technology for their display. The liquid has a unique advantage of having low

power consumption than the LED or cathode ray tube.

Liquid crystal display screen works on the principle of blocking light rather

than emitting light. LCDs require a backlight as they do not emit light by them.

We always use devices which are made up of LCD’s displays which are replacing

the use of cathode ray tube. Cathode ray tube draws more power compared to

LCDs and is also heavier and bigger.

How LCDs are Constructed?

eR

eicireaw'ten

MES er»

imple facts that should be considered while making an LCD:

1. The basic structure of the LCD should be controlled by changing the applied

current.

2. We must use polarized light.

3. The liquid crystal should able be to control both of the operations to

transmit or can also able to change the polarized light.

‘As mentioned above that we need to take two polarized glass pieces filter

in the making of the liquid crystal. The glass which does not have a polarized film

on the surface of it must be rubbed with a special polymer that will create

microscopic grooves on the surface of the polarized glass filter. The grooves

must be in the same direction as the polarized film. Now we have to add a

coating of pneumatic liquid phase crystal on one of the polarizing filters of the

polarized glass. The microscopic channel causes the first layer molecule to align

with filter orientation. When the right angle appears at the first layer piece, we

should add a second piece of glass with the polarized film. The first filter will be

naturally polarized as the light strikes it at the starting stage.

Thus the light travels through each layer and guided on the next with the

help of a molecule. The molecule tends to change its plane of vibration of the

light to match its angle. When the light reaches the far end of the liquid crystal

substance, it vibrates at the same angle as that of the final layer of the molecule

vibrates. The light is allowed to enter into the device only if the second layer of

the polarized glass matches with the final layer of the molecule.

How LCDs Work?

The principle behind the LCD’s is that when an electrical current is applied

to the liquid crystal molecule, the molecule tends to untwist. This causes the

angle of light which is passing through the molecule of the polarized glass and

also cause a change in the angle of the top polarizing filter. As a result, a little

light is allowed to pass the polarized glass through a particular area of the LCD.

Thus that particular area will become dark compared to others. The LCD works

onthe principle of blocking light. While constructing the LCD’s, a reflected mirror

is arranged at the back. An electrode plane is made of indium-tin-oxide which is

gent on top and a polarized glass with a polarizing qq

Fe ng film js

' pottom of the device. The complete region of the is also added on the

7 LCD has to

common electrode and above it should be the liquid crystal sin enclosed bya

er,

Next comes the second piece of glass with an el

rectangle on the bottom and, on top,

considered that both the pieces are kept

current, the light passes through the fron!

‘ectrode in the form of the

another Polarizing film. it must be

at the right angles. When there is no

it of the LCD it will be reflected by the

mirror and bounced back. As the electrode is connected to a battery the current

from it will cause the liquid crystals between the common-plane electrode and

the electrode shaped like a rectangle to untwist. Thus the light is blocked from

passing through. That particular rectangular area appears blank.

Advantages of an LCD’s:

+ LCD's consumes less amount of power compared to CRT and LED

+ LCD’s are consist of some microwatts for display in comparison to some mill

watts for LED’s

+ LCDs are of low cost

+ Provides excellent contrast |

+ LCD's are thinner and lighter when compared to cathode-ray tube and LED

Disadvantages of an LCD’s:

+ Require additional light sources

+ Range of temperature is limited for operation

+ Low reliability

+ Speed is very low

+ LCD’s need an AC drive

Applications of Liquid Crystal Display

ions inthe fi ience and

Liquid crystal technology has major applications in the field of sc

engineering as well on electronic devices.

+ Liquid crystal thermometer

+ Optical imaging

+ The liquid crystal display technology is alse app!

the radio frequency waves in the waveguide

Used in the medical applications

licable in the visualization of

LCD illumination

When it comes to LCD illumination there are three types.

Reflective - The display is illuminated by light that is reflected off of the LCD

backplane.

Transflective - The display is illuminated by either reflected light or a

backlight.

Transmissive - The display is illuminated by a backlight

rs

SS

ii

Reflective Transflective Transmissive

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5808)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (843)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (346)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Power System ControlsDocument10 pagesPower System ControlsSindhu V MNo ratings yet

- Research Methodology and Intellectual Property RightsDocument2 pagesResearch Methodology and Intellectual Property RightsSindhu V MNo ratings yet

- Advanced Digital Signal Processing (ADSP) For Decreasing Power DissipationDocument4 pagesAdvanced Digital Signal Processing (ADSP) For Decreasing Power DissipationSindhu V MNo ratings yet

- Candidate Copy Bank Copy: Beneficiary Account No Beneficiary Account NoDocument1 pageCandidate Copy Bank Copy: Beneficiary Account No Beneficiary Account NoSindhu V MNo ratings yet

- Sindhu.v (17gaee7092) PDFDocument20 pagesSindhu.v (17gaee7092) PDFSindhu V MNo ratings yet

- Surge Current Protection Using Superconductors: Sindhu VDocument23 pagesSurge Current Protection Using Superconductors: Sindhu VSindhu V MNo ratings yet

- Tour ReportDocument15 pagesTour ReportSindhu V MNo ratings yet