Professional Documents

Culture Documents

Atul Limited: Polymers Division

Uploaded by

santosh mhetreOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Atul Limited: Polymers Division

Uploaded by

santosh mhetreCopyright:

Available Formats

Technical Data Sheet

PAA-140

ATUL LIMITED

Polymers Division LAPOX® PAA-140

(New code AH 713)

Description:

Lapox PAA-140 is a medium viscosity polyaminoamide resin based on dimerized fatty acid and

polyethylene polyamine. This epoxy hardener is designed for use with liquid or solid epoxy resins to

produce protective and decorative solvent based coatings with excellent flexibility and adhesion to

most substrates.

Advantages

Excellent Chemical resistance

Excellent solvent resistance

Improved flexibility

Good moisture resistance

Good intercoat adhesion

Superior corrosion resistance

High peel strength

Applications

General purpose epoxy adhesive

Maintenance coating

Primers / topcoat

High solid enamel paints

Typical Data

Property Unit Test Method Value

Appearance -- Visual Yellow brown liquid

Colour GS ASTM D 1544 Max 9

Mixing Ratio with BLR ( EEW

pbw --- 35 - 55

190)

Mixing Ratio with BLR ( EEW

pbw --- 20 - 25

450)

Amine Value mg KOH/gm ASTM D 2073 350 - 400

o

Viscosity at 25 C cPs ASTM D 2196 12000 - 18000

1 o BY-K Gardner Gel

Pot Life at 25 C minutes 60 - 80

Timer

o

Density @ 25 C kg/l --- 0.95 – 0.98

1

with 190 EEW Epoxy of 100gms mix mass

Revision No. 01 Issue: Sep. 2009 Page 1 of 2

Technical Data Sheet

PAA-140

Storage and Handling

PAA-140 hardener should be stored in a dry place, preferably in the sealed container; at low

temperature PAA-140 will absorb moisture and carbon dioxide when left in open containers. This

may result in crystallization of the product. Therefore it is recommended that all containers of this

product should be kept tightly closed when not in use and stored in dry and cool place. Under this

condition the shelf life of product is 1 year from the date of manufacturing. Please refer MSDS for

detail safety instructions.

Note

All recommendations for use of our products, whether given by us in writing, verbally are to be implied, from the

results of tests carried out by us, based on the current state of our knowledge. Although the information

contained in this sheet is accurate to the best of our knowledge, no liability can be accepted in respect of such

information and no warranty or conditions are intended in respect of the products described, as the conditions

of application are beyond our control.

For more information, please contact

Atul Limited

P.O. Atul, Dist-Valsad, Gujarat (India) 396020

Phone: (91 2632) 233 204/205/514/269 Fax: (91 2632) 233 639 / 053

Email- po@atul.co.in , Website: www.atul.co.in

Revision No. 01 Issue: Sep. 2009 Page 2 of 2

You might also like

- The Effect of Isoprenyl Ether Polymer Molecular Structure On Cementitious CompositesDocument11 pagesThe Effect of Isoprenyl Ether Polymer Molecular Structure On Cementitious Compositessantosh mhetreNo ratings yet

- C4RA02362EDocument28 pagesC4RA02362Esantosh mhetreNo ratings yet

- Tds. Technical Data Sheet Tds. Technical Data Sheet: Polyurethane Waterproofing MembraneDocument9 pagesTds. Technical Data Sheet Tds. Technical Data Sheet: Polyurethane Waterproofing Membranesantosh mhetreNo ratings yet

- Mass Product Data SheetDocument1 pageMass Product Data Sheetsantosh mhetreNo ratings yet

- Safety Data Sheet: Poly (N-Isopropylacrylamide), Carboxylic Acid TerminatedDocument7 pagesSafety Data Sheet: Poly (N-Isopropylacrylamide), Carboxylic Acid Terminatedsantosh mhetreNo ratings yet

- FU B20 DAT BK620500 Prop GBDocument5 pagesFU B20 DAT BK620500 Prop GBsantosh mhetreNo ratings yet

- Joy Product Data SheetDocument1 pageJoy Product Data Sheetsantosh mhetreNo ratings yet

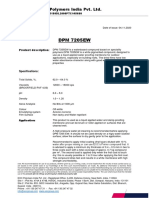

- DPM 7205EW: EOC Polymers India Pvt. LTDDocument2 pagesDPM 7205EW: EOC Polymers India Pvt. LTDsantosh mhetreNo ratings yet

- Eoc Pipl - Bci 7923B - TDSDocument1 pageEoc Pipl - Bci 7923B - TDSsantosh mhetreNo ratings yet

- Kem Proof: Elastomeric Waterproof Exterior CoatingDocument4 pagesKem Proof: Elastomeric Waterproof Exterior Coatingsantosh mhetreNo ratings yet

- Li 6090 - TDS - Eoc PiplDocument2 pagesLi 6090 - TDS - Eoc Piplsantosh mhetreNo ratings yet

- EOC PIPL - Exodisp C 7376 - TDSDocument1 pageEOC PIPL - Exodisp C 7376 - TDSsantosh mhetreNo ratings yet

- United States Patent: Anderson Et Al. (45) Date of Patent: Feb. 22, 2005Document19 pagesUnited States Patent: Anderson Et Al. (45) Date of Patent: Feb. 22, 2005santosh mhetreNo ratings yet

- Adhesive Brochure ENDocument12 pagesAdhesive Brochure ENsantosh mhetreNo ratings yet

- Eoc Pipl - Li 6061Document2 pagesEoc Pipl - Li 6061santosh mhetreNo ratings yet

- Eoc Pipl - Exodisp C 7301 Ci - TdsDocument2 pagesEoc Pipl - Exodisp C 7301 Ci - Tdssantosh mhetreNo ratings yet

- Eoc Pipl - Exodisp C 7305 - TDSDocument1 pageEoc Pipl - Exodisp C 7305 - TDSsantosh mhetreNo ratings yet

- Calcium Nitrate Corrossion Inhibitor TestDocument6 pagesCalcium Nitrate Corrossion Inhibitor Testsantosh mhetreNo ratings yet

- Plastic-Metal SF Resin (GB) ! SECTION 1: Identification of The Substance/mixture and of The Company/undertakingDocument10 pagesPlastic-Metal SF Resin (GB) ! SECTION 1: Identification of The Substance/mixture and of The Company/undertakingsantosh mhetreNo ratings yet

- Technical Review of Calcium Nitrite Corrosion Inhibitor in ConcreteDocument10 pagesTechnical Review of Calcium Nitrite Corrosion Inhibitor in Concretesantosh mhetreNo ratings yet

- Waterborne Acrylic Primer Nacorr Synergy With Halox SW-111: Formulation CI-102Document2 pagesWaterborne Acrylic Primer Nacorr Synergy With Halox SW-111: Formulation CI-102santosh mhetreNo ratings yet

- Potholes and Repair Techniques For Local Authorities PDFDocument108 pagesPotholes and Repair Techniques For Local Authorities PDFsantosh mhetreNo ratings yet

- Pothole Patching: A Review On Materials and Methods February 2016Document17 pagesPothole Patching: A Review On Materials and Methods February 2016santosh mhetreNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- P6200he PdsDocument2 pagesP6200he PdsStuart Goodswen100% (1)

- TDS Jotafloor TopcoatDocument5 pagesTDS Jotafloor TopcoatWilliam SukyonoNo ratings yet

- LePage Epoxy Steel, 25-mL Canadian TireDocument5 pagesLePage Epoxy Steel, 25-mL Canadian Tireming_zhu10No ratings yet

- 1 s2.0 S0040603105004569 MainDocument4 pages1 s2.0 S0040603105004569 MainRIZKY ROMADHONA ROMADHONANo ratings yet

- QMC® EPO-MASTER 50 - English - v1.0.0Document4 pagesQMC® EPO-MASTER 50 - English - v1.0.0Ahmed TahaNo ratings yet

- CNSLDocument18 pagesCNSLrafeekNo ratings yet

- Technical Data: PR-1776M Class B Low Weight Fuel Tank SealantDocument2 pagesTechnical Data: PR-1776M Class B Low Weight Fuel Tank SealantEDUARDONo ratings yet

- Nitomortar HBDocument4 pagesNitomortar HBMansoor AliNo ratings yet

- Ethylene A MinesDocument58 pagesEthylene A Minescarlos_bautista_55No ratings yet

- Loctite MaintenanceDocument44 pagesLoctite MaintenancemmkattaNo ratings yet

- Villaseal - Tehnicki List enDocument3 pagesVillaseal - Tehnicki List enaminachNo ratings yet

- ASTM Testing ProcedureDocument7 pagesASTM Testing Procedurederecka100% (1)

- Selection and Application of Board Level Underfill MaterialsDocument5 pagesSelection and Application of Board Level Underfill MaterialsCamilo Souza0% (2)

- Epoxy Curing Agent BrochureDocument9 pagesEpoxy Curing Agent Brochureavinash3285No ratings yet

- MT-HN-RCTI-13 - Sealing CracksDocument20 pagesMT-HN-RCTI-13 - Sealing CracksManuela Angulo TrianaNo ratings yet

- Siemens Transformers Materials Influence Diagnostics Stray GassingDocument6 pagesSiemens Transformers Materials Influence Diagnostics Stray GassingmanuelNo ratings yet

- 2015 Glass and Glass Fiber UpdateDocument25 pages2015 Glass and Glass Fiber UpdateSandra MoriNo ratings yet

- PDS - Ultraguard EP 52Document1 pagePDS - Ultraguard EP 52Maurice DavisNo ratings yet

- Nitoflor EPU100Document4 pagesNitoflor EPU100Allan DerickNo ratings yet

- Interseal 547 PDFDocument4 pagesInterseal 547 PDFSUBHOMOYNo ratings yet

- NSF 61 PaintDocument2 pagesNSF 61 Paintraviraj londheNo ratings yet

- Irving Skeist, Jerry Miron (Auth.), Irving Skeist Ph.D. (Eds.) - Handbook of Adhesives-Springer US (1990)Document784 pagesIrving Skeist, Jerry Miron (Auth.), Irving Skeist Ph.D. (Eds.) - Handbook of Adhesives-Springer US (1990)Dung Nguyen100% (1)

- Arlon 38NDocument4 pagesArlon 38NRavindrakumar ParvathiniNo ratings yet

- Pyroclad X1: Selection & Specification DataDocument6 pagesPyroclad X1: Selection & Specification DataDuongthithuydungNo ratings yet

- 6077d17c9db8e Dr. Fixit Superseal 4500 PuhDocument4 pages6077d17c9db8e Dr. Fixit Superseal 4500 PuhAdityaVikramVermaNo ratings yet

- Faststeel: Repair and Rebuild Anything Made of SteelDocument2 pagesFaststeel: Repair and Rebuild Anything Made of SteelRaheel AhmedNo ratings yet

- Nitomortar TC2000 Nitomortar TC2000: Constructive SolutionsDocument3 pagesNitomortar TC2000 Nitomortar TC2000: Constructive SolutionsalbertooooooNo ratings yet

- Corotech V440 - TDS EN OKF PDFDocument3 pagesCorotech V440 - TDS EN OKF PDFAPEX SONNo ratings yet

- ABB Transformers Dimensions and Other Technical InformationsDocument22 pagesABB Transformers Dimensions and Other Technical InformationsAbdul Muqeem Mohammed100% (1)

- AralditeDocument7 pagesAralditeRohit RanaNo ratings yet