Professional Documents

Culture Documents

Hit Re 500 + Hit V PDF

Uploaded by

ErlanggaRizkiFauzi0 ratings0% found this document useful (0 votes)

75 views21 pagesOriginal Title

HIT RE 500 + HIT V.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

75 views21 pagesHit Re 500 + Hit V PDF

Uploaded by

ErlanggaRizkiFauziCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 21

Paes

PS eR Sao}

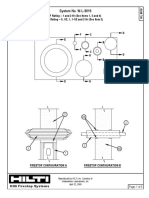

HIT-RE 500 mortar with HIT-V / HAS rod

Injection mortar system

Ranafite

Hilt

HIT-RE 500

330 mi foil pack

{also available

as 500m

y and 1400 m

foil pack)

Static mixer

HAS rod

= SAFEset technology driling and

borehole cleaning in one step.

with Hitt hollow drill bit

‘suitable for non-cracked concrete

20/25 to C 50/60

~ high loading capacity

suitable for dry and water

saturated concrete

~ under water application

- large diameter applications

~ high corrosion resistant

= long working time at elevates

temperatures

~ odourless epoxy

=_embedment depth range:

from 40... 160 mm for M8

to 120 ... 600 mm for M3C

AIT-V roe

s =n HCR

i a highMo} |SAOB Sareset

Smaledge Variable ‘eon Tigh Diamond ili SAFEset

Concrete distance ambodmeni ,,FF@_, Comson rosin lee -—_technoloy with

and spacing depth resistance roles hollow dil bit

European CE PROFIS

Technical ni ‘Anchor design

‘Approval Conformity software

Approvals / certificates

Description Authority / Laboratory No. | date of issue

ropean technical apgroval a) DIBt Berlin =1A-04/0027 | 2013-06-26

=| “JB 3565 74595 1 2006-10-25

Fire test report IBMB, Braunschweig JB 3588 / 4825 | 2008-11-18

Assessment report (a) warrngioniie WE 3278048 1 2013-07-10

a) Alldata given in this section according ETA-04/0027, issue 2013-06-26,

556

09/2014

eRe uc

Basic loading data (for a single anchor)

All data inthis section applies to For details see Simplified design method

Correct setting (See setting instruction)

No edge distance end spacing influence

+ Stoai failure

= Base material thickness, as specified inthe table

- Qne typical embedment depth, as spectiec in the table

- Qne anchor materia, as specified in the tables

= Concrete C 20/25, fs ine = 25 Nim?

= Temperature range |

‘min. base material terrperature -40°C, max. feng term/short term base material temperature +24°C/40°C)

- Installation temperature range +5°C to *4(°C

Embedment depth ® and base material thickness for the basic lcading data.

Mean ultimate resistance, characteristic resistance, design resistance, recommended

loads.

[Anchor size Ma] Mic | Miz | wie | M20 | M24 | M27 | M30 | M33 | m6 | M30

Typical embedment depth{mm] | @0_| 9c | 110 | 125 | 470 | 210 | 240 | 270 | 300 | 330 | 360

Base material thickness [mm] tic | 120 [140 | 165 | 220 | 270 | aoc | 340 | 300 | 410 | 450

a) The allowed range of embedment depth 1s Shown in the setting cetails. The corresponcing load values can be

calculated according tc the simplified design method

For hammer drilled holes and hollow drill bit:

Mean ultimate resistance: concrete C 20/25 — fex.cuve = 25 Nimm®, anchor HIT-V 5.8

ETA-04/0027, issue 2013-06-26 ‘Additional Hilti

for hammer drilling and hollow drill bit technical data

[Anchor size map] mac [maz] te | M20 [M24 | M27 [wan | M33 | wae | 39

Tensile Neon AIT-VS@ kN | 486 | 90.5 | 44.1 | 3.0 |120,2|185.6|241,5|205.1|364.4|428.5| 459.5

ShearVaun HIT-V5@ (kN | 9¢ [15.6[ 224] 44.0] 64: | 924 [120.8] 147.0] 162,2|214.5] 256.2

Characteristic rasistanea: concrete C 20/25 — fexcube = 25 Nimm?, anchor HIT-V 5.8

ETA-04/0027, issue 2013-06-26 Adi Hilt

forhammer drilling and hallow dil hit technical data

[Anchor size a] Mac | M12] mie | M20 [M24 | M27 [30 | M32 | wae | wae

Tensile Nx HIT-V5@ KN | 186 | 29.6 | 420 | 70,6 |111,¢|153,7|187.8|224.0|262,4|302,7|344,

Shearv HiT-vse@ kN | 90 [456 21.0 [ 39.0] 610 | ac |176.0|740,0[773.5[204,3] 244,.¢

Design resistance: concrete C 20/25 — fucube = 25 Nimm*, anchor HIT-V 5.8

ETA-04/0027, issue 2013-06-26

for hammer drilling and hollow drill bit

[Anchor size ms | mac [M12] mae | 20 | M24 | mi27 | M30 | M33 | M36 | M39

TensileNge HIT-V58 [kN | 12.0 | 19,3 | 27,7 | 336 | 83,3 | 73.2 | 89,4 |106,7|125.0|144,2| 164,

ShearVks HiT-V5@ kN | 7.2 [120] 168] 31,2] 488 70.4 | 92.0 ]112,¢] 198.8] 163,4] 195.2

Recommended loads ® cancrate © 20/25 = fekcube = 25 Nimm?, anchor HIT-V 5.8

ETA-04/0027, issue 2013-06-26

for hammer drilling and hollow drill bit technical data

(Anchor size ms [mac [ M12 | mae | 20 | M24 | 27 | M30 | M33 | M36 | M30

TensileNee HIT-V5@__IkN | 8€ | 138 | 19.8 | 24.0 | 38.1 | 622 | 63.9 | 76.2 | 89.2 |103,0[ 117.4

[ShearVee HiT-V5@ kN | 5.4 | 86 | 120] 22.8] 349] 502 | 657 | a0. [997 [116 7] 139.4

a) With overall partial safely factor for action 7 = 1,4, The partial salety factors for action depend on the type of

‘ading and shall be teken from national regtiations.

9/2014 587

Paes

PS eR Sao}

Moan ultimate rosistance: concrete C 20/25 — fs... = 25 Nimm’, anchor HIT-V 5.8

ETA-04/0027. issue 2073-06-26 for diamond drilling

[Anchor size ms | mio | Miz | mie | zo | M24 | M27 [| M30

Tensile Naum _HIT-V 5.8 (kN) | a9 | 305 | 447 | 830 | t292 | 4059 | 2475 | 267.2

fsnearVaun HiT-vss tk] 96 | asa | 204 | 4x0 | ot | 924 | s208 | 47,0

Characteris tance: concrete C 20/25 — fescue = 25 Nimm?, anchor HIT-V 5.8

ETA-04/0027, issue 2073-06-26 for diamond drilling

[Anchor size ms | mio | miz | mie | zo | m24 | m27 [M30

TensileNa HiT-V58 tkN | a0 | geo | azo | 7o6 | 1119 | 1537 | 1832 | 2163

[snearve HiT-ves tk] go | 450 [ 240 | 390 | 6x0 | a0 | 1150 | 1400

Design resistance: concrete C 20/25 — feacube = 25 Nimm?, anchor HIT-V 5.8

ETA-04/0027, fesue 2013-06-26 for diamond driling

[Anchor size MB M10 Miz M16 ‘M20. M24 M27 M30.

TensieNes HT-V58 tk | 120 | 193 | 2a0 | ax6 | 33 | 792 | ov | 1090

fsnearVas —HiT-v58 kN] 72 | 120 [ tea | 242 | aaa | rma | on | 1120

Recommended loads *!: concrete C 20/25 = fckcube= 25 Nimm?, anchor HIT-V 5.8

ETA-04/0027, issue 2013-06-26 for diamond drilling

[Anchor size Me [| mio [ Miz | MiG | M20 | M24 | M27 | M30

TensileNe HITV5S€ kN | 6 | 136 | 200 | 240 | 361 | 523 | 623 | 736

Shear Vie HIT-V5@ KN | 5.4 ae | 120 | 223 | 349 | 503 | 657 | 0c

a] With overall partial safety factor for action = 1,4. The partial salety factors for action depend on the type of

joading and shall be teken from national regLiations.

558 09/2014

Paes

Pe

Service temperature range

Hilt HIT-RE_ 500 injecton mortar may be applied in the temperature ranges given below. Ar elevated base material

‘temperature may lead to a reduction ofthe design bond resistance.

; Maximum long term] Maximum short ferm

Temperature range Fated base material base material

temperature temperature

Temperature range =40°C to 40°C 424°C +20 °C.

rremperature range | =40°C10¥58°C +35°C +58°C

Temperature range I =A0*C10470°C 443°C +70°C.

Max short term base material temperature

Short-term elevated base material temperatures are those that oocur over brief intervals, e.g. as a resut of

diumal cycling

Max long term base material temperature

Long-term elevated base material temperatures are roughly constant over significant periocs of time,

Materials

Mechanical properties of HIT-V / HAS

‘Additional Hilt

Data according ETA-04/0027, issue 2013.06.26 {4ctional Hi

[Anchor size ms_[wa0 [wiz [wire | wz0 [za [wr [M30 M33 | M36 | M39

HiT-VHiAS 68 _[Nimm]| 500 | 600 | 500 | 500 | 500 | 500 | 00 | 500_| 600 | 500 | 500

Nominal “HITVIHAS 8.8 [N/mm] @00 | 00 |"@00 | 00 [200 | 00 | 200 | 00 | 200 | 200 | 200

itengt fg_HUEMHAS-R_—Nmm}|-7oo_[-roo_[-ro0-[-ron-|-7o|-roo_|-s00—[-so0—_so0_[-500_[-500

HILVRAS-HGK_[Nimme|] wou | wuu | wu | wu | suv | rv | rw | rw | suv | oud | ow

HITAIHAS & 8 —[N/mme}}-400-|-400-} 400] 400°} 400" 400-] 400" -400-|-400-} 400] 400"

Yicld _—-HIT-VIHAS 8.8 _[Nimmél| 640 | 640 | 640 | 640 | 640 | 640 | 640 | 640 | 640 | 620 | 610

strength fy. HITVHAS-R _[Nimme]] 450 | 450 | 480] 450 | 480 | a0 | 210 | 210 | 210 | 210 | 210

HIEVAS-HOR_[Wmmre]] 600 | 600 | 600 | 600 | 600 | 400 | 400 | 400 | 250 | 250 | 250

Stressed HAS. Immr]_ [328 [523 | 76.2 | 144 | 225 | 324 | 427 | 519 | B47 | 759 | 913

section A; HIT V [mm] | 36.6 | 58.0 | 84,3 | 157 | 245 | 353 | 159 | 561 | 604 | B17 | 976

Moment of Has trome)_| 27.0 | 64,1 | 93 | 244 | ara | 209 | 274 | +700 | 2324 | 2049 | 3094

resistance

iw ITV tame]_[ 372 [623 | 09 | 277 | sat | 935 [ 1387 | tava | 27e| 3204] 4201

9/2014 559

Paes

PS eR Sao}

Material quality

HAS 5.8 M6 — M24

Part Material

Threaded roc Strength class 58, Ar > 8% ductile

AIT) steel galvanized 2 5 pm,

F) hot dipped galvanized 2 45 um,

Threaded 106

AIT-VIF)

AS 8.8 M27 = M3

Strength class 8.8, Ae > 8% ductile

steel galvanized > 5 um,

(F) hot dipped galvanized 2 45 um,

Threaded roc

AIT-VAR, HAS-R

Stainless steel grade M4, Ac > 8% ductile

strenath class 70 for < M24 and class 50 for M27 to M30, 1.4401; 1.4404;

1.4578, 1.457%, 1.4036, 1.4362

Threaded roc

HIT-V-HCR, HAS-HCR

High corrosion resistart steel, 1 4529; 7 4565

strength < M20: Ry. = 800 Nimm?, Ro = 640 Nimm?, A > 8% ductile

M24 to M30: R= 700 Nimm?, Rso2 = 400 Nimm*, As > 8% ductile

Washer

‘SO 7089

‘Steel galvanized hot cipped galvanizes

Stainless steel, 1,440 1.4404, 1.4578, 14571, 1.4430, 1.4962,

High corrosion resistart steel, 1.4529; 1.4565

Strength class 8

steel galvanized 2 5 um,

hot dipped aalvanized 2 45 um,

Strength class 70, stairess steel grade Ad

1.4401, 4-404; 4.4576, 1.457%, 1.4439, 1.4362

Strength class 70, high corrosion resistant steel

1.4529; 1.4565

Anchor dimensions

[Anchor size M8 | Mi¢ | M12 | M16 M20 | M24 | M27 | M30 | M33) M36 | M39

frenirets glel/eE/SlF 1s} 8] s)e g

[Anchor embedment depth [mm 80_| 90 | 140 | 125 | 170 | 210 | 2ac | 270 | 300 | 330 | 360

[Anchor rod)

HIT-V, HIT-V-R, HIT-VHCR

‘Anchor rods HIT-V (-R / CR) are available in variabie length

Hilti recommended tools

Setting

installation equipment

[Anchor size M8 M10 M12 M16 M20 M24 M2? M30

Rotary hammer TEI—TE1E TE40-TE7C

[Other fools, ‘Compressed air gun or Blow oul pump set of Geaning brushes, Gepenser

[Additional

DD EC-1, DD 100 ... DD xxx®

a) For anchors in diamond driled holes load values for combined pul-out and concrete core resistance have fo be

reduced (see section "Setting instruction”)

560

09/2014

Paes

Pe

Setting instruction

Bore hole drilling

a) Hilti hollow drill bit

(or ary and wet concrete only]

Drillhole tothe required embedmert depth with an appropriately sized

HiicTE-CD or TE-YD hollow dri bit with il vacuum attachment. This

dling system removes the dust and cleans the bore hole during driling

‘when used in acoordance with the users manual

‘After driling is complete, proceed to the ‘injection preparation’ step in the

instructions for use

b) Hammer drilling

(Giy or wet concrete and instalation in flooded holes (no sea water))

Drill Hole to the required embedment depth with a hammer drill set in

‘otation-hammer mode using an appropriately sized carbide drill bit

Tor Gry and wet concrete only)

Diamond coring is perrrissible when diamond core driling machine and

the corresponding core bit are used

Bore hole cleaning Just before setting an anchor, the bore hole must be tree of dust anc debris.

a) Manual Cleaning (NC) non-cracked concrete only

for bore hole diameters diss 20mm and bore hole depth tus 20d or hs 260 mm (d = diameter cf element

The Hilti manual pump may be used for blowing out bore holes up to

diameters c)s 20 mm and embedment depths up to Fars 10d

Blow out at least 4 times from the back of the bore hole until return air

stream is free of noticeable dust

Brush 4 times with the specified brish size (brush diameter = bore hole)

by inserting the steel brush Hilt HIT-2B to the back of the tole (ifneedec

with extension) in a twsting motion and removing it

The brush must produce natural resistance as i enters the bore hole -if

‘tot the brush is too small and must be replaced with the proper brush

diameter

Blow out again with manual pump at least 4 times unti return air strearr is

free of noticeable dust.

9/2014

561

Paes

PS eR Sao}

b) Compressed air cleaning (CAC)

{or all bore hole diameters doand all bore hole dept he

Blow 2 times from the back of the hole (I needed with nozzle extension}

over the hole length wth oil-free compressec ai (min. 6 bar at 6 m'/t)

Unt retum air stream is free of noticeable dust

Bore hole diameter 2 32 mm the compressor must supply a minimum air

flow of 140 m¢hour

Bush 2 times with The specified Brish size by inserting the steel Brish

Hit HIT-RB to the back ofthe hoe if needed with extension) ina twisting

motion and removing it

The brush must produce natural resistance as it enters the bore hole =if

‘nat the brush is too small and must be replaced with the proper brush

diameter.

Blow again with compressed air 2 times until return air stream is free of

noticeable dust.

) Cleaning for under water

{or all bore hole diameters duand all bore hole deptr h

Flush 2 times the hole by inserting a water hese (water-line pressure) to

the back of the hole unfil water runs clear

Brush 2 Tmes wit Te spectied brish size by inserting the Steel brush

Hit HIT-RB to the back ofthe hoe if needed with extension) in a twisting

motion and removing it

The brush must produce natural resistance as it enters the bore hole - if

‘ot the brush is too srralf and must be replaced withthe proper brush

diameter

Flush again 2 times the hole by inserting a water hose (water-line

pressure) tothe back ofthe hole until water runs clear

d) Cleaning of hammer drilled holes and diamond cored holes

{or al bore hole diameters doand all bore hole deptr ho

Flush 2 times the hole by inserting a water hese (water-line pressure) to

the back of the hole until water runs clear

Brush 2 times with the specified brish size by inserting the steel Brush

Hi HIT-RB to the back of the Fole (if needed with extension) in a twisting

motion and removing it

The brush must produce natural resistance aé it enters the bore hole -if

‘not the brush is too srralf and must be replaced withthe proper brush

diameter.

562 09/2014

Paes

Pe

Flush again 2 times the hole by inserting a water hose (water-tiné

pressure) to the back ofthe hole until water runs clear

Blow 2 times from the back of the hole (i needed with nozzle extension)

over the hole length wth oil-free compressec air (min. 6 bar at 6 m*/t)

Until retum air stream is free of noticeable dust and water.

Bore hole diameter 2 32 mm the compressor must supply a minimum air

flow of 440 m'#hour.

Brush 2 times with the specified brish size by inserting the steel brush

Hit HIT-RB to the back of the Fole (if needed with extension) in a twisting

motion and removing it

The brush must produce natural resistance ae t enters the bore hole = if

‘ot the brush is too small and must be replaced with the proper brush

diameter.

Bow again with compressed air 2 times until etumn air stream is free of

noticeable dust and water.

Tighily attach new Hill mixing nozzle FIT-RE-M fo fol pack manifoe

(nug ft), Do not modify the mixing nozzle. Observe the instruction for use

ofthe dispenser and rrortar

Check foil pack holder for proper function. Dc not use damaged foil packs

Tholders

Insert fol pack into foi pack holder and put holder into HIT-cispenser,

The fol pack opens automatically as dispensing is infiated Discard intial

adhesive. Depending on the size of the foil peck an intial amount of

adhesive has to be discarded

Discard quantities are

2 strokes for 320 ml foi pack

3 strokes for 5C0 mi fol pack

{55 ml for 140€ mi foil pack.

9/2014 563

Paes

PS eR Sao}

Inject adhesive from the back of the borehole without forming air void

Inject the adheeive etarting at the back of the hole, slowly withdrawing the

mixer wth each trigger pull

Fill holes approximately 2/3 ful. tis required that the annular gap between

the anchor and the concrete is completely filled with adhesive along the

emhedment length

‘After injection is completed, depressurize the dispenser by pressing the

roleaee trigger. The will prevent further adhesive diecharge from the.

mixer

‘Overhead instalation andlor nstallalion with embedment depth he >

250mm,

For overhead installation the injection is only possible with the aid of

extensions and piston plugs. Assemble HiT-RE-M mixer, extension(s) and

appropriately sized piston plug HIT-SZ_ Insert piston plug to back of the

hole-and inject adhesive: During injection the piston plug wil-be naturally

extruded out of the hare hole by the adhasive pressure.

Under water application: fl borehole completely with mortar

Before use, verily that the elements dry and free of oi and other

contaminants,

Mark and ect clement to the required embedment depth untill working time

Thesk as elapsed,

For overhead installation use piston plugs and fix embedded paris with

0.9, wedges HIT-OHW.

Loading the anchor:

After required curing time tare the anchor can he Inadedt

‘The epplied installation torque shall net excoed Tas

For detailed informaticn on installation see instruction for use given wth the package of the product.

564 09/2014

eRe uc

Pa VAI

Curing time for general conditions

Data according ETA(4/0027, issue 2013-06-26

Temperature Working time in which anchor | Curing time before anchor

of the base material can be inserted and adjusted tus can be fully loaded toys

40°C ‘12min 4h

30°C 1039S, 22min Bh

20°C 10 29°C 20min 12h

I5"Cto19°C 30min 24h

TO"Cto 14°C ‘30min aah

S*Cto9C 120 min 72h

For dry concrete curing times may be reduced according to the following table,

For installation temperatures below +5 °C all load values have to be reduced according to the loac

reduction factors given below.

Curing time for dry concrete

‘Additional Hilti technical data

Temperature Workina time in which | Reduced curing time

of the anchor can be inserted | before anchor can be | Load reduction factor

hase material and adjusted ty: fully loaded teu

40°C) 12min 4h 7

30°C 12min ah 4

20°C. 20min 42h 4

15°C 30min 18h 4

70°C ‘30min 24h 7

BoC 7120 mir 36h 7

OC 3h BOR o7

Tec an 72h O68

9/2014

565

Paes

PS eR Sao}

Setting details

Data according ETA04/0027. issue 2013-06-28 | /dtltional Hit

[Anchor size Me | Mac] maz | mie | 20 | M24 [M27 | M30 | 33 | M36 | M39

Nominal diameter of g,— immi| 10 | 12 | 14] 18 | 24 | 26 | 30 | 35 | a7 | ac | a2

Effective anchorage hana _Immi| 40 | 40 | 4@ | 64 | 6c | 96 | 108 | 120 | 432 144 | 156

and nil noie dept - =

range Farax_{men’] 160 | 200 | 240 | 320 | aoc | 480 | 540 | 600 | 660 | 720 | 780

Fe 30mm

2100 mm

Minimum base

material thickness

Diameter of clearance, mm) 9 | 12 | 14 | 18 | 22 | 26 | 30 | 30 | 36 | 39 | 42

olen the ficure

Minimum spacing mj] 40 [50 [ae [ao | oc | 720 | ae | 150 | es | eo | 95

Minimum edge zi ' '

atstance Gn Imm] 40 | 50 ] 6c | 80 | t0¢ | 120 | 135 | 150 | 165 | 180 | 195

(Critical spacing for

bon [mm bert 2c

spitting failure Sirsp 2Grsp

1,0-Fas for h/t 2 2,0 “] l

eamea ea diane g tmm|AGhy= 18h for20> Hite 18 y5/ St

226 hw ford ty. tin aan

(Critical spacing for

[concrete cone failure S** 2cen

(Critical edge distance

for congrete cone rn 15h

failure”

Torquemoment™” Tra Nm] 10 | 20 ] 40 | 60 | 150 | 200] 270] 300] 300 | 960 | 300

For spacing (edge distance) smaller than ortical spacing (ertical edge distance) the design loads have to be

reduced

a) Fernie hat S ttmas (Rag embedment depth)

b) hs base material thickness (h 2 hr)

)__The critical edge cstance for concrete cone failure depends on the embedment depth hand the design bond

resistance. The simplifed formula given in this table is on the save side

d) This is the maximum recommended torcue moment to avoid sitting failure during installation for anchors wth

‘minimum spacing andior edge distance

566 09/2014

Paes

Pe

Simplified design method

Simplified version of the design method according ETAG 001, TR C29, Design resistance according data given n

ETA.04/0027, issue 2009-05-20

‘Influence of concrete strengit

= Influence of edge dstance

Influence of spacing

+ Valid for a group of two anchors. (The methiod may also be appied for anchor groups with more than two

anchors or more thar one edge distance. The influencing factors rust then be considered for each edge

distance and spacing, The calculated design loads are then on the save side: They will be lower than the

exact values according ETAG 001, TR 029. To avoid this, itis recommended to use the anchor design

software PROFIS anctor)

The design method is based on the following emplification:

‘= No different loads are acting on individual anchors (no eccentricity)

The values are valid for one anchor.

For mare complex fastening applications please use the anchor desich Softviare PROFIS Anchor

Tension loading

The design tensile resistance is the lower value of

- Steel resistance: Naas

= Combined pull-out and concrete cone resistence:

Naas = Nora fo. fin: fay

- Concrete cone resistance’ Nege = N’pac* fa fin fay fon fan’ fren

Concrete spiiting resistance (only nop-cracked concrete]

Nagase = Nfede° fe frap fag faap Fan fan

Basic design tensile resistance

Design steel resistance Nras

Data according ETA-04/0027, issue 2013-0626 | Additional Hilt

[anchar iva ma_[ ac [Miz | mie | M20 [24 [M27 | man | M33 | mas | M39

HAS 56 TaN [11.3 [17.3 | 25.3 | 48.0 | 747 [106.7] ~ =

HITV56 ik _[ 12.0 [19.3 | 2,0 | 527 | 62,0 [18,0] 153,53 167.2 |231,3) 272,5|325,3

HAS 88 ik | ||| | --—_[251.3]201.2] 045, [404.8 486.9

he. Hive TKN] 195 [30,7 | 44,7 | 64.0 | 190,7 |168,0]244,7]299.2] 370,” |435,7 [520.5

Ses “HAS (EDR IkN [12.3 | 19.8 [ 28,3 | 54,0 | 64,0 |119,8] 75,9 | 92,¢ [113.2] 132.6] 159.8

HILAR kN_[ 13.8 [21,6 [31,6 | 58,8 | 92,0 [132,1[ 80,4 122.6 |144,3) 172.4

HAS (E}HOR ik [18.0 [28.c | 40,7 | 76,7 |120.c|106,7| 144.8] 175.7] 134.8| 158,“ [190.2

HITV-HCR te [19.3 [30,7 [447 | 84,0 [130,7 [117.6 [152.9] 187, 1[144,6]170.2]203,3

9/2014 567

Paes

PS eR Sao}

Design combined pull-out and concrete cone resistance for anchors *

Nras = Nha fas fun fan fan- fp fen

‘Radtonal Hi

Data according ETA-04/0027, issue 2013-06-26 packer Hi

[Anchor size ME_[ M10 | M12 | MAG | M20 | M24 | M27 | WO | WS | M36 | MOD

[piplealembedment deoth | go | 90 | +10 | 125 | 170 | 210 | 240 | 27a | 300 | 320 | 60

Hammer [faa rome, | 153 | 218 | st¢ | aae | 702 | 1056 | 1957 | 157.6] 171.0] 2082 | 2320

dling (

+ [Nave [Teme | 124 | 175 | 257 | ase | src | e2e |aose| 1932] 136,¢| 162.6 | 186.3

Hiti hollow AR_frange |

bit | Naar Temp >

aa [tt [ramen | 77 | 108 | 150 | 224 | 5¢ | 526 | 530 | rae | e2.1 1118

Nevis Teme | 45 | 204] 29¢ | a59| sec] 754] ar2 |toac| - | - | -

KNI [range

diamone [Nase [Temp shoes 5 TT

ering” [i [Reme, | 123 | 173 | 250 | 264 | a5. | 808 | 679 | 70

Nave [emp 2 bio 3 ¢ el. |] -

wei [rome | 72 | 102 | 150 | 168 | 254 | 230 | ase | ae

2) Additional Hilti technical data (not part of ETA-04/0027, issue 2013-06-26):

The design values for combined pull-out and concrete cone resistance may be increased by 20 % for anchor

installation in dry concrete (concrete not in cortact with water before/curing installation and curing),

Noeae= fa Faun fain > fan fran fren

Design concrete cone resistance * Na,

Niade* fo fisp-f2sp: fasp fn fron

Design splitting resistance Nras:

‘Additional Hilti

Data according ETA-04/0027, issue 2013-06-26 | {ditional Hilti

[Anchor size Me [ Mac] M2 | wie | 20 | M24 [M27 | 30 | M33 | M36 | M39

Neage kN | 17.2 | 20,5 | 27,7 | 336 | 53,3 | 73.2 | 89.4 | 106,7[ 125.0] 144,2] 164.5]

‘Additional Hilt technical data (not part of ETA-04/0027, issue -2013-06-26):

The design values for concrete cone anc spliting resistance may be increased by 20 % for anchor installation

in dry concrete (concrete not in contact with water before/during installation and curing)

Influencing factors

Influence of concrete strength on combined pull-out and concrete cone resistance

Concrete strenath designation

ENV 206) cans | c2sian | eania7 | casas | canis | c anise | ¢ snvan

fac = (occu! 25N/mm*? 1 jo2_| 104 | 106 | 107 | 108 | 109

8) Tacate = conorete COMpreseNe strength, measured ch cubes wih 150 mm side Tengir

Influence of embedment depth on combined pull-out and concrete cone resistance

fap = bedlPeriye

Influence of concrete strength on concrete cone resistance

Concrete strenath desianation

ENV 206) ¢ 20/25 | c 25/30 | c 3037 | c 35/45 | c 4050 | c 45/55 | c 50/60

fe = (fexous/25N/mme = * 4 a11_| 422 | 134 [141 | 148 [155

8) feccux = concrete compressive strength, measured ch cubes with 150 mm side length

568 09/2014

PTGS

Pe

1 # 036%

= 07 +03 lens

073 | 0.76 | 0,79 | 082 | 085 | 088 | 091 | 094 | 097 | 4

= 05{1 + oan)

tase = US{T FOr)

a) The the edge distance shall not be smaller than the minimum edge distance c,, given in the table with the

setting details. These influencing factors must be considered for every edge distance smaller than the critical

edge distance

0,55 | 060 | 065 | 070 | 075 | 060 | 0,65 | 0.90 | 095] 1

Influence of anchor spacing *

a

tf 02}

Se

rag = O51 85ea)

tan = _U,DA1 + SiScrco)

a)__The anchor spacng shall not be smaller than the minimum enchor spacing s, given in the table wih the

setting details. This infiuencing factor must be considered for every anchor spacing

—_

[04 |-05-|

ups] Use) USS pure pure | UB Us| asT Ug}

Influence of embedment depth on concrete cone resistance

fay = (alles)

Influence of reinforcement

astm) a0 50 60 70 0 90] 2100

fen = 0.5 + hy/200mm s* o7* [o7s® [ os” | oss’ | os® [ose [4

a) This factor applies only for dense reinforcement. if in the area of anchorage there = reinforcement with €

spacing 2 150mm (any diameter) or with a diameter = 1Cmm and a spacing > 10Cmm, then a factor fe

may be applied

Shear loading

The design shear resistance is the lower value of

= Steel resistance Veas

- Concrete pryout resistance’ Vaaes = lower Value of Nap anc Naa

~ Conorete edge resistence Vase =

rade fafa Ff Frat fe

9/2014 569

Paes

PS eR Sao}

Basic design shear resistance

Design steel resistance Vras

Data according ETA-04/0027, issue 2013-06-26 | Additional Hilt

[Anchor size Ma [ MAC | M2 | we | M20 | M24 [ M27 [ W90| 33 | M36 | M0

HAS 56 AN | 6é[104[152 [268 448feac] - | - | - | - | -

HIT-V5E TKN | 72 [12.0 | 16.8 [ 31,2 | 48.8 | 704 | 920 | 112.0] 138.6 163.4] 105.2

HAS 88 kN [= | = | - | - 1 - | - (139.2) 168.6 |207,0|242|292.2

Vag, HEEVBE KN [20 [ea Sod 764 [42,8] 147,21 179.21 272,”[261,4|3123

S45 "HAS CEPR Ten | 77 [422 32,7 | 50.6 [ 71. | 45.8 [ 55, | 57,5 | 79,7 | 95,5

HITVR KN [82 [128 36.2 155.1 | 79. [48.5 [58.6 | 726] 85.8 |102,

HAS (EFHCR TKN [10,4 | 16.8 46.4 | 72,0 | 64.¢ | 86.9 (108.7) 80,5 | 94,5 [114,

HIT-V-HCR| KN [12.0 [184 50.4] 76.4] 70. [92.0 [112.0] 86.2 [102, [122.0

Design concrete pryout resistance Vrdcp = lower value” of k Nrap and k + Nrdc

k= 1 for hy < 60 mm

k =2 for hy 2 60 mm

a) Nzag Design combined pul-out and concrete cone resistance

Nace Design concrete cone resistance

Design concrete edge resistance Vrac = V’kac: fi: fn- fr: fas fret’ fc

[Anchor size me | Mic | M12 | M16 M20 | M24 M33 | M36 | M39

Non-cracked concrete

Ve IkN} 5s] 8é | 11,6 | 187 | 27,0 | 36.€ | 44,5 | 53,¢ | 52.1 | 71,7] 81.9

Influencing factors

Influence of concrete strength

Conerete strenath desianation

ten 206) ¢ 2025 | c 25/30 | ¢ 30/37 | c 35/45 | c 4050 | c 45/55 | C 50/60

te = (

a) Eaea

».25Nimmne 9 4 aa 422 | 134 [141 | 148 [155

onorete compressive strength, measured on cubes with 150 mm side length

Influence of angle between load applied and the direction perpendicular to the free edge

Angle 8 or | 10° | 20° | 30° | 40° | 50° | 60° | 70° | 80° | >90°

7

Ci =

f ome 9) BL} 4 —y.ot | t05 | 4.13 | 4.24] 140 | 164 | 4.97 | 2:32 | 250

Influence of base material thickness

hic 0.45 | 0.3 [045 | 06

fe = qhie-oy” <° 0,32 [ 0.48 [0.55 [0.63

1.05 | 1.2 | 1.35 [21,5 |

a4 | oe | 0.95 | 7.00

570 09/2014

eRe uc

Influence of anchor spacing and edge distance * for concrete edge resistance: fi

fa (chhe)"- (1 + / [3-c])- 0,8

Single Group of two anchors s/he

anchor} 0,75 | 1,50/| 2.25 | 3,00 | 3,75 | 4,50 | 5,25 | 6,00 | 6,75 | 7.50 | 8,25 | 9,00 9,75 | 10,50| 11,25

O35) S| 0.36] 0,35] 0,35] 0,35) 0,35] 0,35] 0.3E] 0.35] 0,36] 0.36] 0.35] 0.38

065 0.651 0.65| 0.65) 0,651 0.65) 0.651 0,651 0.65] 0.661 0.651 0.65] 068

7,00) 4,00) 4,00] 4,00] 1,001 4,001 1,00] 1,0¢| 4,001 4,0¢[ 1,001 4,061 4,0¢

1.26] 4.40) 4.40] 4.401 4.40] 4.40] 4.4¢] 4.401 4.4¢| 4.40) 4.401 4.4¢

71.53] 1,66] 1.84] 1,847 1,84] 1.84] 1,84] 7.84] 1.84] 1.84) 1,84] 1.84

182 2,32) 2.32| 232| 2.32) 2.32) 2.32) 2,32] 2.32] 2.37

| 2,12) 2,65] 2,83] 2,83] 2,82] 2,83/ 2,82 2,83] 2,83]

Pa 3,00| 3,19| 3.38] 3.3€| 3.38) 3.38 3.38| 3.38

277: 3,36 3.56| 376] 3.98] 3.95] 3.98 3.95] 3.98

ai 3,73) 3.94] 4.15] 4,36] 4.56) 4.56 456 | 4.56

3.46) 4417 433] 455] 476] 4.98] 5.2C 5.20] 5.20

3.83) 454 496| 5.16] 5.4" [5.62 586 | 5.86

1427 4,917 6,141 5,38] 5,61] 5,65] 5,08 6.55] 6,58

460) 533. 6.08! 3.54| 7,02| 7,26

5,00) 5,75: 6.50) 7,0C1 7,50) 7.75

Sat 618. 8.96: 7A1| 7.73| 7.98| 8.26

583) 6] 8.63 7.42) 7.89] 7,98 8.45] 8.75

6.27) 7.08) 7.9C) 8.451 8.95] 9.26

671 7) 7.55 8.36 8,94] 9,50] 9,78

716 8.02. 8.86: 9.48 0,02 10:31

[767 8.50. ose] 9671 9.97 10,55] 10,86

a) The anchor spacing and the edge distance shall not be smaller tran the minimum anchor spacing zie and the

minimum edge distance Cx

Influence of embedment depth

raid

toe

had

ter

5

O75

14

424

6

1,01

15

473

7

131

16

527

8

1.84

17

584

a

2,00

18

642

10

2.39

19

7,04

0,05 (hy Ja

0,05 - {her 1)"

Influence of edge distance”

cid 4 6 8 10 15 20 30. 40

f= (dcp 077 071 0,67 0,65 0.60 057, 052 0,50

a) The edge dstance shall not be Smaller than the minimum edge Gelance Gr,

Combined tension and shear loading for hammer drilling or hollow drill bit

For combined tension and shear loading see section “Anchor Desian’

Precalculated values

Recommended loads can be calculated by dividing the design resistance by an overall partie! safety factor for

action = 14, The partial safety factors for acon depend on he typeof lacing and shale ake from natona

regulations.

9/2014 571

Paes

PS eR Sao}

Design resistance: concrete C 20/25 — fxcue = 25 Nimm?, Temperature range |

‘Additional Hilt

Data according ETA-04/0027, issue 2013-0626 | Hono ans

[Anchor sive ma | M1C | m2 | M16 | M20 [24 | M27 | M30 | M33 M36 | M39

fEmbedment depth ha. = (mm) | 48 | 0 | 72 | 96 | 120 | tad | 162 | 180 | 198 | 216 | 234

Base material thickness ha= [mm] | toc | 100 | 102 | 132 | 166 | 200 | 222 [250 [272 | 296 | 324

Tensile Na«: single anchor, no edge effects

po dirvse

HIT-V 88

am ITV

SW atrev-Hor

[Shear Vag: single anchor, no edge effects, without lever arm

kN: | ac | 114.2] 147] 226 | 31,6 | 41,6 | 496 | 58,1 | 87,c| 76.3 | 86,1

HIT-V5.E TKN’ [72 [120 [168 [ 31,2 | 48,8 | 704 | 92.0 [110.0] 138.6] 163.4] 1052

HIT-V88 TKN [74.2 [48.4 [27,2 [50,4 | 78,4 [112,6|138,8] 162.6] 187,6|213,8[241,0)

- HIT-V-R TKN [8s [128] 192 [95.3 155.1 [79 [483 [sae | 725 | 85,8 102.5,

HIT-V-HER Tk [41.2 [18.4 [27.2 [50.4] 78.4 | 70s | 92.0 [112.¢) 86, [102,11722.0)

Design resistance: concrete C 20/25 — fuxcws = 25 Nimm?, Temperature range |

‘additional Hilt

Data according ETA-04/0027, issue 2013-06-26 | {ditional Hilti

(Anchor size Ms MC Tra [ne | zo ze [27 [SO | 33 | M36 | Me

[Embedment depth Ta = Imm] 48 | 50 | 72 | 96 | 120 | 144 | 162 | 180 | 198 | 216 | 234

Base material thickness hai= (mm) | 10¢ | 100 | 102 | 132 | 168 | 200 | 222 | 250 | 272 | 296 | 324

Edge distance = Gar= [mm] | 40 | 50 | 60 | 80 | 100] 120 | 135 | 150 | 145) 180 | 195

[Tensile Nae: single anchor, min. edge distance (¢ = Cnic)

+ airvse

a ne IRN | 54 as |129| 182] 23¢|282| 33.2 | 381 | 43.4] 49.2

WG HIT-V-HCR

[Shear Vaq: Single anchor, min edge distance (c = ¢,,,) , without lever arm

HIT-V58

- HIT-V88

AIT-VR

Con_HIT-V-HCR

KN | 34] 4¢ | 67 | 108] 157) 21.4] 26.0) 31.1 | 36.5] 422 | 483

‘N

Design resistance: concrete C 20/25 ~ fex.cune = 25 Nim

(load values are valid for single anchor)

Data according ETA-04/0027, issue 2013-0626 | Additional Hii

technical data

[Anchor size ma [mic [12 | mite | zo [M24 | mi27 | m30 | 33 | M36 | M39

[Embedment depth Fa. =Imml| 48 | 80 | 72 | 96 | 120 | 144 | fez | 180 | 198 | 216 | 234

Base material thickness f= [mm] | 10¢ | 100 | 102 | 432 | 16e | 200 | 222 | 250 | 272 | 296 | 324

‘Temperature range |

Spacing S= Ey (mm) | 40 | 50 | 60 [ ac | 100 | 120 | 435 | 150 | 165 | 160 | 195

[Tensile Na: double anchor, no edge effects, min. spacing (S = §,.,)

po tinvse

ee NE KN | 5.1] 70 | 88 | 135 | 190] 24¢ | 296 | sae | 40.1 | ase

Sm_HIT-V-HOR

[Shear Vas: double anchor, no edge effects, min. spacing ‘without lever arm

HIT-VB5 8 KN [72 [120 [168 | 312 | 488 88,7 [103.5] 119.5] TBE] 1540

sr HIVES TKN [72 [48.4 [26,2 | 405 1565 88.7 [103 9119.5] 136.6] 164.0

eS aimvR TKN [72 [128 [192 [35.3 §5,1 48.3] 58. | 72,¢ [85,¢ [102.5

HIT-V-HOR KN | 72 118.4 [263 | 4051 565 88,7 1103.5] 86,€ [102,7]122.0]

572 09/2014

eRe uc

Pei)

Design resistance: concrete C 20/25 — fxcue = 25 Nimm?, Temperature range |

‘Additional Hilt

Data according ETA-04/0027, issue 2013-06-26 | Scynirat data

[Anchor sive ma | Mi1C | m2 | M16 | M20 [M24 | M27 | M30 | M33 M36 | M39

lEmbedment depth Pasye= {mm] | 80_| 90 | 110 | 125 | 170 | 210 | 2ac | 270 | 300 | 330 | 360

Base material thickness haw= (mm) | 110 | 120 | 140 | 167 | 216 | 266 | 300 | 340 | 374 | 410 | 450

TTensile Na,: single anchor, no edge effects.

HIT-V 58 KN 42.0 [49,3 [ 27,7 33.6 [53.5 | 73 | 604 [106.7] 125.0] 144.2] 1645

HIT-V88 TKN [15.3 [20,2 [27,7 [33.61 53.3[ 732 | 69.4 [106.7 |125.0|1442|1643

> HIT-VR TKN [13,8 [20,£ [27-7 [33,6 63,3 73.2 | 60,4 | 98,2 [122.6 |144 2/1643

HIT-V-HGR kN [15,3 | 20, [27,7 | 33,6 | 63,3 73.2 | 69,4 |106,7|125.0|1442| 1643

[Shear Vea: single anchor, no edge effects, without lever arm

HIT-VBE KN [72 [120] 168 | 31,2 | 488 | 704] 920 [110188] TOS AL EZ

HIT-VBE kN [12.0 [ 48.4 [27,2 | 50,4 | 78.4 |112,8|147,2|179.2|222 [2614/3123

- HITVR KN | 82 [126 | 19.2] 353 [55,1] 795 [483 (58e [728 85.e [102.5

s HIT-V-HCR TkN’ [12,0 [18.4 | 27,2 | 50,4] 78,4 | 70.5 | 92,0 [112,¢] 86,¢ | 102,71 122.0)

15 Nimm?, Temperature range |

Design resistance: concrete C 20/25 — fercu

Aa

Data according ETA-04/0027, issue 2013-0626 | Winona it

[Anchor size. me [ Mic [M2 | M16 | M20 | M24 [M27 | M30 | M33 | M36 | M39

lEmbedment depth Fuwe= (mm) | 80 | 90 | 140 [ 125 | 470 | 210 | 2ac | 270 | 300 | 330 | 360

Base material thickness fine [mm] | 110 | 120 | 140 | 16: | 21e | 266 | 0c | 340 [374 | 410 | 450

nal Hitt

Edgedistance O=Gae= (mm) | 40 | 50 | 60 | 60 | 100 | 120 | 135] 150 | 165 | 180 | 195

[Tensile Nac: single anchor, min. edge distance (¢ = Gui.)

+ Hives

aimee KN’ | 8.2 | 10.0] 13.2] 168 | 26,1] 35¢ | 43.3 51,4 | 50,¢ | 59.7 | 786

on HIT-V-HOR

[Shear Vag: Single anchor_min edge distance (c= cn.) , without lever arm

HIT-V58

oe ay ee iw | 37 | 53 415 | 17.2] 236 | 29.0] 34 | 41.1 | a7.8| 54

Gow HIT-V-HCR

Design resistance: concrete C 20/25 ~ Fu cae

(load values are valig for single anchor)

Data according ETA-04/0027, issue 2013-06-26 | Additional Hilt

[Anchor size ma] wae [mi | te | M20 | m2 [27 30 | M33 | M36 | M39

fEmbedment depth Fi 0 | 90 | 110 | 125 | 170 [ 210 | 2a0 | 270 | 300 | 330 | 360

Base material ticks fn 1c | 120 [140 [167 | 2te [268 | 30c [340 [ara | 410 | 450

‘Temperature range |

Spacing 3 = Sr 40_| 50 | 60 | a0) toc | 120 | 195 | 150 | 165 | 180 [ 195

[Tensile Naz: double anchor, no edge effects, min. spacing (s = Spi)

po Hise

oa’ Kn’ | 9.2 | 116 | 155 | 192 | 30,1 | 442 | 50.3) 59¢ | 70.1 | 80.8 | o20

em AIT 2 15 | 182 | S01 | az is ;

‘Sm _HIT-V-HOR

[Shear Vag: double anchor, no edge effects, min. spacing (S = §,,) , without lever arm

HIT-V58 kN [7.2 [12.0] 16,8 | 31,2 | 48,6 | 70,4 92,0 [112.0] 1388) 103.4] 1052

sor HiVae TKN [12.0 (48.4 [27,2 [50.4 78.4 [112.8 [147,2]177.C|207.0]2385|271,5

SP Fiver KN | 82 [128 | 19.2 [35.3 | 95,1 | 79 [48.3 [58 | 726 | 85,€ [102.5

HIT-V-HOR aN [2.01484 [27.2 [50.41 78.4 70¢ [92.0112 c) 86.6 1102717220]

9/2014 573

Paes

PS eR Sao}

Design resistance: concrete C 20/25 — fxcue = 25 Nimm?, Temperature range |

‘Additional Hilt

Data according ETA-04/0027, issue 2013-06-26 | Scynirat data

[Anchor sive ma | MiC | m2 | M16 | M20 [M24 | M27 | M30 | M33 M36 | M39

[Embedment depth faz= Imm] | 96 | 120 | 144 | 192 | 24c | 288 | 324 | 360 | 396 | 432 | 468

Base material thickness hai= (mm) | 126 | 150 | 174 | 228 | 286 | 344 | 384 | 430 | 470 [512 | 5568

TTensile Na,: single anchor, no edge effects.

HIT-V 58 TKN | 42,0 [49,3 | 28,0] 527 | 62.0 [117 5] 140.2] 104.3] 100.5] 215, 5]243,6

HIT-V88 TKN [18.4 [28,7 [41,4 [640 | 89.4 [117,5|140-2] 164.3 |189,5|215,5|243.5

> HIT-VR TKN [13.8 [24,5 [31,6 | 58,8 | 69,4 [177.5] 60,4 | 98,2 122.6] 1442] 172.4

AIT-V-HOR kN [18.4 [287 [41.4 | 64.0 | 89.4 [117.5] 140.2] 164.2] 144.6 |170.2|203,3

[Shear Vea: single anchor, no edge effects, without lever arm

HIT-VBE KN [72 [120 | 168 | 31,2 | 488 | 704] 920 [11188] TOS AL EZ

HIT-V8E TKN [12,0 [48-4 [27.2 [ 50.4 | 78.4 [112.8] 147,2]179.2| 222," [261.4 312.3

- HITVR KN | 82 [126 | 19.2] 353 [55,1] 795 [483 (58e [728 85.e [102.5

s HIT-V-HCR TkN’ [12,0 [18.4 | 27,2 | 50,4] 78,4 | 70.5 | 92,0 [112,¢] 86,¢ | 102,71 122.0)

15 Nimm?, Temperature range |

Design resistance: concrate C 20/25 = furcu

‘Additional Hilt

Data according ETA-04/0027, issue 2013-06-26 | {Chondl iit

[Anchor size. me [ Mic [M2 | M16 | M20 [M24 [M27 | 30 | M33 | M36 | M30

[Embedment depth faz= [mm] | 96 | 120 | 14a | 192 | 240 | zee | 324 | 360 | 396 | 432 | 468

Base material thickness hx= [mm] | 126 | 150 | 174 | 228 | 288 | 344 | 384 [430 | 470 | 512 | 558

Edge distance c= Gu= [mm] 40 | 50 | 60 | 80 | 100] 120] 195 150 | 165 | 100 | 195

[Tensile Nac: single anchor, min edge distance (¢ = Gq.)

HIT-V5E

J 5Tv8e ay | 9¢ | 141 | 86] an6 avo | 52¢ | 627 | 728 | axe one lice

Gon_HIT-V-HOR,

[Shear Vaqi single anchor_min edge distance (c= ¢q,) without lever arm

sIT-V5e

> ay ee ww | 3¢ | 57 | ze | 28] 189] 258 | 31.8 | 38:1 | 450 | 52.2 | 60.0

Gon HIT-V.HER

Design resistance: concrete C 20/25 ~ fer case

(load values are valic for single anchor)

‘Additional Hilt

Data according ETA-04/0027, issue 2013-06-26 | factional Hilt

(Anchor size mae [mac [a2 [wt | m0 [ze [27 [M30 [M33 | M36 | M39

lEmbedment depth et 96_| 120 | 144 | 192 | 2ac | 288 | 324 | 360 | 396 | 432 [468

Base material thickness fn 126 | 150 | 174 | 228 | 288 | 344 | 384 | 430 | 470 | 812 | 558

‘Temperature range |

Spacing 3 = Sr 40_| 50 | 60 | a0) 10c | 120 | 195 | 150 | 165 | 180 | 195

[Tensile Nac: double anchor, no edge effects, min. spacing (s = Sais)

po Aevse

oe ie kW | 11.8] 47.3 | 22.7 | 349 | 48,8 | 642 | 766 | 89,7 |103,5|117.¢] 133.0

Se_HIT-VHOR

[Shear Vac: double anchor, no edge effects, min. spacing ‘without lever arm

HIT-V58 KN [72 [120 [468 | 31,2 | 488 92.0 [112.0] 138.6 | TSA TOBT

sor HIVBE TKN [12.0 [18.4 [27,2 [5041 784 47 2]179-2| 222," (261.4312,

ee AVR TKN| 83 (12.8 [19.2 [ 353.1 65,1 48,5 | 88 | 72, | 85,8 [102.5

HIT-VHGR kN [420] 18.4 [27,2 [504] 784 92.0 [112.0] 86. [102.7] 7122.0]

574 09/2014

9/2014

375

DR Le Sete

with HIT-CS(-F) rod

Combined tension and shear loading

The following equations must be Wit

Satisfied By = No Nag anc

Svs By = Vee! Ves

< ,

fst Neg (Vse) = tension (shear)

By + ByS4,2 oF Bet+ ES design action

Nag (Vee) = tension (shear)

design resistance ™

Annex C of ETAG 001 ‘Simplified design method

a = 20 if Nqgand Vaeare governed by stee!_| Failure mode isnot corsidered forthe simplified method

falure a = 1,8 farallfailire mndes (leading to

a = 1,8 forallother failure modes conservative results

554 9/2014

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (589)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (842)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5806)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- When Competence Counts.: Atmospheric Corrosion of Fastening and Installation SystemsDocument8 pagesWhen Competence Counts.: Atmospheric Corrosion of Fastening and Installation SystemsErlanggaRizkiFauziNo ratings yet

- Approval Document ASSET DOC LOC 963Document5 pagesApproval Document ASSET DOC LOC 963ErlanggaRizkiFauziNo ratings yet

- Approval Document ASSET DOC LOC 750Document5 pagesApproval Document ASSET DOC LOC 750ErlanggaRizkiFauziNo ratings yet

- Firestop CEJ 421 PDocument4 pagesFirestop CEJ 421 PErlanggaRizkiFauziNo ratings yet

- Jurnal Opt 4Document12 pagesJurnal Opt 4ErlanggaRizkiFauziNo ratings yet