Professional Documents

Culture Documents

Automig 100S-G / Tigfil 100S-G: AWS A/SFA 5.28

Uploaded by

Jagannath SahuOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Automig 100S-G / Tigfil 100S-G: AWS A/SFA 5.28

Uploaded by

Jagannath SahuCopyright:

Available Formats

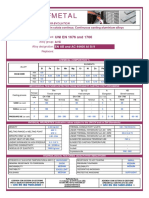

AUTOMIG 100S-G / GMAW/GTAW

LOW ALLOY STEEL

TIGFIL 100S-G (High Strength)

COPPER COATED MEDIUM ALLOYED WIRE FOR HIGH STRENGTH LOW ALLOY

CLASSIFICATION : AWS A/SFA 5.28 APPROVALS :

ER100S-G -

KEY FEATURES :

• Copper coated alloy steel wire • Exhibit high strength as well as low temperature

• Ni-Cr-Mo alloyed toughness

• Smooth feedability, low spatter • Radiographic quality

GMAW: DCEP

WELDING POSITION :

GTAW: DCEN

Shielding Gas Gas Flow Rate, LPM Stickout, mm

GMAW: CO2 15-20 10-20

GTAW: Ar 10-15 -

TYPICAL APPLICATIONS :

• Welding of HY 80 and other similar grade materials • Joining large vehicles and crane manufacturing

• Welding of high strength and low alloy steels • Suitable for single and multi-pass welding of

low alloy steels

STORAGE / HANDLING :

Keep dry during storage and handling

CHEMICAL COMPOSITION OF BARE SOLID WIRE, Wt% :

C Mn Si Cr Ni Mo V S P

Typical 0.08 1.5 0.5 0.3 1.4 0.3 0.08 0.015 0.015

MECHANICAL PROPERTIES OF ALL WELD METAL :

CVN Impact at

Condition UTS, MPa YS, MPa EL%

-40°C, J

Typical As Welded 800 710 24 60

Mechanical properties will vary with the type of shielding gas used.

PACKING DATA :

Ø, mm Kg/Spool

Automig 100S-G 1.2 15

1.6 15

Ø x L, mm Primary Box, Kg No. of Primary Boxes Net Wt. of Carton, Kg

1.6 x 1000 5 4 20

Tigfil 100S-G

2.0 x 1000 5 4 20

2.5 x 1000 5 4 20

PASSION FOR WELDING SINCE 1951 www.adorwelding.com

26

You might also like

- Weld Like a Pro: Beginning to Advanced TechniquesFrom EverandWeld Like a Pro: Beginning to Advanced TechniquesRating: 4.5 out of 5 stars4.5/5 (6)

- Iso 10721-1-1997Document119 pagesIso 10721-1-1997Jagannath SahuNo ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Conducting Polymer LECTURE3 07012021Document27 pagesConducting Polymer LECTURE3 07012021Manteg SinghNo ratings yet

- Current SSPC Standards June2019Document7 pagesCurrent SSPC Standards June2019Aleksander Segura Tinoco100% (1)

- SB Ibl P CBL Submersible Power CableDocument23 pagesSB Ibl P CBL Submersible Power CableMuhammad ShahrukhNo ratings yet

- Automig 110S-G / Tigfil 110S-G: AWS A/SFA 5.28Document1 pageAutomig 110S-G / Tigfil 110S-G: AWS A/SFA 5.28Jagannath SahuNo ratings yet

- Automig 80S-G / Tigfil 80S-G: AWS A/SFA 5.28Document1 pageAutomig 80S-G / Tigfil 80S-G: AWS A/SFA 5.28Jagannath SahuNo ratings yet

- Automig 90S-G / Tigfil 90S-G: Classification: ApprovalsDocument1 pageAutomig 90S-G / Tigfil 90S-G: Classification: ApprovalsJagannath SahuNo ratings yet

- CWC-BookletF1 24Document1 pageCWC-BookletF1 24Jagannath SahuNo ratings yet

- Automig 80s G Tigfil 80s GDocument1 pageAutomig 80s G Tigfil 80s Gvijaysvm999No ratings yet

- Tiginox 385: Classification: en Iso 14343-ADocument1 pageTiginox 385: Classification: en Iso 14343-AJagannath SahuNo ratings yet

- Automig 90S-B9 / Tigfil 90S-B9: EN ISO 21952-A AWS A/SFA 5.28Document1 pageAutomig 90S-B9 / Tigfil 90S-B9: EN ISO 21952-A AWS A/SFA 5.28satnamNo ratings yet

- CWC-BookletF1 12Document1 pageCWC-BookletF1 12satnamNo ratings yet

- CWC-BookletF1 15Document1 pageCWC-BookletF1 15satnamNo ratings yet

- CWC-BookletF1 17Document1 pageCWC-BookletF1 17satnamNo ratings yet

- NiCu-7 solid wire for welding nickel-copper alloysDocument1 pageNiCu-7 solid wire for welding nickel-copper alloyssatnamNo ratings yet

- Automig 80S-B2 / Tigfil 80S-B2: Classification: ApprovalsDocument1 pageAutomig 80S-B2 / Tigfil 80S-B2: Classification: ApprovalssatnamNo ratings yet

- AUTOMIG 80S-Ni1 / TIGFIL 80S-Ni1: AWS A/SFA 5.28 EN ISO 14341-A EN ISO 636-ADocument1 pageAUTOMIG 80S-Ni1 / TIGFIL 80S-Ni1: AWS A/SFA 5.28 EN ISO 14341-A EN ISO 636-AsatnamNo ratings yet

- Tigfil 80S-B2 SPL: AWS A/SFA 5.28 EN ISO 21952-ADocument1 pageTigfil 80S-B2 SPL: AWS A/SFA 5.28 EN ISO 21952-AsatnamNo ratings yet

- Tiginox 308H: Classification: ApprovalsDocument1 pageTiginox 308H: Classification: ApprovalsJagannath SahuNo ratings yet

- Automig 70S A1 - Tigfil 70S A1Document1 pageAutomig 70S A1 - Tigfil 70S A1Vaibhavi ganganeNo ratings yet

- Miginox 310 / Tiginox 310: Classification: en Iso 14343-ADocument1 pageMiginox 310 / Tiginox 310: Classification: en Iso 14343-AJagannath SahuNo ratings yet

- AUTOMIG 5356 / TIGFIL 5356: Classification: ApprovalsDocument1 pageAUTOMIG 5356 / TIGFIL 5356: Classification: ApprovalssatnamNo ratings yet

- AUTOMIG 5183 / TIGFIL 5183: Classification: ApprovalsDocument1 pageAUTOMIG 5183 / TIGFIL 5183: Classification: ApprovalssatnamNo ratings yet

- Tigfil 90S-B3 SPL: Classification: Aws A/Sfa 5.28Document1 pageTigfil 90S-B3 SPL: Classification: Aws A/Sfa 5.28satnamNo ratings yet

- Domex 650 MC Hot Rolled, Extra High Strength, Cold Forming SteelDocument2 pagesDomex 650 MC Hot Rolled, Extra High Strength, Cold Forming SteelHugo RodriguezNo ratings yet

- AUTOMIG 80S Ni1 - TIGFIL 80S Ni1Document1 pageAUTOMIG 80S Ni1 - TIGFIL 80S Ni1Kalyan Chakravathi A GNo ratings yet

- Merit S-G: Lincoln Electric China Gmaw Solid WireDocument2 pagesMerit S-G: Lincoln Electric China Gmaw Solid Wiredev-nullNo ratings yet

- Echnical Ulletin: Used For Joining in Large Vehicle and Crane ManufacturingDocument1 pageEchnical Ulletin: Used For Joining in Large Vehicle and Crane ManufacturingSungJun ParkNo ratings yet

- AUTOMIG 4043 / TIGFIL 4043: Classification: ApprovalsDocument1 pageAUTOMIG 4043 / TIGFIL 4043: Classification: ApprovalssatnamNo ratings yet

- Automig 4043 - Tigfil 4043Document1 pageAutomig 4043 - Tigfil 4043Muhammad Whisnu NugrahaNo ratings yet

- Merit S-6: Lincoln Electric China Gmaw Solid WireDocument2 pagesMerit S-6: Lincoln Electric China Gmaw Solid Wirelovaldes62No ratings yet

- Stainless SteelDocument1 pageStainless SteelSadashiva sahoo100% (1)

- C-Mn Steel Solid Filler Rod for GTAW WeldingDocument1 pageC-Mn Steel Solid Filler Rod for GTAW WeldingsatnamNo ratings yet

- TIGFIL 70S-6: AWS A/SFA 5.18 EN ISO 636-A Csa W48Document1 pageTIGFIL 70S-6: AWS A/SFA 5.18 EN ISO 636-A Csa W48satnamNo ratings yet

- CWC-BookletF1 36 PDFDocument1 pageCWC-BookletF1 36 PDFJagannath SahuNo ratings yet

- GMAW/GTAW Welding of Aluminium Alloys with ER1100 WireDocument1 pageGMAW/GTAW Welding of Aluminium Alloys with ER1100 WiresatnamNo ratings yet

- Miginox 308lsi: Aws A/Sfa 5.9 EN ISO 14343-ADocument1 pageMiginox 308lsi: Aws A/Sfa 5.9 EN ISO 14343-AJagannath SahuNo ratings yet

- Automig FC 71 T1Document1 pageAutomig FC 71 T1Sushil BhansaliNo ratings yet

- Domex 650 MC Hot Rolled, Extra High Strength, Cold Forming SteelDocument2 pagesDomex 650 MC Hot Rolled, Extra High Strength, Cold Forming SteelBo WangNo ratings yet

- Miginox 309L / Tiginox 309L: Aws A/Sfa 5.9 EN ISO 14343-ADocument1 pageMiginox 309L / Tiginox 309L: Aws A/Sfa 5.9 EN ISO 14343-AJagannath SahuNo ratings yet

- GTAW Tigfil 70S-2 Triple Deoxidized Copper Coated C-Mn Steel Filler RodDocument1 pageGTAW Tigfil 70S-2 Triple Deoxidized Copper Coated C-Mn Steel Filler RodSureshNo ratings yet

- Automig 70S-6 N: EN ISO 14341-A AWS A/SFA 5.18 Csa W48Document1 pageAutomig 70S-6 N: EN ISO 14341-A AWS A/SFA 5.18 Csa W48satnamNo ratings yet

- Automig FC 71T-1: AWS A/SFA 5.20 EN ISO 17632 A AWS A/SFA 5.36Document1 pageAutomig FC 71T-1: AWS A/SFA 5.20 EN ISO 17632 A AWS A/SFA 5.36satnamNo ratings yet

- MIGINOX 2209 / TIGINOX 2209: Gmaw / Gtaw Duplex Stainless SteelDocument1 pageMIGINOX 2209 / TIGINOX 2209: Gmaw / Gtaw Duplex Stainless SteelV U P RaoNo ratings yet

- Midalloy ER80S-B6 Welding Wire Technical BulletinDocument1 pageMidalloy ER80S-B6 Welding Wire Technical Bulletinjoel cisnerosNo ratings yet

- PDS - Bohler N ER 70 S-2 NACE PDFDocument1 pagePDS - Bohler N ER 70 S-2 NACE PDFwesley59No ratings yet

- Welding ConsumablesDocument79 pagesWelding Consumablesazam RazzaqNo ratings yet

- CWC-BookletF1 10Document1 pageCWC-BookletF1 10satnamNo ratings yet

- Supabase X Plus 2Document1 pageSupabase X Plus 2Michael FortunaNo ratings yet

- Miginox 307: Classification: en Iso 14343-ADocument1 pageMiginox 307: Classification: en Iso 14343-AJagannath SahuNo ratings yet

- GBTDocument1 pageGBTRaviTeja BhamidiNo ratings yet

- Miginox 347 / Tiginox 347: Classification: ApprovalsDocument1 pageMiginox 347 / Tiginox 347: Classification: ApprovalsJagannath SahuNo ratings yet

- Primacore MW 71Document2 pagesPrimacore MW 71rjan7peNo ratings yet

- Miginox 316lsi: Aws A/Sfa 5.9 EN ISO 14343-ADocument1 pageMiginox 316lsi: Aws A/Sfa 5.9 EN ISO 14343-AJagannath SahuNo ratings yet

- Cromoten 9 1Document1 pageCromoten 9 1Muhammad UsmanNo ratings yet

- Gb8417domex500mc PDFDocument2 pagesGb8417domex500mc PDFMario MereniNo ratings yet

- Tigfil 70S-2: Aws A/sfa 5.18 en Iso 636-ADocument1 pageTigfil 70S-2: Aws A/sfa 5.18 en Iso 636-AsatnamNo ratings yet

- The Aluminium Evolution: Continuous Casting Aluminium AlloysDocument2 pagesThe Aluminium Evolution: Continuous Casting Aluminium AlloysHareth MRAIDINo ratings yet

- X-Tract Electrical Submersible Pump CableDocument2 pagesX-Tract Electrical Submersible Pump CableHarry RincónNo ratings yet

- NAAMM Metal Bar Grating Manual 531 - Part17Document2 pagesNAAMM Metal Bar Grating Manual 531 - Part17Jagannath SahuNo ratings yet

- MGB 532-XX First Ballot 02122019 Part2Document1 pageMGB 532-XX First Ballot 02122019 Part2Jagannath SahuNo ratings yet

- MGB 532-XX First Ballot 02122019 Part7Document1 pageMGB 532-XX First Ballot 02122019 Part7Jagannath SahuNo ratings yet

- SSPC PA1 2016 - Part10Document1 pageSSPC PA1 2016 - Part10Jagannath SahuNo ratings yet

- SSPC PA1 2016 - Part1Document1 pageSSPC PA1 2016 - Part1Jagannath SahuNo ratings yet

- Piercing Line and Dark Cloud Cover candlestick patternsDocument2 pagesPiercing Line and Dark Cloud Cover candlestick patternsJagannath SahuNo ratings yet

- 10 PRICE ACTION CANDLESTICK PATTERNS YOU MUST KNOW - Part6Document2 pages10 PRICE ACTION CANDLESTICK PATTERNS YOU MUST KNOW - Part6Jagannath SahuNo ratings yet

- NAAMM Metal Bar Grating Manual 531 - Part2Document2 pagesNAAMM Metal Bar Grating Manual 531 - Part2Jagannath SahuNo ratings yet

- 10 Price Action Candlestick Patterns You Must Know - Part10Document2 pages10 Price Action Candlestick Patterns You Must Know - Part10Jagannath SahuNo ratings yet

- 10 PRICE ACTION CANDLESTICK PATTERNS YOU MUST KNOW - Part3Document2 pages10 PRICE ACTION CANDLESTICK PATTERNS YOU MUST KNOW - Part3Jagannath SahuNo ratings yet

- Interpreting SNT TC 1A PDF 6Document1 pageInterpreting SNT TC 1A PDF 6Jagannath SahuNo ratings yet

- 10 Price Action Candlestick Patterns You Must Know - Part4Document2 pages10 Price Action Candlestick Patterns You Must Know - Part4Jagannath SahuNo ratings yet

- Interpreting SNT TC 1A PDF 7Document1 pageInterpreting SNT TC 1A PDF 7Jagannath SahuNo ratings yet

- Interpreting SNT TC 1A PDF 3Document1 pageInterpreting SNT TC 1A PDF 3Jagannath SahuNo ratings yet

- GMAW GTAW MIGINOX 347Si STAINLESS STEELDocument1 pageGMAW GTAW MIGINOX 347Si STAINLESS STEELJagannath SahuNo ratings yet

- 10 PRICE ACTION CANDLESTICK PATTERNS YOU MUST KNOW - Part2Document2 pages10 PRICE ACTION CANDLESTICK PATTERNS YOU MUST KNOW - Part2Jagannath SahuNo ratings yet

- Interpreting SNT TC 1A PDF 2Document1 pageInterpreting SNT TC 1A PDF 2Jagannath SahuNo ratings yet

- Interpreting SNT TC 1A PDF 1Document1 pageInterpreting SNT TC 1A PDF 1Jagannath SahuNo ratings yet

- Interpreting SNT TC 1a - Part3 PDFDocument2 pagesInterpreting SNT TC 1a - Part3 PDFஅன்புடன் அஸ்வின்No ratings yet

- Miginox 316lsi: Aws A/Sfa 5.9 EN ISO 14343-ADocument1 pageMiginox 316lsi: Aws A/Sfa 5.9 EN ISO 14343-AJagannath SahuNo ratings yet

- STD 2nd MathsDocument2 pagesSTD 2nd MathsJagannath SahuNo ratings yet

- Miginox 347 / Tiginox 347: Classification: ApprovalsDocument1 pageMiginox 347 / Tiginox 347: Classification: ApprovalsJagannath SahuNo ratings yet

- Miginox 308lsi: Aws A/Sfa 5.9 EN ISO 14343-ADocument1 pageMiginox 308lsi: Aws A/Sfa 5.9 EN ISO 14343-AJagannath SahuNo ratings yet

- Tiginox 385: Classification: en Iso 14343-ADocument1 pageTiginox 385: Classification: en Iso 14343-AJagannath SahuNo ratings yet

- Mary Kom's Journey to Becoming India's Most Decorated BoxerDocument16 pagesMary Kom's Journey to Becoming India's Most Decorated BoxerJagannath SahuNo ratings yet

- CWC-BookletF1 36 PDFDocument1 pageCWC-BookletF1 36 PDFJagannath SahuNo ratings yet

- Miginox 310 / Tiginox 310: Classification: en Iso 14343-ADocument1 pageMiginox 310 / Tiginox 310: Classification: en Iso 14343-AJagannath SahuNo ratings yet

- Miginox 309L / Tiginox 309L: Aws A/Sfa 5.9 EN ISO 14343-ADocument1 pageMiginox 309L / Tiginox 309L: Aws A/Sfa 5.9 EN ISO 14343-AJagannath SahuNo ratings yet

- Material Selection For Chemical Process Equipment: Engr. Sandino Michael Angelo G. Aguilar, Che Subject InstructorDocument26 pagesMaterial Selection For Chemical Process Equipment: Engr. Sandino Michael Angelo G. Aguilar, Che Subject InstructorGautam VadnereNo ratings yet

- DEVELOPMENT OF GFRP IRRIGATION WATER GATESDocument11 pagesDEVELOPMENT OF GFRP IRRIGATION WATER GATESHanhan Ahmad SNo ratings yet

- Construction: Pompidou Center, ParisDocument10 pagesConstruction: Pompidou Center, ParisHusna AfifiNo ratings yet

- Sheel PilesDocument15 pagesSheel Pilesعصام ايادNo ratings yet

- Properties and Selection of Construction MaterialsDocument74 pagesProperties and Selection of Construction MaterialsCG GK ONLINE TESTNo ratings yet

- Material Selection Using Ashby MethodDocument6 pagesMaterial Selection Using Ashby MethodRaúl AnelNo ratings yet

- مواصفات التعبئة والتغليف سبتمبر 2020Document330 pagesمواصفات التعبئة والتغليف سبتمبر 2020mohamed masoud0% (1)

- Ryton QC160N and QC160P: Polyphenylene Sulfide AlloysDocument2 pagesRyton QC160N and QC160P: Polyphenylene Sulfide AlloysJustin HendrixNo ratings yet

- Kelco-Crete DG-FDocument3 pagesKelco-Crete DG-FPelleNo ratings yet

- Claretech BVL: Typical Characteristics DescriptionDocument1 pageClaretech BVL: Typical Characteristics DescriptionFaizsyah WaryNo ratings yet

- Polymer Abbreviations: Abbreviation Chemical NameDocument5 pagesPolymer Abbreviations: Abbreviation Chemical NameProcess LibraryNo ratings yet

- Keskes Materials - Techn PDFDocument5 pagesKeskes Materials - Techn PDFm sai ravi tejaNo ratings yet

- Engr: Temoor Abbas Larik: QUCEST Larkana Campus Mechanical Engineering DepartmentDocument42 pagesEngr: Temoor Abbas Larik: QUCEST Larkana Campus Mechanical Engineering DepartmentTemoor AbbasNo ratings yet

- Glass Recycling Process: By: Charo Mel TabloDocument42 pagesGlass Recycling Process: By: Charo Mel TabloCharo Mel TabloNo ratings yet

- CNC Grinding Machine GuideDocument15 pagesCNC Grinding Machine GuidejishnuNo ratings yet

- Structural Lightweight Concrete in Hong Kong: Now, New, NextDocument6 pagesStructural Lightweight Concrete in Hong Kong: Now, New, NextSteven F. S. BruniNo ratings yet

- Science 5 Quarter 1 Module 3 Week 3Document6 pagesScience 5 Quarter 1 Module 3 Week 3Vhacie TorresNo ratings yet

- PC5300NC5330 MetricDocument20 pagesPC5300NC5330 MetricSakthi VelNo ratings yet

- Block Data Sheet En771Document1 pageBlock Data Sheet En771ivanNo ratings yet

- Retrofitting of RC Structure Using FRP Laminate: AbstractDocument10 pagesRetrofitting of RC Structure Using FRP Laminate: AbstractYo Yo AkNo ratings yet

- Lockable Dowels - Precast PDFDocument12 pagesLockable Dowels - Precast PDFkamakshiNo ratings yet

- FAQ: What's The Difference Between Canvas Micarta and Linen Micarta? How Do They Compare To G-10?Document1 pageFAQ: What's The Difference Between Canvas Micarta and Linen Micarta? How Do They Compare To G-10?kayraNo ratings yet

- TSM1501G: Toyota Engineering StandardDocument12 pagesTSM1501G: Toyota Engineering StandardMiguel FelipeNo ratings yet

- Bs 5400 Part 7Document24 pagesBs 5400 Part 7Ivy PaulNo ratings yet

- Technical Data Probes DatasheetDocument5 pagesTechnical Data Probes DatasheetasfsndNo ratings yet

- Technical Product Information: Halfen Huc Universal ConnectionDocument28 pagesTechnical Product Information: Halfen Huc Universal ConnectionJack KenningNo ratings yet

- Cast LiveniDocument36 pagesCast LiveniСлободан ЗорнићNo ratings yet

- TrainingDocument8 pagesTrainingTenzin WangchukNo ratings yet

- Premium Acrylic Sealant Technical Data SheetDocument2 pagesPremium Acrylic Sealant Technical Data SheetArex NadaNo ratings yet