Professional Documents

Culture Documents

List of Materials: FM/7.4/01/001 Ferro Alloys & Fluxes For Melting Shop

Uploaded by

Tarun ChakrabortyOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

List of Materials: FM/7.4/01/001 Ferro Alloys & Fluxes For Melting Shop

Uploaded by

Tarun ChakrabortyCopyright:

Available Formats

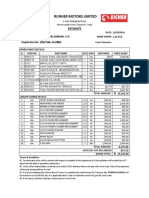

Form No.

List of Materials

FM/7.4/01/001

FERRO ALLOYS & FLUXES FOR MELTING SHOP:

Sl. Materials Name ** Specification / Supplier Size in mm

No. (or Otherwise) ±10%

1 Ferro Silicon (lumps)* Si-70-75, Al- 0-1.75(max) 10-150

2 Ferro Silicon (Chip)* Si-70-75, Al- 0-1.5(max) 4-12

3 Ferro Silicon (Innoculant Si-70-75, Al- 0-1.75(max) 0.25-3

Powder)*

4 (a) High Carbon Ferro C-6.0-9.0, S-0-..05(max), P-0-0.4 max, 10-100

Manganese * Si-0-1.50(max), Mn-70-75

4(b) Low Carbon Ferro C-0-1.5(max), S-0-.05(max), P-0-0.4 10-100

Manganese* max, Si-1.50(max), Mn-70-75

5 High Carbon Ferro C-6.0-9.0, S-0.005-0.05(max), Si-0.1-2.0 25-100

Chromium* (lump) (max), Cr-58-70

6 Low Carbon Ferro C-0-0.20(max), S-0-0.02(max), Si-0- 20-75

Chromium*(lump) 1.50 (max), Cr-60-75

7 Ferro Vanadium* (Low Al) Al- 0-0.5, C-0.05-0.40(max), S-0-0.05 10-30

(max), Si- 0-1.5, V-48-55 (min)

8 Ferro Vanadium* (ordinary) Al- 0.05-1.5, C-0.05-0.40(max), S-0- 10-30

0.05 Si- 0.05-1.5, V-48-55

9 Ferro Molybdenum* C-0-0.10, S-0-0.10(max), Mo-58-75 10-100

11 Ferro Phosphorous* P-20-30 10-50

12 Ferro Titanium* S-0.005-0.05, Ti-30-75 10-30

13 Aluminium notch bar* Al-97-99.5 0.9-1.2 Kg/pc

14 Aluminium Shots* Al- 97-99.5% 3-6

15 Barinoc Chips Si-70-75% 2-6

16 Carbo Coke*/C.P.C Fixed Carbon- 98.0-99.99% 2-7

18 Burnt Lime* SiO2 –0.5-3.0%, CaO-85-95%, MgO-0- 20-100

10 % (air tight packing)

19 Calcium Silicide Chips)* Si-55-65, Ca-28-38% 10-30

20 Ferro Nickel (Shots/lumps)* Ni-35(min), S-0.04(max) 3-6

21 Ferro Boron B-15-20%, Si-0-2%, Al-0-1% 10-30

Free from moisture

22 Pure Nickel* Ni-99.8-99.999% 10-100

23 Nickel Magnesium* Ni-79-82, Mg-16-18 50-75

24 Ferro Silicon Magnesium* Si-40-50, Mg-8-10 25-50

25 Ferro Tungsten* W-60-70%, S-0.005-0.05 25-75

26 Lime Stone* SiO2- 0-1.5%, CaO-50-60, MgO- 0-8%, 20-70

LOI-40-60

27 Fluorspar * CaF2-80-99% 20-50

28 Graphite DC-2 Fixed Carbon-98-99.99 100mesh-90-100%

retained

10 mesh-0-5% retained

29 Ferro Niobium Nb–60-70%, C-0-0.10, S-0.005-0.05 % 10 – 40

30 Ferro Chrome Powder C-6.0-9.0, S-0.005-0.05(max), Si-0.1-2.0 0.25-2

(max), Cr-58-70

APPROVED BY : Head of Organisation ISSUED BY : MR

REVISION NO. : 0 ISSUE NO. : 3

PAGE NO. : 1 of 5 ISSUE DATE : 01.06.2009

Form No. List of Materials

FM/7.4/01/001

FERRO ALLOYS & FLUXES FOR MELTING SHOP:

Sl. Materials Name ** Specification / Supplier Size in mm

No. (or Otherwise) ±10%

31 Ferrous Sulphide* S-15-30% 10-40

32 Mish Metal Rare earth.>70%, Ca>1.5% NA

Free from moisture

33 Zircinoc for in-mould Si-70-75% 1-3

34 Zircinoc chips Si-70-75% 2-6

35 Copper (Pure) Cu-99.7-99.99% NA

36 Iron Ore Fe-50-70% NA

FOUNDRY MATERIALS:

Sl. Materials Name ** Specification / Supplier Size in mm

No. (or Otherwise) ±10%

1(a) Bentonite* Powder Na-Base, Swelling-95-98, Jell- 30-50, 200 mesh – 0-5%

pH-7-11 retained

1(b) Bentonite* (Kutch) Na-Base, Swelling-98-99.5, Jell- 50-70, 200 mesh – 0-5%

pH-7-11 retained

1(c) Green Bond Bentonite* Na-Base, Swelling-98-99.9, Jell- 60-75, 200 mesh – 0-5%

pH-7-11 retained

2 (a) Fire clay (for Melting SiO2-50-55, Al2O3-30-45 30 mesh- 0-5%

grade)* retained, 100 mesh-

90-100% retained

2 (b) Fire clay (for Foundry SiO2-50-60, Al2O3-30 -60 200 mesh– 0-5%

grade)* retained

3 Clay sand* Clay-45-55 NA

4 (a) Silica sand* SiO2-98(min), Clay-1.0(max) AFS-24-30

4 (b) Allahabad Sand SiO2- 99-99.98%, Clay-0-0.02 max AFS 50-54

4 (c) Silica sand (Special quality) SiO2-97-99, Clay-1.0(max) AFS-25-35

5 Zirconium Paint* PH-6.5-7.5, ZrO2-58-62, Water-25-35 NA

6 Graphite powder for spray Fixed Carbon-98-99.99%, 200 mesh – 0-5%

retained

7 Ferrogen(Flux)* Foseco make or equivalent NA

Zircon Flour (Special ZrO2-60% Min, % retention – 140 sieve As indicated in spec

8 (a) Grade)* < 2%, 200 sieve 10-15%, 240 sieve 15-

20%, 300 sieve 10-15%, 350 sieve 1-5%

8 (b) Zircon Flour (Ordinary)* ZrO2-63-70, % retention –200 sieve 0-5% As indicated in spec

9 Silica Flour * SiO2-98% Min, % retention – 140 sieve As indicated in spec

< 3%, 200 sieve 10-15%, 240 sieve 10-

15%, 300 sieve 20-30%, 350 sieve 1-5%

10 Zircon Sand* ZrO2 – 60-70% As indicated in spec

APPROVED BY : Head of Organisation ISSUED BY : MR

REVISION NO. : 0 ISSUE NO. : 3

PAGE NO. : 2 of 5 ISSUE DATE : 01.06.2009

Form No. List of Materials

FM/7.4/01/001

MELTING SCRAP:

Sl. Materials Name ** Specification / Supplier Size in mm

No. (or Otherwise)±10%

1 SG-Scrap Rolls* P-0.10(max), S-0.015(max) NA

2 CC-Scrap Rolls Si-<0.9,Cr<0.5, P<0.5, Mn<0.4 NA

3 Steel-Scrap Rolls C-2% max, S<0.05, P<0.04, Mn- NA

1.2(max), Si-0.7 max

4 ICDP Scrap Rolls C-2.5-3.5, Si-0.6-1.3, Mn-0.4-0.9, P- NA

0.1 max, S-0.04 max, Ni- 2.8-4.6, Cr-

0.65-2 (max), Mo-0.2-0.5

5 IC Scrap Rolls C-2.5-3.5, Si-0.6-1.3, Mn-0.4-1.2, P- NA

0.15 max, S-0.08 max, Ni- 1.5-2.5, Cr-

0.8-1.5 (max), Mo-0.2-0.5

6 HSS Scrap Rolls C-0.8-2.2, Si-0.3-0.9, Mn-0.4-0.9, P-0.1 NA

max, S-0.02 max, Ni- 0.4-1.5, Cr-3-6

(max), Mo-2-9, Ni- 2 max, V- 1-6, W- 3

max

C.I/Broken Ingot Mould* C-<4.00, Si<2.0, Mn<0.50, P<0.20, NA

S<0.10, Cr-0.20(max)

5 Sponge Iron* C-0.2(max), S-0.035(max), P- 3-20

0.05(max), Metallisation-81(min)

6 Steel Scrap* S<0.05, P<0.05, NA

7 Pig Iron (SG Grade) C-3.2-4.5%, Si-2.5%max, Mn- NA

0.45%Max., P.-0.1%max S-0.02%max.

8 Pig Iron (Hollow Grade) C-3.2-4.5%,Si-0.6%,Mn-0.45%Max., NA

P-0.15%max S-0.05%max.

9 Sorel Pig C-4-4.5%, S-0.0008% max, Si- .02-.03% NA

10 Side Trimming (Hi-Cr) C-0.01-0.6, Mn-0.1-0.5, P-0.01-0.05, S- NA

0.005-0.025, Si-0.001-0.1

MATERIALS FOR MACHINE SHOP:

Sl. Materials Name ** Specification / Supplier Size in mm

No. (or Otherwise)±10%

1 Carbide Insert and tips* Sandvik, Kennametal, Ceratizit, Seco NA

2 Grinding wheel* Grindwell Norton, Carborandum NA

MATERIALS FOR MAINTENANCE DEPARTMENT (MECHANICAL):

Sl. Materials Name ** Specification / Supplier Size in mm

No. (or Otherwise)±10%

1 V-Belts Fenner, Dunlop, Hilton Dimensions

2 Bearings SKF or equivalent NA

3 Lubricating Oil BPCL/IOCL NA

APPROVED BY : Head of Organisation ISSUED BY : MR

REVISION NO. : 0 ISSUE NO. : 3

PAGE NO. : 3 of 5 ISSUE DATE : 01.06.2009

Form No. List of Materials

FM/7.4/01/001

MATERIALS FOR MAINTENANCE DEPARTMENT (MECHANICAL):

Sl. Materials Name ** Specification / Supplier Size in mm

No. (or Otherwise)±10%

3 a) Grade 150 a) Viscosity @ 400C, cSt 142, Flash point NA

264°C, Pour point –14°C

b) Grade 68 b) Viscosity @ 400C, cSt 65.4, Flash point

249°C, Pour point –19°C

c) Grade46 c) Viscosity @ 400C, cSt 45, Flash point

249°C, Pour point –19°C

d) Grade 220 d) Viscosity @ 400C, cSt 212.5, Flash

point 270°C, Pour point –12°C

e) Grade 460 e) Viscosity @ 400C, cSt 442.5, Flash

point 275°C, Pour point –5°C

MATERIALS FOR MAINTENANCE DEPARTMENT (ELECTRICAL):

Sl. Materials Name ** Specification / Supplier Size in mm

No. (or Otherwise)±10%

1 Power cables Nicco, ICC, Gloster NA

2 Control cables Nicco, Finolex, Evershine KDK, Lapp NA

3 Electrodes Essab, Advani-Oerlikon, L & T, Valency NA

4 Temperature cont- Masibus, Sietex, TIEL, Industrial, NA

roller/recorders Instrumentation, Siemens, MB control

5 Insulating motor Dr. Beck NA

varnish

6 Super enamel copper Debidayal, Indo-American, Magnet, NA

winding wire HWP,HTP

7 Thermocouple Tips* Positherm / Fykays or Equivalent NA

SPECIFICATION FOR FORGED BLANK:

Sl. Materials Name ** Specification / Supplier Size in mm

No. (or Otherwise)±10%

1 Forged Blank* C 0.5-1.1, Mn- 0.2 –1.1, P- 0.025 (max), S As per PR/Drg.

- 0.015 (Max) , Si –0.2-1.0 , Ni- 0.02-0.6, Ultrasonic-

Cr 2.5--5.5, Mo-0.1-0.6 , V- 0.001-0.25 conforming ASTM

A 388-2001

1 Forged Blank Annealed C--0.8 to 0.92%, Si--0.30 to 0.45%, Ultrasonic--Solid

(a) Mn--0.30 to 0.45%, P-- 0.025%MAX, forged blank

S--0 to 0.008%,Ni--0.30% MAX, conforming ASTM

Mo--0.08 to 0.30%, V--0.005 to 0.03%, Gas A 388-2001.

content -- H=2 ppm max, N=70-90 ppm Blank Dimension --

max, O=15 ppm & All togather gas content As Per Purchase

should be less than 120 ppm ASTM Grain Requisition & / or

Size--6 to 8, hardness--30 SH D(approx). Drawing

Macro Etch Test--As per ASTM A381-1995.

Inclusion Rating--A-1.0/1.5max , B-1.5/0.5

max ,C-0.5 max ,D-1.0/1.5 max of thin &

thick series. MP Test to be done as per

ASTM E 709-2001.

* These materials are Standard Items

** Elements are given in weight percent.

APPROVED BY : Head of Organisation ISSUED BY : MR

REVISION NO. : 0 ISSUE NO. : 3

PAGE NO. : 4 of 5 ISSUE DATE : 01.06.2009

Form No. List of Materials

FM/7.4/01/001

SPECIFICATION FOR FORGED BLANK:

Sl. No. Materials Name ** Specification / Supplier Size in mm

(or Otherwise)±10%

1(b) Forged Blank-Ind C--0.8 to 0.92%, Si--0.30 to 0.45%, Mn- Ultrasonic--Solid

Hardened -0.30 to 0.45%, P-- 0.025%MAX, S--0 forged blank

to 0.008%,Ni--0.30% MAX, Mo--0.08 conforming ASTM

to 0.30%, V--0.005 to 0.03%, Gas A 388-2001.

content -- H=2ppm max, N=70-90ppm Blank Dimension &

max, O=25-30ppm & All together gas Hardness -- As Per

content should be less than 120 ppm. Purchase

ASTM Grain Size--6 to 8, Macro Etch Requisition & / or

Test--As per ASTM A381-1995. Drawing . (As

Inclusion Rating--A-1.0/1.5 max, applicable),

B-1.5/0.5 max , C-0.5 max ,D-1.0/1.5

max of thin & thick series. MP Test to

be done as per ASTM E 709-2001

1 (c) Forged Blank Volume C--0.8 to 0.92%, Si--0.30 to 0.45%, Mn- Ultrasonic--Solid

Hardened -0.30 to 0.45%, P-- 0.025%MAX, S--0 forged blank

to 0.008%,Ni--0.30% MAX, Mo--0.08 conforming ASTM

to 0.30%, V--0.005 to 0.03%, Gas A 388-2001.

content -- H=2ppm max, N=70-90ppm Blank Dimension &

max, O=25-30ppm & All together gas Hardness -- As Per

content should be less than 120 ppm. Purchase

ASTM Grain Size--6 to 8, Macro Etch Requisition & / or

Test--As per ASTM A381-1995. Drawing (As

Inclusion Rating--A-1.0/1.5 max , applicable),

B-1.5/0.5 max , C-0.5 max ,D-1.0/1.5

max of thin & thick series. MP Test to

be done as per ASTM E 709-2001.

APPROVED BY : Head of Organisation ISSUED BY : MR

REVISION NO. : 0 ISSUE NO. : 3

PAGE NO. : 5 of 5 ISSUE DATE : 01.06.2009

You might also like

- Anticorodal50 Englisch 01Document1 pageAnticorodal50 Englisch 01dmalfazNo ratings yet

- Sinter PlantDocument12 pagesSinter PlantRajan Bhandari100% (1)

- Sinter Making0260307Document47 pagesSinter Making0260307honeygupta12150% (2)

- Cobre Polvo HandbookDocument5 pagesCobre Polvo HandbookJavo BarrelNo ratings yet

- Fly Ash - An Emerging Alternative Building Material: © 1999, NMI, Jamshedpur, Pp. 59-67Document9 pagesFly Ash - An Emerging Alternative Building Material: © 1999, NMI, Jamshedpur, Pp. 59-67NikhilNo ratings yet

- Silica/Sand Specifications: Particle Size Analysis and PropertiesDocument1 pageSilica/Sand Specifications: Particle Size Analysis and PropertiesforuzzNo ratings yet

- Forged Engineering DataDocument4 pagesForged Engineering DataretrogradesNo ratings yet

- Solid Bronze Bearing: Technical DataDocument6 pagesSolid Bronze Bearing: Technical DatadangminhNo ratings yet

- SilcoTek Coatings For High Purity ApplicationsDocument30 pagesSilcoTek Coatings For High Purity ApplicationsKommu RohithNo ratings yet

- Sepction - 2Document4 pagesSepction - 2k koradiaNo ratings yet

- Fused Silica DatasheetDocument2 pagesFused Silica DatasheetLuis Antonio SotoNo ratings yet

- Condemning Volvo FH16Document1 pageCondemning Volvo FH16gilar herliana putraNo ratings yet

- BabbittDocument3 pagesBabbittEyner David Cubides ContrerasNo ratings yet

- Vulcan Industrial Engineering Co. Pvt. LTDDocument3 pagesVulcan Industrial Engineering Co. Pvt. LTDk koradiaNo ratings yet

- Material Safety Data Sheet: For Welding Consumables and Related ProductsDocument2 pagesMaterial Safety Data Sheet: For Welding Consumables and Related ProductsVinodhkanna GandhiNo ratings yet

- Saw ProcessDocument55 pagesSaw ProcessSatheesh KumarNo ratings yet

- Duplex Stainless SteelsDocument25 pagesDuplex Stainless Steelspym1506gmail.comNo ratings yet

- Phosphate RockDocument3 pagesPhosphate RockManoj Kumar AcharyNo ratings yet

- LECO GDS Configuration Request Form: To Be Filled Out by Leco Sales - Not by ProspectDocument3 pagesLECO GDS Configuration Request Form: To Be Filled Out by Leco Sales - Not by ProspectOscar MartinezNo ratings yet

- Table eDocument4 pagesTable eRawal Chemical ComplexNo ratings yet

- Babbitt Bearing AlloysDocument2 pagesBabbitt Bearing AlloysMurad Alam100% (1)

- Price MetalsDocument5 pagesPrice MetalsThe UniversNo ratings yet

- Basics in Mineral Processing-GeneralDocument18 pagesBasics in Mineral Processing-Generalmakedo33100% (7)

- Properties of Engineering Material - Waleed NassefDocument1 pageProperties of Engineering Material - Waleed NassefWaleed NassefNo ratings yet

- Timfold Product Page PDFDocument2 pagesTimfold Product Page PDFVlado KaucicNo ratings yet

- Synopsis of EN 197-1 Cement Reactions and ProductionDocument8 pagesSynopsis of EN 197-1 Cement Reactions and ProductionJulia Montelin PowersNo ratings yet

- DSM-0239.0 Amdry Braze SuperalloysDocument4 pagesDSM-0239.0 Amdry Braze SuperalloysjctenkoNo ratings yet

- MSDS Leadframe (16 Items)Document8 pagesMSDS Leadframe (16 Items)bennisg8No ratings yet

- Fused Silica DatasheetDocument2 pagesFused Silica Datasheetkats2404No ratings yet

- TB 600 v1Document106 pagesTB 600 v1Saud Affan100% (1)

- Aluminium Diecasting MaterialDocument2 pagesAluminium Diecasting MaterialzainudinNo ratings yet

- CW50MMDocument96 pagesCW50MMപോൾ വീട്ടിൽ ബീനോയ്No ratings yet

- Montana 120Document84 pagesMontana 120Abdul BasithNo ratings yet

- TDS Spec MicaMira MTM-OR18 Rev2Document1 pageTDS Spec MicaMira MTM-OR18 Rev2Fabio Arboleda TorresNo ratings yet

- Reci 1500W Fiber Laser Cutting Data 30um)Document2 pagesReci 1500W Fiber Laser Cutting Data 30um)morteza hamishegiNo ratings yet

- Raw Materials For Steel MakingDocument10 pagesRaw Materials For Steel MakingsaileshNo ratings yet

- Al Si 10 MgaDocument2 pagesAl Si 10 MgaNinad DoraleNo ratings yet

- Hervé Et Al. (2010a)Document22 pagesHervé Et Al. (2010a)Gabriel GonzálezNo ratings yet

- Hot Dip Galvanizing and Corrosion CategoriesDocument2 pagesHot Dip Galvanizing and Corrosion CategoriesLaxman DuggiralaNo ratings yet

- Hinged 42mm2 PDFDocument120 pagesHinged 42mm2 PDFViswanathan Kannoor67% (3)

- Vortex 70Document92 pagesVortex 70MajazNo ratings yet

- Introduction To Iron Making and Blast Furnace TechnologyDocument24 pagesIntroduction To Iron Making and Blast Furnace TechnologyDevansh MankarNo ratings yet

- (Carbon) C: - 0-2746-5148, 08-1565-5678 1 5Document5 pages(Carbon) C: - 0-2746-5148, 08-1565-5678 1 5Suriyachai NiamsornNo ratings yet

- ASME BPVC - II.A-2017 SA-182/SA-182M: Table 2Document1 pageASME BPVC - II.A-2017 SA-182/SA-182M: Table 2rajeshNo ratings yet

- Product Code:: Pkg/Ro/41 Special SteelsDocument9 pagesProduct Code:: Pkg/Ro/41 Special SteelsPranav TripathiNo ratings yet

- Physical Properties Dust & BindersDocument3 pagesPhysical Properties Dust & BindersYogesh PatilNo ratings yet

- Specification SummaryDocument25 pagesSpecification SummaryDeepak KumarNo ratings yet

- Properties FCD 50Document5 pagesProperties FCD 50dwi Kuntoro100% (1)

- Welding Filler Metals For Power Plant EngineeringDocument20 pagesWelding Filler Metals For Power Plant EngineeringShoaib AhmedNo ratings yet

- Latitude Deg SI US /G: Table 2: Engineering Constants A) Acceleration of GravityDocument6 pagesLatitude Deg SI US /G: Table 2: Engineering Constants A) Acceleration of GravityASIM KUMAR SRIVASTAVANo ratings yet

- Sliding Thermal BreakDocument64 pagesSliding Thermal BreakSaud AffanNo ratings yet

- Trade Effluent Discharge LimitsDocument2 pagesTrade Effluent Discharge Limitsjiaolei9848No ratings yet

- Milling Speeds and FeedsDocument1 pageMilling Speeds and FeedsirinaNo ratings yet

- TB-62mm - V1 Rev2Document84 pagesTB-62mm - V1 Rev2Mohsin KhanNo ratings yet

- Sedimentary Rock and The Production of SedimentDocument8 pagesSedimentary Rock and The Production of SedimentS Hashim RizviNo ratings yet

- Notes Betoni0Document80 pagesNotes Betoni0shahede sehNo ratings yet

- The Uniqueness of Biological Materials: International Series of Monographs in Pure and Applied Biology: ZoologyFrom EverandThe Uniqueness of Biological Materials: International Series of Monographs in Pure and Applied Biology: ZoologyNo ratings yet

- 9001.2015 Company ProfileDocument2 pages9001.2015 Company ProfileTarun ChakrabortyNo ratings yet

- Phesgo Patient Quick HitDocument32 pagesPhesgo Patient Quick HitTarun ChakrabortyNo ratings yet

- 9001.2015 Vision StatementDocument1 page9001.2015 Vision StatementTarun ChakrabortyNo ratings yet

- What Have We Done For You Lately?: by Reginald D. Forrest, Sorelmetal Technical ServicesDocument3 pagesWhat Have We Done For You Lately?: by Reginald D. Forrest, Sorelmetal Technical ServicesTarun ChakrabortyNo ratings yet

- 4) Supplier Development Specialist Profile - Metallurgist 23.07.19Document2 pages4) Supplier Development Specialist Profile - Metallurgist 23.07.19Tarun ChakrabortyNo ratings yet

- Management Team: Organizational Chart Q-013-003aDocument3 pagesManagement Team: Organizational Chart Q-013-003aTarun ChakrabortyNo ratings yet

- S.G.Iron GuidelinesDocument28 pagesS.G.Iron GuidelinesTarun Chakraborty100% (3)

- Runner Motors Limited: EstimateDocument2 pagesRunner Motors Limited: EstimateTarun Chakraborty100% (1)

- Country Presentation On: WelcomeDocument52 pagesCountry Presentation On: WelcomeTarun ChakrabortyNo ratings yet

- Costing Calculation of Hard Product MachiningDocument1 pageCosting Calculation of Hard Product MachiningTarun ChakrabortyNo ratings yet

- Ductile Iron Flanged Fittings: SpecificationsDocument20 pagesDuctile Iron Flanged Fittings: SpecificationsTarun ChakrabortyNo ratings yet

- Electrotherm India LTD PDFDocument11 pagesElectrotherm India LTD PDFTarun ChakrabortyNo ratings yet

- Automatic Metal Pouring PDFDocument4 pagesAutomatic Metal Pouring PDFTarun ChakrabortyNo ratings yet

- Casting Simulation Software - Applications and BenefitsDocument4 pagesCasting Simulation Software - Applications and BenefitsTarun ChakrabortyNo ratings yet

- QualityimprovementDocument6 pagesQualityimprovementTarun ChakrabortyNo ratings yet

- Ferro TungstenDocument9 pagesFerro TungstenTarun ChakrabortyNo ratings yet

- B978 075064284 2 - 50008 9Document5 pagesB978 075064284 2 - 50008 9Tarun ChakrabortyNo ratings yet

- 1railway SleepersDocument7 pages1railway SleepersTarun ChakrabortyNo ratings yet

- Flow Domo CaproleunaDocument1 pageFlow Domo CaproleunatotpityiNo ratings yet

- Percent Composition and Molecular Formula WorksheetDocument6 pagesPercent Composition and Molecular Formula WorksheetMarky CieloNo ratings yet

- HW3 ImperfectionDocument3 pagesHW3 ImperfectiondthNo ratings yet

- Elgacore DWA 50Document2 pagesElgacore DWA 50rodofgodNo ratings yet

- Analisis Genesa Hidrogeokimia Airtanah Menggunakan Diagram Piper Segiempat Di Wilayah PesisirDocument11 pagesAnalisis Genesa Hidrogeokimia Airtanah Menggunakan Diagram Piper Segiempat Di Wilayah PesisirDini AuliaNo ratings yet

- Wayne - Simmons - Sundrop FuelsDocument24 pagesWayne - Simmons - Sundrop Fuelsandrew_savage5387No ratings yet

- ENK Enzyme Kinetics Lab ManualDocument11 pagesENK Enzyme Kinetics Lab ManualVanesha AnesNo ratings yet

- Welding SectionsDocument184 pagesWelding SectionsvmgobinathNo ratings yet

- LEAP GENCHEM2 Q4 AcidsBasesDocument6 pagesLEAP GENCHEM2 Q4 AcidsBasesJoshua Libo-onNo ratings yet

- Common Food AdulterationDocument17 pagesCommon Food AdulterationAbhaySharmaNo ratings yet

- Dual Filter Multibasket Ow: Complete Solutions For Liquid FiltrationDocument4 pagesDual Filter Multibasket Ow: Complete Solutions For Liquid FiltrationJairo Andrés FANo ratings yet

- 9701 m19 QP 12 PDFDocument16 pages9701 m19 QP 12 PDFShakeelNo ratings yet

- Experiment 4Document5 pagesExperiment 4Nur ShazieyahNo ratings yet

- Xii-Board 3RD 33% Chemistry DRT - 2 - 20.11.2023Document2 pagesXii-Board 3RD 33% Chemistry DRT - 2 - 20.11.2023lgtv3679No ratings yet

- ASTM A36-A36M-2008 Standard Specification For Carbon Structural Steel PDFDocument3 pagesASTM A36-A36M-2008 Standard Specification For Carbon Structural Steel PDFmasv792512100% (2)

- AntacidsDocument16 pagesAntacidsPedroCordovageNo ratings yet

- Science Behind AntifreezeDocument2 pagesScience Behind AntifreezenagsraviNo ratings yet

- Clandestine PDFDocument84 pagesClandestine PDFcucku4u100% (2)

- Assessment of Friction Stir Welding On Aluminium 3D Printing MaterialsDocument6 pagesAssessment of Friction Stir Welding On Aluminium 3D Printing MaterialsShaik SyahmanNo ratings yet

- Ethylene Ethanol DEE H2O: Senyawa Input Reaktor Output Reaktor KG/HR Kmol/hr KG/HRDocument11 pagesEthylene Ethanol DEE H2O: Senyawa Input Reaktor Output Reaktor KG/HR Kmol/hr KG/HRyohanamd14No ratings yet

- Best SpeakersDocument22 pagesBest Speakersgheo23No ratings yet

- Bartlett-Snow™ Rotary Kilns: For High Temperature ApplicationsDocument2 pagesBartlett-Snow™ Rotary Kilns: For High Temperature Applicationsmick hughesNo ratings yet

- Self Assembled Nanoreactors PDFDocument46 pagesSelf Assembled Nanoreactors PDFandra mNo ratings yet

- Demo InflatingaballoonDocument4 pagesDemo InflatingaballoonjowieNo ratings yet

- EorDocument42 pagesEorAthaurrohman Alfaina Shidiq100% (2)

- Astm D 3517Document12 pagesAstm D 3517Rostarina AnggrainiNo ratings yet

- Boralite Beheshti2020 PDFDocument15 pagesBoralite Beheshti2020 PDFMatchem BensafiNo ratings yet

- Methyl AcetateDocument3 pagesMethyl AcetatetranhungNo ratings yet

- Flow Assurance - Managing Flow Dynamics and Production ChemistryDocument15 pagesFlow Assurance - Managing Flow Dynamics and Production Chemistryfaisalzhuida100% (1)

- AFCONA - 4201 TDS EngDocument1 pageAFCONA - 4201 TDS EngHamood AbdoNo ratings yet