Professional Documents

Culture Documents

Document Responsibility: Pumps, Seals and Mixers SABP-G-017 Issue Date: 10 April 2010 Next Planned Update: TBD Equipment Criticality Assessment

Uploaded by

jmz mtz0 ratings0% found this document useful (0 votes)

33 views1 pageThis document defines key terms related to equipment criticality assessment, including mean time to repair, preventive maintenance, process hazard analysis, redundancy, reliability-centered maintenance, and risk. It also lists acronyms commonly used in equipment criticality analysis such as CAPEX, CI, ECA, FFS, FMECA, FTA, GI, GOSP, HazOp, HSE, LOPA, LPO, and MBOD.

Original Description:

Original Title

SABP-G-017 6

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document defines key terms related to equipment criticality assessment, including mean time to repair, preventive maintenance, process hazard analysis, redundancy, reliability-centered maintenance, and risk. It also lists acronyms commonly used in equipment criticality analysis such as CAPEX, CI, ECA, FFS, FMECA, FTA, GI, GOSP, HazOp, HSE, LOPA, LPO, and MBOD.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

33 views1 pageDocument Responsibility: Pumps, Seals and Mixers SABP-G-017 Issue Date: 10 April 2010 Next Planned Update: TBD Equipment Criticality Assessment

Uploaded by

jmz mtzThis document defines key terms related to equipment criticality assessment, including mean time to repair, preventive maintenance, process hazard analysis, redundancy, reliability-centered maintenance, and risk. It also lists acronyms commonly used in equipment criticality analysis such as CAPEX, CI, ECA, FFS, FMECA, FTA, GI, GOSP, HazOp, HSE, LOPA, LPO, and MBOD.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

Document Responsibility: Pumps, Seals and Mixers SABP-G-017

Issue Date: 10 April 2010

Next Planned Update: TBD Equipment Criticality Assessment

Mean Time to Repair (MTTR): basic measure of the maintainability of

repairable items, it represents the average (mean) time required to repair a failed

equipment.

Preventive Maintenance: maintenance carried out at predetermined intervals,

equipment condition or according to prescribed criteria and intended to reduce

the probability of failure or the degradation of the function of an equipment.

Process Hazard Analysis: detailed examination of a process in order to

identify and characterize any hazards associated with that process.

Redundancy: the existence of more than one means at a given instant of time

for performing a required function.

Reliability-Centered Maintenance: process used to determine the

maintenance requirements of any physical asset in its operating context.

Risk: combination of the probability, (or frequency) of occurrence of a defined

hazard and the magnitude of the consequences of the occurrence.

1.7 Acronyms Definition

CAPEX: Capital Expenditures

CI: Criticality Index

ECA: Equipment Criticality Analysis

FFS: Fitness for Service

FMECA: Failure Modes Effect and Criticality Analysis

FTA: Fault Tree Analysis

GI: General Instructions

GOSP: Gas Oil Separation Plant

HazOp: Hazard and Operability Analysis

HSE: Health Safety and Environment

LOPA: Layers of Protection Analysis

LPO: Lost Production Opportunities

MBOD: Thousand Barrels per Operating Day

Page 6 of 20

You might also like

- Reliability, Maintainability and Risk: Practical Methods for EngineersFrom EverandReliability, Maintainability and Risk: Practical Methods for EngineersRating: 4.5 out of 5 stars4.5/5 (3)

- Sabp-G-017 (2016)Document19 pagesSabp-G-017 (2016)tromix100% (2)

- RAMS Knowledge SharingDocument29 pagesRAMS Knowledge SharingJAYNo ratings yet

- HSE-RM-ST08 - Emergency System Survivability Assessment (ESSA)Document22 pagesHSE-RM-ST08 - Emergency System Survivability Assessment (ESSA)GKNo ratings yet

- Sabp J 510Document7 pagesSabp J 510KrishnamoorthyNo ratings yet

- Inspection and Remaining Life Evaluation of Process Plant EquipmentDocument27 pagesInspection and Remaining Life Evaluation of Process Plant Equipmentabisat02100% (2)

- HSE Plan For RBI ProjectsDocument47 pagesHSE Plan For RBI ProjectsChandresh SinghNo ratings yet

- The Safety Critical Systems Handbook: A Straightforward Guide to Functional Safety: IEC 61508 (2010 Edition), IEC 61511 (2015 Edition) and Related GuidanceFrom EverandThe Safety Critical Systems Handbook: A Straightforward Guide to Functional Safety: IEC 61508 (2010 Edition), IEC 61511 (2015 Edition) and Related GuidanceRating: 5 out of 5 stars5/5 (1)

- Additional-Content-Hazard Identification Studies ExternalDocument16 pagesAdditional-Content-Hazard Identification Studies Externalli100% (1)

- System Safety Engineering: Training Course WorkbookDocument104 pagesSystem Safety Engineering: Training Course WorkbookRusli Saga100% (1)

- Calculation PoF and CoFDocument10 pagesCalculation PoF and CoFHamidNo ratings yet

- Sabp A 082Document27 pagesSabp A 082Ahmed BoraeyNo ratings yet

- Mechanical Integrity FINALDocument7 pagesMechanical Integrity FINALSimon TounsiNo ratings yet

- TITAN - Multi Axis Machine - RA Report PDFDocument54 pagesTITAN - Multi Axis Machine - RA Report PDFBharath KumarNo ratings yet

- Gas and Oil Reliability Engineering: Modeling and AnalysisFrom EverandGas and Oil Reliability Engineering: Modeling and AnalysisRating: 4.5 out of 5 stars4.5/5 (6)

- Determine Sis and SIL Using HAZOPS: Process Safety Progress March 2010Document11 pagesDetermine Sis and SIL Using HAZOPS: Process Safety Progress March 2010Badrun Ahamd100% (1)

- Nsspu-Gp 06-10-1Document103 pagesNsspu-Gp 06-10-1John DryNo ratings yet

- Risk Based Inspection Demonstrating ValueDocument10 pagesRisk Based Inspection Demonstrating Valueingmetal9104100% (1)

- CoP 05 Risk Assessment and Control Revised 07 - 12 - 2017Document65 pagesCoP 05 Risk Assessment and Control Revised 07 - 12 - 2017qaqc marinery100% (1)

- Sabp-G-017 13Document1 pageSabp-G-017 13jmz mtzNo ratings yet

- Document Responsibility: Pumps, Seals and Mixers SABP-G-017 Issue Date: 10 April 2010 Next Planned Update: TBD Equipment Criticality AssessmentDocument1 pageDocument Responsibility: Pumps, Seals and Mixers SABP-G-017 Issue Date: 10 April 2010 Next Planned Update: TBD Equipment Criticality Assessmentjmz mtzNo ratings yet

- PVP2004 3019Document10 pagesPVP2004 3019King SabiNo ratings yet

- Definitions and Nomenclature: Acceptable RiskDocument3 pagesDefinitions and Nomenclature: Acceptable RiskFebbyNo ratings yet

- Journal of Loss Prevention in The Process Industries: Haijun Hu, Guangxu Cheng, Yun Li, Yiping TangDocument6 pagesJournal of Loss Prevention in The Process Industries: Haijun Hu, Guangxu Cheng, Yun Li, Yiping TangAramis Alfonso LlanesNo ratings yet

- Document Responsibility: Pumps, Seals and Mixers SABP-G-017 Issue Date: 10 April 2010 Next Planned Update: TBD Equipment Criticality AssessmentDocument1 pageDocument Responsibility: Pumps, Seals and Mixers SABP-G-017 Issue Date: 10 April 2010 Next Planned Update: TBD Equipment Criticality Assessmentjmz mtzNo ratings yet

- A Short Report Determination of Safety Integrity Level (SIL) Using LOPA Method in The Emergency Shutdown System (ESD) of Hydrogen UnitDocument5 pagesA Short Report Determination of Safety Integrity Level (SIL) Using LOPA Method in The Emergency Shutdown System (ESD) of Hydrogen Unitsalman1111aNo ratings yet

- Risk Based Inspection Methodology and Software Applied AST 1670794528Document13 pagesRisk Based Inspection Methodology and Software Applied AST 1670794528Udayakumar SundarNo ratings yet

- Reliability Evaluation and Risk Based Maintenance in A Process PlantDocument8 pagesReliability Evaluation and Risk Based Maintenance in A Process PlantMectrosoft Creative technologyNo ratings yet

- 21 Determine SIS and SIL Using HazOpsDocument11 pages21 Determine SIS and SIL Using HazOpsMarco Antonio Cruz MéndezNo ratings yet

- Prosiding C-6 GUNAWANDocument7 pagesProsiding C-6 GUNAWANAfiq IkhwanNo ratings yet

- Part2-Maintenance Policy and ManagementDocument15 pagesPart2-Maintenance Policy and ManagementZhamelyo DhanyeloNo ratings yet

- Modelo para RBMDocument6 pagesModelo para RBMJosé Luis CastroNo ratings yet

- Risk Management With Maintenance and Repair Strategy 1692480961Document8 pagesRisk Management With Maintenance and Repair Strategy 1692480961athlon03No ratings yet

- External Hazards Document Type: Unique Document ID and Revision No: Date Issued: Review Date: Prepared By: Approved By: Record ReferenceDocument84 pagesExternal Hazards Document Type: Unique Document ID and Revision No: Date Issued: Review Date: Prepared By: Approved By: Record ReferenceAmar MistryNo ratings yet

- Guide To Finding and Using Reliability Data For QRA: Source ResponsibleDocument42 pagesGuide To Finding and Using Reliability Data For QRA: Source Responsibleeng.tomasoniNo ratings yet

- James J. Rooney - Joe H. Turner - John S. Arendt - A Preliminary Hazards Analysis of A Fluid Catalytic Cracking Unit Complex (1988) (Document8 pagesJames J. Rooney - Joe H. Turner - John S. Arendt - A Preliminary Hazards Analysis of A Fluid Catalytic Cracking Unit Complex (1988) (JacekNo ratings yet

- Historical Incidents and Incentives For ChangeDocument8 pagesHistorical Incidents and Incentives For ChangealexmontellNo ratings yet

- RBM JR Railway PDFDocument4 pagesRBM JR Railway PDFNur Azizah NasutionNo ratings yet

- GAPP ArticleDocument3 pagesGAPP ArticleAnthony CollierNo ratings yet

- Annals of Nuclear Energy: Gopika Vinod, Pavan K. Sharma, T.V. Santosh, M. Hari Prasad, K.K. VazeDocument7 pagesAnnals of Nuclear Energy: Gopika Vinod, Pavan K. Sharma, T.V. Santosh, M. Hari Prasad, K.K. VazeJude OkoyeNo ratings yet

- Dokumen - Tips - Condition Based Fault Tree AnalysisDocument11 pagesDokumen - Tips - Condition Based Fault Tree AnalysisAjit MokalNo ratings yet

- Chapter Three:: Preventive Maintinance, Concepts, Modeling and AnalysisDocument26 pagesChapter Three:: Preventive Maintinance, Concepts, Modeling and AnalysisKhalid WaleedNo ratings yet

- 000 Impact of TPM 11 9 05Document32 pages000 Impact of TPM 11 9 05Omar KhaledNo ratings yet

- Applied R&M Manual For Defence Systems Part A - GeneralDocument6 pagesApplied R&M Manual For Defence Systems Part A - GeneralvedipiNo ratings yet

- MIL BasedDocument5 pagesMIL BasedsaahithyaalagarsamyNo ratings yet

- Energies 15 06263 v2Document27 pagesEnergies 15 06263 v2Tomas Muñoz VergaraNo ratings yet

- Sabp G 012Document13 pagesSabp G 012Erol DAĞNo ratings yet

- Chap 6 (6-3 R and M) FFDocument54 pagesChap 6 (6-3 R and M) FFAbeyu AssefaNo ratings yet

- RBI of ASTDocument10 pagesRBI of ASTangelo.petteNo ratings yet

- Glossary: Andon (J) Availability Failure Modes and Effects Analysis (FMEA)Document3 pagesGlossary: Andon (J) Availability Failure Modes and Effects Analysis (FMEA)Juan Camilo MolanoNo ratings yet

- IA Findings WarehouseDocument3 pagesIA Findings WarehouseSreekanth PCNo ratings yet

- Evaluasi Penjadwalan Perawatan Mesin Hanger Shot Blast Kazo Dengan RCM Ii (Studi Kasus: Foundry Plant Perusahaan Manufaktur)Document6 pagesEvaluasi Penjadwalan Perawatan Mesin Hanger Shot Blast Kazo Dengan RCM Ii (Studi Kasus: Foundry Plant Perusahaan Manufaktur)Ratna TryNo ratings yet

- Reliability Engineering and System Safety: SciencedirectDocument10 pagesReliability Engineering and System Safety: SciencedirectAndres AngaritaNo ratings yet

- Aero-Engine Maintenance Cost Optimization by RCMDocument6 pagesAero-Engine Maintenance Cost Optimization by RCMchrysobergiNo ratings yet

- Software Risk ManagementDocument20 pagesSoftware Risk ManagementAye CleofasNo ratings yet

- Fanr RG 004 Final Approved VersionDocument19 pagesFanr RG 004 Final Approved VersionSaju GeorgeNo ratings yet

- Layer of Protection Analysis and Inherently Safer Processes (1999)Document7 pagesLayer of Protection Analysis and Inherently Safer Processes (1999)Gli OxalNo ratings yet

- Energies 15 06263Document29 pagesEnergies 15 06263tomo tomoNo ratings yet

- Risk Based Maintenance - Khan and HaddaraDocument14 pagesRisk Based Maintenance - Khan and Haddaragkvish@gmail.com100% (1)

- RELIABILITY BasicsDocument4 pagesRELIABILITY BasicsChandrani BasuNo ratings yet

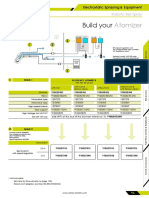

- MKT00101EN B CATALOG 2016 Electrostatic Liquid Finishing 72Document1 pageMKT00101EN B CATALOG 2016 Electrostatic Liquid Finishing 72jmz mtzNo ratings yet

- MKT00101EN B CATALOG 2016 Electrostatic Liquid Finishing 67Document1 pageMKT00101EN B CATALOG 2016 Electrostatic Liquid Finishing 67jmz mtzNo ratings yet

- MKT00101EN - B-CATALOG-2016-Electrostatic-Liquid-Finishing 58Document1 pageMKT00101EN - B-CATALOG-2016-Electrostatic-Liquid-Finishing 58jmz mtzNo ratings yet

- MKT00101EN - B-CATALOG-2016-Electrostatic-Liquid-Finishing 49Document1 pageMKT00101EN - B-CATALOG-2016-Electrostatic-Liquid-Finishing 49jmz mtzNo ratings yet

- MKT00101EN B CATALOG 2016 Electrostatic Liquid Finishing 85Document1 pageMKT00101EN B CATALOG 2016 Electrostatic Liquid Finishing 85jmz mtzNo ratings yet

- MKT00101EN B CATALOG 2016 Electrostatic Liquid Finishing 73Document1 pageMKT00101EN B CATALOG 2016 Electrostatic Liquid Finishing 73jmz mtzNo ratings yet

- MKT00101EN B CATALOG 2016 Electrostatic Liquid Finishing 97Document1 pageMKT00101EN B CATALOG 2016 Electrostatic Liquid Finishing 97jmz mtzNo ratings yet

- MKT00101EN B CATALOG 2016 Electrostatic Liquid Finishing 87Document1 pageMKT00101EN B CATALOG 2016 Electrostatic Liquid Finishing 87jmz mtzNo ratings yet

- MKT00101EN B CATALOG 2016 Electrostatic Liquid Finishing 59Document1 pageMKT00101EN B CATALOG 2016 Electrostatic Liquid Finishing 59jmz mtzNo ratings yet

- MKT00101EN B CATALOG 2016 Electrostatic Liquid Finishing 74Document1 pageMKT00101EN B CATALOG 2016 Electrostatic Liquid Finishing 74jmz mtzNo ratings yet

- MKT00101EN B CATALOG 2016 Electrostatic Liquid Finishing 93Document1 pageMKT00101EN B CATALOG 2016 Electrostatic Liquid Finishing 93jmz mtzNo ratings yet

- MKT00101EN B CATALOG 2016 Electrostatic Liquid Finishing 64Document1 pageMKT00101EN B CATALOG 2016 Electrostatic Liquid Finishing 64jmz mtzNo ratings yet

- MKT00101EN B CATALOG 2016 Electrostatic Liquid Finishing 65Document1 pageMKT00101EN B CATALOG 2016 Electrostatic Liquid Finishing 65jmz mtzNo ratings yet

- MKT00101EN B CATALOG 2016 Electrostatic Liquid Finishing 61Document1 pageMKT00101EN B CATALOG 2016 Electrostatic Liquid Finishing 61jmz mtzNo ratings yet

- MKT00101EN B CATALOG 2016 Electrostatic Liquid Finishing 70Document1 pageMKT00101EN B CATALOG 2016 Electrostatic Liquid Finishing 70jmz mtzNo ratings yet

- MKT00101EN - B-CATALOG-2016-Electrostatic-Liquid-Finishing 56Document1 pageMKT00101EN - B-CATALOG-2016-Electrostatic-Liquid-Finishing 56jmz mtzNo ratings yet

- MKT00101EN B CATALOG 2016 Electrostatic Liquid Finishing 66Document1 pageMKT00101EN B CATALOG 2016 Electrostatic Liquid Finishing 66jmz mtzNo ratings yet

- MKT00101EN B CATALOG 2016 Electrostatic Liquid Finishing 60Document1 pageMKT00101EN B CATALOG 2016 Electrostatic Liquid Finishing 60jmz mtzNo ratings yet

- MKT00101EN B CATALOG 2016 Electrostatic Liquid Finishing 63Document1 pageMKT00101EN B CATALOG 2016 Electrostatic Liquid Finishing 63jmz mtzNo ratings yet

- MKT00101EN B CATALOG 2016 Electrostatic Liquid Finishing 81Document1 pageMKT00101EN B CATALOG 2016 Electrostatic Liquid Finishing 81jmz mtzNo ratings yet

- MKT00101EN B CATALOG 2016 Electrostatic Liquid Finishing 90Document1 pageMKT00101EN B CATALOG 2016 Electrostatic Liquid Finishing 90jmz mtzNo ratings yet

- MKT00101EN B CATALOG 2016 Electrostatic Liquid Finishing 91Document1 pageMKT00101EN B CATALOG 2016 Electrostatic Liquid Finishing 91jmz mtzNo ratings yet

- PPH 707 Icwb-M: High Performance FlexibilityDocument1 pagePPH 707 Icwb-M: High Performance Flexibilityjmz mtzNo ratings yet

- MKT00101EN - B-CATALOG-2016-Electrostatic-Liquid-Finishing 53Document1 pageMKT00101EN - B-CATALOG-2016-Electrostatic-Liquid-Finishing 53jmz mtzNo ratings yet

- MKT00101EN - B-CATALOG-2016-Electrostatic-Liquid-Finishing 52Document1 pageMKT00101EN - B-CATALOG-2016-Electrostatic-Liquid-Finishing 52jmz mtzNo ratings yet

- MKT00101EN - B-CATALOG-2016-Electrostatic-Liquid-Finishing 48Document1 pageMKT00101EN - B-CATALOG-2016-Electrostatic-Liquid-Finishing 48jmz mtzNo ratings yet

- MKT00101EN B CATALOG 2016 Electrostatic Liquid Finishing 69Document1 pageMKT00101EN B CATALOG 2016 Electrostatic Liquid Finishing 69jmz mtzNo ratings yet

- MKT00101EN - B-CATALOG-2016-Electrostatic-Liquid-Finishing 44Document1 pageMKT00101EN - B-CATALOG-2016-Electrostatic-Liquid-Finishing 44jmz mtzNo ratings yet

- MKT00101EN - B-CATALOG-2016-Electrostatic-Liquid-Finishing 46Document1 pageMKT00101EN - B-CATALOG-2016-Electrostatic-Liquid-Finishing 46jmz mtzNo ratings yet

- MKT00101EN - B-CATALOG-2016-Electrostatic-Liquid-Finishing 47Document1 pageMKT00101EN - B-CATALOG-2016-Electrostatic-Liquid-Finishing 47jmz mtzNo ratings yet