Professional Documents

Culture Documents

Datasheet: Kit Contents - NI 9201 - NI 9201 Getting Started Guide

Datasheet: Kit Contents - NI 9201 - NI 9201 Getting Started Guide

Uploaded by

Todor ToshkovOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Datasheet: Kit Contents - NI 9201 - NI 9201 Getting Started Guide

Datasheet: Kit Contents - NI 9201 - NI 9201 Getting Started Guide

Uploaded by

Todor ToshkovCopyright:

Available Formats

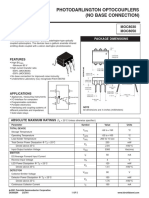

DATASHEET

NI 9201

8 AI, ±10 V, 12 Bit, 500 kS/s Aggregate

• DSUB, screw-terminal, or spring-terminal connectivity

• 250 Vrms, CAT II, channel-to-earth isolation (screw and

spring terminal); 60 VDC, CAT I, channel-to-earth isolation

(DSUB)

• -40 °C to 70 °C operating range, 5 g vibration, 50 g shock

The NI 9201 is an analog input module for CompactDAQ and CompactRIO systems. The

NI 9201 provides eight channels of ±10 V input with 500 kS/s sample rate.

• NI 9201

Kit Contents

• NI 9201 Getting Started Guide

• NI 9927 Backshell Connector Kit (Screw Terminal)

Accessories • NI 9981 Backshell Connector Kit (Spring Terminal)

• NI 9924 Screw-Terminal Block (DSUB)

C SERIES ANALOG INPUT MODULE COMPARISON

Product Signal Sample

Channels Simultaneous Resolution Connectivity

Name Levels Rate

Screw-Terminal,

NI 9201 ±10 V 8 Single-Ended 500 kS/s No 12-Bit Spring-Terminal,

DSUB

±200 mV, ±1 V, 32 Single-Ended, Spring-Terminal,

NI 9205 250 kS/s No 16-Bit

±5 V, ±10 V 16 differential DSUB

±200 mV, ±1 V, 32 Single-Ended,

NI 9206 250 kS/s No 16-Bit Spring-Terminal

±5 V, ±10 V 16 Differential

NI 9207 ±10 V 8 Differential 500 S/s No 24-Bit DSUB

32 Single-Ended,

NI 9209 ±10 V 500 S/s No 24-Bit DSUB

16 Differential

Screw-Terminal,

NI 9215 ±10 V 4 Differential 100 kS/s/ch Yes 16-Bit Spring-Terminal,

BNC

Spring-Terminal,

NI 9220 ±10 V 16 Differential 100 kS/s/ch Yes 16-Bit

DSUB

Screw-Terminal,

NI 9221 ±60 V 8 Single-Ended 800 kS/s No 12-Bit Spring-Terminal,

DSUB

Screw-Terminal,

NI 9222 ±10 V 4 Differential 500 kS/s/ch Yes 16-Bit

BNC

Screw-Terminal,

NI 9223 ±10 V 4 Differential 1 MS/s/ch Yes 16-Bit

BNC

NI C Series Overview

NI provides more than 100 C Series modules for measurement, control, and communication

applications. C Series modules can connect to any sensor or bus and allow for high-accuracy

measurements that meet the demands of advanced data acquisition and control applications.

• Measurement-specific signal conditioning that connects to an array of sensors and signals

• Isolation options such as bank-to-bank, channel-to-channel, and channel-to-earth ground

• -40 °C to 70 °C temperature range to meet a variety of application and environmental

needs

• Hot-swappable

2 | ni.com | NI 9201 Datasheet

The majority of C Series modules are supported in both CompactRIO and CompactDAQ

platforms and you can move modules from one platform to the other with no modification.

CompactRIO

CompactRIO combines an open-embedded architecture

with small size, extreme ruggedness, and C Series

modules in a platform powered by the NI LabVIEW

reconfigurable I/O (RIO) architecture. Each system

contains an FPGA for custom timing, triggering, and

processing with a wide array of available modular I/O to

meet any embedded application requirement.

CompactDAQ

CompactDAQ is a portable, rugged data acquisition platform

that integrates connectivity, data acquisition, and signal

conditioning into modular I/O for directly interfacing to any

sensor or signal. Using CompactDAQ with LabVIEW, you

can easily customize how you acquire, analyze, visualize,

and manage your measurement data.

Software

LabVIEW Professional Development System for Windows

• Use advanced software tools for large project development

• Generate code automatically using DAQ Assistant and Instrument

I/O Assistant

• Use advanced measurement analysis and digital signal processing

• Take advantage of open connectivity with DLLs, ActiveX,

and .NET objects

• Build DLLs, executables, and MSI installers

NI 9201 Datasheet | © National Instruments | 3

NI LabVIEW FPGA Module

• Design FPGA applications for NI RIO hardware

• Program with the same graphical environment used for desktop and

real-time applications

• Execute control algorithms with loop rates up to 300 MHz

• Implement custom timing and triggering logic, digital protocols, and

DSP algorithms

• Incorporate existing HDL code and third-party IP including Xilinx IP

generator functions

• Purchase as part of the LabVIEW Embedded Control and Monitoring

Suite

NI LabVIEW Real-Time Module

• Design deterministic real-time applications with LabVIEW

graphical programming

• Download to dedicated NI or third-party hardware for reliable

execution and a wide selection of I/O

• Take advantage of built-in PID control, signal processing, and

analysis functions

• Automatically take advantage of multicore CPUs or set

processor affinity manually

• Take advantage of real-time OS, development and debugging

support, and board support

• Purchase individually or as part of a LabVIEW suite

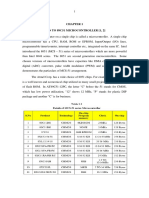

NI 9201 Input Circuitry

AI0

Overvoltage Isolated

Mux Buffer

AI7 Protection ADC

COM

NI 9201

• Input signals are scanned, buffered, conditioned, and then sampled by a single ADC.

• Each AI channel provides an independent signal path and ADC, enabling you to sample

all channels simultaneously.

4 | ni.com | NI 9201 Datasheet

NI 9201 Specifications

The following specifications are typical for the range -40 °C to 70 °C unless otherwise noted.

All voltages are relative to COM unless otherwise noted.

Caution Do not operate the NI 9201 in a manner not specified in this document.

Product misuse can result in a hazard. You can compromise the safety protection

built into the product if the product is damaged in any way. If the product is

damaged, return it to NI for repair.

Input Characteristics

Number of channels 8

ADC resolution 12 bits

Type of ADC Successive approximation register (SAR)

Table 1. Sample Rate (Aggregate)

Maximum Sample Rate Maximum Sample Rate

Mode (R Series Expansion Chassis) (All Other Chassis)

Single Channel 475 kS/s 800 kS/s

Scanning 475 kS/s 500 kS/s

Input range ±10 V

Measurement voltage, channel-to-COM (V)

Minimum ±10.3

Typical ±10.53

Maximum ±10.8

Overvoltage protection, channel-to-COM ±100 V

Table 2. NI 9201 Accuracy (Excludes Noise)

Percent of Reading Percent of Range1

Measurement Conditions (Gain Error) (Offset Error)

Typical (25 °C, ±5 °C) ±0.04% ±0.07%

Calibrated

Maximum (-40 °C to 70 °C) ±0.25% ±0.25%

1 Range equals 10.53 V

NI 9201 Datasheet | © National Instruments | 5

Table 2. NI 9201 Accuracy (Excludes Noise) (Continued)

Percent of Reading Percent of Range1

Measurement Conditions (Gain Error) (Offset Error)

Typical (25 °C, ±5 °C) ±0.26% ±0.46%

Uncalibrated2

Maximum (-40 °C to 70 °C) ±0.67% ±1.25%

Stability

Gain drift ±34 ppm/°C

Offset drift ±100 μV/°C

Input bandwidth (-3 dB) 690 kHz min

Input impedance

Resistance 1 MΩ

Capacitance 5 pF

Input noise, code-centered

RMS 0.7 LSBrms

Peak-to-peak 5 LSB

No missing codes 12 bits

DNL -0.9 to 1.5 LSB

INL ±1.5 LSB

Crosstalk, at 10 kHz -75 dB

Settling time, to 1 LSB 2 μs

MTBF 1,092,512 hours at 25 °C; Bellcore Issue 2,

Method 1, Case 3, Limited Part Stress Method

Power Requirements

Power consumption from chassis

Active mode 1 W maximum

Sleep mode 1 mW maximum

Thermal dissipation (at 70 °C)

Active mode 1 W maximum

Sleep mode 32 mW maximum

1 Range equals 10.53 V

2 Uncalibrated accuracy refers to the accuracy achieved when acquiring in raw or unscaled modes

where the calibration constants stored in the module are not applied to the data.

6 | ni.com | NI 9201 Datasheet

Physical Characteristics

If you need to clean the module, wipe it with a dry towel.

Tip For two-dimensional drawings and three-dimensional models of the C Series

module and connectors, visit ni.com/dimensions and search by module number.

Screw-terminal wiring

Gauge 0.2 mm2 to 2.5 mm2 (26 AWG to 14 AWG)

copper conductor wire

Wire strip length 13 mm (0.51 in.) of insulation stripped from

the end

Temperature rating 90 °C minimum

Torque for screw terminals 0.5 N · m to 0.6 N · m

(4.4 lb · in. to 5.3 lb · in.)

Wires per screw terminal One wire per screw terminal; two wires per

screw terminal using a 2-wire ferrule

Ferrules 0.25 mm2 to 2.5 mm2

Spring-terminal wiring

Gauge 0.2 mm2 to 2.5 mm2 (30 AWG to 12 AWG)

copper conductor wire

Wire strip length 10 mm (0.39 in.) of insulation stripped from

the end

Temperature rating 90 °C minimum

Wires per spring terminal One wire per spring terminal; two wires per

spring terminal using a 2-wire ferrule

Ferrules 0.25 mm2 to 2.5 mm2

Connector securement

Securement type Screw flanges provided

Torque for screw flanges 0.2 N · m (1.80 lb · in.)

Weight

NI 9201 with screw terminal 165 g (5.8 oz)

NI 9201 with spring terminal 152 g (5.4 oz)

NI 9201 with DSUB 142 g (5.0 oz)

NI 9201 Datasheet | © National Instruments | 7

NI 9201 with Screw Terminal and NI 9201 with Spring

Terminal Safety Voltages

Connect only voltages that are within the following limits.

Channel-to-COM ±60 VDC maximum

Channel-to-channel None

Channel-to-earth ground

Continuous 250 Vrms, Measurement Category II

Withstand 2,300 Vrms, verified by a 5 s dielectric

withstand test

Measurement Category II is for measurements performed on circuits directly connected to the

electrical distribution system. This category refers to local-level electrical distribution, such as

that provided by a standard wall outlet, for example, 115 V for U.S. or 230 V for Europe.

Caution Do not connect the NI 9201 with screw terminal or NI 9201 with spring

terminal to signals or use for measurements within Measurement Categories III or

IV.

NI 9201 with DSUB Safety Voltages

Connect only voltages that are within the following limits.

Channel-to-COM ±60 VDC maximum

Channel-to-channel None

Channel-to-earth

Continuous 60 VDC, Measurement Category I

Withstand 1,000 Vrms, verified by a 5 s dielectric

withstand test

Measurement Category I is for measurements performed on circuits not directly connected to

the electrical distribution system referred to as MAINS voltage. MAINS is a hazardous live

electrical supply system that powers equipment. This category is for measurements of voltages

from specially protected secondary circuits. Such voltage measurements include signal levels,

special equipment, limited-energy parts of equipment, circuits powered by regulated low-

voltage sources, and electronics.

Caution Do not connect the NI 9201 with DSUB to signals or use for

measurements within Measurement Categories III or IV.

Note Measurement Categories CAT I and CAT O are equivalent. These test and

measurement circuits are not intended for direct connection to the MAINS building

installations of Measurement Categories CAT II, CAT III, or CAT IV.

8 | ni.com | NI 9201 Datasheet

Hazardous Locations

U.S. (UL) Class I, Division 2, Groups A, B, C, D, T4;

Class I, Zone 2, AEx nA IIC T4

Canada (C-UL) Class I, Division 2, Groups A, B, C, D, T4;

Class I, Zone 2, Ex nA IIC T4

Europe (ATEX) and International (IECEx) Ex nA IIC T4 Gc

Safety and Hazardous Locations Standards

This product is designed to meet the requirements of the following electrical equipment safety

standards for measurement, control, and laboratory use:

• IEC 61010-1, EN 61010-1

• UL 61010-1, CSA 61010-1

• EN 60079-0:2012, EN 60079-15:2010

• IEC 60079-0: Ed 6, IEC 60079-15; Ed 4

• UL 60079-0; Ed 5, UL 60079-15; Ed 3

• CSA 60079-0:2011, CSA 60079-15:2012

Note For UL and other safety certifications, refer to the product label or the Online

Product Certification section.

Electromagnetic Compatibility

This product meets the requirements of the following EMC standards for sensitive electrical

equipment for measurement, control, and laboratory use:

• EN 61326 (IEC 61326): Class A emissions; Industrial immunity

• EN 55011 (CISPR 11): Group 1, Class A emissions

• AS/NZS CISPR 11: Group 1, Class A emissions

• FCC 47 CFR Part 15B: Class A emissions

• ICES-001: Class A emissions

Note For EMC declarations and certifications, and additional information, refer to

the Online Product Certification section.

Note For EMC compliance, operate this device with double-shielded cables.

NI 9201 Datasheet | © National Instruments | 9

CE Compliance

This product meets the essential requirements of applicable European Directives, as follows:

• 2014/35/EU; Low-Voltage Directive (safety)

• 2014/30/EU; Electromagnetic Compatibility Directive (EMC)

• 94/9/EC; Potentially Explosive Atmospheres (ATEX)

Online Product Certification

Refer to the product Declaration of Conformity (DoC) for additional regulatory compliance

information. To obtain product certifications and the DoC for this product, visit ni.com/

certification, search by model number or product line, and click the appropriate link in the

Certification column.

Shock and Vibration

To meet these specifications, you must panel mount the system.

Operating vibration

Random (IEC 60068-2-64) 5 grms, 10 Hz to 500 Hz

Sinusoidal (IEC 60068-2-6) 5 g, 10 Hz to 500 Hz

Operating shock (IEC 60068-2-27) 30 g, 11 ms half sine; 50 g, 3 ms half sine;

18 shocks at 6 orientations

Environmental

Refer to the manual for the chassis you are using for more information about meeting these

specifications.

Operating temperature -40 °C to 70 °C

(IEC 60068-2-1, IEC 60068-2-2)

Storage temperature -40 °C to 85 °C

(IEC 60068-2-1, IEC 60068-2-2)

Ingress protection IP40

Operating humidity (IEC 60068-2-78) 10% RH to 90% RH, noncondensing

Storage humidity (IEC 60068-2-78) 5% RH to 95% RH, noncondensing

Pollution Degree 2

Maximum altitude 2,000 m

Indoor use only.

10 | ni.com | NI 9201 Datasheet

Environmental Management

NI is committed to designing and manufacturing products in an environmentally responsible

manner. NI recognizes that eliminating certain hazardous substances from our products is

beneficial to the environment and to NI customers.

For additional environmental information, refer to the Minimize Our Environmental Impact

web page at ni.com/environment. This page contains the environmental regulations and

directives with which NI complies, as well as other environmental information not included in

this document.

Waste Electrical and Electronic Equipment (WEEE)

EU Customers At the end of the product life cycle, all NI products must be

disposed of according to local laws and regulations. For more information about

how to recycle NI products in your region, visit ni.com/environment/weee.

电子信息产品污染控制管理办法(中国 RoHS)

中国客户 National Instruments 符合中国电子信息产品中限制使用某些有害物

质指令(RoHS)。关于 National Instruments 中国 RoHS 合规性信息,请登录

ni.com/environment/rohs_china。(For information about China RoHS

compliance, go to ni.com/environment/rohs_china.)

Calibration

You can obtain the calibration certificate and information about calibration services for the

NI 9201 at ni.com/calibration.

Calibration interval 1 year

NI 9201 Datasheet | © National Instruments | 11

Refer to the NI Trademarks and Logo Guidelines at ni.com/trademarks for information on NI trademarks. Other product and

company names mentioned herein are trademarks or trade names of their respective companies. For patents covering NI

products/technology, refer to the appropriate location: Help»Patents in your software, the patents.txt file on your media, or the

National Instruments Patent Notice at ni.com/patents. You can find information about end-user license agreements (EULAs)

and third-party legal notices in the readme file for your NI product. Refer to the Export Compliance Information at ni.com/

legal/export-compliance for the NI global trade compliance policy and how to obtain relevant HTS codes, ECCNs, and other

import/export data. NI MAKES NO EXPRESS OR IMPLIED WARRANTIES AS TO THE ACCURACY OF THE INFORMATION

CONTAINED HEREIN AND SHALL NOT BE LIABLE FOR ANY ERRORS. U.S. Government Customers: The data contained in

this manual was developed at private expense and is subject to the applicable limited rights and restricted data rights as set forth

in FAR 52.227-14, DFAR 252.227-7014, and DFAR 252.227-7015.

© 2016 National Instruments. All rights reserved.

373783A-02 Mar16

You might also like

- Beginning Digital Electronics through ProjectsFrom EverandBeginning Digital Electronics through ProjectsRating: 5 out of 5 stars5/5 (1)

- (V2.0) H.264 Series DVR User's Installation and Operation ManualDocument60 pages(V2.0) H.264 Series DVR User's Installation and Operation ManualVinicius MalheirosNo ratings yet

- Extreme Risk FinanceDocument322 pagesExtreme Risk FinanceThomas Thomas100% (2)

- SAP BW On HANA - Complete Reference GuideDocument23 pagesSAP BW On HANA - Complete Reference GuidejanakiramyelikeNo ratings yet

- Data Warehousing in The Age of Artificial IntelligenceDocument94 pagesData Warehousing in The Age of Artificial Intelligencejwtan2010No ratings yet

- AutomationDesk PresentationDocument21 pagesAutomationDesk PresentationBalaji Potnuri100% (1)

- NI 9215 DatasheetDocument12 pagesNI 9215 DatasheetJuan José CárdenasNo ratings yet

- 374188a 02 PDFDocument14 pages374188a 02 PDFThomas ThomasNo ratings yet

- Datasheet: Kit Contents - NI 9229 - NI 9229 Getting Started GuideDocument14 pagesDatasheet: Kit Contents - NI 9229 - NI 9229 Getting Started GuideChecho260493No ratings yet

- Datasheet: - NI 9230 - NI 9230 Getting Started Guide Kit ContentsDocument18 pagesDatasheet: - NI 9230 - NI 9230 Getting Started Guide Kit ContentsGilbertoAndresDuarteNo ratings yet

- Datasheet: Kit Contents - NI 9263 - NI 9263 Getting Started GuideDocument12 pagesDatasheet: Kit Contents - NI 9263 - NI 9263 Getting Started GuideThomas ThomasNo ratings yet

- 6n137 DatasheetDocument16 pages6n137 Datasheetnested.slkNo ratings yet

- 374238a 02Document14 pages374238a 02AhMadi OuaSsimNo ratings yet

- 6N137, VO2601, VO2611, VO2630, VO2631, VO4661: Vishay SemiconductorsDocument16 pages6N137, VO2601, VO2611, VO2630, VO2631, VO4661: Vishay SemiconductorsMahfud Adhi AnsoriNo ratings yet

- Datasheet: Kit Contents - NI 9472 NI 9472 Getting Started GuideDocument12 pagesDatasheet: Kit Contents - NI 9472 NI 9472 Getting Started GuideChecho260493No ratings yet

- 6 N 137Document16 pages6 N 137Estênio Xavier VarjãoNo ratings yet

- Vishay Semiconductors: FeaturesDocument10 pagesVishay Semiconductors: FeaturesZulfiqar AhmedNo ratings yet

- 6N137, VO2601, VO2611, VO2630, VO2631, VO4661: Vishay SemiconductorsDocument12 pages6N137, VO2601, VO2611, VO2630, VO2631, VO4661: Vishay SemiconductorsЮра ПетренкоNo ratings yet

- DAQ SystemDocument10 pagesDAQ Systemgimmyhead_69No ratings yet

- Datasheet: Kit Contents - NI 9209 - NI 9209 Getting Started GuideDocument10 pagesDatasheet: Kit Contents - NI 9209 - NI 9209 Getting Started Guidevijay vijayNo ratings yet

- Audio Digital Resistor: DS1666, DS1666SDocument8 pagesAudio Digital Resistor: DS1666, DS1666SMuhammad WaqasNo ratings yet

- compactRIO FlyerDocument4 pagescompactRIO FlyerZealot FiveNo ratings yet

- ntmd4n03r2 DDocument10 pagesntmd4n03r2 DKyaw ThuNo ratings yet

- ILD615, ILQ615: Vishay SemiconductorsDocument12 pagesILD615, ILQ615: Vishay SemiconductorsAmine EmineNo ratings yet

- Datasheet942 Digital Ip C&TDocument5 pagesDatasheet942 Digital Ip C&Tsaloni_mehtaNo ratings yet

- Adum 7510Document12 pagesAdum 7510Med SamiNo ratings yet

- AD9240Document24 pagesAD9240luze YuNo ratings yet

- Datasheet KDN-relays V1.3pdfDocument12 pagesDatasheet KDN-relays V1.3pdfAhmedKhaledSalahNo ratings yet

- SFH6345Document10 pagesSFH6345kukurikuyuNo ratings yet

- Adc 78 H 90Document26 pagesAdc 78 H 90moacirmenezes51No ratings yet

- Bic 2200 eDocument24 pagesBic 2200 eHassan NaveedNo ratings yet

- Mitsubishi : 8-Bit 8-Ch Multiplying D-A Converter With Buffer AmplifiersDocument6 pagesMitsubishi : 8-Bit 8-Ch Multiplying D-A Converter With Buffer AmplifiersquinquinoNo ratings yet

- Adc F09Document61 pagesAdc F09abdala67No ratings yet

- Ucc21520 PDFDocument48 pagesUcc21520 PDFRAKESH KUMARNo ratings yet

- Dac Ad7541Document8 pagesDac Ad7541api-26783388No ratings yet

- CA3162Document8 pagesCA3162marcelo riveraNo ratings yet

- Adc 108 S 022Document28 pagesAdc 108 S 022EmirNo ratings yet

- SN 65 HVD 33Document32 pagesSN 65 HVD 33craigslist_nNo ratings yet

- Vishay Semiconductors: FeaturesDocument10 pagesVishay Semiconductors: FeaturesKapil GalwaniNo ratings yet

- AD7819Document12 pagesAD7819IrvinRamAltNo ratings yet

- Sudkabel Garnituren ENGDocument20 pagesSudkabel Garnituren ENGShin Hye ParkNo ratings yet

- Ad5308 5318 5328 PDFDocument28 pagesAd5308 5318 5328 PDFAndres Fernandez FernandezNo ratings yet

- Irlr024, Irlu024, Sihlr024, Sihlu024: Vishay SiliconixDocument11 pagesIrlr024, Irlu024, Sihlr024, Sihlu024: Vishay SiliconixPabloNo ratings yet

- AD5259Document22 pagesAD5259greencubesindiaNo ratings yet

- DatasheetDocument12 pagesDatasheetDandy PrasetyoNo ratings yet

- Analog-Digital Converters: By: Saumya Ranjan BehuraDocument62 pagesAnalog-Digital Converters: By: Saumya Ranjan Behuraparth bhardwajNo ratings yet

- MCP3204 MCP3208 PDFDocument20 pagesMCP3204 MCP3208 PDFCarlos PosadaNo ratings yet

- Ad 5259Document22 pagesAd 5259VISHNU RAVINDRANATHNo ratings yet

- Digital: Quadrature To RS232 AdapterDocument1 pageDigital: Quadrature To RS232 AdapterSSobreiraNo ratings yet

- NCP1252 Current Mode PWM Controller For Forward and Flyback ApplicationsDocument20 pagesNCP1252 Current Mode PWM Controller For Forward and Flyback Applicationspolice017789No ratings yet

- MAX500 MaximIntegratedProductsDocument12 pagesMAX500 MaximIntegratedProductsj guadalupeNo ratings yet

- Adc 12 D 040Document31 pagesAdc 12 D 040miri10861No ratings yet

- Rmia 45Document3 pagesRmia 45oscaremfzqwxxwxxNo ratings yet

- IRFPF40Document11 pagesIRFPF40samuel celinNo ratings yet

- Xc800 App OcdsDocument22 pagesXc800 App OcdskrrishNo ratings yet

- PCI-9112 Datasheet en 2Document1 pagePCI-9112 Datasheet en 2filippo sartoriNo ratings yet

- Motorola - MC14053B PDFDocument9 pagesMotorola - MC14053B PDFVieira BrunoNo ratings yet

- DAC DesignDocument32 pagesDAC DesignGeovanny ArguelloNo ratings yet

- Toyota cn-ts6270kDocument14 pagesToyota cn-ts6270kPoon Electronic Training CentreNo ratings yet

- DG401, DG403, DG405: Vishay SiliconixDocument15 pagesDG401, DG403, DG405: Vishay SiliconixytnateNo ratings yet

- Mcp320x 12-Bit AdcDocument34 pagesMcp320x 12-Bit AdcGeoFurrielNo ratings yet

- MCP413X/415X/423X/425X: 7/8-Bit Single/Dual SPI Digital POT With Volatile MemoryDocument82 pagesMCP413X/415X/423X/425X: 7/8-Bit Single/Dual SPI Digital POT With Volatile MemoryEyeVeeNo ratings yet

- Transistor 2021 Pag 3Document6 pagesTransistor 2021 Pag 3StuxnetNo ratings yet

- A Wide-Area Deep Ocean Floor Mapping System DesignDocument22 pagesA Wide-Area Deep Ocean Floor Mapping System DesignThomas ThomasNo ratings yet

- Housing in A Smart CityDocument7 pagesHousing in A Smart CityThomas ThomasNo ratings yet

- KBU10005 THRU KBU1010: Single Phase Silicon Bridge RectifierDocument2 pagesKBU10005 THRU KBU1010: Single Phase Silicon Bridge RectifierThomas ThomasNo ratings yet

- Contract Performance in Offshore Systems Development: Role of Control MechanismsDocument45 pagesContract Performance in Offshore Systems Development: Role of Control MechanismsThomas ThomasNo ratings yet

- Oil Prices and Stock Market Price in NigeriaDocument17 pagesOil Prices and Stock Market Price in NigeriaThomas ThomasNo ratings yet

- Oil Prices and Stock Market Price in NigeriaDocument17 pagesOil Prices and Stock Market Price in NigeriaThomas ThomasNo ratings yet

- Photodarlington Optocouplers (No Base Connection) : DescriptionDocument8 pagesPhotodarlington Optocouplers (No Base Connection) : DescriptionThomas ThomasNo ratings yet

- 1 Amp. Glass Passivated Bridge Rectifier: B40C1000....... B380C1000Document3 pages1 Amp. Glass Passivated Bridge Rectifier: B40C1000....... B380C1000Thomas ThomasNo ratings yet

- Cheng-Yi Cheng - Yi: KBU 10A/15A/25A/35A SERIESDocument2 pagesCheng-Yi Cheng - Yi: KBU 10A/15A/25A/35A SERIESThomas ThomasNo ratings yet

- Tc1014/Tc1015/Tc1185: 50ma, 100ma and 150ma Cmos Ldos With Shutdown and Reference BypassDocument21 pagesTc1014/Tc1015/Tc1185: 50ma, 100ma and 150ma Cmos Ldos With Shutdown and Reference BypassThomas ThomasNo ratings yet

- SP490E / SP491E: Enhanced Full-Duplex RS-485 TransceiversDocument13 pagesSP490E / SP491E: Enhanced Full-Duplex RS-485 TransceiversThomas ThomasNo ratings yet

- SP490E / SP491E: Enhanced Full-Duplex RS-485 TransceiversDocument13 pagesSP490E / SP491E: Enhanced Full-Duplex RS-485 TransceiversThomas ThomasNo ratings yet

- Smart High-Side Power Switch For Industrial Applications 1 Channel: 1 X 200mDocument19 pagesSmart High-Side Power Switch For Industrial Applications 1 Channel: 1 X 200mThomas ThomasNo ratings yet

- COMET 300: Description AdvantagesDocument2 pagesCOMET 300: Description AdvantagesThomas ThomasNo ratings yet

- General Purpose Transistor: High Speed Switching FeaturesDocument4 pagesGeneral Purpose Transistor: High Speed Switching FeaturesThomas ThomasNo ratings yet

- SP3222EB/SP3232EB True +3.0V To +5.5V RS-232 Transceivers: FeaturesDocument23 pagesSP3222EB/SP3232EB True +3.0V To +5.5V RS-232 Transceivers: FeaturesThomas ThomasNo ratings yet

- BYV29G-600: 1. Product ProfileDocument11 pagesBYV29G-600: 1. Product ProfileThomas ThomasNo ratings yet

- 2N2905A Silicon PNP Transistor Small Signal Switching TO 39 Type PackageDocument2 pages2N2905A Silicon PNP Transistor Small Signal Switching TO 39 Type PackageThomas ThomasNo ratings yet

- TSL2580, TSL2581: Light-to-Digital ConverterDocument52 pagesTSL2580, TSL2581: Light-to-Digital ConverterThomas ThomasNo ratings yet

- Ultra-Low-Power, 10Msps, Dual 8-Bit ADC: General Description FeaturesDocument22 pagesUltra-Low-Power, 10Msps, Dual 8-Bit ADC: General Description FeaturesThomas ThomasNo ratings yet

- Lite-On Technology Corporation: FeaturesDocument6 pagesLite-On Technology Corporation: FeaturesThomas ThomasNo ratings yet

- 4.8 KHZ, Ultralow Noise, 24-Bit Sigma-Delta Adc With Pga and Ac ExcitationDocument44 pages4.8 KHZ, Ultralow Noise, 24-Bit Sigma-Delta Adc With Pga and Ac ExcitationThomas ThomasNo ratings yet

- A6H Half-Pitch DIP Switch: Ordering InformationDocument2 pagesA6H Half-Pitch DIP Switch: Ordering InformationThomas ThomasNo ratings yet

- 17512-2019-Winter-Model-Answer-Paper (Msbte Study Resources)Document36 pages17512-2019-Winter-Model-Answer-Paper (Msbte Study Resources)Aditya BorleNo ratings yet

- Program Imc Nov 2017 v2Document11 pagesProgram Imc Nov 2017 v2Alvaro Balvin VelasquezNo ratings yet

- Introduction To SAP HanaDocument30 pagesIntroduction To SAP Hanaanupamrc100% (2)

- Gartner 361501-2019-Planning-Guide-For-Data-And-AnalyticsDocument44 pagesGartner 361501-2019-Planning-Guide-For-Data-And-AnalyticsVladikNo ratings yet

- Bca 303seDocument220 pagesBca 303seMagesh Kid0% (1)

- 0llcomputer Applications CBSE 9th Answer PDFDocument94 pages0llcomputer Applications CBSE 9th Answer PDFGopi JampaniNo ratings yet

- TOA Nx100 BrochureDocument4 pagesTOA Nx100 Brochuregoku011No ratings yet

- LAWO PI - MADI - SRC - enDocument2 pagesLAWO PI - MADI - SRC - enfjavierpoloNo ratings yet

- TFT SDK ManualDocument107 pagesTFT SDK ManualRenier ServenNo ratings yet

- Quality 4.0 Digital Transformation of Quality ManagementDocument50 pagesQuality 4.0 Digital Transformation of Quality ManagementAYOUB DAOUIMNo ratings yet

- Visualization Technology-Based Construction Safety Management: A ReviewDocument24 pagesVisualization Technology-Based Construction Safety Management: A ReviewninjaNo ratings yet

- Impact of Mit DatabaseDocument6 pagesImpact of Mit DatabasePraveen Chand GNo ratings yet

- RTOS QuestionsDocument18 pagesRTOS Questionsvijay_mane2001No ratings yet

- Os Unit-1Document26 pagesOs Unit-1Furquan MohsinNo ratings yet

- SIRTOS A Simple Real Time Operating SystemDocument6 pagesSIRTOS A Simple Real Time Operating Systemmiguel angelNo ratings yet

- Direction Finding PresentationDocument35 pagesDirection Finding PresentationFoolraserNo ratings yet

- Embedded Interview QuestionsDocument6 pagesEmbedded Interview QuestionsFirdaus AlamNo ratings yet

- Operatig SystemDocument29 pagesOperatig SystemRadhika BadbadeNo ratings yet

- CL05 - Reducing Waste With FactoryTalk Analytics LogixAI Embedded Analytics - Version 2Document56 pagesCL05 - Reducing Waste With FactoryTalk Analytics LogixAI Embedded Analytics - Version 2Paulo Vinícius100% (1)

- Project Management: 3.1. ESTIMATE OF COSTS AND DURATION ............................................. ......... 1Document29 pagesProject Management: 3.1. ESTIMATE OF COSTS AND DURATION ............................................. ......... 1mohamed bangouraNo ratings yet

- An-Ind-1-007 Using Matlab With CanoeDocument15 pagesAn-Ind-1-007 Using Matlab With CanoeCoolboy RoadsterNo ratings yet

- ETSI TS 123 107: Technical SpecificationDocument43 pagesETSI TS 123 107: Technical SpecificationRanjish BhaskaranNo ratings yet

- Giotto - A Time-Triggered Language For Embedded ProgrammingDocument16 pagesGiotto - A Time-Triggered Language For Embedded Programming天黑黑No ratings yet

- Concept, Construction and First Results of A Test Bench For Automotive Power NetsDocument8 pagesConcept, Construction and First Results of A Test Bench For Automotive Power NetsmacorcheroNo ratings yet

- 08 - Chapter 1 PDFDocument47 pages08 - Chapter 1 PDFMalcolm DopaimNo ratings yet

- Project Request For Proposal: Due Monday April 11, 2016 (Or Sooner)Document1 pageProject Request For Proposal: Due Monday April 11, 2016 (Or Sooner)Ahmed HamoudaNo ratings yet