Professional Documents

Culture Documents

Rdso Fish Plate Book

Uploaded by

Tuff qualityOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Rdso Fish Plate Book

Uploaded by

Tuff qualityCopyright:

Available Formats

22.

TOLERANCES

22.1 Fishplates (except fish plates combination) - The hole shall be clean and without burrs

on either side. The diameter and the position of the holes shall be in accordance with those

shown on the plan subject to the following tolerances: -

(a) (i)Diameter of the hole (except joggle fish plate) +0.8mm

- 0.0mm

(ii)Diameter of the hole (for joggle fish plate) +1.5mm

-0.0mm

(b) Position of the holes- The distance between the centre of any hole with respect to the

centre of any of the remaining holes shall not vary by more than + 0.4mm (+0.6mm for 1.0

mt. fish plate) from the exact dimension either horizontally or vertically.

Should the diameter of any of the holes exceed the specified dimension by more than

0.8mm (except joggle fish plate) and 1.5mm (for joggle fish plate) or should the position of

any hole with respect to the position of other holes vary from the specified dimension by

more than 0.4mm (0.6mm for 1.0 mt. fish plate) either horizontally or vertically, the

fishplate or the fishplates in which such variations occur should be rejected.

(c) Overall length + 1.5 mm

(d) Between surfaces of - 0.2mm

fishing planes of

fishplate

(e) Thickness + 0.5 mm

(f) Straightness

(i) Horizontal- 0.16 mm per 100 mm of length

(i) Vertical- 0.1 mm per 100 mm of length

(Centre should not be lower than the ends)

(g) End Squareness- ± 2 mm

(h) Machined notch of joggled fish plates (at top) +0.3 mm

(at bottom) +0.5 mm

(i) Weight tolerance and base of payment – Provided the dimensional tolerances given

above are strictly maintained, payment shall be based on the actual weight of the fish plates.

Payment for any excess weight shall only be made upto 2% of the nominal weight; in the event

of deficiency in weight occurring, the actual weight shall, in all cases, be the basis for payment.

Note- However, for those fish plates where nominal weight is presently not available, till such

time the same is made available, following should be adopted -

(1)Dimensional tolerances for thickness +0.2 mm

-0.5 mm

(2)Provided the dimensional tolerances given above are strictly maintained, payment shall be

based on the actual weight of fish plates. Once nominal weights of the fish plates are made

available, this note shall stand as withdrawn for such fishplates. The nominal weight of a fish

plate shall be considered as being the average weight of 100 parts manufactured to the exact

dimensions given in the approved drawing, which shall initially be done promptly by Quality

Assurance (Civil) Directorate of RDSO.

22.2 For Fishplate combination - The following tolerances will be permitted: -

(a) Diameter of holes +1.00mm

- 0.00mm

(b) Overall length ± 1.5mm

(c) Between surfaces of - 0.2 mm

fishing planes of

fishplates

(d) Thickness +0.5 mm

(e) Straightness

(i) Horizontal- 0.16 mm per 100 mm of length

(i) Vertical- 0.1 mm per 100 mm of length

(Centre should not be lower than the ends)

(f) End Squareness- ± 2 mm

(g) Weight tolerance and base of payment – Provided the dimensional tolerances given

above are strictly maintained, payment shall be based on the actual weight of the fish plates.

Payment for any excess weight shall only be made upto 2% of the nominal weight; in the event

of deficiency in weight occurring, the actual weight shall, in all cases, be the basis for payment.

Note- However, for those fish plates where nominal weight is presently not available, till such

time the same is made available, following should be adopted -

(1)Dimensional tolerances for thickness +0.2 mm

-0.5 mm

(2)Provided the dimensional tolerances given above are strictly maintained, payment shall be

based on the actual weight of fish plates. Once nominal weights of the fish plates are made

available, this note shall stand as withdrawn for such fish plates. The nominal weight of a fish

plate shall be considered as being the average weight of 100 parts manufactured to the exact

dimensions given in the approved drawing, which shall initially be done promptly by Quality

Assurance (Civil) Directorate of RDSO.

23. CHECKING OF DIMENSIONS

During the course of manufacture, the Inspector will have every fishplate checked on an

approved nipple gauge, and in addition to this check, 3 percent of the pairs of fishplates shall be

bolted to the two specified rail sections to check the fit.

The ‘fit’ of fishplates shall be tested by attempts to insert small feeler gauges of size 0.2mm

between fishing angles or fishplates and rails.

24. NOTCHES FOR DOG SPIKES OR COACH SCREWS

The notches for dog spikes or coach screws may be punched hot or cold. All burrs caused by

the punching shall be removed. The accuracy of the notches shall be tested by nipple gauge

hinged to the bolt nipple gauge in order that the fishplates may be gauged at one setting.

You might also like

- Ribbed Slabs2Document3 pagesRibbed Slabs2Engineeri TadiyosNo ratings yet

- Analysis and Design of Ribbed SlabDocument7 pagesAnalysis and Design of Ribbed Slabtesh100% (1)

- Parkers: BS EN 10258: 1997Document3 pagesParkers: BS EN 10258: 1997JagankumarNo ratings yet

- ME - 403 Power Plant EngineeringDocument42 pagesME - 403 Power Plant Engineering4arunpandeyNo ratings yet

- Tolerances To EN 10029 For Hot Rolled Plate 3mm and Above: GeneralDocument5 pagesTolerances To EN 10029 For Hot Rolled Plate 3mm and Above: GeneralKumar NawneetNo ratings yet

- Bill of Quantities/Schedules of Prices: Ite M Description Official Use Tenderer'S UseDocument93 pagesBill of Quantities/Schedules of Prices: Ite M Description Official Use Tenderer'S UseBOBANSO KIOKONo ratings yet

- Aashto T-99-10Document12 pagesAashto T-99-10Roberto VasquezNo ratings yet

- Acceptance Criteria For Workmanship of Various ActivitiesDocument11 pagesAcceptance Criteria For Workmanship of Various ActivitiesVenkat MacharlaNo ratings yet

- Summarized of BallastDocument1 pageSummarized of BallastPrasanta ParidaNo ratings yet

- SSAB General Product Information Strenx Hardox Armox Toolox 2018 PDFDocument11 pagesSSAB General Product Information Strenx Hardox Armox Toolox 2018 PDFAslam ShaikhNo ratings yet

- PVElite Design GuidelinesDocument7 pagesPVElite Design Guidelinesndrarly100% (2)

- Basics About Rails: by (N.R. Kale) Axen/IricenDocument45 pagesBasics About Rails: by (N.R. Kale) Axen/IricenshujaNo ratings yet

- Conversion FactorsDocument10 pagesConversion FactorsJohn MofireNo ratings yet

- A Do HHGDocument9 pagesA Do HHGMj CabangananNo ratings yet

- DIN 7168 General tolerances for linear and angular dimensionsDocument1 pageDIN 7168 General tolerances for linear and angular dimensionsAnwarNo ratings yet

- Method B7 - The Determination of The Treton Impact Value of Aggregate.Document3 pagesMethod B7 - The Determination of The Treton Impact Value of Aggregate.GUO LEI100% (1)

- En 10029 Quarto Plate TolerancesDocument4 pagesEn 10029 Quarto Plate TolerancesDiyanto AntoNo ratings yet

- BS 00957-2008 (2009)Document12 pagesBS 00957-2008 (2009)faisal.hammad.workNo ratings yet

- Standard EN10029Document4 pagesStandard EN10029Florin JipaNo ratings yet

- Erection Procedure for Installing Vessels 2R-204 and 2R-205Document4 pagesErection Procedure for Installing Vessels 2R-204 and 2R-205คุณพ่อน้อง บิ๊กบอสNo ratings yet

- Drawing NotesDocument8 pagesDrawing NotesPancerniZawszeWierniNo ratings yet

- En 10278 PDFDocument3 pagesEn 10278 PDFErnestoNo ratings yet

- BS en 10278 Tolerante Dimensionale Bare Rotunde Si PatrateDocument3 pagesBS en 10278 Tolerante Dimensionale Bare Rotunde Si PatrateNicolae PoputoaiaNo ratings yet

- My - Spreadsheet - SlabDocument26 pagesMy - Spreadsheet - SlabBilal Ahmed Barbhuiya50% (2)

- Fig. 1: Lab Vane Shear ApparatusDocument2 pagesFig. 1: Lab Vane Shear ApparatusKishanNo ratings yet

- Lastra Singola - It.enDocument4 pagesLastra Singola - It.enyogeshNo ratings yet

- Technical Specifications Simple Turnout: 1.1 GeneralDocument9 pagesTechnical Specifications Simple Turnout: 1.1 GeneralKang RondaNo ratings yet

- BS 6263 Tubes ToleranceDocument2 pagesBS 6263 Tubes TolerancePramod RaghuvanshiNo ratings yet

- Structural Tolerances Bs4 - 2004Document4 pagesStructural Tolerances Bs4 - 2004Anonymous 8bH7sXpcEHNo ratings yet

- Measure and Calculate Areas & VolumesDocument6 pagesMeasure and Calculate Areas & VolumesXavi RedondoNo ratings yet

- En 10029 For Hot Rolled Plate 3mm and AboveDocument4 pagesEn 10029 For Hot Rolled Plate 3mm and AboveIlkin hasanovNo ratings yet

- Jis G3141Document0 pagesJis G3141johnnyquest_86No ratings yet

- C134Document4 pagesC134maria tNo ratings yet

- Reinforced Concrete Design: By: Dr. Haleem K. HussainDocument65 pagesReinforced Concrete Design: By: Dr. Haleem K. HussainNHEM KEAMNo ratings yet

- Cold Rolled Steel Sections - Specification: Kenya StandardDocument30 pagesCold Rolled Steel Sections - Specification: Kenya StandarddexterisNo ratings yet

- SASO 186 GS 1421: Hollow Blocks From Burnt Clay For WallsDocument8 pagesSASO 186 GS 1421: Hollow Blocks From Burnt Clay For WallsomerNo ratings yet

- Ring Piston C6.4Document3 pagesRing Piston C6.4JebrodNo ratings yet

- Round Timber Piles: Standard Specification ForDocument7 pagesRound Timber Piles: Standard Specification ForJosé Ramón GutierrezNo ratings yet

- Time of Setting of Hydraulic Cement by Vicat Needle: Standard Test Method ForDocument3 pagesTime of Setting of Hydraulic Cement by Vicat Needle: Standard Test Method ForSebastián RodríguezNo ratings yet

- Perhitungan Kaca & Allumunium Canopy KOMDocument22 pagesPerhitungan Kaca & Allumunium Canopy KOMengineering trimatraNo ratings yet

- Dabchick Association of South Africa: Measurement Procedure For Dabchick Class BoatsDocument4 pagesDabchick Association of South Africa: Measurement Procedure For Dabchick Class BoatskilpsNo ratings yet

- D 1587 - 94 Rde1odctukve PDFDocument6 pagesD 1587 - 94 Rde1odctukve PDFLupita CarelyNo ratings yet

- Dr. A. Vinoth Jebaraj on tolerances and interchangeable partsDocument22 pagesDr. A. Vinoth Jebaraj on tolerances and interchangeable partsNikhil VermaNo ratings yet

- JIS G 3193-1990 Dims., Mass & Permissable Variations o Hot Rolled ST Plates, Sheets & StripsDocument10 pagesJIS G 3193-1990 Dims., Mass & Permissable Variations o Hot Rolled ST Plates, Sheets & Stripspu2r.v6No ratings yet

- BS en 755-7 PDFDocument6 pagesBS en 755-7 PDFRok HermanNo ratings yet

- SECTION 01 58 16 Temporary Interior Signage Part 1 General DescriptionDocument1 pageSECTION 01 58 16 Temporary Interior Signage Part 1 General DescriptionاحمدعليNo ratings yet

- Tyre Flap Specification AS35083SEP2016Document5 pagesTyre Flap Specification AS35083SEP2016Purchase and Stores Officer Contract Cell-IINo ratings yet

- Cement Compressive Strength Test ProceduresDocument9 pagesCement Compressive Strength Test ProceduresjimsonNo ratings yet

- Tolerances According To en 10162 Standards: Outside DimensionsDocument1 pageTolerances According To en 10162 Standards: Outside DimensionsJuan Carlos PlataNo ratings yet

- Moisture-Density Relations of Soils Using A 2.5-kg (5.5-lb) Rammer and A 305-mm (12-In.) DropDocument13 pagesMoisture-Density Relations of Soils Using A 2.5-kg (5.5-lb) Rammer and A 305-mm (12-In.) DropJulio César ChávezNo ratings yet

- FilterationDocument22 pagesFilterationMohit SharmaNo ratings yet

- Aashto T 180Document14 pagesAashto T 180Hugo EscalanteNo ratings yet

- (786412530) Exhibit 4 - 2 - Asme TolerancesDocument4 pages(786412530) Exhibit 4 - 2 - Asme TolerancesMohd SharainiNo ratings yet

- COLD FORMED STEEL PIPES AND SECTIONSDocument7 pagesCOLD FORMED STEEL PIPES AND SECTIONSArnold TunduliNo ratings yet

- C 4 - 02 - QzqtmdiDocument6 pagesC 4 - 02 - Qzqtmdimhamed1No ratings yet

- APPENDIX IV - Development Canoe RulesDocument5 pagesAPPENDIX IV - Development Canoe RuleshaujesNo ratings yet

- Investment Castings, Surface Acceptance Standards, Visual ExaminationDocument2 pagesInvestment Castings, Surface Acceptance Standards, Visual ExaminationDarwin DarmawanNo ratings yet

- Tolerancing SystemDocument24 pagesTolerancing SystemLenis Enrique Julio QuintanaNo ratings yet

- 10 10 2022 BallastDocument53 pages10 10 2022 Ballastprincebh3No ratings yet

- First Article Inspection Report: Purchase Order Number Supplier NameDocument8 pagesFirst Article Inspection Report: Purchase Order Number Supplier NameTuff qualityNo ratings yet

- Lathe Tail StockDocument2 pagesLathe Tail StockShaswata BoseNo ratings yet

- Handbook of DrawingDocument302 pagesHandbook of DrawingTucc195% (22)

- Guide To Drawing PDFDocument21 pagesGuide To Drawing PDFAmigo IncomodoNo ratings yet

- Phthalate Esters and Their Potential Risk in PET Bottled Water Stored Under Common ConditionsDocument13 pagesPhthalate Esters and Their Potential Risk in PET Bottled Water Stored Under Common ConditionsTuff qualityNo ratings yet

- Yu-Tao LIU, Cheng-Hui LI and Ying-Jie ZHANGDocument7 pagesYu-Tao LIU, Cheng-Hui LI and Ying-Jie ZHANGTuff qualityNo ratings yet

- 01chapters1 2Document45 pages01chapters1 2lewisNo ratings yet

- Stress Strain Diagram for Ductile and Brittle MaterialsDocument15 pagesStress Strain Diagram for Ductile and Brittle MaterialsWaqas Qureshi100% (5)

- ORF Monograph Fountain Pen StoryDocument40 pagesORF Monograph Fountain Pen StoryTuff qualityNo ratings yet

- Mechanics of Materials: Stress and Strain - Axial LoadingDocument42 pagesMechanics of Materials: Stress and Strain - Axial LoadingTuff qualityNo ratings yet

- Performance Evaluation of Rotavator BaseDocument9 pagesPerformance Evaluation of Rotavator BasevodounnouNo ratings yet

- HW 2Document2 pagesHW 2Tuff qualityNo ratings yet

- Independent Auditor'S Report To The Members of HT Mobile Solutions LimitedDocument47 pagesIndependent Auditor'S Report To The Members of HT Mobile Solutions LimitedTuff qualityNo ratings yet

- Pump Types: © Tuthill Corporation. All Rights Reserved. Tuthill ConfidentialDocument67 pagesPump Types: © Tuthill Corporation. All Rights Reserved. Tuthill ConfidentialTemesgenNo ratings yet

- Phthalate Esters and Their Potential Risk in PET Bottled Water Stored Under Common ConditionsDocument13 pagesPhthalate Esters and Their Potential Risk in PET Bottled Water Stored Under Common ConditionsTuff qualityNo ratings yet

- Revised PDW ManualDocument78 pagesRevised PDW ManualGorack ShirsathNo ratings yet

- Circullar On Reducing Weight of BagsDocument2 pagesCircullar On Reducing Weight of BagsNDTVNo ratings yet

- India: QM (Rfuoq$emfttrd Af6Document6 pagesIndia: QM (Rfuoq$emfttrd Af6Tuff qualityNo ratings yet

- Hruska Clinic Recommended Shoe List For 2020: Qualities of A Good ShoeDocument2 pagesHruska Clinic Recommended Shoe List For 2020: Qualities of A Good ShoeTuff qualityNo ratings yet

- Gait Research Laboratory, Program in Physical Therapy Northern Arizona University PO Box 15015, Flagstaff, AZ, 86011Document4 pagesGait Research Laboratory, Program in Physical Therapy Northern Arizona University PO Box 15015, Flagstaff, AZ, 86011Tuff qualityNo ratings yet

- HT Product Catalog 2019-2020Document612 pagesHT Product Catalog 2019-2020Tuff qualityNo ratings yet

- Choosing The Right School Bag: Association of Paediatric Chartered PhysiotherapistsDocument2 pagesChoosing The Right School Bag: Association of Paediatric Chartered PhysiotherapistsTuff qualityNo ratings yet

- Recommend Athletic ShoesDocument7 pagesRecommend Athletic ShoesolegNo ratings yet

- Circullar On Reducing Weight of BagsDocument2 pagesCircullar On Reducing Weight of BagsNDTVNo ratings yet

- Jute Bags Jute Sacks Gunny Bags Manufacturing PDFDocument39 pagesJute Bags Jute Sacks Gunny Bags Manufacturing PDFTuff qualityNo ratings yet

- Sports ShoesDocument10 pagesSports ShoesTuff qualityNo ratings yet

- Athletic Shoes: Tips For Finding The Correct ShoesDocument2 pagesAthletic Shoes: Tips For Finding The Correct ShoesTuff qualityNo ratings yet

- Heavy School Bags PDFDocument2 pagesHeavy School Bags PDFArshad Baig MughalNo ratings yet

- PROJECT PROFILE ON PRINTED JUTE BAG MANUFACTURINGDocument9 pagesPROJECT PROFILE ON PRINTED JUTE BAG MANUFACTURINGafham84No ratings yet

- FMFastener PDFDocument16 pagesFMFastener PDFTuff qualityNo ratings yet

- Iso21940-32 Vibration MechanicalDocument24 pagesIso21940-32 Vibration MechanicalmuhdmsohNo ratings yet

- IS 3455 (1971): Gauging practice for plain workpiecesDocument20 pagesIS 3455 (1971): Gauging practice for plain workpiecesAVINASHNo ratings yet

- Mensuration ModuleDocument29 pagesMensuration Moduleprince abeNo ratings yet

- Indian StandardDocument11 pagesIndian StandardPramukh Test houseNo ratings yet

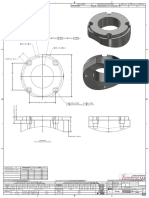

- JAM003MQN406 spacer dimensionsDocument1 pageJAM003MQN406 spacer dimensionsSebastian Davila hernandezNo ratings yet

- Differences Between Statistical Process ControlDocument9 pagesDifferences Between Statistical Process ControlAlemu HaileNo ratings yet

- Material Submittal (Supports & Grating) PDFDocument244 pagesMaterial Submittal (Supports & Grating) PDFCyril J PadiyathNo ratings yet

- Wrought Titanium-6Aluminum-4Vanadium ELI (Extra Low Interstitial) Alloy For Surgical Implant Applications (UNS R56401)Document4 pagesWrought Titanium-6Aluminum-4Vanadium ELI (Extra Low Interstitial) Alloy For Surgical Implant Applications (UNS R56401)bishow100% (1)

- Lichtgitter GRP ManualDocument68 pagesLichtgitter GRP ManualGeorgi KalchevNo ratings yet

- SAP Material MasterDocument8 pagesSAP Material MasterAshish VermaNo ratings yet

- Bookmkr3 UkDocument106 pagesBookmkr3 UkraduroNo ratings yet

- Specification FOR Plain and Master Setting Ring Gauges (Size Range From 1 Up To and Including 315 MM)Document4 pagesSpecification FOR Plain and Master Setting Ring Gauges (Size Range From 1 Up To and Including 315 MM)Ashish DubeyNo ratings yet

- GD T by James D MeadowsDocument12 pagesGD T by James D MeadowsHubertNo ratings yet

- Steel Tube Handbook WebDocument130 pagesSteel Tube Handbook Webwferry27100% (1)

- BSI Standards Publication: Copper and Copper Alloys - Seamless, Round Tubes For General PurposesDocument52 pagesBSI Standards Publication: Copper and Copper Alloys - Seamless, Round Tubes For General PurposesRehan Ahmad100% (1)

- ISO-8336-2009 (En)Document56 pagesISO-8336-2009 (En)Edward CarrilloNo ratings yet

- Process Planning Fundamentals ExplainedDocument24 pagesProcess Planning Fundamentals ExplainedJackson ..No ratings yet

- Notes, Parts and Assemblies A Model of A Maudslay Marine Type Vertical Steam EngineDocument1 pageNotes, Parts and Assemblies A Model of A Maudslay Marine Type Vertical Steam EngineJayaramakrishna YakambariNo ratings yet

- BS 970 Part3 Specification For Wrought Steels For Mechanical and Allied Engineering PurposesDocument3 pagesBS 970 Part3 Specification For Wrought Steels For Mechanical and Allied Engineering PurposesVincent IsaNo ratings yet

- SAE J 673-1993 Automotive Safety Glasses PDFDocument9 pagesSAE J 673-1993 Automotive Safety Glasses PDFmonkey1929100% (1)

- Metrology Course SHeetDocument7 pagesMetrology Course SHeetMuhammad FaisalNo ratings yet

- Disclosure To Promote The Right To Information: IS 9550 (2001) : Bright Steel Bars (MTD 4: Wrought Steel Products)Document14 pagesDisclosure To Promote The Right To Information: IS 9550 (2001) : Bright Steel Bars (MTD 4: Wrought Steel Products)anand.bharadwajNo ratings yet

- Iso 10135 2007 en PDFDocument11 pagesIso 10135 2007 en PDFsurdesh kumar0% (1)

- Bushings & Hubs DODGEDocument22 pagesBushings & Hubs DODGEPercy TorresNo ratings yet

- ME-311 Machine Design - Lecture 3Document27 pagesME-311 Machine Design - Lecture 3Muhammad Zun Nooren BangashNo ratings yet

- ME 216: Engineering Metrology: Fundamentals of Geometric Tolerances Fundamentals of Geometric TolerancesDocument23 pagesME 216: Engineering Metrology: Fundamentals of Geometric Tolerances Fundamentals of Geometric TolerancesLakshya MaletiNo ratings yet

- Module 7 - Materials Management Configuration For Goods Receipts Reach - Ucf.eduDocument12 pagesModule 7 - Materials Management Configuration For Goods Receipts Reach - Ucf.eduAjitabh SinghNo ratings yet

- Dimensions and Tolerances For Plastic BottlesDocument17 pagesDimensions and Tolerances For Plastic BottlesAshokNo ratings yet

- Astm A 810Document4 pagesAstm A 810Fa ChNo ratings yet

- Aalco Metals LTD - Copper and Copper Alloys EN Standards For Copper Alloys - 245Document4 pagesAalco Metals LTD - Copper and Copper Alloys EN Standards For Copper Alloys - 245dkffNo ratings yet