Professional Documents

Culture Documents

ADI Heat Tint Article

Uploaded by

Diogo Roesler MeloCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ADI Heat Tint Article

Uploaded by

Diogo Roesler MeloCopyright:

Available Formats

Bela V.

Kovacs, Sr

Atmosphere Furnace Co/Technical Center

Livonia, MI

It is difficult even for the expert eye to common phases that appear in ADI, desired or

identify the various phases in austempered not.

ductile iron (ADI) on a black and white The most undesirable phase is the

micrograph or during microscopic examination. metastable unreacted retained austenite. It

Austenite, undissolved ferrite and eutectic usually appears in the cell boundary area due to

carbide are all white etching phases in the solute segregation. This austenite is prone to

austempered matrix structure. These phases are martensitic transformation either on cooling to

the most difficult ones to distinguish from each room temperature or when a part is stressed,

other. such as during machining. This austenite is

A simple technique has been developed to represented by the light blue color. Note the

solve this problem. With this technique the dark blue martensite plates embedded in the

various phases appear in different and vibrant light blue austenite. The purple or high carbon

colors under the microscope with excellent austenite in the matrix is stable both

consistency. The procedure for the sample mechanically and thermally. The beige acicular

preparation is the following. ferrite needles are mixed with the purple high

An unmounted ADI sample is polished (or carbon austenite. This combination of phases,

removed from the mount after polishing) and high carbon austenite and acicular ferrite,

etched with 2.4% Nital. The purpose of etching constitutes the desired austempered matrix

is to give definition to the phase boundaries and structure.

not to develop colors. The sample is then heated Massive eutectic carbide particles are

in an oven at about 500F for four to eight hours shown in cream color. Heat tinting is also useful

in air, without protective atmosphere and cooled to detect undissolved ferrite produced by silicon

to room temperature. The sample will appear segregation. This ferrite is stable and is in

dark blue to the naked eye when in it prepared equilibrium with austenite during austenitization,

properly and ready for metallographic thus making austenitization incomplete.

examination. This process is called heat tinting. The above technique is a powerful tool to

Heat tinting is an oxidation process and determine phase distribution accurately in ADI or

causes the various phases to appear in distinct any cast iron. It is simple, inexpensive and

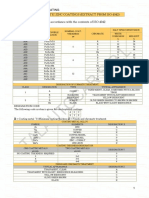

colors. These colors in ADI are: available to any size foundry operation. Toaster

ovens quite often are suitable for heat tinting.

unreacted austenite……………...light blue

reacted high carbon austenite….purple This technique was developed while the

ferrite……………………………....beige author was associated with the research

eutectic carbide…………………..white or cream staff of the Ford Motor Co.

martensite…………………………dark blue

The higher the carbon content in the reacted The author is indebted to L. Bartosiewicz

austenite, the darker the purple color. The for taking the photograph shown in this

carbon content can be estimated in the reacted report.

austenite by its color.

The matrix structure shown in the For a free copy of this article circle No. 314 on

accompanying color micrograph is neither Reader Service Card.

desired nor representative of ADI structure.

However, it is a good illustration of all the

You might also like

- Tint EtchingDocument7 pagesTint EtchingAida LizethNo ratings yet

- Technical Data Sheet: Performa 560Document10 pagesTechnical Data Sheet: Performa 560Diego NavaNo ratings yet

- 1709574-Tds-Dual Name-Bonderite M-MN 117 Known As Bonderite MN 117Document5 pages1709574-Tds-Dual Name-Bonderite M-MN 117 Known As Bonderite MN 117Armas Caselis ErickNo ratings yet

- Tripass ELV 2000Document7 pagesTripass ELV 2000thanh duc LeNo ratings yet

- CCARD Color CardDocument2 pagesCCARD Color CardJonNo ratings yet

- Manual 8XX Titrando ENDocument38 pagesManual 8XX Titrando ENLê Duy ThăngNo ratings yet

- New Concepts Non Cyanide Alkaline ZincDocument35 pagesNew Concepts Non Cyanide Alkaline ZincJOSE ANGEL CARRASCO100% (1)

- TP3937202 1998 C70 ConvertibleDocument152 pagesTP3937202 1998 C70 ConvertibleMk KmNo ratings yet

- Zinc Nickel Electroplating Guide ZyliteDocument9 pagesZinc Nickel Electroplating Guide ZyliteBryan DixNo ratings yet

- RAL Descriptive Colour Chart PDFDocument4 pagesRAL Descriptive Colour Chart PDFArun KumarNo ratings yet

- Liquitex Color Chart Heavy BodyDocument2 pagesLiquitex Color Chart Heavy BodyaleNo ratings yet

- Nickel Electroplating: Power SupplyDocument6 pagesNickel Electroplating: Power Supplyyonathan fausaNo ratings yet

- How To Polish MetalDocument9 pagesHow To Polish Metaldecio ventura rodrigues miraNo ratings yet

- Techseal Silver SL GDocument11 pagesTechseal Silver SL GAnh Quang NgoNo ratings yet

- Preparation of Zinc Alloy Die Castings For ElectroplatingDocument4 pagesPreparation of Zinc Alloy Die Castings For ElectroplatingFrancisco BocanegraNo ratings yet

- Discover the specs of OLA S1 electric scooterDocument6 pagesDiscover the specs of OLA S1 electric scooterYash LokhandeNo ratings yet

- 45 Manufacturing ProcessDocument45 pages45 Manufacturing ProcessOtunba Olakunle Sunday AjayiNo ratings yet

- Plasma Nitriding Process - DataDocument11 pagesPlasma Nitriding Process - Datayadu kumar singhNo ratings yet

- PCB Surface FinishDocument7 pagesPCB Surface FinishEulises QuinteroNo ratings yet

- 2013-09-16 Birkin Track Car Price ListDocument4 pages2013-09-16 Birkin Track Car Price ListxyuxyuxyuNo ratings yet

- Zylite Stabilizer Ds v05Document5 pagesZylite Stabilizer Ds v05Santiago TuestaNo ratings yet

- Etchant Selection Guide (SS Superalloy) 11-2015Document3 pagesEtchant Selection Guide (SS Superalloy) 11-2015Malik Ansar HayatNo ratings yet

- Electrolytic Zinc Coating PDFDocument2 pagesElectrolytic Zinc Coating PDFzoran100% (1)

- ASTM 1148 Solubilidad en AguaDocument3 pagesASTM 1148 Solubilidad en AguaLisNo ratings yet

- DSMTS-0072.5 Cr2O3Document4 pagesDSMTS-0072.5 Cr2O3Remco van den BergNo ratings yet

- SPCCDocument10 pagesSPCCDeepak JainNo ratings yet

- BWS 100 - 2007Document54 pagesBWS 100 - 2007Maxii Yevara100% (1)

- Catalog Italkit 2018-2020 EngDocument340 pagesCatalog Italkit 2018-2020 EngPaul BlokNo ratings yet

- 2006 SW Import ColorBookDocument54 pages2006 SW Import ColorBookfadimtNo ratings yet

- Astm B555-86 (2018)Document5 pagesAstm B555-86 (2018)Reshan Viduranga100% (1)

- Semilux 100 Ds v05Document28 pagesSemilux 100 Ds v05Tran Manh VuNo ratings yet

- Buffoli Booklet - USA PhoscoatingDocument138 pagesBuffoli Booklet - USA PhoscoatingMark GarrettNo ratings yet

- Arkote 31 Epoxy Primer (30608P3250)Document3 pagesArkote 31 Epoxy Primer (30608P3250)akosirhockzNo ratings yet

- Zinc PlatingDocument3 pagesZinc Platingjavier.garcia6281No ratings yet

- Hull Cell ReviewDocument4 pagesHull Cell ReviewR.SubramanianNo ratings yet

- TALAT Lecture 4703: Design and Calculation of Adhesive JointsDocument9 pagesTALAT Lecture 4703: Design and Calculation of Adhesive JointsCORE MaterialsNo ratings yet

- Martensitic TransformationsDocument38 pagesMartensitic TransformationsquitzlcoatlNo ratings yet

- Electroless Ag PlatingDocument4 pagesElectroless Ag PlatingozhedzojhNo ratings yet

- Casting Is A Manufacturing Process by Which A Liquid Material Is (Usually) Poured Into ADocument10 pagesCasting Is A Manufacturing Process by Which A Liquid Material Is (Usually) Poured Into Ajoella_bediaNo ratings yet

- Aluminium and Its Alloys: EF420 Lecture 11 John TaylorDocument48 pagesAluminium and Its Alloys: EF420 Lecture 11 John TaylorzorazhrNo ratings yet

- Plating - Interpharm PDFDocument4 pagesPlating - Interpharm PDFvasudev_nNo ratings yet

- Determination of Sulfate ConcentrationDocument3 pagesDetermination of Sulfate Concentrationm daneshpourNo ratings yet

- Stationery Price ListDocument13 pagesStationery Price ListFitriah MohamadNo ratings yet

- Schaffler DiagramDocument6 pagesSchaffler DiagramNikesh KoliNo ratings yet

- Chromium PlatingDocument66 pagesChromium PlatingManikandan SudharsanNo ratings yet

- UTStudio3 User Guide 2013-07-30Document77 pagesUTStudio3 User Guide 2013-07-30Ramakrishnan AmbiSubbiahNo ratings yet

- Zinc Coatings PDFDocument12 pagesZinc Coatings PDFMuhammadImaduddienSalamNo ratings yet

- Spraying Device LD/U3 Arc Spraying: Parts List PL 96939 EN 09Document16 pagesSpraying Device LD/U3 Arc Spraying: Parts List PL 96939 EN 09a.n.87711990100% (1)

- Grit Size Conversion ChartDocument2 pagesGrit Size Conversion ChartEn Tip100% (2)

- Thermal Spray Materials Guide 022006 PDFDocument176 pagesThermal Spray Materials Guide 022006 PDFHemant BhatnagarNo ratings yet

- Argalux 64 Ds v11Document23 pagesArgalux 64 Ds v11Tran Manh Vu100% (1)

- Yamaha Project ReportDocument19 pagesYamaha Project ReportRohit OberoiNo ratings yet

- Instructions PDFDocument10 pagesInstructions PDFKiss Mátyás JuliánuszNo ratings yet

- Metallographic Printing Methods for Detecting ImpuritiesDocument3 pagesMetallographic Printing Methods for Detecting ImpuritiesAnup Tigga100% (1)

- Powder Coating Guide for Metal FinishingDocument31 pagesPowder Coating Guide for Metal FinishingNikhil OtavanekarNo ratings yet

- 6 Grinding & Other Abrasive ProcessesDocument82 pages6 Grinding & Other Abrasive Processessakali ali100% (1)

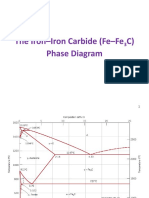

- The Iron-Iron Carbide (Fe-Fe C) Phase DiagramDocument32 pagesThe Iron-Iron Carbide (Fe-Fe C) Phase DiagramNisaNo ratings yet

- EtchingDocument11 pagesEtchingOlgalycos100% (1)

- 2 Iron-Carbon Alloy SystemDocument36 pages2 Iron-Carbon Alloy SystemYour EntertainerNo ratings yet

- This Content Downloaded From 200.129.187.61 On Tue, 02 Aug 2022 12:59:55 UTC:56 UTCDocument4 pagesThis Content Downloaded From 200.129.187.61 On Tue, 02 Aug 2022 12:59:55 UTC:56 UTCGuilherme Dos Santos MoreiraNo ratings yet

- GOST Steels PDFDocument88 pagesGOST Steels PDFDiogo Roesler MeloNo ratings yet

- Heat Treatment of SteelsDocument18 pagesHeat Treatment of SteelsRajeev SaiNo ratings yet

- Severstal Steel Products Catalogue PDFDocument208 pagesSeverstal Steel Products Catalogue PDFDiogo Roesler MeloNo ratings yet

- Heat Treatment of SteelsDocument18 pagesHeat Treatment of SteelsRajeev SaiNo ratings yet

- Sae J412 - General Characteristics and Heat Treatments of SteelsDocument26 pagesSae J412 - General Characteristics and Heat Treatments of SteelsDiogo Roesler Melo0% (1)

- Bachelor's Program Chemical Engineering Academic Year 2021-2022+timeslots 26-08-2021Document1 pageBachelor's Program Chemical Engineering Academic Year 2021-2022+timeslots 26-08-2021rozio32No ratings yet

- Refra EnergíaDocument6 pagesRefra EnergíaRicardor123No ratings yet

- Investment Casting ProcessesDocument10 pagesInvestment Casting ProcessesPragyan Kumar PradhanNo ratings yet

- Capitulo 1 de Libro Heat Exchanger Design HandbookDocument2 pagesCapitulo 1 de Libro Heat Exchanger Design Handbookricva_rjNo ratings yet

- Fracture Mechanics Syllabus PDFDocument4 pagesFracture Mechanics Syllabus PDFPaquita LonddonNo ratings yet

- Technical Sheet EUROSTAR Lightning Protection SystemsDocument2 pagesTechnical Sheet EUROSTAR Lightning Protection SystemsnabaroonNo ratings yet

- The Metallurgy of Power BoilersDocument2 pagesThe Metallurgy of Power Boilersdineshkbunker08No ratings yet

- Flexural Fatigue Characteristics of Pervious Concrete StatisticalDocument15 pagesFlexural Fatigue Characteristics of Pervious Concrete Statisticalangie chaparroNo ratings yet

- ASME B30.2 Lifting LugDocument8 pagesASME B30.2 Lifting LugEliza Nightry De Large100% (1)

- EL NR Blend PU Foam PRIMDocument9 pagesEL NR Blend PU Foam PRIMGlasst Innovacion 2019No ratings yet

- NANO CONCRETE IMPROVES STRENGTH AND DURABILITYDocument31 pagesNANO CONCRETE IMPROVES STRENGTH AND DURABILITYAshish BatraNo ratings yet

- 28 - 2D Seismic Response Analysis of Bridge AbundmentDocument22 pages28 - 2D Seismic Response Analysis of Bridge AbundmentgiselNo ratings yet

- COLUMN SEISMIC DETAILINGDocument20 pagesCOLUMN SEISMIC DETAILINGArnel SalvadorNo ratings yet

- Experiment 1 (Diffusion)Document8 pagesExperiment 1 (Diffusion)James Laurence RavizNo ratings yet

- A K Singh Q P - 12 Odd-2Document2 pagesA K Singh Q P - 12 Odd-2Saurabh SinghNo ratings yet

- Materials For Reformer Furnace Tubes History of EvolutionDocument7 pagesMaterials For Reformer Furnace Tubes History of EvolutionAPI100% (1)

- Strengthening Dapped Ends of Precast Double Tees With Externally Bonded FRP Reinforcement by NanniDocument11 pagesStrengthening Dapped Ends of Precast Double Tees With Externally Bonded FRP Reinforcement by Nannigulilero_yoNo ratings yet

- European Steel and Alloy Grades: About Us EN 10209Document2 pagesEuropean Steel and Alloy Grades: About Us EN 10209farshid KarpasandNo ratings yet

- Quantum Revolution Changed Our UnderstandingDocument56 pagesQuantum Revolution Changed Our Understandinglittleitaly5No ratings yet

- 4 - Rotary DryerDocument24 pages4 - Rotary DryerkhawarNo ratings yet

- DS DMH 400 PomDocument1 pageDS DMH 400 PomESTEFANY DE LOS SANTOSNo ratings yet

- Mcqs Preparation For Engineering Competitive Exams: Peb Beam Welding SystemDocument9 pagesMcqs Preparation For Engineering Competitive Exams: Peb Beam Welding SystemMukul TiwariNo ratings yet

- Polymers and Polymers BlendsDocument51 pagesPolymers and Polymers Blendsziradagreat539No ratings yet

- Basic Concept of Tra Fop Rot NDocument69 pagesBasic Concept of Tra Fop Rot NRanjith KumarNo ratings yet

- The Effects of Shear Stud Distribution On The Fatigue Behavior of Steel-Concrete Composite BeamsDocument24 pagesThe Effects of Shear Stud Distribution On The Fatigue Behavior of Steel-Concrete Composite BeamsPatel TosifNo ratings yet

- Capillary ActionDocument13 pagesCapillary ActionEvelyn HernándezNo ratings yet

- GME Online Test and Interview SyllabusDocument3 pagesGME Online Test and Interview SyllabusNimish Singh100% (1)

- Unit-2 BookDocument64 pagesUnit-2 BookPuzzle SolverNo ratings yet

- Performance-Based Seismic Upgrade of A 14-Story Suspended Slab Building Using State-of-the-Art Analysis and Construction TechniquesDocument16 pagesPerformance-Based Seismic Upgrade of A 14-Story Suspended Slab Building Using State-of-the-Art Analysis and Construction TechniquesSiva KrishnaNo ratings yet

- ARIJIT GUHA Road Development in India August2016Document42 pagesARIJIT GUHA Road Development in India August2016Goutam ChakrabortyNo ratings yet