Professional Documents

Culture Documents

Approval Document ASSET DOC LOC 963

Uploaded by

ErlanggaRizkiFauziOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Approval Document ASSET DOC LOC 963

Uploaded by

ErlanggaRizkiFauziCopyright:

Available Formats

S IFI

AS

WL 8019

System No. W-L-8019

CL

ED

C US F Rating -- 1 and 2 Hr (See Items 1, 3 and 4)

Classified by

Underwriters Laboratories, Inc.

T Rating -- 0, 1/2, 1, 1-1/2 and 2 Hr (See Item 2)

to UL 1479 and CAN/ULC-S115

D

F C

E

B

F

C

G D

B A

E G A

3

4A

2

3

2 4B

1

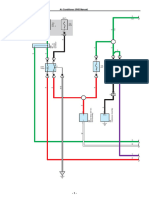

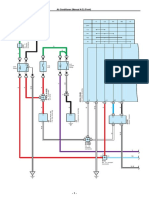

FIRESTOP CONFIGURATION A FIRESTOP CONFIGURATION B

Reproduced by HILTI, Inc. Courtesy of

Underwriters Laboratories, Inc.

April 22, 2005

Hilti Firestop Systems Page: 1 of 5

S IFI

AS

WL 8019

System No. W-L-8019

CL

ED

C US F Rating -- 1 and 2 Hr (See Items 1, 3 and 4)

Classified by

Underwriters Laboratories, Inc.

T Rating -- 0, 1/2, 1, 1-1/2 and 2 Hr (See Item 2)

to UL 1479 and CAN/ULC-S115

3A 2

2

3

3B

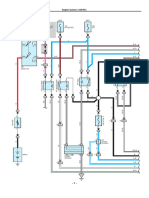

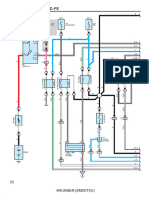

FIRESTOP CONFIGURATION C FIRESTOP CONFIGURATION D

4

2 3

3 1

FIRESTOP CONFIGURATION E FIRESTOP CONFIGURATION F

Reproduced by HILTI, Inc. Courtesy of

Underwriters Laboratories, Inc.

April 22, 2005

Hilti Firestop Systems Page: 2 of 5

S IFI

AS

WL 8019

System No. W-L-8019

CL

ED

C US F Rating -- 1 and 2 Hr (See Items 1, 3 and 4)

Classified by

Underwriters Laboratories, Inc.

T Rating -- 0, 1/2, 1, 1-1/2 and 2 Hr (See Item 2)

to UL 1479 and CAN/ULC-S115

2

1

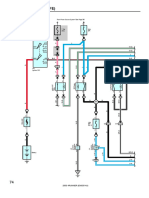

FIRESTOP CONFIGURATION G

1. Wall Assembly -- The 1 or 2 hr fire-rated gypsum board/stud wall assembly shall be constructed of the materials and in the manner described in

the individual U400 Series Wall or Partition Design in the UL Fire Resistance Directory and shall include the following construction features:

A. Studs -- Steel studs 3-1/2 in. deep, fabricated from 25 MSG galv steel, spaced max 24 in. OC.

B. Gypsum Board* -- The gypsum board type, number of layers, fastener type and sheet orientation shall be as specified in the individual Wall

and Partition Design. Max area of opening is 450 sq in with max dimension of 30 in.

The hourly F Rating of the firestop system is equal to the hourly fire rating of the wall asembly in which it is installed.

2. Through Penetrants -- A max of seven firestop configurations may be installed within the opening. The space between firestop configurations.

Unless otherwise indicated, the space between firestop configurations and periphery of opening shall be min 3/8 in. Pipe, conduit, tubing or cables

to be rigidly supported on both sides of floor or wall assembly. The T Rating of the sytem is dependent on the firestop configurations, as shown in

the table below. Any combination of the following firestop configurations detailed herein may be used:

1 Hr F Rating 2 Hr F Rating

Firestop Configuration

T Rating Hr T Rating Hr

A 0 1/2

B 1 1-1/2

C 1/2 1

D 0 0

E 1 2

F 0 0

G 0 0

Reproduced by HILTI, Inc. Courtesy of

Underwriters Laboratories, Inc.

April 22, 2005

Hilti Firestop Systems Page: 3 of 5

S IFI

AS

WL 8019

System No. W-L-8019

CL

ED

C US F Rating -- 1 and 2 Hr (See Items 1, 3 and 4)

Classified by

Underwriters Laboratories, Inc.

T Rating -- 0, 1/2, 1, 1-1/2 and 2 Hr (See Item 2)

to UL 1479 and CAN/ULC-S115

2. Cables -- Max 4 in. diam tightly bundled cable. The min space between adjacent penetrants shall be 4 in. Cable bundle may be any combination

of the following types and sizes of cables:

G. Max 25 pair No. 24 AWG copper telephone cable with polyvinyl chloride (PVC) insulation and jacket materials.

H. Max 7/C No. 12 AWG cable with PVC insulation and jacket materials.

I. Multiple fiber optical communication cables with PVC jacket material and having a max outside diameter of 3/8 in.

J. Max 3/C No. 12 AWG steel clad cables with PVC insulation and jacket materials.

K. Max 3/C No. 8 AWG cablew with ground with PVC insulation and jacket materials.

L. Max RG 59 coaxial cables with PVC insulation and jacket materials.

3. Fill, Void or Cavity Material* - Foam -- Fill materiial applied within annulus flush with both surfaces of the wall. Min fill material thickness for 1 hr F

Rating is 4-3/4 in. Min fill material thickness for 2 hr F Rating is 6 in.

HILTI CONSTRUCTION CHEMICALS, DIV OF HILTI INC -- CP 620 Fire Foam

Firestop Configuration B

2. Copper Tuber or Pipe -- Nom 1 in. diam (or smaller) Type L copper tube or nom 1 in diam (or smaller) Regulary (or heavier) copper pipe. Min

space between adjacent penetrants shall be 3 in.

3. Tube Insulation - Plastics+ -- Nom 3/4 in. thick acrylonitrile butadiene/polyvinyl chloride (AB/PVC) flexible foam furnished in the form of tubing.

The min space between adjacent penetrants shall be 1-1/2 in.

See Plastics+ (QMFZ2) category in the Plastics Recognized Component Directory for names of manufacturers. Any Recognized Component

tube insulation material meeting the above specifications and having a UL 94 Flammability Classificationof 94-5VA may be used.

4. Firestop System -- The firestop system shall consist of the following:

A. Fill, Void or Cavity Material* - Wrap Strip -- Nom 3/16 in thick by 1 in wide intumescent wrap strip. The wrap strip is continuously wrapped

around the outer circumference of the pipe covering one time and held in place with tape. Wrap strips are installed flush with each side of wall.

HILTI CONSTRUCTION CHEMICALS, DIV OF HILTI INC -- CP 648-E W45/1-3/4 Wrap Strip

B. Fill, Void or Cavity Material* - Foam -- Fill material applied within annulus flush with both surfaces of the wall. Min fill material thickness for 1

hr F Rating is 4-3/4 in. Min fill material thickness for 2 hr F Rating is 6 in.

HILTI CONSTRUCTION CHEMICALS, DIV OF HILTI INC -- CP 620 Fire Foam

Firestop Configuration C

2. Polyvinyl Chloride (PVC) Pipe -- Nom 2 in. diam (or smaller) Schedule 40 solid or cellular core PVC pipe for use in closed (process or supply) or

vented (drain, waste or vent) piping system. The min space between non-metallic penetrants shall be 1 in. The min space between metallic

penetrants shall be 3-1/2 in.

3. Firestop System -- The firestop shall consist of the following:

A. Fill, Void or Cavity Material* - Wrap Strip -- Nom 3/16 in thick by 1 in wide intumescent wrap strip. The wrap strip is continuously wrapped

around the outer circumference of the pipe covering one time and held in place with tape. Wrap strips are installed flush with each side of wall.

HILTI CONSTRUCTION CHEMICALS, DIV OF HILTI INC -- CP 648-E W25/1" Wrap Strip

B. Fill, Void or Cavity Material* - Foam -- Fill material applied within annulus flush with both surfaces of the wall. Min fill material thickness for 1

hr F Rating is 4-3/4 in. Min fill material thickness for 2 hr F Rating is 6 in.

HILTI CONSTRUCTION CHEMICALS, DIV OF HILTI INC -- CP 620 Fire Foam

Reproduced by HILTI, Inc. Courtesy of

Underwriters Laboratories, Inc.

April 22, 2005

Hilti Firestop Systems Page: 4 of 5

S IFI

AS

WL 8019

System No. W-L-8019

CL

ED

C US F Rating -- 1 and 2 Hr (See Items 1, 3 and 4)

Classified by

Underwriters Laboratories, Inc.

T Rating -- 0, 1/2, 1, 1-1/2 and 2 Hr (See Item 2)

to UL 1479 and CAN/ULC-S115

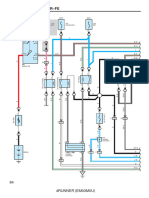

Firestop Configuration D

2. Through Penetrant -- One metallic pipe, conduit or tube to be installed either concentrically or eccentrically within the firestop system. The min

annular space between the pipe, conduit or tube and the periphery of the opening shall be min. 0 in. (point contact). The annular space between

adjacent penetrants shall be min 3-1/2 in. The following types and sizes of metallic pipes, conduits or tubes may be used:

Steel Pipe -- Nom 4 in. diam (or smaller) Schedul 10 (or heavier) steel pipe.

Iron Pipe -- Nom 4 in. diam (or smaller) cast or ductile iron pipe.

Conduit -- Nom 4 in. diam (or smaller) rigid steel conduit.

Conduit -- Nom 4 in. diam (or smaller) steel electrical metallic conduit.

Copper Tubing -- Nom 4 in. diam (or smaller) Type L (or heavier) copper tubing.

Copper Pipe -- Nom 4 in. diam (or smaller) Regular (or heavier) copper pipe.

3. Fill, Void or Cavity Material* - Foam -- Fill material applied within annulus flush with both surfaces of the wall. Min fill material thickess for 1 hr F

Rating is 4-3/4 in. Min fill material thickness for 2 hr F Rating is 6 in.

HILTI CONSTRUCTION CHEMICALS, DIV OF HILTI INC -- CP 620 Fire Foam

Firestop Configuration E

2. Steel Pipe -- Nom 8 in. diam (or smaller) Schedule 40 (or heavier) steel pipe.

3. Pipe Covering Materials* -- Nom 1-1/2 in. thick hollow cylindrical heavy density (min 3.5 pcf) glass fiber units jacketed on the outside with an

all-service jacket. Longitudinal joints sealed with metal fasteners or factory-applied, self-sealing lap tape. Transverse joints secured with metal

fasteners of with butt tape supplied with product. The min space between adjacent penetrants shall be 2 in.

See Pipe and Equipment Covering - Materials (BRGU) Category in the Building Materials Directory for names of manufacturers. Any pipe

covering meeting the above specifications and bearing the UL Classification Marking with a Flame Spread Index of 25 or less and a Smoke

Developed Index of 50 or less may be used.

4. Fill, Void or Cavity Mateiral* - Foam -- Fill material applied within annulus flush with both surfaces of the wall. Min fill material thickness for 1 hr F

Rating is 4-3/4 in. Min fill material thickness for 2 hr F Rating is 6 in.

HILTI CONSTRUCTION CHEMICALS, DIV OF HILTI INC -- CP 620 Fire Foam

Firestop Configuration F

2. Flexible Conduit -- Nom 1 in. diam (or smaller) flexible steel conduit. The min space between adjacent penetrants shall be 3-1/2 in.

3. Fill, Void or Cavity Mateiral* - Foam -- Fill material applied within annulus flush with both surfaces of the wall. Min fill material thickness for 1 hr F

Rating is 4-3/4 in. Min fill material thickness for 2 hr F Rating is 6 in.

HILTI CONSTRUCTION CHEMICALS, DIV OF HILTI INC -- CP 620 Fire Foam

Firestop Configuration G

2. Steel Duct -- Nom 6 in. diam (or smaller) No. 28 gauge (or heavier) galve steel duct. The min space between adjacent penetrants shall be 1-1/2

in.

3. Fill, Void or Cavity Material* - Foam -- Fill material applied within annulus flush with both surfaces of the wall. Min fil material thickness for 1 hr F

Rating is 4-3/4 in. Min fill material thickness for 2 hr F Rating is 6 in.

HILTI CONSTRUCTION CHEMICALS, DIV OF HILTI INC -- CP 620 Fire Foam

*Bearing the UL Classification Mark

Reproduced by HILTI, Inc. Courtesy of

Underwriters Laboratories, Inc.

April 22, 2005

Hilti Firestop Systems Page: 5 of 5

You might also like

- Wiring Ecu CalyaDocument22 pagesWiring Ecu Calyakurnia wan100% (4)

- Io LS-F111P 20170718 PDFDocument7 pagesIo LS-F111P 20170718 PDFJess RojasNo ratings yet

- Engine Control: 2002 RAV4 (EWD466U)Document10 pagesEngine Control: 2002 RAV4 (EWD466U)Jorge Negretti100% (2)

- 6 Vios / Yaris (Cont. Next Page) : Engine ControlDocument5 pages6 Vios / Yaris (Cont. Next Page) : Engine ControlHenryHutabaratNo ratings yet

- Quiz Review: FIT Level 1 Exam: Student: Paul ColmenaresDocument8 pagesQuiz Review: FIT Level 1 Exam: Student: Paul ColmenaresNegro Tour's Reicin'gNo ratings yet

- FM Global Property Loss Prevention Data Sheets: Fire Protection For Gas Turbines and Electric GeneratorsDocument40 pagesFM Global Property Loss Prevention Data Sheets: Fire Protection For Gas Turbines and Electric GeneratorshhNo ratings yet

- Approval Document ASSET DOC LOC 750Document5 pagesApproval Document ASSET DOC LOC 750ErlanggaRizkiFauziNo ratings yet

- Firestop Application Handbook (Macau) - Part-7 PDFDocument35 pagesFirestop Application Handbook (Macau) - Part-7 PDFSharoon S raoNo ratings yet

- Engine Control (2UZ-FE) : 2003 4RUNNER (EWD514U)Document12 pagesEngine Control (2UZ-FE) : 2003 4RUNNER (EWD514U)Luis RocaNo ratings yet

- Starter Cut Relay PDFDocument2 pagesStarter Cut Relay PDFPhang KumwingNo ratings yet

- Plfy P VCM e DatabookDocument16 pagesPlfy P VCM e Databookวทัญญู ขาวศรีNo ratings yet

- Engine Control SystemDocument13 pagesEngine Control SystemKiddNo ratings yet

- MFL69729212 01 Q S00 Eng PDFDocument45 pagesMFL69729212 01 Q S00 Eng PDFduongdemuiNo ratings yet

- DI27Document5 pagesDI27Erln LimaNo ratings yet

- Construction Norms: Ry1 - AssemblyDocument1 pageConstruction Norms: Ry1 - AssemblyНиколай БалездровNo ratings yet

- Sydney (YSSY)Document68 pagesSydney (YSSY)NeethNo ratings yet

- S32k144evb SCH 29248 RBDocument6 pagesS32k144evb SCH 29248 RB정현우No ratings yet

- Air Conditioner (RHD Manual)Document13 pagesAir Conditioner (RHD Manual)Christian Chicana DiazNo ratings yet

- Control Engine ECS 1GRDocument19 pagesControl Engine ECS 1GRChristian Vinueza VillavicencioNo ratings yet

- 99 2rzfe EcuDocument10 pages99 2rzfe EcuAlejandro Narvaez100% (1)

- 4 RUNNER 2003 Engine Control (1GR-FE)Document8 pages4 RUNNER 2003 Engine Control (1GR-FE)Jamsyare MendozaNo ratings yet

- Activitat - 2007 Toyota Camry (Codi Motor 2GR-FE)Document20 pagesActivitat - 2007 Toyota Camry (Codi Motor 2GR-FE)gomarizismaelNo ratings yet

- Signal - HazardDocument1 pageSignal - Hazardtuan anh nguyễnNo ratings yet

- Stop Light SwitchDocument6 pagesStop Light Switchjeremih alhegnNo ratings yet

- Enginecontrol VVTi EnglishDocument13 pagesEnginecontrol VVTi EnglishSatrio Ongis NadeNo ratings yet

- sơ đồ hộp số ECT và ATDocument11 pagessơ đồ hộp số ECT và ATnamnguyen.2808199No ratings yet

- Api 53a PDFDocument1 pageApi 53a PDFGaurang SolankiNo ratings yet

- Fxs HV Cruse ShiftDocument25 pagesFxs HV Cruse ShiftblendedvitaminNo ratings yet

- Cd700 Accugrade For 320D, 322D, Electrical System 323D, 324D, 325D and 330D ExcavatorDocument2 pagesCd700 Accugrade For 320D, 322D, Electrical System 323D, 324D, 325D and 330D ExcavatorFranklin Beaumont100% (1)

- Diagrama SiennaDocument18 pagesDiagrama SiennaAchinga AquelachingaNo ratings yet

- Freedom BLDC Motor Driver Shield: RevisionsDocument6 pagesFreedom BLDC Motor Driver Shield: RevisionsVitaliy BespalovNo ratings yet

- Cannot Operate All DoorsDocument16 pagesCannot Operate All DoorsDannyDDannyDNo ratings yet

- Air ConditionerDocument2 pagesAir ConditionerĐ HNo ratings yet

- Dell/Compal Confidential: Schematic DocumentDocument7 pagesDell/Compal Confidential: Schematic Documentsantiago rodriguezNo ratings yet

- Engine Control (1zz-Fe, 1zz-Fbe, 3zz-Fe)Document15 pagesEngine Control (1zz-Fe, 1zz-Fbe, 3zz-Fe)Mas YadNo ratings yet

- 4RUNNER 2007 Engine Control For 1GR-FEDocument14 pages4RUNNER 2007 Engine Control For 1GR-FEJamsyare MendozaNo ratings yet

- Air Conditioner (Manual A/C) (Front) : G144 (A), G145 (B)Document6 pagesAir Conditioner (Manual A/C) (Front) : G144 (A), G145 (B)Thảo Đào ThuNo ratings yet

- Avr-Iot WG: Debugger Atmega4808 Winc1510Document16 pagesAvr-Iot WG: Debugger Atmega4808 Winc1510lalalala123No ratings yet

- Engine Control (1NZ-FE)Document13 pagesEngine Control (1NZ-FE)Mas YadNo ratings yet

- 4 RUNNER 2003 Engine Control (2UZ-FE)Document7 pages4 RUNNER 2003 Engine Control (2UZ-FE)Jamsyare MendozaNo ratings yet

- Approval Document ASSET DOC LOC 2179580Document4 pagesApproval Document ASSET DOC LOC 2179580aNo ratings yet

- Qdoc - Tips Wiring Diagram AvanzaDocument33 pagesQdoc - Tips Wiring Diagram Avanzario iskandarNo ratings yet

- 4RUNNER 2006 Engine Control For 2UZ-FEDocument14 pages4RUNNER 2006 Engine Control For 2UZ-FEJamsyare MendozaNo ratings yet

- ECT and A/T Indicator, Engine ControlDocument19 pagesECT and A/T Indicator, Engine ControlAdin VifaldhiNo ratings yet

- 017ecs-2uzfe 1Document12 pages017ecs-2uzfe 1Zanabazar tserendulamNo ratings yet

- ECT and A/T Indicator, Engine ControlDocument26 pagesECT and A/T Indicator, Engine ControlTrương Công ĐạtNo ratings yet

- Fuel+circuit+4+runnerDocument10 pagesFuel+circuit+4+runnerChristopher OrellanaNo ratings yet

- Engine Control (1GR-FE) : 2003 4RUNNER (EWD514U)Document10 pagesEngine Control (1GR-FE) : 2003 4RUNNER (EWD514U)Luis Roca100% (1)

- Compal Confidential: Schematics Document Mobile Penryn uFCPGA With Intel Cantiga - GM+ICH9-M SFF Core LogicDocument36 pagesCompal Confidential: Schematics Document Mobile Penryn uFCPGA With Intel Cantiga - GM+ICH9-M SFF Core LogicdanielNo ratings yet

- ECM Power Source CircuitDocument4 pagesECM Power Source CircuitErln LimaNo ratings yet

- COMPAL LA 3301P IBQ00 REV 1.0 (ComunidadeTecnica - Com.br)Document59 pagesCOMPAL LA 3301P IBQ00 REV 1.0 (ComunidadeTecnica - Com.br)Carlos Tome De SousaNo ratings yet

- Engine Control (5Vz-Fe) : System OutlineDocument10 pagesEngine Control (5Vz-Fe) : System OutlineTdco SonicoNo ratings yet

- Panasonic Plasma+tv+ Power TX P42GT20 PDFDocument4 pagesPanasonic Plasma+tv+ Power TX P42GT20 PDFGoana HernandezNo ratings yet

- PD-DX404 ManualDocument7 pagesPD-DX404 ManualSie Manuel SanchezNo ratings yet

- 23 Ind Wo Ac + AudioDocument1 page23 Ind Wo Ac + Audiobudi yantoNo ratings yet

- REF615Document73 pagesREF615RICARDO RUIZNo ratings yet

- Wiring DiagramDocument85 pagesWiring DiagramAlfredo Lopez AvellaNo ratings yet

- Section x2Document1 pageSection x2rahul.sopanengineersNo ratings yet

- Ampeg PF-350 Jack Board SchematicsDocument1 pageAmpeg PF-350 Jack Board SchematicsArif SusiloNo ratings yet

- Dell Latitude E4310 Compal LA-5691P SchematicsDocument51 pagesDell Latitude E4310 Compal LA-5691P SchematicsCarlos ZarateNo ratings yet

- TREMstop Acrylic Data SheetDocument4 pagesTREMstop Acrylic Data SheetAdhi WiyatnoNo ratings yet

- STI User Guide 2007 EditionDocument20 pagesSTI User Guide 2007 Editionmk779900mkNo ratings yet

- Hot StopDocument30 pagesHot StopaNo ratings yet

- Specseal LC Endothermic Firestop Sealant: ApplicationsDocument2 pagesSpecseal LC Endothermic Firestop Sealant: ApplicationsKarim TarekNo ratings yet

- Duct Wrap Architect Specification - 0Document5 pagesDuct Wrap Architect Specification - 0Javed BhattiNo ratings yet

- Firestop Technician Job DescriptionDocument2 pagesFirestop Technician Job DescriptionHilary TerryNo ratings yet

- TEC-042226 - MET-DoR-002c-Hilti CP606 - Submittal PDFDocument5 pagesTEC-042226 - MET-DoR-002c-Hilti CP606 - Submittal PDFvelmurug_balaNo ratings yet

- 7 Verona Place BROOKLYN, NY 11216Document20 pages7 Verona Place BROOKLYN, NY 11216Acxel D. Castillo100% (1)

- Firestop: B-Line Series Cable Tray Systems EatonDocument6 pagesFirestop: B-Line Series Cable Tray Systems EatonibharNo ratings yet

- AC291Document11 pagesAC291Mike JuniorNo ratings yet

- Hilti CFS-COS Firestop Composite Sheet Installation Guide PDFDocument14 pagesHilti CFS-COS Firestop Composite Sheet Installation Guide PDFJustin UyarNo ratings yet

- Fire Protection Engineering Systems Design Per NFPADocument12 pagesFire Protection Engineering Systems Design Per NFPAMohsin Khan50% (2)

- Roofing TechniqueDocument30 pagesRoofing TechniqueLuke Obusan100% (1)

- Technical Manual For ETA 08 0213 For CFS CU Firestop Cushion For Penetrations Approval Document ASSET DOC 2398866Document12 pagesTechnical Manual For ETA 08 0213 For CFS CU Firestop Cushion For Penetrations Approval Document ASSET DOC 2398866Maria Paula CheheidNo ratings yet

- FM Approval of Firestop ContractorsDocument16 pagesFM Approval of Firestop ContractorsMohamed Rafi MNo ratings yet

- C Aj 1609Document2 pagesC Aj 1609vhin84No ratings yet

- FirestopDocument14 pagesFirestopsebasgen17No ratings yet

- Fire Stopping Mechanical and ElectricalDocument7 pagesFire Stopping Mechanical and Electricaljack.simpson.changNo ratings yet

- ASTM E814-13a (Reapproved 2017)Document12 pagesASTM E814-13a (Reapproved 2017)Djaffar SalahouiNo ratings yet

- 23 - 05 - 29 - Hangers and Support For HVAC Piping and EquipmentDocument8 pages23 - 05 - 29 - Hangers and Support For HVAC Piping and EquipmentVo Kien CuongNo ratings yet

- CP 653 BA Technical-information-ASSET-DOC-LOC-1540979Document1 pageCP 653 BA Technical-information-ASSET-DOC-LOC-1540979AdityaNo ratings yet

- Parking Facilities and Vapor Intrusion Mitigation: Design and Operation Considerations For Parking Facilities As Vapor Intrusion Mitigation OptionsDocument35 pagesParking Facilities and Vapor Intrusion Mitigation: Design and Operation Considerations For Parking Facilities As Vapor Intrusion Mitigation OptionsMRFNo ratings yet

- CP 648 E Technical-information-ASSET-DOC-LOC-1540977Document1 pageCP 648 E Technical-information-ASSET-DOC-LOC-1540977AdityaNo ratings yet

- CFS BL Technical Information ASSET DOC LOC 1540921Document1 pageCFS BL Technical Information ASSET DOC LOC 1540921AdityaNo ratings yet

- WL7223Document1 pageWL7223Juvenal GutierrezNo ratings yet

- Assignment 5ADocument5 pagesAssignment 5AprazNo ratings yet

- Approval Document ASSET DOC LOC 2179580Document4 pagesApproval Document ASSET DOC LOC 2179580aNo ratings yet

- Hilti - Seismic Brochure en W4039Document12 pagesHilti - Seismic Brochure en W4039xpertsteelNo ratings yet