Professional Documents

Culture Documents

Cat014 Eng

Uploaded by

cara tomateOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Cat014 Eng

Uploaded by

cara tomateCopyright:

Available Formats

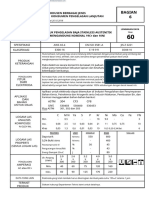

MECHANICAL SEAL

As tro n g lin k of your sy

stem

UM3AØUM3A

MECHANICAL

SEAL

UM3AØUM3A

10a 1a 2a 9a 3a 13 12 4 3 9 2 1 10

PRODUCT

SIDE

CAT014 ENG REV 12.09

PRESSURIZED BARRIER

LIQUID

ELEMENTS:

A double monobloc version is

available to reduce axial bulk, 1 STATIONARY SEAT 1a STATIONARY SEAT

suitable for dangerous, toxic, 2a ROTARY FACE

2 ROTARY FACE

inflammable, highly abrasive,

gaseous liquids and situations in 3 THRUST RING 3a THRUST RING

which it is necessary to avoid

atmospheric emissions. 4 SEAL BODY 9a ROTARY FACE “O” RING

Particularly suitable for dryers and 9 ROTARY FACE “O” RING 10a STATIONARY SEAT “O” RING

top-entry agitators.

Available cartridge execution with 10 STATIONARY SEAT “O” RING

and without bearing included.

The UM3A Ø UM3A is a double 12 SETSCREW

component seal with a type A

13 SPRING

pinned stationary seat, multi-spring

and suitable for rotation in either

direction.

Equipped with three drive lugs on OPERATING CONDITIONS:

the rotating body it can tolerate DIAMETER:

DIAMETER SPEED:

SPEED PRESSURE:

PRESSURE TEMPERATURE

TEMPERATURE:

strong vibration and mechanical (mm) (m/sec) (bar) (°C)

stresses.

The “O” ring is easily removed and 100 20 12 +250

refitted when assembling the seal

on shafts with keyways, threads 20

or sharp edges.

0 0 –100

CHARACTERISTICS:

DOUBLE BI-DIRECTIONAL RESISTANT TO

ACIDS & BASES

FLUIGAM RESISTANT TO DIRTY & TOXIC

(energized MECHANICAL LIQUIDS

dynamic “O” ring) STRESS

MECHANICAL SEAL

l1

UM3AØUM3A

l4 l3 l4 l7

STATIONARY SEAT: 1 1a

SOLID TYPE A

Cr-Mo Steel: Y1

Silicon Carbide: U31

TYPE A WITH INSERT

d1

d4

d6

d3

d7

AISI 316+Tungsten Carbide: K22

SOLID TYPE R(3) Spina d8

l5 l6 9

e

l5x20° l6 5

0.2 max

0.5 Seal d1 d3 d4 d6 d7 d8 l1 l3 l4 l5 l6 l7 d9 m s e

Diam.

h6 min. H11 H8 ± 0,5 ± 0,5 H8

20 20 34 36 29 35 3 60 40 10 2 5 9 40 32,5 1 4

22 22 36 38 31 37 3 60 40 10 2 5 9 42 34,5 1 4

s

24 24 38 40 33 39 3 63 43 10 2 5 9 43 36,5 1 4

25 25 39 41 34 40 3 63 43 10 2 5 9 46 37,5 1 4

°

28

0

28 42 44 37 43 3 64 44 10 2 5 9 48 40,5 1 4

3

30 30 44 46 39 45 3 64 44 10 2 5 9 50 42,5 1 4

5

d9

d4

32 32 46 48 42 48 3 64 44 10 2 5 9 53 45,5 1 4

m

d1

33 33 47 49 42 48 3 64 44 10 2 5 9 53 45,5 1 4

Cr-Mo Steel: Y1

Silicon Carbide: U31 35 35 49 51 44 50 3 64 44 10 2 5 9 60 47,5 1 4

38 38 54 58 49 56 4 69 47 11 2 6 9 62 53,5 3 6

TYPE R WITH INSERT

40 40 56 60 51 58 4 69 47 11 2 6 9 65 55,5 3 6

43 43 59 63 54 61 4 69 47 11 2 6 9 67 58,5 3 6

45 45 61 65 56 63 4 69 47 11 2 6 9 70 60,5 3 6

48 48 64 68 59 66 4 69 47 11 2 6 9 72 63,5 3 6

AISI 316+Tungsten Carbide: K22 50 50 66 70 62 70 4 74 48 13 2,5 6 9 75 67,5 1,5 6

STATIONARY SEAT “O” RING: 10 10a 53 53 69 73 65 73 4 74 48 13 2,5 6 9 77 70,5 1,5 6

Nitrile Rubber: G 55 55 71 75 67 75 4 74 48 13 2,5 6 9 86 72,5 1,5 6

Ethylene Propylene: D

Fluoroelastomer: V 58 58 78 83 70 78 4 82 56 13 2,5 6 9 88 75,5 1,5 6

Perfluoroelastomer: G711 60 60 80 85 72 80 4 82 56 13 2,5 6 9 91 77,5 1,5 6

PTFE: T

63 63 83 88 75 83 4 82 56 13 2,5 6 9 93 80,5 1,5 6

ROTARY FACE: 2 2a

65 65 85 90 77 85 4 82 56 13 2,5 6 9 96 82,5 1,5 6

SOLID 68 68 88 93 81 90 4 86 56 15 2,5 7 9 98 87,5 0,5 6

70 70 90 95 83 92 4 88 58 15 2,5 7 9 103 89,5 0,5 6

75 75 99 104 88 97 4 91 61 15 2,5 7 9 108 94,5 0,5 6

Graphite Resins impregnated: Z31 80 80 104 109 95 105 4 92 61 15,5 3 7 9 120 102,5 0,5 6

Graphite Antimony impregnated: Z11

Silicon Carbide: U31 85 85 109 114 100 110 4 92 61 15,5 3 7 9 125 107,5 0,5 6

90 90 114 119 105 115 4 94 63 15,5 3 7 9 130 112,5 0,5 6

WITH INSERT

95 95 119 124 110 120 4 94 63 15,5 3 7 9 135 117,5 0,5 6

100 100 124 129 115 125 4 94 63 15,5 3 7 9 140 122,5 0,5 6

Dimensions subject to modifications without notice.

AISI 316+Graphite Resins impreg.: Z32 Example:

AISI 316+Silicon Carbide: U32

AISI 316+Tungsten Carbide: K22 To order the seals shown on this page for shaft 30 mm and material shown in the table below:

ROTARY FACE “O” RING: 9 9a 2a 2 1a 1 9a 9 10a 10 13 4 12 3 3a

Nitrile Rubber: G

Ethylene Propylene: D Product side Z32 U31 T3 T

Fluoroelastomer: V E E

Perfluoroelastomer: G711 Atmospheric side Z32 Y1 V V

PTFE with AISI 316 spring: T3 (4)

The code will be: UM3A030UM3A - Z32U31T3TEE/Z32Y1VEE

13 NOTES:

SPRINGS: 1) The material shown on this page is only part of the available range, for other products stock items, please call our Technical

AISI 316: E Sales Office.

Hastelloy C: I 2) The material should be chosen according to the operating conditions. All queries should be sent to our Technical Sales Office.

3) The last letter of the product code UM3AØUM3A shows the type A stationary seat with a slot for an antirotation pin: or if a

stationary seat with chamfer for use of an axial lock ring fitted, please request type R. The product code will then be UM3RØUM3R.

OTHER METAL PARTS: 4 12 3 3a 4) When the material of the seal on the stationary seat “O” ring is the same as the seal on the rotary face “O” ring the product

AISI 316: E code is not repeated.

FLUITEN ITALIA SpA 20016 PERO (Milano) Italy • Via L. da Vinci, 14

Tel. +39 02.339403.1 Fax +39 02.3538641 E-mail: info@fluiten.it • www.fluiten.it

You might also like

- Cub Cadet 1650 PDFDocument46 pagesCub Cadet 1650 PDFkbrckac33% (3)

- OPERATORS MANUAL - 544G - EnglishDocument336 pagesOPERATORS MANUAL - 544G - EnglishRaul E. Soli100% (2)

- VleDocument34 pagesVleAndinNo ratings yet

- Operation & Maintenance Manual of Air Blaster SystemDocument25 pagesOperation & Maintenance Manual of Air Blaster SystemSahil Goutham100% (5)

- CATALOG FCA Campina-EDocument21 pagesCATALOG FCA Campina-EClaudiu Ovidiu TeacaNo ratings yet

- Kod SizingDocument2 pagesKod SizingCan YıldırımNo ratings yet

- Modelling Methods of Continuous Casting PDFDocument24 pagesModelling Methods of Continuous Casting PDFPrakash SarangiNo ratings yet

- Hamworthy Compressor ManualDocument5 pagesHamworthy Compressor Manualdhairya sindhi100% (1)

- ABB 66kV EDF ManualDocument129 pagesABB 66kV EDF ManualMartin ManuelNo ratings yet

- Breaker HB200 Spare PartsDocument44 pagesBreaker HB200 Spare PartsVetriNo ratings yet

- Norma AsmeDocument70 pagesNorma AsmeElena Estefania PerdomoNo ratings yet

- Cat005 EngDocument2 pagesCat005 Engcara tomateNo ratings yet

- Cat005 EngDocument2 pagesCat005 EngserdarNo ratings yet

- Mechanical Seal Bm3aDocument2 pagesMechanical Seal Bm3aserdarNo ratings yet

- Polutry Sheds - DWGSDocument4 pagesPolutry Sheds - DWGSKarna Satish KumarNo ratings yet

- Durasin & Shockfast Comparsion EnglishDocument1 pageDurasin & Shockfast Comparsion Englishhassan hamdyNo ratings yet

- Sa Series: Submersible Stainless Steel PumpsDocument36 pagesSa Series: Submersible Stainless Steel PumpsĐình Sơn HoàngNo ratings yet

- Brosur Pompa Banjir HCP (LA-HCP-Osmo-1)Document2 pagesBrosur Pompa Banjir HCP (LA-HCP-Osmo-1)plenyunNo ratings yet

- InstructionsDocument2 pagesInstructionsmithuntcvNo ratings yet

- ARCAP - Grades and PropertiesDocument7 pagesARCAP - Grades and PropertiesEminent RishNo ratings yet

- NSN 308post File 2019 12 11 145456.en - IdDocument1 pageNSN 308post File 2019 12 11 145456.en - Idabu yazidNo ratings yet

- Asco Series 290 Angle Body Full CatalogDocument12 pagesAsco Series 290 Angle Body Full CatalogJuan Sebastián BustosNo ratings yet

- Conac p69 74 FormWorkDocument6 pagesConac p69 74 FormWork_at_to_No ratings yet

- PG1 Dril Chucks enDocument44 pagesPG1 Dril Chucks enalexs04No ratings yet

- Ceres SpecDocument2 pagesCeres Specyenling456No ratings yet

- Automig 100S-G / Tigfil 100S-G: AWS A/SFA 5.28Document1 pageAutomig 100S-G / Tigfil 100S-G: AWS A/SFA 5.28Jagannath SahuNo ratings yet

- Stoody 104TJ SAW005Document1 pageStoody 104TJ SAW005Juaros LeonNo ratings yet

- Mil-Dtl-38999 2015 - Corsair - Electrical - CatalogDocument106 pagesMil-Dtl-38999 2015 - Corsair - Electrical - CatalogAVDBNo ratings yet

- List Thick - Ducting 1Document1 pageList Thick - Ducting 1Aris KhoerumanNo ratings yet

- Magnetrol TD2-8D00-032 + Tma-A210-007Document1 pageMagnetrol TD2-8D00-032 + Tma-A210-007BRUNONo ratings yet

- NAS1836Document3 pagesNAS1836Ray DutchmanNo ratings yet

- Blastrite Brown Aluminium Oxide - ALCABDocument1 pageBlastrite Brown Aluminium Oxide - ALCABYoutube For EducationNo ratings yet

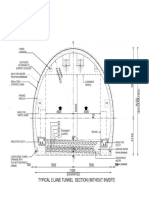

- '2 Lane Without InvertDocument1 page'2 Lane Without InvertShivendra KumarNo ratings yet

- Datasheet For Bucket Elevator (M-3102)Document1 pageDatasheet For Bucket Elevator (M-3102)Joe GrosirNo ratings yet

- Efficiency Becomes Power: SeriesDocument6 pagesEfficiency Becomes Power: SeriesAhmer CamdzicNo ratings yet

- BRB Anti Vibration Mounts BRB Anti Vibration Mounts: Technical Characteristics ApplicationsDocument8 pagesBRB Anti Vibration Mounts BRB Anti Vibration Mounts: Technical Characteristics ApplicationsJairo Andres Romero QuirogaNo ratings yet

- MANUAL 2021 ONIX E ONIX DARK - CompressedDocument16 pagesMANUAL 2021 ONIX E ONIX DARK - CompressedRoberto DeiquesNo ratings yet

- Nas 1714Document2 pagesNas 1714YossiNo ratings yet

- Advanced Oilfield Technology Company: Member of Al Sulaimi GroupDocument1 pageAdvanced Oilfield Technology Company: Member of Al Sulaimi GroupPRASHANT KANTENo ratings yet

- 2M Series: Smaller, Lighter-Weight Alternative For D38999 PerformanceDocument55 pages2M Series: Smaller, Lighter-Weight Alternative For D38999 PerformanceAlejandro JimenezNo ratings yet

- Tschan Barrel Coupling 1343602917Document12 pagesTschan Barrel Coupling 1343602917Carlos Catalán PinoNo ratings yet

- JosamDocument274 pagesJosamdavid0775No ratings yet

- Track Side Indicator Boards and Sign AgesDocument41 pagesTrack Side Indicator Boards and Sign AgesGishnu100% (1)

- Boards OheDocument41 pagesBoards OheMounikaNo ratings yet

- Handbook - Trackside Indicator Boards & SignagesDocument41 pagesHandbook - Trackside Indicator Boards & Signageskausik nath100% (1)

- SS Case Brass Pressure Gauge - Economical - India Pressure GaugeDocument6 pagesSS Case Brass Pressure Gauge - Economical - India Pressure GaugeIndiapressure gaugeNo ratings yet

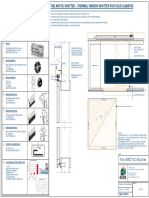

- The Arctic Shutter - Thermal Window Shutter For Cold ClimatesDocument1 pageThe Arctic Shutter - Thermal Window Shutter For Cold ClimatesKhanh DamNo ratings yet

- Electrical Specifications: 3 Rock TechnologyDocument2 pagesElectrical Specifications: 3 Rock Technologyryu winataNo ratings yet

- Mander - Priestley - Park (1988) - Observed Stress-Strain Behavior of Confined ConcreteDocument23 pagesMander - Priestley - Park (1988) - Observed Stress-Strain Behavior of Confined ConcreteSalvatore MirandaNo ratings yet

- POWERMASTER Impact-SocketDocument30 pagesPOWERMASTER Impact-SocketManoj DoshiNo ratings yet

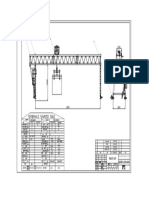

- MG120T-33 12 Segmented Beam Gantry crane-MODELDocument1 pageMG120T-33 12 Segmented Beam Gantry crane-MODELNgoc Duy NguyenNo ratings yet

- Carbonsteel SteelmetalguidebookDocument18 pagesCarbonsteel SteelmetalguidebookEyob AdNo ratings yet

- Img 015Document1 pageImg 015davidNo ratings yet

- DAKAR enDocument2 pagesDAKAR enAvel MahundinganNo ratings yet

- RÖHM Drill Chucks 06.2023 enDocument44 pagesRÖHM Drill Chucks 06.2023 enAndrew KlubokNo ratings yet

- Marax - Pl62X: Line ProDocument16 pagesMarax - Pl62X: Line ProTam Jia TernNo ratings yet

- Water Cleaning and Blasting Catalogue 2021 V1 1Document36 pagesWater Cleaning and Blasting Catalogue 2021 V1 1Nikola AngjelkovskiNo ratings yet

- HYD691 Datasheet: Introducing The Hyd691... Standard Materials of ConstructionDocument4 pagesHYD691 Datasheet: Introducing The Hyd691... Standard Materials of ConstructionIdehen KelvinNo ratings yet

- Metal Building Systems ManualDocument4 pagesMetal Building Systems ManualTrần Tiến0% (1)

- SD 0100CT1902 Sec-16 PDFDocument22 pagesSD 0100CT1902 Sec-16 PDFFerdi BayuNo ratings yet

- Air Master VCDDocument16 pagesAir Master VCDameer pNo ratings yet

- ROBA-stop - M: Electromagnetic Safety BrakesDocument20 pagesROBA-stop - M: Electromagnetic Safety BrakesRafael LinarezNo ratings yet

- Kochadai Sheet 5Document1 pageKochadai Sheet 5அம்ரு சாந்திவேலுNo ratings yet

- Spheron 6000ADocument2 pagesSpheron 6000APLASTIC LAB CBDNo ratings yet

- Anglo–American Microelectronics Data 1968–69: Manufacturers A–PFrom EverandAnglo–American Microelectronics Data 1968–69: Manufacturers A–PNo ratings yet

- Understanding Lightning and Lightning Protection: A Multimedia Teaching GuideFrom EverandUnderstanding Lightning and Lightning Protection: A Multimedia Teaching GuideNo ratings yet

- Plastics in Building Structures: Proceedings of a Conference Held in London, 14-16 June 1965From EverandPlastics in Building Structures: Proceedings of a Conference Held in London, 14-16 June 1965No ratings yet

- Nodia and Company: Gate Solved Paper Civil Engineering 2008Document16 pagesNodia and Company: Gate Solved Paper Civil Engineering 2008Raj BakhtaniNo ratings yet

- BS 1st Semester 20210415Document9 pagesBS 1st Semester 20210415MUHAMMAD NAEEM IQBALNo ratings yet

- Ornek WPS (ASME IX)Document1 pageOrnek WPS (ASME IX)kaynakteknolojiNo ratings yet

- Lempco DieProductsDocument46 pagesLempco DieProductsCarlos PalloNo ratings yet

- Hitachi EX200LC-5 Hydraulic ExcavatorDocument3 pagesHitachi EX200LC-5 Hydraulic Excavatorveera_swamy275% (4)

- Advanced Topics in Bending of BeamsDocument6 pagesAdvanced Topics in Bending of Beamsjones100% (1)

- (SCAC Tropical) Cycle Logic (Eng) - 180914Document33 pages(SCAC Tropical) Cycle Logic (Eng) - 180914Tehnika SiingNo ratings yet

- DEAN RA Bulletin8 24 10 PDFDocument6 pagesDEAN RA Bulletin8 24 10 PDFPatricia J ÁngelesNo ratings yet

- Manufacturing Technologies of Finned TubesDocument11 pagesManufacturing Technologies of Finned TubesK.S.MAYILVAGHANANNo ratings yet

- 1 Semester, 2013/2014Document2 pages1 Semester, 2013/2014pseudobbNo ratings yet

- Two-Dimensional Flow of Water Through Soils: Soil Mechanics-I (CENG-2202) Chapter 5: Seepage Through SoilsDocument8 pagesTwo-Dimensional Flow of Water Through Soils: Soil Mechanics-I (CENG-2202) Chapter 5: Seepage Through SoilsbiniNo ratings yet

- Forward KinematicsDocument183 pagesForward KinematicsYuan HuNo ratings yet

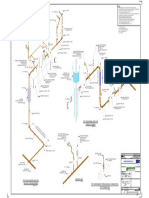

- Piping DWGDocument1 pagePiping DWGkapsarcNo ratings yet

- Drssd07 - Wind On Billboard Frame Struct - CbeDocument23 pagesDrssd07 - Wind On Billboard Frame Struct - CbeNikki Abinoja Sumer100% (1)

- VR17 17ME1204: Siddhartha Engineering CollegeDocument2 pagesVR17 17ME1204: Siddhartha Engineering CollegeDr K Nagamalleswara Rao Associate Professor, ME , VRSECNo ratings yet

- Steam Explosion in Ammonia Plant: W.K. (Bill) Taylor, P. EngDocument10 pagesSteam Explosion in Ammonia Plant: W.K. (Bill) Taylor, P. Engvaratharajan g rNo ratings yet

- Sea Level Sea Level: State Point & Process ReportDocument3 pagesSea Level Sea Level: State Point & Process ReportPracticalHVACNo ratings yet

- DATA SHEET FireDos FD25000 StationaryDocument4 pagesDATA SHEET FireDos FD25000 StationaryPrince GeorgeNo ratings yet

- CNG Relief Valve v5.1 PDFDocument2 pagesCNG Relief Valve v5.1 PDFDavid EspinozaNo ratings yet

- Z002888-0 BlowBy Measuring ToolDocument3 pagesZ002888-0 BlowBy Measuring ToolmarioNo ratings yet

- Machine Frames, Bolted Connections, and WeldedDocument19 pagesMachine Frames, Bolted Connections, and WeldedwinstonsequeiraNo ratings yet