Professional Documents

Culture Documents

The Ultra Rib 2 System Is Designed To Meet The Strictest Tightness, Durability and Strength Requirements

The Ultra Rib 2 System Is Designed To Meet The Strictest Tightness, Durability and Strength Requirements

Uploaded by

arjun 11Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

The Ultra Rib 2 System Is Designed To Meet The Strictest Tightness, Durability and Strength Requirements

The Ultra Rib 2 System Is Designed To Meet The Strictest Tightness, Durability and Strength Requirements

Uploaded by

arjun 11Copyright:

Available Formats

Gravity Sewer

Systems

UPONOR INFRASTRUCTURE

Uponor Gravity Sewer

System ULTRA RIB 2

The Ultra Rib 2 system is designed

to meet the strictest tightness,

durability and strength requirements.

Uponor Ultra Rib 2 Gravity Sewer System 67

5.2 Uponor Sewer System

Gravity Sewer

Ultra Rib 2

Systems

The Uponor Ultra Rib 2 Gravity Sewer Ultra Rib 2 considerably outperforms all

System offers the optimal solution current Nordic and European standards for

for wastewater drainage. Ultra Rib 2, underground sewer systems. The system's

commercially available since 1999, is reliability is further enhanced by our tight-

the only sewer system on the market ened safety performance requirements,

with rib-stiffened pipes and fittings which are verified by deflection, impact

made entirely from seamless SN 8 class resistance and Strohhalm testing. Strict in-

polypropylene (PP). house material and process requirements,

combined with external quality controls,

In the development of the Ultra Rib 2 guarantee a system service life of over

system, close attention has been paid to 100 years when the Uponor installation

maximising the service life of the system. instructions are followed.

Key features of Ultra Rib 2 include:

• durable long-life materials Uponor Ultra Rib 2 Gravity Sewer

• rib-stiffened structure designed for System – sealing

maximum stiffness, strength and The system's sealing rings are designed

lightness to withstand both internal and external

• jointing methods for easy and pressure. To ensure protection from sand

ultra‑reliable installation and gravel, the seals are set deep within

• outstanding mechanical properties the socket. As required, the system can

including at low temperatures be delivered with standard seals or oil/

petrol resistant seals. Standard sealing

rings are made from styrene butadiene

rubber (SBR). Oil and petrol resistant

seals are made from nitrile rubber (NBR)

and are marked yellow for easy identifica-

tion. The seals are fitted in the second rib

groove from the spigot end of the pipe.

68 Uponor Ultra Rib 2 Gravity Sewer System

Gravity Sewer

Systems

The Uponor Ultra Rib 2 pipes and fittings Pipe dimensions

provide a comprehensive sewer pipe Outside diameter (mm) Inside diameter (mm)

system. The pipe is coloured terra cotta 200 175

on the outside, and has a light grey inner 250 220

315 277

surface for optimum visibility during

450 396

camera inspection. 560 493

Table 5.2.1

System and material specifications

Properties PP Unit Standard/test method

Density 900 kg/m3 ISO 1183

Ring stiffness Pipes SN8 kN/m2 ISO 9969

Fittings SN8 kN/m2 ISO 9969

Long-term elastic modulus E50 425 MPa ISO 527-2

Short-term elastic modulus E0 1650 MPa ISO 527-2

Thermal expansion factor 0,18 mm/m · °C

Thermal conductivity 0,22 W/m · °C DIN 52 612 (23 °C)

Maximum continuous operating temperature 85 °C

Maximum momentary operating temperature 100 °C

Max. angle of joint deflection 2 °

Table 5.2.2

Uponor Ultra Rib 2 Gravity Sewer System 69

Approvals & Markings

Gravity Sewer

Systems

Approvals

The Ultra Rib 2 system carries the Nordic The INSTA-CERT certificates for all

Poly Mark and is INSTA-CERT certified Uponor products can be viewed on our

and approved in the Nordic countries website at www.uponor.fi.

(Finland, Sweden, Norway and Denmark).

Ultra Rib 2 pipe markings

The figure below shows the markings for

Uponor Ultra Rib piping. Explanations for

the markings are given in the following

table.

SEWER ULTRA RIB2 PP 315/277 SN8 UD EN 13476 ❄ ➁ 18 01 2007 13

Example markings on Ultra Rib 2 pipe

SEWER ULTRA RIB 2 PP 315/277 SN8

Manufacturer Application Product Material: Outer and inner Stiffness class

polypropylene diameter

UD EN 13476 ❄ ➁ 18 01 2007 13

Application area, Product Nordic Poly Snowflake symbol. Production unit Production date:

UD = underground standard Mark Pipe can be ➁ = Hadsund day/month/year/hour

drainage and sewer handled in low

within the building temperatures

structure and out-

side the building

Table 5.2.3

70 Uponor Ultra Rib 2 Gravity Sewer System

Markings for Ultra Rib 2 fittings

Gravity Sewer

Explanations of the markings for Ultra

Systems

Rib 2 fittings are given below.

Sample markings for Ultra Rib 2 branch sockets

UD PP U1

ULTRA RIB2 SN8

DN/OD 200/200-45°

1 U1

UD PP U1

2

Application area UD = Production date: Recyclable/raw material Material: Production unit

underground drainage month/year 05 = polypropylene polypropylene U1 = Nastola,

and sewerage within Finland

the building structure

and outside the

building

1 U1

2

DN/OD

ULTRA RIB 2 SN8 45SDgr

200/200

Product Stiffness class Nominal outer diameter Socket branch 45° Nordic Poly Mark

Table 5.2.4

Uponor Ultra Rib 2 Gravity Sewer System 71

Ultra Rib 2 Sewer System Design

Gravity Sewer

Systems

Structural design

The “Structural design” section of the 1.1, 1.2 and 1.3. The coefficient takes

Wastewater Systems chapter specifies a account of the branches and inspec-

number of design criteria, for which gen- tion chambers typically incorporated in

erally applicable experience-based data wastewater sewer systems. The charts

exists. If these criteria are met, no addi- are based on the inside pipe diameter,

tional design calculations are required. although pipe size is expressed according

to the outside diameter. References are

Flow design made in the various charts to the flow

When determining the pipe system’s design examples presented in the Waste-

dimensions, it is important to ensure that water Systems introductory section.

the system has sufficient flow and self-

cleaning capacity to ensure trouble-free After pipe design, the self-cleaning

operation. The main design principles are capacity and pipe gradient need to be

presented in the introductory section of determined, based on the chosen pipe

the Gravity Sewers chapter. Flow charts size and design flow rate, for which pur-

for the Ultra Rib 2 pipe systems, which pose self-cleaning diagrams for different

use a roughness coefficient value of sized Ultra Rib 2 gravity sewer pipes are

0.25 mm, are presented in appendices presented in appendices 2.1 – 2.5.

72 Uponor Ultra Rib 2 Gravity Sewer System

Ultra Rib 2 Sewer System Installation

Gravity Sewer

Systems

Next, the structural adjustment and joint-

ing of Ultra Rib 2 pipes and fittings is

described. This section covers

• Ultra Rib 2 pipe installation

• jointing with Ultra Rib 2 socket bends,

branches and slip couplers

• installing Ultra Rib 2 adaptors for

concrete pipe

• joints and spigot/socket base clearance

The fittings of the Ultra Rib 2 sewer

system are also used in Uponor's Dupplex

sewer system and PP stormwater system.

2. Fit the seal in the second rib groove

from the spigot end of the pipe.

Ultra Rib 2 pipe installation

1. Cut the pipe along the rib groove using 3. Apply lubricant on the inside of the

a fine-tooth saw. Deburr the cut edges socket. To facilitate jointing, also apply the

with a blade or file. lubricant on the spigot end sealing ring.

Uponor Ultra Rib 2 Gravity Sewer System 73

Gravity Sewer

Systems

4. The joint is complete when the pipe end is pushed all the way into the base of the

socket. The pipes can also be slotted together by levering against the rearmost socket,

e.g. with a spade. When doing so, to avoid damaging the socket position a piece of

wood between the socket and the spade.

Joints and clearances

To ensure a sound joint, Ultra Rib 2 pipe

must be sawn as true as possible along

the rib groove. A well-fitted joint should

leave no gap between the spigot end and

socket base. This will not be achieved if

the pipe is cut unevenly. Final inspection

of the completed pipeline is carried out by

the developer or the developer's agent.

74 Uponor Ultra Rib 2 Gravity Sewer System

Joining an Ultra Rib 2 pipe branch to an existing pipeline

Gravity Sewer

Systems

1. Branching off or onto an existing pipe- 2. Cut the pipe along the rib groove using

line is performed using a branch fitting, a fine-tooth saw. Deburr the cut edges

into which the existing line is inserted at with a blade or file.

both ends and couplers are fitted over the

joints. Begin by marking off the length of

the branch fitting on the existing pipe.

3. Apply lubricant inside the socket ends 4. Cut the equivalent length of the branch

of the couplers. Fit a seal into the second fitting (as previously marked off) from the

groove on each spigot end of the branch existing pipe and install

fitting. Slot the branch fitting and the the branch assembly into place.

couplings together, by pushing firmly all

the way to the base of the coupling.

Uponor Ultra Rib 2 Gravity Sewer System 75

Installing an Ultra Rib 2 pipe adaptor for coupling to a concrete pipe socket

Gravity Sewer

Systems

Coupling to a concrete pipe socket is performed using a spigot adaptor, with a sealing

ring fitted onto the adaptor's collar. Push the adaptor all the way to the base of the

concrete pipe socket; the sealing ring will roll into place, sealing the joint. No lubricant is

used in the concrete pipe joint.

76 Uponor Ultra Rib 2 Gravity Sewer System

Installing an Ultra Rib 2 pipe adaptor for coupling to a concrete pipe spigot end

Gravity Sewer

Systems

Coupling to the spigot end of a concrete pipe is performed using a socket adaptor. Fit

a seal onto the spigot end of the concrete pipe. Push the adaptor into place over the

seal and carefully apply heat to the adaptor's flange; the flange will shrink onto the

concrete pipe, forming a tight joint. No lubricant is used in the concrete pipe joint.

Uponor Ultra Rib 2 Gravity Sewer System 77

Gravity Sewer

Systems

78

You might also like

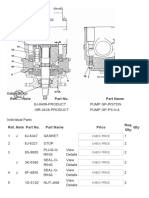

- Nissan Sentra 2009 Service Manual Nissan Sentra 2009 Service ManualFUEL SYSTEM PDFDocument13 pagesNissan Sentra 2009 Service Manual Nissan Sentra 2009 Service ManualFUEL SYSTEM PDFDavid BNo ratings yet

- Standard Tap and Drill Size ChartDocument2 pagesStandard Tap and Drill Size ChartmathiprakashNo ratings yet

- RF and Microwave Engineering Lab Manual-Lab 01Document10 pagesRF and Microwave Engineering Lab Manual-Lab 01usama khalid50% (2)

- Nitrogen Generation Packages LRDocument12 pagesNitrogen Generation Packages LRthinkpadNo ratings yet

- Omsco Drillpipe CatalogueDocument24 pagesOmsco Drillpipe Cataloguerwinmill100% (3)

- Manual Arc Flash SKM Power ToolsDocument120 pagesManual Arc Flash SKM Power ToolsMarino VillalbaNo ratings yet

- Air Leak TestingDocument5 pagesAir Leak Testingkusdiyanta67% (3)

- Material Handling Equipment SteelDocument114 pagesMaterial Handling Equipment SteelZahir Khira100% (1)

- Wave Energy Conversion Ocean Thermal Energy PDFDocument136 pagesWave Energy Conversion Ocean Thermal Energy PDFcio100% (1)

- Computer Aided Quality ControlDocument17 pagesComputer Aided Quality ControlMFNo ratings yet

- Zxun Uspp Series Hlrauc Feature List - v4Document280 pagesZxun Uspp Series Hlrauc Feature List - v4Sushant Baral100% (1)

- Parts ManualsDocument3 pagesParts ManualsLenin GullapalliNo ratings yet

- ID-PRC 19 - PE Coating RepairDocument7 pagesID-PRC 19 - PE Coating Repaircloud23No ratings yet

- VAI-ME-SPC-111 Pipe Insulation Technical Specification - Rev ADocument8 pagesVAI-ME-SPC-111 Pipe Insulation Technical Specification - Rev AAdvis100% (1)

- Captura de Tela 2023-11-29 À(s) 20.19.42Document44 pagesCaptura de Tela 2023-11-29 À(s) 20.19.42Julio SantosNo ratings yet

- Elliot-Recon 1500 Vacuum Tube Tester Catalog 2017Document4 pagesElliot-Recon 1500 Vacuum Tube Tester Catalog 2017naidu60606No ratings yet

- Serving The World in Pneumatic and Vacuum Conveying ProductsDocument8 pagesServing The World in Pneumatic and Vacuum Conveying ProductsoganuluNo ratings yet

- Leakage Detection Butterfly Valves L Line Sudmo LeafletDocument2 pagesLeakage Detection Butterfly Valves L Line Sudmo LeafletChemicalProgrammerNo ratings yet

- PW Bro Mig Mag Welding Torches enDocument12 pagesPW Bro Mig Mag Welding Torches enjfbbhhzzqvNo ratings yet

- Flye en AmTube Belts 200421 WebDocument2 pagesFlye en AmTube Belts 200421 WebSybille AnibeNo ratings yet

- 1466 - BUI-1000 - Metric-V-Belts-v2 (Bando)Document2 pages1466 - BUI-1000 - Metric-V-Belts-v2 (Bando)TheEdgeNo ratings yet

- PreInsulated Tech Guide 2014Document60 pagesPreInsulated Tech Guide 2014portocala12No ratings yet

- MPDFDocument2 pagesMPDFMohammed BaderNo ratings yet

- Silentflow Blower Package Pressure and VacuumDocument8 pagesSilentflow Blower Package Pressure and VacuumahmedNo ratings yet

- Underground Drainage and Sewer SystemDocument8 pagesUnderground Drainage and Sewer SystemshehanNo ratings yet

- Brochure SILENT FLOW EN (All - Version)Document8 pagesBrochure SILENT FLOW EN (All - Version)MiguelOliveira1No ratings yet

- WP Contentuploads201905B211 PDFDocument8 pagesWP Contentuploads201905B211 PDFWendel AlmeidaNo ratings yet

- 7562 Apfd5 1627815430tubeshor Groundworks RMD KwikformDocument12 pages7562 Apfd5 1627815430tubeshor Groundworks RMD KwikformGopu RNo ratings yet

- Excluder 2Document10 pagesExcluder 2Žan KržanNo ratings yet

- Catalogue 2021-HD: Belt Maintenance Equipment - Belt Lacing 750kN/mDocument48 pagesCatalogue 2021-HD: Belt Maintenance Equipment - Belt Lacing 750kN/mjohn deereNo ratings yet

- Cooper MEDC CU1SEM024506RDI1MR Conjunto Sinalizador e Sirene Inmetro Ficha Tecnica Catalogo DatasheetDocument2 pagesCooper MEDC CU1SEM024506RDI1MR Conjunto Sinalizador e Sirene Inmetro Ficha Tecnica Catalogo DatasheetPeter PenhaNo ratings yet

- Paling - Soil Waste & Vent System - 04062015 PDFDocument44 pagesPaling - Soil Waste & Vent System - 04062015 PDFJonNo ratings yet

- Pe-Rt/Al/Pe-Rt Multilayer Pipe: Technische InformationDocument4 pagesPe-Rt/Al/Pe-Rt Multilayer Pipe: Technische InformationLloyd Ki'sNo ratings yet

- Itaan Pharma Offer For HVAC - R0 - 27.05.22 (1) - 15Document2 pagesItaan Pharma Offer For HVAC - R0 - 27.05.22 (1) - 15Srikanth ChagantipatiNo ratings yet

- Prysmian Esp Cable DW 205 R PDFDocument2 pagesPrysmian Esp Cable DW 205 R PDFJava Cable Center50% (2)

- Katalog Fastact-1actuatorDocument12 pagesKatalog Fastact-1actuatormuhamad bastianNo ratings yet

- MN 110 Pi Ovra Limpet Mine OkDocument2 pagesMN 110 Pi Ovra Limpet Mine OkfogdartNo ratings yet

- Emitterline LeverDocument2 pagesEmitterline LevervictorNo ratings yet

- Mediumpressure PDFDocument104 pagesMediumpressure PDFJean DuboisNo ratings yet

- 5 Belt CleanersDocument24 pages5 Belt CleanersPhongsak SihanatNo ratings yet

- P04 GB ATEX Rotary Lobe Pumps 01Document8 pagesP04 GB ATEX Rotary Lobe Pumps 01Rahmadi PutraNo ratings yet

- Aeroquip - A-HOOV-MC001-E1 - Overview - LRDocument6 pagesAeroquip - A-HOOV-MC001-E1 - Overview - LRMarcelo MalagoNo ratings yet

- Uponor Infra Gravity Systems ENG PDFDocument72 pagesUponor Infra Gravity Systems ENG PDFarjun 11No ratings yet

- Pecor QuattroDocument2 pagesPecor QuattroVincentiu RautaNo ratings yet

- JBP Company Profile - 2023Document25 pagesJBP Company Profile - 2023naomi.manaNo ratings yet

- PVC Ror Og FittingsDocument20 pagesPVC Ror Og FittingsOsama sayedNo ratings yet

- J2 Vibrating Wire CrackmeterDocument4 pagesJ2 Vibrating Wire CrackmeterJoão Vermelho SaúdeNo ratings yet

- FITELS178Document4 pagesFITELS178xiaoliminNo ratings yet

- DKM CP DN25-65 En1Document24 pagesDKM CP DN25-65 En1brilian pungkyNo ratings yet

- BBR H Bar System Flyer Rev3 1219Document8 pagesBBR H Bar System Flyer Rev3 1219Юлия ДамNo ratings yet

- ms-02-316 Pre-Insulated Tubing BundlesDocument12 pagesms-02-316 Pre-Insulated Tubing BundleskicsnerNo ratings yet

- ms-02-316 Pre-Insulated Tubing BundlesDocument12 pagesms-02-316 Pre-Insulated Tubing BundleskicsnerNo ratings yet

- Aeid 205 265 Atomfeld 205 265-13932991575625889Document11 pagesAeid 205 265 Atomfeld 205 265-13932991575625889nedahejran1393No ratings yet

- Angus Fire HoseDocument16 pagesAngus Fire HoseANo ratings yet

- Angus Hose Product GuideDocument16 pagesAngus Hose Product GuidevamsixNo ratings yet

- Wheelprobe2: Innovation, Flexibility, PerformanceDocument6 pagesWheelprobe2: Innovation, Flexibility, PerformanceDeyvi ChambillaNo ratings yet

- Self-Recuperative Burners High Speed Free FlameDocument17 pagesSelf-Recuperative Burners High Speed Free FlameKarl WeierstrassNo ratings yet

- Atg UvmDocument1 pageAtg UvmnattaponamornNo ratings yet

- Opti-Core LSZH Indoor-Outdoor All-Dielectric Fiber Optic CableDocument2 pagesOpti-Core LSZH Indoor-Outdoor All-Dielectric Fiber Optic CableBruno SusinNo ratings yet

- LOT 4 - Technical Specs - 132 KV Transmission Line AccessoriesDocument13 pagesLOT 4 - Technical Specs - 132 KV Transmission Line AccessoriesPeters Clever OkelloNo ratings yet

- Corona & Plasma: For ExtrusionDocument8 pagesCorona & Plasma: For ExtrusionHuy Tuan QuachNo ratings yet

- Fire DamperDocument4 pagesFire DamperHooi Mun WeiNo ratings yet

- BR Bluerov2 Datasheet rev2022-R4ROV PDFDocument2 pagesBR Bluerov2 Datasheet rev2022-R4ROV PDFIbidhi EskanderNo ratings yet

- Amtronic Profiles DP1300Document32 pagesAmtronic Profiles DP1300Handriono OnoNo ratings yet

- D-Agent - 1 - Work-388-S-Upload-3300 XL 8mm Proximity Transducer System Datasheet - 141194Document42 pagesD-Agent - 1 - Work-388-S-Upload-3300 XL 8mm Proximity Transducer System Datasheet - 141194Moises Alejandro Ordoñez GuerraNo ratings yet

- ESP Cables: Exploration & ProductionDocument2 pagesESP Cables: Exploration & ProductionHimawan Sigit NugrohoNo ratings yet

- 3300 XL 8mm Proximity Transducer System: Product DatasheetDocument36 pages3300 XL 8mm Proximity Transducer System: Product Datasheetjosejohn1No ratings yet

- Mos3200 Bs 2000m FP Product DataDocument4 pagesMos3200 Bs 2000m FP Product DataJeromeNo ratings yet

- APM 620 602 - Final MinDocument2 pagesAPM 620 602 - Final MinIman FerisendyNo ratings yet

- Plumbing Checklist: Slab RoughDocument1 pagePlumbing Checklist: Slab Rougharjun 11No ratings yet

- Model: FB Junior Series - Technical Data Sheet (Page 1) Model: FB Junior Series - Technical Data Sheet (Page 1)Document3 pagesModel: FB Junior Series - Technical Data Sheet (Page 1) Model: FB Junior Series - Technical Data Sheet (Page 1)arjun 11No ratings yet

- Water: Verification of Calculation Method Using Monte Carlo Method For Water Supply Demands of Office BuildingDocument21 pagesWater: Verification of Calculation Method Using Monte Carlo Method For Water Supply Demands of Office Buildingarjun 11No ratings yet

- Clamps & Hangers PDFDocument4 pagesClamps & Hangers PDFarjun 11No ratings yet

- Civil & Environmental Preliminary Design Guide: For Undeveloped SitesDocument38 pagesCivil & Environmental Preliminary Design Guide: For Undeveloped Sitesarjun 11No ratings yet

- Maintenance Matters 06 Decks BalconiesDocument6 pagesMaintenance Matters 06 Decks Balconiesarjun 11No ratings yet

- 02 Arch - Stru CoordinationDocument70 pages02 Arch - Stru Coordinationarjun 11No ratings yet

- Basement Floor Drainage & Sump Plan - 30-6-20Document1 pageBasement Floor Drainage & Sump Plan - 30-6-20arjun 11No ratings yet

- Rigid PVC Pressure Pipes and Fittings: Jeevan Bhar Ka Saath..Document8 pagesRigid PVC Pressure Pipes and Fittings: Jeevan Bhar Ka Saath..arjun 11No ratings yet

- Testo 6740 Instruction ManualDocument28 pagesTesto 6740 Instruction ManualDeyvid RabelloNo ratings yet

- Simulation Agenda Creation AssignmentDocument4 pagesSimulation Agenda Creation AssignmentHajera UnnisaNo ratings yet

- Vert Heater TreaterDocument2 pagesVert Heater TreaterJaveed KhanNo ratings yet

- Karl Benz Wiki - 04Document1 pageKarl Benz Wiki - 04Binoj V JanardhananNo ratings yet

- Kim White: 15 Rosewood Lane Owings Mills, MD 21117 (410) 902-8877 Cell# 443 992-3281Document1 pageKim White: 15 Rosewood Lane Owings Mills, MD 21117 (410) 902-8877 Cell# 443 992-3281Kim WhiteNo ratings yet

- Structure Repairs & Rehabilitation Presentation No.3Document98 pagesStructure Repairs & Rehabilitation Presentation No.3Sougata DasNo ratings yet

- Soss Module PCL IDocument3 pagesSoss Module PCL Ijyotpreet_110No ratings yet

- R12 ChangesDocument37 pagesR12 ChangesManishNo ratings yet

- Layout 5a PDFDocument1 pageLayout 5a PDFDelila VeispahićNo ratings yet

- Hydrofracking - What Everyone Needs To KnowDocument132 pagesHydrofracking - What Everyone Needs To KnowEK63100% (1)

- Resistência Ao Amarrotamento (Winkle Tester) - AATCC 128 - 2009Document2 pagesResistência Ao Amarrotamento (Winkle Tester) - AATCC 128 - 2009raissaNo ratings yet

- Creating Material GroupsDocument5 pagesCreating Material GroupsAnirban LahaNo ratings yet

- Product Catalog 2013: Defense and TechnologyDocument70 pagesProduct Catalog 2013: Defense and Technologyk000No ratings yet

- AESGP 51st Annual MeetingDocument5 pagesAESGP 51st Annual MeetingaesgpNo ratings yet

- License Server Installation 311Document4 pagesLicense Server Installation 311Michael BenhamouNo ratings yet

- Category Grading System Weight: 1 Performance Grade 2 Performance Grade Grade For Blogs Activity D Smithsonian DiscussionDocument2 pagesCategory Grading System Weight: 1 Performance Grade 2 Performance Grade Grade For Blogs Activity D Smithsonian DiscussionAlvaro Martin Cañapataña CcoraNo ratings yet

- Closed-Loop Positioning SystemsDocument25 pagesClosed-Loop Positioning Systemsfarah nazNo ratings yet

- HardeningGuide Vsphere50 v1.0Document469 pagesHardeningGuide Vsphere50 v1.0esigcarmichaelNo ratings yet

- GreeDocument9 pagesGreechewzy145313No ratings yet