Professional Documents

Culture Documents

Executive Summary

Uploaded by

Divyashini MohanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Executive Summary

Uploaded by

Divyashini MohanCopyright:

Available Formats

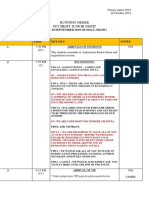

EXECUTIVE SUMMARY

The main objective we are doing this project is to produce ethylene. Our company

needs to produce 99.9% purity of ethylene from raw material given which is sweet natural

gas. Natural gas consists of some components, which are methane, ethane, nitrogen, water,

carbon dioxide and hydrogen.

To produce ethylene, the feed or raw material which is natural gas need to go

through some of the process selection that have been chosen. In our production, ethylene is

produced from natural gas through the oxidative coupling of methane (OCM). So firstly,

3192.76 kmol/hr of natural gas which equivalent to 1 million ton per year will enter the

OCM reactor together with the oxygen from the air separation unit (ASU). Then it will go to

the next unit process which is cooler and then isothermal compressor followed by acid gas

removal which consists of amine absorber and amine regenerator.

These units need amine as a solvent to separate dissolved gases from the main

stream. The solvent that we used are monoethanolamine (MEA) which functions to separate

carbon dioxide partially from the main stream. Next, dryer is designed to increase the

production of ethylene by removing 100% composition of water. After dryer, demethanizer

is used to heat up the inlet gas feed just enough to release methane between the others.

Then, C2 splitter to split between C2 compounds such as ethane and ethylene to increase

the purification of ethylene produce and the purify of ethylene that we get at the end of our

process is 99.96%. Finally, we need to change the ethylene product from gas to liquid. So,

we used condenser for some reasons.

Furthermore, a recycle stream is also introduced to our plant in order to increase the

production of ethylene and decrease the waste produced by the company. The bottom

stream from the demethanizer is recycled back to the reactor. Purging is done to prevent

the accumulation inside the reactor. The recycle stream increased the final yield from

1.439% to 2.975%.

In this project, natural gas that we used in producing ethylene is directly buy from

supplier and the average price is around RM 574.835 per ton. For the selling price, the

average price is RM 5342.48 per ton and our target profit for the year 2020 is RM

19,501,776.41.

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5795)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Lecture 3 - Process SafetyDocument79 pagesLecture 3 - Process SafetyDivyashini MohanNo ratings yet

- Example of Event Running Order With Emcee ScriptDocument7 pagesExample of Event Running Order With Emcee ScriptDivyashini MohanNo ratings yet

- Safety Concepts: Dr. Mus'ab Abdul RazakDocument34 pagesSafety Concepts: Dr. Mus'ab Abdul RazakDivyashini MohanNo ratings yet

- Lecture 5 - Industrial HygieneDocument50 pagesLecture 5 - Industrial HygieneDivyashini MohanNo ratings yet

- Air Pollution: Lecture Week 8 ECH3501 Pollution Control EngineeringDocument59 pagesAir Pollution: Lecture Week 8 ECH3501 Pollution Control EngineeringDivyashini MohanNo ratings yet

- 7 Wastewater Treatment Systems Week 7Document41 pages7 Wastewater Treatment Systems Week 7Divyashini MohanNo ratings yet

- 9 Air Pollution Week 9Document44 pages9 Air Pollution Week 9Divyashini MohanNo ratings yet

- Edible Water PodsDocument2 pagesEdible Water PodsDivyashini MohanNo ratings yet

- 6 Wastewater Treatment Systems Week 6Document46 pages6 Wastewater Treatment Systems Week 6Divyashini MohanNo ratings yet

- 12 Hazardous Waste Management Week 12Document62 pages12 Hazardous Waste Management Week 12Divyashini MohanNo ratings yet

- 3 Water Treatment Lecture Week 3Document28 pages3 Water Treatment Lecture Week 3Divyashini MohanNo ratings yet

- Types of Biomolecules Proteins, Carbohydrates, Fats, LipidsDocument33 pagesTypes of Biomolecules Proteins, Carbohydrates, Fats, LipidsDivyashini MohanNo ratings yet

- Lab 11&12Document9 pagesLab 11&12Divyashini MohanNo ratings yet

- Chapter 3 SterilizationDocument44 pagesChapter 3 SterilizationDivyashini MohanNo ratings yet

- Chapter 1 Basic Biology For Engineer: Microbial Diversity Taxonomy Cell Naming Gram StainDocument42 pagesChapter 1 Basic Biology For Engineer: Microbial Diversity Taxonomy Cell Naming Gram StainDivyashini MohanNo ratings yet

- Lecture 2b - Accident ConceptDocument36 pagesLecture 2b - Accident ConceptDivyashini MohanNo ratings yet

- Complete The Task During Your Designated Lab SessionDocument1 pageComplete The Task During Your Designated Lab SessionDivyashini MohanNo ratings yet

- Problem Set 2 PDFDocument2 pagesProblem Set 2 PDFDivyashini MohanNo ratings yet

- Exercise (Sedimentation) PDFDocument20 pagesExercise (Sedimentation) PDFDivyashini MohanNo ratings yet

- Equipment DesignDocument11 pagesEquipment DesignDivyashini MohanNo ratings yet

- Running Order For Chemy JuniorDocument7 pagesRunning Order For Chemy JuniorDivyashini MohanNo ratings yet

- Type of ControllerDocument2 pagesType of ControllerDivyashini MohanNo ratings yet