Professional Documents

Culture Documents

Should Be Completed and Who Should Do It) .: 10 Equipment Criticality Assessment Update

Uploaded by

jmz mtz0 ratings0% found this document useful (0 votes)

13 views1 pageOriginal Title

SABP-G-017 19

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

13 views1 pageShould Be Completed and Who Should Do It) .: 10 Equipment Criticality Assessment Update

Uploaded by

jmz mtzCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

Document Responsibility: Pumps, Seals and Mixers SABP-G-017

Issue Date: 10 April 2010

Next Planned Update: TBD Equipment Criticality Assessment

Recommendations categorized by criticality classes; and finally

Actions log to implement recommendations and path forward (what to do, when it

should be completed and who should do it).

10 Equipment Criticality Assessment Update

The equipment criticality assessment, ECA, is a living process and has to be updated if

any of the following occurs:

Change in operating business plan

New strategic imperatives from plant management or from corporate management

Plant/equipment upgrade and/or extension

Every two years, update the reliability inputs to the equipment criticality

11 Team Composition

The equipment criticality assessment is to be performed by a multidisciplinary team

including maintenance, operation and engineering. Field operators and machinists shall

also be involved during this assessment as they are subject matter experts of their areas.

Dynamic and Reliability Analysis Unit from Consulting Services Department can also

be consulted if the team needs clarifications on a specific task during the assessment.

The lead engineer of this initiative has to follow the outlined execution procedure and

can be either from maintenance, operation or reliability group.

Page 19 of 20

You might also like

- Maintenance and Operational Reliability: 24 Essential Building BlocksFrom EverandMaintenance and Operational Reliability: 24 Essential Building BlocksNo ratings yet

- Benchmarking Best Practices for Maintenance, Reliability and Asset ManagementFrom EverandBenchmarking Best Practices for Maintenance, Reliability and Asset ManagementNo ratings yet

- WMT ISI - Deposit Bonus Program - Test Assessment - V0.1Document13 pagesWMT ISI - Deposit Bonus Program - Test Assessment - V0.1Natsu ENDNo ratings yet

- Planned Maintenance Step 2 Audit SheetDocument4 pagesPlanned Maintenance Step 2 Audit SheetDũng Tây NinhNo ratings yet

- Roles and Responsibilities of Plant Pre-Commissioning, Commissioning and Acceptance Test RunDocument11 pagesRoles and Responsibilities of Plant Pre-Commissioning, Commissioning and Acceptance Test RunArsalan QadirNo ratings yet

- Assignment 9 (Akash)Document3 pagesAssignment 9 (Akash)Deepak WasgeNo ratings yet

- Itil Change Management A Beginners GuideDocument17 pagesItil Change Management A Beginners Guidedesi1992No ratings yet

- Information Technology Change Management Policy and ProceduresDocument16 pagesInformation Technology Change Management Policy and Procedureszingman100% (1)

- Ch-2-Maintenance Support Processes1Document59 pagesCh-2-Maintenance Support Processes1Eden SibhatNo ratings yet

- P3.48 Building Maintenance Final ReportDocument16 pagesP3.48 Building Maintenance Final ReportThulasi Ram MangatiNo ratings yet

- Develop A Maintenance and Reliability PlanDocument5 pagesDevelop A Maintenance and Reliability Planjak4442001100% (1)

- The 7 Steps For Rolling Out An Early Equipment Management SystemDocument32 pagesThe 7 Steps For Rolling Out An Early Equipment Management SystemJavier R- Colina M.No ratings yet

- B PNP DRD CA2 Audit ReportDocument3 pagesB PNP DRD CA2 Audit ReportRaymond SmithNo ratings yet

- Changes Contained in The 10th Edition of API 510, Pressure Vessel Inspection Code: In-Service Inspection, Rating, Repair, and AlterationDocument3 pagesChanges Contained in The 10th Edition of API 510, Pressure Vessel Inspection Code: In-Service Inspection, Rating, Repair, and AlterationAARON HERRERANo ratings yet

- SRE - Ch.07 - Requirements ManagementDocument26 pagesSRE - Ch.07 - Requirements Managementone thousand oneNo ratings yet

- Maintenance Engineering & Reliability Engineering Lecture 4Document12 pagesMaintenance Engineering & Reliability Engineering Lecture 4Athar Iqbal50% (2)

- Change Approval Board TemplateDocument9 pagesChange Approval Board TemplateJonathan Kwame Kwesi100% (2)

- IATF 16949 Webinar Slides 3.7.17 Final PDFDocument47 pagesIATF 16949 Webinar Slides 3.7.17 Final PDFmilou88No ratings yet

- IATF 16949 Webinar Slides 3.7.17 Final PDFDocument47 pagesIATF 16949 Webinar Slides 3.7.17 Final PDFwanphen kawnawanichNo ratings yet

- Cqi 11Document73 pagesCqi 11dwimukh360No ratings yet

- Change Management Ais 5Document2 pagesChange Management Ais 5Trisha Kate Yumul ParaisoNo ratings yet

- Lec 2 Integrated Logistics Support - Fin - 1Document61 pagesLec 2 Integrated Logistics Support - Fin - 1Gürkan Özbil100% (1)

- Software Quality & Systems Engineering ProgramDocument7 pagesSoftware Quality & Systems Engineering ProgramSeri CharoensriNo ratings yet

- 08 - IT AUDIT CISA-System DevelopmentDocument38 pages08 - IT AUDIT CISA-System DevelopmentHamza NaeemNo ratings yet

- Preventive MaintenanceDocument19 pagesPreventive Maintenancefaizan9970% (1)

- Change Management v1.0Document12 pagesChange Management v1.0pushpendrasbNo ratings yet

- AS9100C WhitePaperDocument10 pagesAS9100C WhitePaperlugarxNo ratings yet

- Isa: I S A C 2.0: System Development Acquisition and Maintenance 1.0 Chapter 1: Introduction To SDLCDocument96 pagesIsa: I S A C 2.0: System Development Acquisition and Maintenance 1.0 Chapter 1: Introduction To SDLCDigantNo ratings yet

- Sap MMDocument9 pagesSap MMBala KasireddyNo ratings yet

- 10 Steps To Asset CareDocument13 pages10 Steps To Asset CareDamianNo ratings yet

- Eel Ics3 07 0511Document11 pagesEel Ics3 07 0511Gizaw TadesseNo ratings yet

- Sabp G 008Document78 pagesSabp G 008Mahesh Kumar100% (1)

- 7.0 SupportDocument28 pages7.0 SupportprashantNo ratings yet

- How To Use This Template: Application Maintenance WorkflowDocument6 pagesHow To Use This Template: Application Maintenance WorkflowCamelia NițeNo ratings yet

- IT Change Management PolicyDocument25 pagesIT Change Management PolicyowenNo ratings yet

- ITIL Introduction PresentationDocument46 pagesITIL Introduction PresentationDESMOND5166410100% (1)

- Allied Reliability Pocket GlossaryDocument46 pagesAllied Reliability Pocket GlossaryHugoCabanillasNo ratings yet

- Assignment No 4Document4 pagesAssignment No 4heemishaNo ratings yet

- Determine Maintenace StrategyDocument18 pagesDetermine Maintenace StrategyJalel Bejo GudinaNo ratings yet

- Facility Condition AssesmentDocument26 pagesFacility Condition Assesmentisaac100% (1)

- Maintenance ManagementDocument20 pagesMaintenance ManagementRiya GuptaNo ratings yet

- Change Management: Process & ImplementationDocument5 pagesChange Management: Process & ImplementationAnantNo ratings yet

- 00 Saip 72Document6 pages00 Saip 72Erin JohnsonNo ratings yet

- Guidewire Upgrade FactoryDocument12 pagesGuidewire Upgrade FactoryVenkatesh Venky DabbaraNo ratings yet

- Section 6. Investigation Recommendations: Seclion 6, Lnvestigatior. Becomn-RendationsDocument7 pagesSection 6. Investigation Recommendations: Seclion 6, Lnvestigatior. Becomn-RendationsOSDocs2012No ratings yet

- P I: C D: Hase Oncept EvelopmentDocument2 pagesP I: C D: Hase Oncept EvelopmentSohil RaieenNo ratings yet

- The Systems Life CycleDocument4 pagesThe Systems Life CyclebluckyNo ratings yet

- Change Management Policies and ProceduresDocument3 pagesChange Management Policies and ProceduresAhmed Ali Syed BrilliantNo ratings yet

- PTC 2015 ToftDocument12 pagesPTC 2015 ToftRabindra RaiNo ratings yet

- Preventive MaintenanaceDocument19 pagesPreventive MaintenanaceMohammed NerissaNo ratings yet

- LifeTech-Engineering-Services - Asset Integrity ManagementDocument14 pagesLifeTech-Engineering-Services - Asset Integrity Managementyogolain100% (1)

- 10 Software MaintenanceDocument14 pages10 Software MaintenancearkiaraNo ratings yet

- Systems Engineering Management in Dod AcquisitionDocument18 pagesSystems Engineering Management in Dod AcquisitionGeovanna Miranda ArceNo ratings yet

- Improvement of The Maintenance Management Process of Complex Technical Systems Which Demand High ReliabilityDocument8 pagesImprovement of The Maintenance Management Process of Complex Technical Systems Which Demand High ReliabilityRUPERTNo ratings yet

- Software Maintenance Productivity Measurement HowDocument13 pagesSoftware Maintenance Productivity Measurement HowDương Việt TùngNo ratings yet

- PM-6 ChangeControl and Configuration ManagementDocument21 pagesPM-6 ChangeControl and Configuration ManagementBizuayehu DesalegnNo ratings yet

- Information Systems Auditing: The IS Audit Follow-up ProcessFrom EverandInformation Systems Auditing: The IS Audit Follow-up ProcessRating: 2 out of 5 stars2/5 (1)

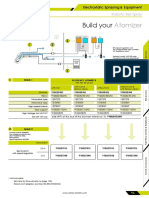

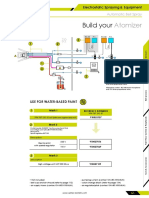

- MKT00101EN B CATALOG 2016 Electrostatic Liquid Finishing 67Document1 pageMKT00101EN B CATALOG 2016 Electrostatic Liquid Finishing 67jmz mtzNo ratings yet

- MKT00101EN B CATALOG 2016 Electrostatic Liquid Finishing 85Document1 pageMKT00101EN B CATALOG 2016 Electrostatic Liquid Finishing 85jmz mtzNo ratings yet

- MKT00101EN B CATALOG 2016 Electrostatic Liquid Finishing 72Document1 pageMKT00101EN B CATALOG 2016 Electrostatic Liquid Finishing 72jmz mtzNo ratings yet

- MKT00101EN - B-CATALOG-2016-Electrostatic-Liquid-Finishing 58Document1 pageMKT00101EN - B-CATALOG-2016-Electrostatic-Liquid-Finishing 58jmz mtzNo ratings yet

- MKT00101EN - B-CATALOG-2016-Electrostatic-Liquid-Finishing 49Document1 pageMKT00101EN - B-CATALOG-2016-Electrostatic-Liquid-Finishing 49jmz mtzNo ratings yet

- MKT00101EN B CATALOG 2016 Electrostatic Liquid Finishing 73Document1 pageMKT00101EN B CATALOG 2016 Electrostatic Liquid Finishing 73jmz mtzNo ratings yet

- MKT00101EN B CATALOG 2016 Electrostatic Liquid Finishing 97Document1 pageMKT00101EN B CATALOG 2016 Electrostatic Liquid Finishing 97jmz mtzNo ratings yet

- MKT00101EN B CATALOG 2016 Electrostatic Liquid Finishing 66Document1 pageMKT00101EN B CATALOG 2016 Electrostatic Liquid Finishing 66jmz mtzNo ratings yet

- MKT00101EN B CATALOG 2016 Electrostatic Liquid Finishing 74Document1 pageMKT00101EN B CATALOG 2016 Electrostatic Liquid Finishing 74jmz mtzNo ratings yet

- MKT00101EN B CATALOG 2016 Electrostatic Liquid Finishing 65Document1 pageMKT00101EN B CATALOG 2016 Electrostatic Liquid Finishing 65jmz mtzNo ratings yet

- MKT00101EN B CATALOG 2016 Electrostatic Liquid Finishing 64Document1 pageMKT00101EN B CATALOG 2016 Electrostatic Liquid Finishing 64jmz mtzNo ratings yet

- MKT00101EN B CATALOG 2016 Electrostatic Liquid Finishing 70Document1 pageMKT00101EN B CATALOG 2016 Electrostatic Liquid Finishing 70jmz mtzNo ratings yet

- MKT00101EN B CATALOG 2016 Electrostatic Liquid Finishing 93Document1 pageMKT00101EN B CATALOG 2016 Electrostatic Liquid Finishing 93jmz mtzNo ratings yet

- MKT00101EN - B-CATALOG-2016-Electrostatic-Liquid-Finishing 56Document1 pageMKT00101EN - B-CATALOG-2016-Electrostatic-Liquid-Finishing 56jmz mtzNo ratings yet

- MKT00101EN B CATALOG 2016 Electrostatic Liquid Finishing 61Document1 pageMKT00101EN B CATALOG 2016 Electrostatic Liquid Finishing 61jmz mtzNo ratings yet

- PPH 707 Icwb-M: High Performance FlexibilityDocument1 pagePPH 707 Icwb-M: High Performance Flexibilityjmz mtzNo ratings yet

- MKT00101EN B CATALOG 2016 Electrostatic Liquid Finishing 63Document1 pageMKT00101EN B CATALOG 2016 Electrostatic Liquid Finishing 63jmz mtzNo ratings yet

- MKT00101EN B CATALOG 2016 Electrostatic Liquid Finishing 90Document1 pageMKT00101EN B CATALOG 2016 Electrostatic Liquid Finishing 90jmz mtzNo ratings yet

- MKT00101EN B CATALOG 2016 Electrostatic Liquid Finishing 87Document1 pageMKT00101EN B CATALOG 2016 Electrostatic Liquid Finishing 87jmz mtzNo ratings yet

- MKT00101EN B CATALOG 2016 Electrostatic Liquid Finishing 91Document1 pageMKT00101EN B CATALOG 2016 Electrostatic Liquid Finishing 91jmz mtzNo ratings yet

- MKT00101EN B CATALOG 2016 Electrostatic Liquid Finishing 60Document1 pageMKT00101EN B CATALOG 2016 Electrostatic Liquid Finishing 60jmz mtzNo ratings yet

- MKT00101EN B CATALOG 2016 Electrostatic Liquid Finishing 81Document1 pageMKT00101EN B CATALOG 2016 Electrostatic Liquid Finishing 81jmz mtzNo ratings yet

- MKT00101EN - B-CATALOG-2016-Electrostatic-Liquid-Finishing 44Document1 pageMKT00101EN - B-CATALOG-2016-Electrostatic-Liquid-Finishing 44jmz mtzNo ratings yet

- MKT00101EN B CATALOG 2016 Electrostatic Liquid Finishing 69Document1 pageMKT00101EN B CATALOG 2016 Electrostatic Liquid Finishing 69jmz mtzNo ratings yet

- MKT00101EN B CATALOG 2016 Electrostatic Liquid Finishing 59Document1 pageMKT00101EN B CATALOG 2016 Electrostatic Liquid Finishing 59jmz mtzNo ratings yet

- MKT00101EN - B-CATALOG-2016-Electrostatic-Liquid-Finishing 48Document1 pageMKT00101EN - B-CATALOG-2016-Electrostatic-Liquid-Finishing 48jmz mtzNo ratings yet

- MKT00101EN - B-CATALOG-2016-Electrostatic-Liquid-Finishing 52Document1 pageMKT00101EN - B-CATALOG-2016-Electrostatic-Liquid-Finishing 52jmz mtzNo ratings yet

- MKT00101EN - B-CATALOG-2016-Electrostatic-Liquid-Finishing 46Document1 pageMKT00101EN - B-CATALOG-2016-Electrostatic-Liquid-Finishing 46jmz mtzNo ratings yet

- MKT00101EN - B-CATALOG-2016-Electrostatic-Liquid-Finishing 53Document1 pageMKT00101EN - B-CATALOG-2016-Electrostatic-Liquid-Finishing 53jmz mtzNo ratings yet

- MKT00101EN - B-CATALOG-2016-Electrostatic-Liquid-Finishing 47Document1 pageMKT00101EN - B-CATALOG-2016-Electrostatic-Liquid-Finishing 47jmz mtzNo ratings yet