Professional Documents

Culture Documents

Ppe PDF

Uploaded by

Yekhant ZinOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ppe PDF

Uploaded by

Yekhant ZinCopyright:

Available Formats

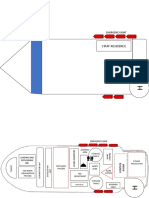

PPE MATRIX

ADDITIONAL PPE/

NATURE OF ACTIVITY/OPERATION HAND HEAD EYE EAR FACE FALL FOOT COVERALL FLOATATION RESPIRATORY

COMMENTS

DECK

ON DECK (Eg. CARGO WATCHES, GANGWAY WATCHES, DECK

FULL SLEEVES

ROUNDS, GENERAL WALKING ETC)

ANCHOR STATIONS FULL SLEEVES

CONTAINER LASHING FULL SLEEVES

GENERAL GREASING FULL SLEEVES

HELICOPTER OPERATIONS FULL SLEEVES

HIGH PRESSURE CLEANING FULL SLEEVES RAIN WEAR

MOORING FULL SLEEVES

GANGWAY/ PILOT LADDER RIGGING FULL SLEEVES

WIRE HANDLING FULL SLEEVES

WORKING ALOFT FULL SLEEVES

WORKING OVERSIDE FULL SLEEVES

ENGINE ROOM

IN ENGINE ROOM (Eg. ER ROUNDS , GENERAL WALKING ETC) FULL SLEEVES

ROTATING WORKSHOP MACHINERY – FIXED WELDING APRON

BOILER/EVAPORATOR CHEMICAL TESTS FULL SLEEVES

CLEANING BOILER BURNER SWIRLERS FULL SLEEVES

SCAVENGE SPACE CLEANING AND INSPECTION RUBBER BOOTS FULL SLEEVES

DISPOSIBLE BOILERSUIT / KNEE

PADS

MAIN ENGINE CRANKCASE INSPECTION RUBBER BOOTS FULL SLEEVES DISPOSIBLE BOILERSUIT

ELECTRICAL WORK - LOW VOLTAGE LOW VOLTAGE UV PROTECTED FULL SLEEVES

ELECTRICAL WORK - HIGH VOLTAGE HIGH VOLTAGE UV PROTECTED FULL SLEEVES

GAS CUTTING AND BRAZING WELDING GLOVES WELDING GOGGLES FULL SLEEVES WELDING APRON

HANDLING / DOSING CHEMICALS CHEMICAL RESISTANT GLOVES FULL SLEEVES CHEMICAL RESISTANT APRON

HANDLING STEAM WELDING GLOVES FULL SLEEVES WELDING APRON

HIGH PRESSURE EQUIPMENT (COMPRESSORS ETC) FULL SLEEVES

LEAD ACID BATTERIERS, CHECKING CHEMICAL RESISTANT GLOVES FULL SLEEVES CHEMICAL RESISTANT APRON

WELDING WELDING GLOVES WELDING SHIELD FULL SLEEVES WELDING APRON/SPATS

GALLEY AND ACCOMMODATION

CHOPPING FOOD CHAIN MAIL CHEF'S APRON

HANDLING HOT FOOD OVEN GLOVES CHEF'S APRON

LIGHT DUTY ACCOMMODATION CLEANING

GENERAL

ALL MECHANICAL LIFTING / MANUAL LIFTING OPERATIONS

FULL SLEEVES

SAFETY DRILLS FULL SLEEVES

ENCLOSED OR CONFINED SPACE ENTRY FULL SLEEVES KNEE PADS

HANDLING GARBAGE FULL SLEEVES PVC APRON

HANDLING PAINTS FULL SLEEVES

ENSURE SPACE IS WELL

VENTILATED

PAINTING IN OPEN AREAS FULL SLEEVES

PAINTING IN CLOSED AREAS( STORE ROOMS, COMPARTMENTS, ENSURE SPACE IS WELL

FULL SLEEVES

VOID SPACES ETC) VENTILATED

TANK CLEANING, WATER ONLY FULL SLEEVES RAIN WEAR

TANK CLEANING, WITH CHEMICALS CHEMICAL RESISTANT GLOVES FULL SLEEVES CHEMICAL RESISTANT APRON

USING PORTABLE POWER TOOLS FULL SLEEVES WELDING APRON

MANDATORY

RECOMMENDED

* This matrix shall be used when determining basic minimum PPE requirements for jobs to be carried onboard.

* It has been made taking into consideration health & safety of our crew and basis Injury reports where potential incidents could’ve been prevented had the right PPE been used.

* Prior undertaking any job, it is each individual’s responsibility to assess & ensure compliance with the matrix. Head of Departments shall ensure implementation of the procedure making certain required PPE is readily available onboard.

* The Matrix is to assist in the “SAFE” way of working, helping more of our colleagues ‘GET HOME SAFE’.

Revision no. 11

Date of revision: 15 May 2015

You might also like

- Stol CH 701 Control Systems SchematicDocument1 pageStol CH 701 Control Systems SchematicTomas Ortiz Laverde100% (2)

- CS 563 Hydraulic PDFDocument2 pagesCS 563 Hydraulic PDFanggieNo ratings yet

- Completion & Workover.Document9 pagesCompletion & Workover.msu6383No ratings yet

- Cessna 340A - Cessna 340A Reference Manual - Rev 0 PDFDocument367 pagesCessna 340A - Cessna 340A Reference Manual - Rev 0 PDFLucas Knight100% (6)

- Brakes Hawker 789 MTM FlightSafetyDocument21 pagesBrakes Hawker 789 MTM FlightSafetyAQS Centro capacitacion aereaNo ratings yet

- Bimota YB11Document86 pagesBimota YB11tsirvoulis0% (1)

- The Gate Shall Be Operated by Rope Drum Hoist: Key PlanDocument1 pageThe Gate Shall Be Operated by Rope Drum Hoist: Key Planbalwant_negi7520No ratings yet

- Boiler Ash Handeling System Gyanendra Sharma NPTI DelhiDocument46 pagesBoiler Ash Handeling System Gyanendra Sharma NPTI DelhiNPTINo ratings yet

- Backhoe Loaders: Service Training MalagaDocument7 pagesBackhoe Loaders: Service Training MalagaMahmmod Al-QawasmehNo ratings yet

- Topography of A Bird: External FeaturesDocument1 pageTopography of A Bird: External FeaturesSergio MNo ratings yet

- Ground Floor Plan On Site Dev'T Plan 1: Common Area / Outdoor SeatingDocument1 pageGround Floor Plan On Site Dev'T Plan 1: Common Area / Outdoor SeatingMichael DaviesNo ratings yet

- EMELYN ModelDocument1 pageEMELYN Modelmapcont18No ratings yet

- S03 MAIN - GANTRY - CRANE DSHEP-ModelDocument1 pageS03 MAIN - GANTRY - CRANE DSHEP-Modelbalwant_negi7520No ratings yet

- RUSH100: Operator'S ManualDocument10 pagesRUSH100: Operator'S ManualDaniel ŘehákNo ratings yet

- 24Th Vfs F5E Mission Briefing and Navigation Log 24Th Vfs F5E Mission Briefing and Navigation LogDocument2 pages24Th Vfs F5E Mission Briefing and Navigation Log 24Th Vfs F5E Mission Briefing and Navigation LogStray CatNo ratings yet

- Line UpDocument1 pageLine UpMark Adrian EspinosaNo ratings yet

- Bitacora de Limpieza Imagen 2022Document11 pagesBitacora de Limpieza Imagen 2022cerdoindomable09No ratings yet

- FF 18-055Document1 pageFF 18-055kanakyadav2931No ratings yet

- Clothing Headwear Footwear Gloves Eyewear Hearing Fall Arrest Masks PFDDocument1 pageClothing Headwear Footwear Gloves Eyewear Hearing Fall Arrest Masks PFDQHSE MGSNo ratings yet

- Fp-Miscellaneous DetailsDocument1 pageFp-Miscellaneous DetailscarylNo ratings yet

- HES Bid Set Fire Protection DrawingsDocument5 pagesHES Bid Set Fire Protection DrawingsMansoor Abdul KhaderNo ratings yet

- Forte SE-Musicians Guide RevCDocument374 pagesForte SE-Musicians Guide RevCLJANo ratings yet

- Bulk Bag Unloaders 20505-5Document6 pagesBulk Bag Unloaders 20505-5Andrew Jackson100% (1)

- Construction Material-KIM ModelDocument1 pageConstruction Material-KIM Modelneil alconesNo ratings yet

- ROOFTOPDocument1 pageROOFTOPJen AgabinNo ratings yet

- NICHROMEDocument2 pagesNICHROMEliluche01No ratings yet

- Floor Plan: Produced by An Autodesk Student VersionDocument4 pagesFloor Plan: Produced by An Autodesk Student VersionManvendra NigamNo ratings yet

- Process Flow Diagram (Yakult Phiippines Sbr-Iceas WWTF)Document1 pageProcess Flow Diagram (Yakult Phiippines Sbr-Iceas WWTF)Darwin FabonNo ratings yet

- Ground Floor Plan: Scale 1:500Document1 pageGround Floor Plan: Scale 1:500Ronielle MercadoNo ratings yet

- 3 Acre Mall-ModelDocument1 page3 Acre Mall-Modeldarapaneni sudharshanNo ratings yet

- History of AthleticsDocument3 pagesHistory of AthleticsRishi VandhyaNo ratings yet

- Shop Lay OutDocument1 pageShop Lay OutChristopher SilangNo ratings yet

- Electric RopDocument2 pagesElectric RopJair Ancelmo Villar PalominoNo ratings yet

- Auditorium FplanDocument1 pageAuditorium FplanllnrjsprNo ratings yet

- Technical Specifications: Air CompressorsDocument1 pageTechnical Specifications: Air CompressorsSuprionoNo ratings yet

- RENR7439 - 320D Excavators Hydraulic System - Attachment - SysDocument2 pagesRENR7439 - 320D Excavators Hydraulic System - Attachment - SysMarcelo ItoNo ratings yet

- Acs 50 Air Handling Unit Dimensions Table: Outlet Nozzle Inlet Nozzle Heat Recovery Exhaust & Fresh AirDocument1 pageAcs 50 Air Handling Unit Dimensions Table: Outlet Nozzle Inlet Nozzle Heat Recovery Exhaust & Fresh AirMudassar NoreNo ratings yet

- Staff Residence: Emergency BoatDocument5 pagesStaff Residence: Emergency BoatBhinitha ChandrasagaranNo ratings yet

- HallwayDocument1 pageHallwayalbert adventoNo ratings yet

- Fire-Fighter's Smoke-Control Station (FSCS Series) : Product ManualDocument34 pagesFire-Fighter's Smoke-Control Station (FSCS Series) : Product ManualErnesto OtazuNo ratings yet

- ELN-PRG-IN-01-HK-002 Panel Schematic Diagram V-260 Rev 0Document11 pagesELN-PRG-IN-01-HK-002 Panel Schematic Diagram V-260 Rev 0Sendy MaulanaNo ratings yet

- Gear Shifting: Machine Speed Mode Calculation Evl2775Document19 pagesGear Shifting: Machine Speed Mode Calculation Evl2775AlanNo ratings yet

- Proposed STP For Equinox (A1)Document1 pageProposed STP For Equinox (A1)Aly ReyesNo ratings yet

- 5Th and 7Th Floor Plan: Scale 1:300Document1 page5Th and 7Th Floor Plan: Scale 1:300Princess Gonzales LansangNo ratings yet

- 2 Whee LER 2 Whee LER: Service Elevator Service ElevatorDocument9 pages2 Whee LER 2 Whee LER: Service Elevator Service ElevatorSthitapragyan senapatiNo ratings yet

- Fire Escape PlansDocument7 pagesFire Escape PlansSathish Kumar SNo ratings yet

- U-Visc Kinematic Viscometer: ASTM D445 / D446, ISO 3104 / 3105, IP 71Document2 pagesU-Visc Kinematic Viscometer: ASTM D445 / D446, ISO 3104 / 3105, IP 71moh_ichwanuddinNo ratings yet

- Plot 6Document1 pagePlot 6james arajaNo ratings yet

- Hydrant Post Connection: Pump House DiagramDocument1 pageHydrant Post Connection: Pump House Diagrampujan77No ratings yet

- Main Building - Second Floor Schematics: TerraceDocument2 pagesMain Building - Second Floor Schematics: TerraceCalvin Chavez IIINo ratings yet

- Situation Room Radio Room: Director'S T&BDocument3 pagesSituation Room Radio Room: Director'S T&BDarlene AmbrocioNo ratings yet

- 4Th and 6Th Floor Plan: Scale 1:300Document1 page4Th and 6Th Floor Plan: Scale 1:300Princess Gonzales LansangNo ratings yet

- The Ultimate Currency: Solution State of The Art Secure WalletsDocument1 pageThe Ultimate Currency: Solution State of The Art Secure Walletsclick4moneyNo ratings yet

- Mod6 ALEGIANT!!!!Document5 pagesMod6 ALEGIANT!!!!David Paul HensonNo ratings yet

- Different Brand of Different Brand Of: DiversityDocument40 pagesDifferent Brand of Different Brand Of: DiversityGas, Oil & Mining Contractor MagazineNo ratings yet

- VernacularDocument1 pageVernacularLemuel PatduNo ratings yet

- Guide To FEDocument12 pagesGuide To FEIS InnerspaceNo ratings yet

- Plot 7Document1 pagePlot 7james arajaNo ratings yet