0% found this document useful (0 votes)

175 views3 pagesHydrocracking Operations in Refineries

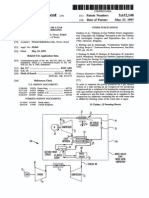

The document summarizes a lecture on hydrocracking operations in petroleum refineries. It discusses the feedstocks and products of hydrocracking, including heavy gas oils producing naphtha, diesel, and other products. It describes the two-stage hydrocracking process using catalysts, hydrogen, heat and pressure to crack heavier molecules. It also outlines the catalyst types used for hydrotreating and hydrocracking, and how operating variables like temperature, pressure and aging affect the process and product selectivity.

Uploaded by

Bipradeep GhoshCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as DOCX, PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

175 views3 pagesHydrocracking Operations in Refineries

The document summarizes a lecture on hydrocracking operations in petroleum refineries. It discusses the feedstocks and products of hydrocracking, including heavy gas oils producing naphtha, diesel, and other products. It describes the two-stage hydrocracking process using catalysts, hydrogen, heat and pressure to crack heavier molecules. It also outlines the catalyst types used for hydrotreating and hydrocracking, and how operating variables like temperature, pressure and aging affect the process and product selectivity.

Uploaded by

Bipradeep GhoshCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as DOCX, PDF, TXT or read online on Scribd