Professional Documents

Culture Documents

SET Duct Manufacturing, Inc.: Spiral Duct Dimensional Guide

Uploaded by

Umen AryanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SET Duct Manufacturing, Inc.: Spiral Duct Dimensional Guide

Uploaded by

Umen AryanCopyright:

Available Formats

SET Duct Manufacturing, Inc.

FOR QUA

AM LIT

TE Y

A

SET

RY

SER

Duct Manufacturing, Inc.

ST

VI N

G DU

TH IN

E NE S OF

ED

7800 Intervale Road - Detroit, Michigan 48238 - Phone: (313) 491-4380 - Fax: (313) 491-4381

• Flat Rolled Steel Processing • Duct Manufacturing

Veteran Owned Minority Owned

Spiral Duct Dimensional Guide

Spiral Duct Dimensional Guide • Issued: January 2011

SET Duct Manufacturing, Inc.

FOR QUA

AM LIT

TE Y

A

SET

RY

SER

Duct Manufacturing, Inc.

ST

VI N

G DU

TH IN

E NE S OF

ED

• Flat Rolled Steel Processing • Duct Manufacturing

7800 Intervale, Detroit, MI 48238

Phone (313) 491-4380 Fax (313) 491-4381

Minority / Veteran Owned

Materials Available

Galvanized, Galvanneal (Paintable), Stainless Steel 304 & 316,

4x4 PCD, 4x1 PCD, Aluminum 3003 H14, Aluminized,

Black Iron, Perforated Galvanized, Expanded Metal, Hot Rolled

Systems Available in Accordance with SMACNA Duct Construction Standards

Low Pressure, Medium Pressure, High Pressure.

Fume Exhaust, Below Ground, Single Wall, Double Wall,

Unlined & Lined Rectangular, Round Spiral, Flat Oval Spiral,

Warm Air Pipe and Fittings, Long Seam Welded Flexible Ductwork

Connection Systems

Couplings, Angle rings (Installed or Loose), AccuFlange™, EcconoFlange™, TDF,

Slip & Drive, Ward Flange™ (Installed), Ductmate™ (Installed), Flex Connectors

Accessories

Duct Sealer, Poly-Vinyl Tape, Hanging Systems, Blast Gates,

Volume Dampers, Gasket, Fasteners, Insulation Pins & Hardware, and much more

OEM Coil and Sheet Stock

36"-60" wide x 96"-144" long

Master Coils up to 10,000# max weight and 20" ID

28 gauge to 12 gauge

Slit to width for Spiral Pipe

Spiral Duct Dimensional Guide • Issued: January 2011

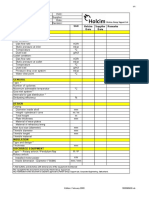

WEIGHT AND GAUGE CHART 28 26 24 22 20 18 16

GAUGE GAUGE GAUGE GAUGE GAUGE GAUGE GAUGE

DIAM. LBS/FT LBS/FT LBS/FT LBS/FT LBS/FT LBS/FT LBS/FT

All Pipe is manufactured with spiral lockseam 3" 0.7 0.8 1.0 1.2 1.5 N/A N/A

construction, seam type RL-1 from minimum G60

galvanized steel meeting ASTM A527 and

4" 0.9 1.1 1.4 1.7 2.0 2.5 N/A

ASTM A653 / A653M 690 5" 1.2 1.3 1.7 2.1 2.4 3.2 N/A

6" 1.4 1.6 2.0 2.5 2.9 3.8 N/A

Standard length is 10 foot sections. Shorter and

7" 1.6 1.9 2.4 2.9 3.4 4.4 N/A

longer lengths can be made to order corrugating 8" 1.8 2.1 2.7 3.3 3.9 5.1 6.3

available. 9" 2.1 2.4 3.1 3.7 4.4 5.7 7.0

10" 2.3 2.7 3.4 4.1 4.9 6.3 7.8

Orders will be shipped according to the gauges 11" 2.5 2.9 3.7 4.6 5.4 7.0 8.6

shown in the grey areas unless specified otherwise. 12" 2.8 3.2 4.1 5.0 5.9 7.6 9.4

These gauges meet or exceed 2005 SMACNA

requirements from -2" to +10" w.g. SMACNA 1995 14" 3.2 3.7 4.8 5.8 6.8 8.9 11.0

Standard Guage also available. 16" 4.3 5.4 6.6 7.8 10.2 12.5

18" 4.8 6.1 7.5 8.8 11.4 14.1

Also available in 304 and 316 Stainless Steel, 3003 20" 5.3 6.8 8.3 9.8 12.7 15.6

H14 Aluminum, P.C.D. Coated, Aluminized, 22" 5.9 7.5 9.1 10.7 14.0 17.2

Galvanneal (Paintable) and Double Wall. 24" 6.4 8.2 9.9 11.7 15.2 18.8

26" 6.9 8.9 10.8 12.7 16.5 20.3

Note: Standard galvanized is normally paintable 28" 9.5 11.6 13.7 17.8 21.8

providing the galvanized material is adequately 30" 10.2 12.4 14.6 19.0 23. 5

prepared for painting "by others".

32" 10.9 13.3 15.6 20.3 25.0

34" 11.6 14.1 16.6 21.6 26.6

Below Ground PCD Gauges 36" 12.3 14.9 17.6 22.9 28.2

4" thru 8" = 26 gauge 38" 12.9 15.7 18.5 24.1 29.7

9" thru 16" = 24 gauge 40" 13.6 16.6 19.5 25.4 31.3

18" thru 24" = 22 gauge 42" 14.3 17.4 20.5 26.7 32.9

26" thru 32" = 20 gauge 44" 18.2 21.5 27.9 34.4

34" thru 60" = 18 gauge 46" 19.0 22.4 29.2 36.0

48" 19.9 23.4 30.5 37.5

Above Ground PCD Gauges 50" 20.7 24.4 31.7 39.1

4" thru 12" = 26 gauge 52" 21.5 25.4 33.0 40.7

13" thru 18" = 24 gauge 54" 22.4 26.3 34.3 42.2

20" thru 24" = 22 gauge 56" 23.2 27.3 35.8 43.8

26" thru 36" = 20 gauge 58" 24.0 28.3 36.8 45.4

38" thru 60" = 18 gauge 60" 24.8 29.3 38.1 46.9

(PCD weights correspond with galvanized chart)

Spiral Duct Dimensional Guide • Issued: January 2011

Fittings are fabricated from hot-dipped galvanized steel FITTINGS

in gauges that meet or exceed 2005 SMACNA standards. DIAMETER MINIMUM GAUGE

(See table at right)

All fittings are male size for slip fit into standard spiral

ducts with the exception of CF couplings or specified

“Female” connections.

Consult Factory for information on High Pressure, welded

fittings.

DIAMETER

Part Number = CN + “A” Part Number = CF + “A” Part Number = EC + “A”

Coupling – Male Coupling – Female (Pipe Size) End Cap - Male

(Slip Fits Into Pipe) (Slip Fits Into Pipe)

Spiral Duct Dimensional Guide • Issued: January 2011

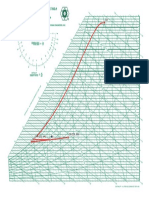

Available Seams

• “Maple Wood” V-Groove

– See Chart to right

• Standard V-Groove

• 1/2” Offset

• Gore Lock

– Note Radius will be 1.0 x A minimum

Part Number = AN30 + “A” Part Number = AN + “A” Part Number = AN60 + “A” Part Number = EW + “A”

30 Deg Angle 45 Deg Angle 60 Deg Angle 90 Deg Angle

Centerline Radius (standard) = 11/2 x A

(Any throat radius required for the job is available)

Part Number = AL30 + “A” Part Number = AL + “A” Part Number = EL60 + “A” Part Number = EL + “A”

30 Deg Angle 45 Deg Angle 60 Deg Angle 90 Deg Angle

Part Number = ALSW + “A” Part Number = ELSW + “A”

45 Deg Angle 1.5CL 90 Deg Elbow 1.5CL

Spiral Duct Dimensional Guide • Issued: January 2011

Part Number = WY + “A” x “B” x “C” Part Number = WYRB + “A” x “B” x “C” Part Number = WYTR + “A” x “B” x “C”

45 Deg Lateral Wye 45 Deg Lateral Wye with Reducing Body 45 Deg Lateral Wye with Reducer

L = (1.414 x C) + 4” L = (1.414 x C) + 4” L = (1.414 x C) + 4” plus LR = A–B (4”MIN)

Spiral Duct Dimensional Guide • Issued: January 2011

Part Number = WX + “A” x “B” x “C” x “D” Part Number = WXRB + “A” x “B” x “C” x “D” Part Number = WXTR + “A” x “B” x “C” x “D”

45 Deg Lateral Cross 45 Deg Lateral Cross with Reducing Body 45 Deg Lateral Cross with Tapered Reducer

L = 1.414 x (Larger of “C” or “D”) + 4" L = 1.414 x (Larger of “C” or “D”) + 4" L = 1.414 x (Larger of “C” or “D”) + 4" plus LR = A-B (4" MIN.)

Part Number = TC + “A” x “B” x “C” Part Number = TCRB + “A” x “B” x “C” Part Number = TCTR + “A” x “B” x “C”

90 Deg Conical Tee 90 Deg Conical Tee with Reducing Body 90 Deg Conical Tee with Tapered Reducer

L = C + 4" L = C + 4" L = C + 4" plus LR = A-B (4" MIN.)

Part Number = CX + “A” x “B” x “C” x “D” Part Number = CXRB + “A” x “B” x “C” x “D” Part Number = CXTR + “A” x “B” x “C” x “D”

90 Deg Conical Cross 90 Deg Conical Cross with Reducing Body 90 Deg Conical Cross with Tapered Reducer

L = Larger of “C” or “D” + 4" L = Larger of “C” or “D” + 4" L = Larger of “C” or “D” + 4" plus LR + A-B (4" MIN.)

Spiral Duct Dimensional Guide • Issued: January 2011

Part Number = TSRB + “A” x “B” x “C”

90 Deg Shoe Tee with Reducing Body

L = C + X + 2” (See Below Chart)

Spiral Duct Dimensional Guide • Issued: January 2011

Bellmouth Part Number = BG + Diameter

4” thru 24” Available in 1” Increments Part Number = SRE + “A” x “B” Sizes available 3” thru 24”

26” thru 48” Available in 2” Increments Eccentric Shown Cast Aluminum Body

50” thru 60” Short Radius in Bellmouth When order please specify Eccentric

Available in 2” Increments or Concentric

Diameter No. Of Vanes

3” thru 4” 1

5” thru 12” 2

13” thru 20” 3

21” thru 36” 4

37” thru 60” 5

Diameter X

3” thru 20” 2”

Part Number = EV + “A” 21” thru 36” 4”

Part Number = ELHT + “A” x “B” 90 Deg Mitered Elbow with Vanes 37” thru 60” 6”

3 – Piece 90 Deg Elbow with Heel Tap Part Number without Vanes = EM

Variable Throat Radius

Part Number = WT + “A” x “B” x “C”

True Wye Part Number = SC + “A” x “B” x “C”

Split Crotch Bullhead Tee

Spiral Duct Dimensional Guide • Issued: January 2011

Part Number = PL + “A” x “B” x “H”

Plenum Box

Spiral Duct Dimensional Guide • Issued: January 2011

AccuFlangeTM are available in Glavanized, Paintable Galvanized, PCD, Stainless Steel and Aluminum materials.

AccuFlangeTM are products of Spinfinity, Pacific, WA, USA

*QUICKDRAWTM closure rings are also available

Spiral Duct Dimensional Guide • Issued: January 2011

Spiral Duct Dimensional Guide • Issued: January 2011

Spiral Duct Dimensional Guide • Issued: January 2011

4x1 PCD (for below ground air systems) has a

4 mil polyvinyl coating on the outside to provide

protection against corrosion from soil.

4x4 PCD (for above or below ground fume exhaust)

has a 4 mil polyvinyl coating on both inside and

outside of duct.

The use of PCD Ductwork eliminates the need for

encasing in concrete, propping up or tying down.

By combining the strength of steel and the

chemical inertness of plastic, PCD Ductwork is both

lightweight, and corrosion resistant.

How PCD is made

The PCD manufacturing process begins with:

1. Prime, hot-dipped, G-60 galvanized steel

PCD is a rugged, durable material that will take that is cleaned and fire treated.

ordinary handling and shipping without damage.

2. A special epoxy primer is bonded to both

It can be cut and formed with regular sheet metal

sides of the metal.

equipment and tools with no harm to the coating.

Even the largest diameter ducts are easily cut with 3. A 4-mil polyvinyl coating is heat-fused to

portable metal-cutting saws. one side (4x1) or both sides (4x4).All joints

should be wrapped to prevent air leakage

Use stainless steel sheet metal screws every 6” to and to keep dirt and sand out of the duct

connect ducts and fittings. system. PCD Tape is recommended as

it is ideal for the usage. It has superior

Ends of fittings are made to slip inside duct unless adhesive qualities, even in extremely hot

otherwise specified by our customer. or extremely cold weather.

All PCD fittings are accurately sized and fabricated

with stainless steel fasteners.

Also available is PCD Duct Sealer. This can be

applied from 1 Gallon (hand or brush applied) or

10.5oz tubes by beading. Approximate coverage is

375 lin. Ft. per gal. @ ¼” bead.

If the PCD coating is scratched or scarred so as to

expose the base metal, apply PCD touch up spray

paint, PCD sealer or PCD tape to cover area. Spray

paint is for touch up purposes only.

Spiral Duct Dimensional Guide • Issued: January 2011

Install Above Water Table:

• The PCD Duct System is not designed to be

waterproof. Installation must be made safely

above the water table. Ducts should not be placed

where water infiltration may occur.

Load Specifications:

Depth: • Non Corrugated Spiral Seam Pipe

• The top of the duct can extend into the cement, – 4” thru 8” = 400 lbs. / Linear Ft.

leaving a minimum of 2 1/2” of cement above the – 9” thru 12” = 600 lbs. / Linear Ft.

top, or the duct can be placed well below the • Corrugated Spiral Seam Pipe

cement. However, the duct should not be placed so – 14” thru 36” = 1800 lbs. / Linear Ft.

deep that the weight on it will exceed the load – All ducts 14” and larger in diameter will

capacities. be corrugated for extra strength.

• Where deeper burial or heavier loading is required;

Trenching and Backfill: duct gauges can be increased per customer request.

• After the excavation has been made, no special Additional bracing can be used to strengthen the duct.

bedding need to used for PCD Duct. It can rest

right on the ground, or be set in sand or light Durability:

aggregate. Pea gravel or sand (or the material • PCD needs no protection in earth from sand,

taken from the trench, if equivalent) can be used to concrete or plaster. It is not affected by the minerals

backfill. Spread the backfill material evenly around and salts found in normal backfilling materials.

the duct making sure there is no gaps, and PCD has also passed thousands of hours of

tamping by hand in place is a recommended practice. accelerated salt spray, humidity cabinet and water

• No cement is needed to fill around the duct, since immersion tests with no loss of adhesion or

the tamped fill holds the duct in place and the corrosion resistance.

plastic coating prevents ground corrosion of the

galvanized steel. This plastic coating is resistant to Specifications for PCD Underground Duct:

any minerals or salts that may be in the backfill soil. • All ducts shall be PCD formed into spiral tubes. All

PCD Duct will not “float” when backfilled to within couplings and fittings shall be factory fabicated

2” of the top of the duct. Concrete is then poured using PCD material and stainless steel accessories.

so that the “tie-down”, work is eliminated. It is • All joints and connections shall be stainless steel

recommended that proper compaction occur at no screw fasteners and taped in accordance with

more than 12” intervals. manufacturer’s recommendations to assure an air-

• CAUTION: tight system.

When backfilling or grading, care should be taken not • Any damage to the coating shall be repaired with

to dump or push heavy loads directly on the duct, PCD Touch up paint, sealer and tape as necessary.

nor should heavy equipment be allowed to run over

the duct.

Large Diameter Ducts

• Special care should be taken with large diameter

ducts. Backfilling and tamping should be done

without damage to the ducts. Temporary bracing

can be used inside the ducts or angle rings can be

permanently installed on the ducts to provide

strength and rigidity. Rings should be primed and

coated with PCD paint if not stainless steel.

Spiral Duct Dimensional Guide • Issued: January 2011

Rectangular Duct Systems Spiral Pipe Systems

Full Length Duct: Standard Length Spiral Seam Pipe:

• TDF construction with stainless steel • 10” sections

corners and accessories. Finished length

will be 56”. Short Length Spiral Seam Pipe:

• S&D construction with PCD cleats. • Available upon request.

Short Duct & Fittings: Spiral Fittings:

• TDF construction with stainless steel • All fittings will be factory fabricated with

corners and accessories. stainless steel rivets and fasteners.

• S&D construction with PCD cleats. • All fitting seams shall be caulked on the

inside with PCD sealer.

PCD Ductmate/Ward flange available upon request • All fittings will be slip fit unless otherwise

specified.

Spiral Duct Dimensional Guide • Issued: January 2011

4x1 PCD Connection of Duct

• Is used for underground systems, it has • PCD is connected in the same manner as

the 4-mil polyvinyl coating on the galvanized systems.

outside for protection from the soil.

• All fittings are made to slip fit into the

• At times SET Duct MFG, Inc. will substitute spiral seam pipe.

4x4 material in place of 4x1.

• Pipe to Pipe will require a coupling.

4x4 PCD

• Is predominantly used in Fume Exhaust

systems but can be used in underground

systems.

• Great for pool applications and other

environments with heavy chlorine

concentrations.

Spiral Duct Dimensional Guide • Issued: January 2011

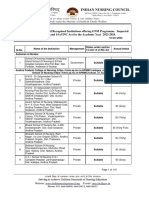

JOB NAME JOB NUMBER PO NUMBER DATE

Qty Liner Qty Liner

1" 1/2" No 1" 1/2" No

Qty Liner Qty Liner

1" 1/2" No 1" 1/2" No

Qty Liner Qty Liner

1" 1/2" No 1" 1/2" No

Spiral Duct Dimensional Guide • Issued: January 2011

Spiral Duct Dimensional Guide • Issued: January 2011

SET Duct Manufacturing, Inc.

313.491.4380

313.491.4381 fax

www.setductmanufacturing.com

M FOR QUA

EA LITY

T

A

SET RY

SER

Duct Manufacturing, Inc.

ST

VI N

G

DU

TH I N

E NE S O F

ED

R

You might also like

- Install and Maintain Modular AHUDocument35 pagesInstall and Maintain Modular AHUAngga HardiyantomoNo ratings yet

- ADC Flexible Duct Performance & Installation Standards. Installation Guidelines. 4th Ed.Document8 pagesADC Flexible Duct Performance & Installation Standards. Installation Guidelines. 4th Ed.John EvansNo ratings yet

- Prima Usaha ACMV Duct Sizing Table 2017 LockedDocument1 pagePrima Usaha ACMV Duct Sizing Table 2017 LockedShaikh Tauseef100% (2)

- MepDocument3 pagesMepGiftson ImmanuelNo ratings yet

- Compressor Capacity Calculations PDFDocument2 pagesCompressor Capacity Calculations PDFNaqqash SajidNo ratings yet

- Pacv D PDFDocument61 pagesPacv D PDFUmen AryanNo ratings yet

- Commercial Kitchen Hood Design Guide 1 031504Document21 pagesCommercial Kitchen Hood Design Guide 1 031504Hwee Peng YeoNo ratings yet

- Capstone PosterDocument1 pageCapstone Posterapi-538849894No ratings yet

- Monetizing Judgments DatasheetDocument9 pagesMonetizing Judgments DatasheetJohnWilliams100% (4)

- Techno Economic Study of Fertiliser PlantDocument56 pagesTechno Economic Study of Fertiliser PlantMohan PNo ratings yet

- Chapter 1 ReviewDocument6 pagesChapter 1 ReviewSolyKalNo ratings yet

- Duct Design For "Super" SupermarketDocument47 pagesDuct Design For "Super" Supermarketkevin_thian_1100% (4)

- Dehumidification Equipment Advance ASHRAE Journal PDFDocument6 pagesDehumidification Equipment Advance ASHRAE Journal PDFThomás ArévaloNo ratings yet

- Chapter One - Introduction to Air Conditioning SystemsDocument273 pagesChapter One - Introduction to Air Conditioning SystemsliliNo ratings yet

- Heat Gain From Electrical and Control Equipment in Industrial Plants, Part II, ASHRAE Research Project RP-1395Document4 pagesHeat Gain From Electrical and Control Equipment in Industrial Plants, Part II, ASHRAE Research Project RP-1395Michael LagundinoNo ratings yet

- Ductwork Order FormDocument5 pagesDuctwork Order FormShaun SullivanNo ratings yet

- ASHRAE Journal - VAV System Duct Main DesignDocument5 pagesASHRAE Journal - VAV System Duct Main DesignJhoNo ratings yet

- Part E - 2 - (HVAC) Engineering DesignDocument69 pagesPart E - 2 - (HVAC) Engineering Designkeya2020No ratings yet

- Heat Load Estimation E20 FormDocument1 pageHeat Load Estimation E20 Formkahwooi88No ratings yet

- Fahu 2 (Te)Document15 pagesFahu 2 (Te)Abdo RagabNo ratings yet

- Duct DesignDocument38 pagesDuct Designwado11No ratings yet

- Design Course Basic - Duct Design 1Document30 pagesDesign Course Basic - Duct Design 1Ali Aimran100% (1)

- District Cooling Systems ExplainedDocument7 pagesDistrict Cooling Systems ExplainedMarzook50% (2)

- PalDuct Phenolic Datasheet MEDocument2 pagesPalDuct Phenolic Datasheet MERamadan RashadNo ratings yet

- Basics of Duct DesignDocument2 pagesBasics of Duct DesignApurv Goyal100% (1)

- ASHRAE Psychrometric ChartDocument8 pagesASHRAE Psychrometric ChartTam Jun HuiNo ratings yet

- ACH580 Drives For HVAC Catalog 3AUA0000186691 RevEDocument36 pagesACH580 Drives For HVAC Catalog 3AUA0000186691 RevESalaar AnsarNo ratings yet

- Fan CurvesDocument13 pagesFan CurvesgravatomNo ratings yet

- Axial AXBDocument20 pagesAxial AXBhoseyliauNo ratings yet

- What Is The Basis For Fan SelectionDocument3 pagesWhat Is The Basis For Fan SelectionsmcsamindaNo ratings yet

- Fume Exhaust Duct Catalog 10 12 8 PDFDocument86 pagesFume Exhaust Duct Catalog 10 12 8 PDFJonathan Arboleda GenesNo ratings yet

- Fan Static Head Calculation SheetDocument1 pageFan Static Head Calculation SheetAhmad Samir ElnazerNo ratings yet

- Product Application Guide: Multiple F An Systems - F Ans in Series and ParallelDocument4 pagesProduct Application Guide: Multiple F An Systems - F Ans in Series and ParallelgonvicNo ratings yet

- PVC Duct Installation GuideDocument10 pagesPVC Duct Installation GuidecitramuaraNo ratings yet

- State of The Art Atrium Smoke ControlDocument12 pagesState of The Art Atrium Smoke ControlBasil OguakaNo ratings yet

- Caryaire Ahu CatalogueDocument11 pagesCaryaire Ahu CatalogueAzher ANo ratings yet

- CO2 Sensor RoomDocument8 pagesCO2 Sensor RoomTrần Khắc ĐộNo ratings yet

- Duct Design: ME 425 - Air Distribution & ASHRAE Outlet SelectionDocument9 pagesDuct Design: ME 425 - Air Distribution & ASHRAE Outlet SelectionAbul ShaikhNo ratings yet

- 2020 AHR Expo - FEI - FINALDocument61 pages2020 AHR Expo - FEI - FINALReinel OrjuelaNo ratings yet

- Ashrae ChartDocument1 pageAshrae Chartalone160162lNo ratings yet

- Air System Sizing Summary For 0008 SMOKING ROOMDocument1 pageAir System Sizing Summary For 0008 SMOKING ROOMSaiful Imran Mohamed YusofNo ratings yet

- Selecting the Right AHUDocument24 pagesSelecting the Right AHUrahulNo ratings yet

- Cyclone SeparatorDocument1 pageCyclone SeparatordadNo ratings yet

- High Velocity Duct Design Tips by TraneDocument50 pagesHigh Velocity Duct Design Tips by TraneInventor SolidworksNo ratings yet

- Rules of Thumb for Duct System DesignDocument1 pageRules of Thumb for Duct System DesignImtiaz AhmedNo ratings yet

- HVAC-Fan & Blowers Selection PDFDocument59 pagesHVAC-Fan & Blowers Selection PDFAaron AngNo ratings yet

- Psychrometric ChartDocument1 pagePsychrometric ChartsudirmanpriyoNo ratings yet

- Air Duct Cleaning Equipment Accessories For Rent/Sale in Middle East - Air-Care Middle EastDocument33 pagesAir Duct Cleaning Equipment Accessories For Rent/Sale in Middle East - Air-Care Middle EastAir-Care Middle EastNo ratings yet

- Kitchen Ventilation Systems PDFDocument69 pagesKitchen Ventilation Systems PDFAzwan AwalludinNo ratings yet

- Fan Fundamentals - Greenheck (May2005)Document24 pagesFan Fundamentals - Greenheck (May2005)jagdishgharoteNo ratings yet

- Air Distribution Engg GuideDocument8 pagesAir Distribution Engg GuideNiong DavidNo ratings yet

- Induction Course for M&E EngineersDocument155 pagesInduction Course for M&E EngineersKHA120096 StudentNo ratings yet

- AC V For Fast Food RestaurantsDocument4 pagesAC V For Fast Food Restaurantselijah namomoNo ratings yet

- Stair Pressurization - Allied ConsultantDocument4 pagesStair Pressurization - Allied ConsultantTiefSeeNo ratings yet

- Duct CalculationsDocument38 pagesDuct CalculationsDilnesa EjiguNo ratings yet

- BACK TO BASICS: DUCT DESIGNDocument17 pagesBACK TO BASICS: DUCT DESIGNAntonio LebrunNo ratings yet

- HVAC Systems Design References GuideDocument4 pagesHVAC Systems Design References GuideFsNo ratings yet

- Sizing DuctsDocument41 pagesSizing DuctsSergio Semm100% (1)

- Ashrae ChartDocument1 pageAshrae ChartHamza FayyazNo ratings yet

- Heat Wheel Technical HandbookDocument29 pagesHeat Wheel Technical Handbooksripriya01No ratings yet

- Holyoake Engineering DataDocument24 pagesHolyoake Engineering DataSantiago J. ramos jr100% (1)

- Uploads Category - Eng - Manuals MANU - A91A0CCF115592B9Application Engineering Manual 1 PDFDocument63 pagesUploads Category - Eng - Manuals MANU - A91A0CCF115592B9Application Engineering Manual 1 PDFprabhanshu241991No ratings yet

- Fire Safety Products Ventilation SystemsDocument14 pagesFire Safety Products Ventilation SystemsirfanNo ratings yet

- Stalargo Stainless Steel I-Beams: For Demanding ApplicationsDocument4 pagesStalargo Stainless Steel I-Beams: For Demanding ApplicationsTushar PatilNo ratings yet

- Conical StrainerDocument2 pagesConical StrainernguyennhatbaoNo ratings yet

- LT0099 19Document7 pagesLT0099 19Jhampier Sánchez ZambranoNo ratings yet

- 12HF InstallManual Ver8 WebDocument6 pages12HF InstallManual Ver8 WebUmen AryanNo ratings yet

- Technical Data Sheet LM24A-SRDocument3 pagesTechnical Data Sheet LM24A-SRUmen AryanNo ratings yet

- Cata - Flange ANSI - pdf1299758077 PDFDocument48 pagesCata - Flange ANSI - pdf1299758077 PDFNikhil PanchalNo ratings yet

- Homeowner's Operating Manual: Must Be Installed by A Trained, Experienced TechnicianDocument36 pagesHomeowner's Operating Manual: Must Be Installed by A Trained, Experienced TechnicianUmen AryanNo ratings yet

- Smacna Guide To Cost RecoveryDocument96 pagesSmacna Guide To Cost RecoveryUmen AryanNo ratings yet

- Honeywell - Thermostat With Motion SensorDocument12 pagesHoneywell - Thermostat With Motion SensorUmen AryanNo ratings yet

- Gulf Cool Therm Polyisocyanurate Insulation Products GuideDocument12 pagesGulf Cool Therm Polyisocyanurate Insulation Products GuideUmen AryanNo ratings yet

- FireandLifeSafetyConceptRevB PDFDocument23 pagesFireandLifeSafetyConceptRevB PDFUmen AryanNo ratings yet

- Zamil Paxnew Series PDFDocument108 pagesZamil Paxnew Series PDFUmen AryanNo ratings yet

- Key HVAC Design ConceptsDocument45 pagesKey HVAC Design ConceptsSatyam BhardwajNo ratings yet

- Lubricants 05 00042Document11 pagesLubricants 05 00042Umen AryanNo ratings yet

- Vapor Pressure and Density NOVEC 1230Document11 pagesVapor Pressure and Density NOVEC 1230maverick2011No ratings yet

- Cmco 2012 Technical Catalogue 30 07804Document1 pageCmco 2012 Technical Catalogue 30 07804Umen AryanNo ratings yet

- WFF - Flanges SpecDocument6 pagesWFF - Flanges SpecKailas NimbalkarNo ratings yet

- Gah 1 1 A A - 1564464910.3406Document2 pagesGah 1 1 A A - 1564464910.3406Umen AryanNo ratings yet

- Thermalcomfort PDFDocument11 pagesThermalcomfort PDFHarsh WadhwaNo ratings yet

- BE - Service Manual P Series 18K24K - 220V PDFDocument72 pagesBE - Service Manual P Series 18K24K - 220V PDFUmen AryanNo ratings yet

- Vapor Pressure and Density NOVEC 1230Document11 pagesVapor Pressure and Density NOVEC 1230maverick2011No ratings yet

- Console Installation ManualDocument30 pagesConsole Installation ManualUmen AryanNo ratings yet

- TRO24-EXT1-Ext Setpnt-140922-ESADocument16 pagesTRO24-EXT1-Ext Setpnt-140922-ESAUmen AryanNo ratings yet

- STULZ Ultrasonic Humidification EC Fan Retrofit Kit BrochureDocument8 pagesSTULZ Ultrasonic Humidification EC Fan Retrofit Kit BrochureUmen AryanNo ratings yet

- IOM 19 SeriesDocument6 pagesIOM 19 SeriesUmen AryanNo ratings yet

- Cat CPCA 06 SRV2017 03 PDFDocument48 pagesCat CPCA 06 SRV2017 03 PDFUmen AryanNo ratings yet

- Diffusers Eng Guidelines2013Document34 pagesDiffusers Eng Guidelines2013Vivek P PNo ratings yet

- ACRC301 Operations and Maintance Manual PDFDocument56 pagesACRC301 Operations and Maintance Manual PDFMcciuken DanielNo ratings yet

- Hvac Product Selection GuideDocument24 pagesHvac Product Selection GuideShadi AlashkarNo ratings yet

- Balancing BasicsDocument14 pagesBalancing BasicspbharrisNo ratings yet

- 9 Tactics of Lifelong GeniusDocument4 pages9 Tactics of Lifelong GeniusApurv MehtaNo ratings yet

- Snorkel: Rapid Training Data Creation With Weak SupervisionDocument17 pagesSnorkel: Rapid Training Data Creation With Weak SupervisionStephane MysonaNo ratings yet

- Fuellas Vs CadanoDocument4 pagesFuellas Vs CadanoMutyaAlmodienteCocjinNo ratings yet

- Here The Whole Time ExcerptDocument18 pagesHere The Whole Time ExcerptI Read YA100% (1)

- Saint Aquinas and Mercantilism School of ThoughtsDocument11 pagesSaint Aquinas and Mercantilism School of ThoughtsKatunga MwiyaNo ratings yet

- E Thesis Uas DharwadDocument5 pagesE Thesis Uas DharwadLori Head100% (1)

- Senguntha KshatriyaDocument34 pagesSenguntha Kshatriyabogar marabuNo ratings yet

- ManpowerGroup Total Employment Management Solution PDFDocument1 pageManpowerGroup Total Employment Management Solution PDFAMERICO SANTIAGONo ratings yet

- Humanistic & Behavioural Approches To Counseling: Lekshmi Priya.K.B 2 MSC Applied PsychologyDocument49 pagesHumanistic & Behavioural Approches To Counseling: Lekshmi Priya.K.B 2 MSC Applied PsychologyAnand ChoubeyNo ratings yet

- Unit 10 Working DrawingsDocument17 pagesUnit 10 Working Drawingsomoak2015No ratings yet

- STQ Issue 4 PDFDocument119 pagesSTQ Issue 4 PDFSiddhartha SinghNo ratings yet

- Cutaneous Abscess Furuncles and CarbuclesDocument25 pagesCutaneous Abscess Furuncles and Carbuclesazmmatgowher_1219266No ratings yet

- HR 111 - Pal RetrenchmentDocument2 pagesHR 111 - Pal RetrenchmentanakpawispartylistNo ratings yet

- PV Launching Digital Wallet AccountDocument1 pagePV Launching Digital Wallet Accountbet47No ratings yet

- Question Bank (ASP)Document3 pagesQuestion Bank (ASP)Gurleen BabraNo ratings yet

- GNM 10102023Document118 pagesGNM 10102023mohammedfz19999No ratings yet

- Chronic Renal FailureDocument1 pageChronic Renal Failurejj_cuttingedges100% (2)

- How To Build A Shed With A Slanted Roof Step-by-Step GuideDocument39 pagesHow To Build A Shed With A Slanted Roof Step-by-Step GuideFederico BarberisNo ratings yet

- англійська 11 final altered PDFDocument192 pagesанглійська 11 final altered PDFАнна НазаренкоNo ratings yet

- Post Graduate Medical (Government Quota) Course Session:2021 - 2022 List of Candidates Allotted On - 04.03.2022 (Round 2)Document104 pagesPost Graduate Medical (Government Quota) Course Session:2021 - 2022 List of Candidates Allotted On - 04.03.2022 (Round 2)Aravind RaviNo ratings yet

- Volume 47, Issue 41, October 7, 2016Document48 pagesVolume 47, Issue 41, October 7, 2016BladeNo ratings yet

- JVC Mini DV and S-VHS Deck Instruction Sheet: I. Capturing FootageDocument3 pagesJVC Mini DV and S-VHS Deck Instruction Sheet: I. Capturing Footagecabonedu0340No ratings yet

- CIR vs. Primetown Property GroupDocument2 pagesCIR vs. Primetown Property GroupElaine Belle OgayonNo ratings yet

- Madbarz Routines Plan: Strength - AdvancedDocument18 pagesMadbarz Routines Plan: Strength - AdvancedJuan Sebastian AnguloNo ratings yet

- On 1 October Bland LTD Opened A Plant For MakingDocument2 pagesOn 1 October Bland LTD Opened A Plant For MakingCharlotteNo ratings yet

- Water and Sanitation CrisisDocument4 pagesWater and Sanitation CrisisKarl EstenzoNo ratings yet