0% found this document useful (0 votes)

41 views52 pagesColloids in Water Treatment Processes

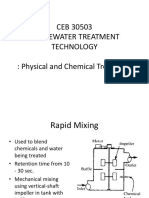

The document discusses coagulation and flocculation processes used in water treatment. [1] Coagulation involves adding chemicals like aluminum and iron salts to destabilize colloidal particles in water by neutralizing their negative charges. [2] Flocculation is the process where the destabilized particles agglomerate into larger flocs that are easier to remove. [3] Jar tests are used to determine the optimum pH and coagulant dose needed to effectively remove turbidity from water samples.

Uploaded by

Eng mohammadCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

41 views52 pagesColloids in Water Treatment Processes

The document discusses coagulation and flocculation processes used in water treatment. [1] Coagulation involves adding chemicals like aluminum and iron salts to destabilize colloidal particles in water by neutralizing their negative charges. [2] Flocculation is the process where the destabilized particles agglomerate into larger flocs that are easier to remove. [3] Jar tests are used to determine the optimum pH and coagulant dose needed to effectively remove turbidity from water samples.

Uploaded by

Eng mohammadCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd