Professional Documents

Culture Documents

Uji Moisture Content

Uploaded by

Suryadi WibowoOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Uji Moisture Content

Uploaded by

Suryadi WibowoCopyright:

Available Formats

Mineral Ore Moisture of Mineral Ore

Volumetric titration (indirect method)by

Karl Fischer Moisture Titrator

JIS M 8211 ISO 7335

Standard JIS K 0113 ISO 760

ASTM E 203 Hydranal manual

1.Abstract

Moisture titration using Karl Fischer reagent is popularly practiced water

determination worldwide as the most reliable method. The procedure is adopted in

many official standards as test method specified in ISO, ASTM, DIN, BS and JIS.

Mineral ores are hard to dissolve in Karl Fischer solvent, and therefore, the indirect

method using an oven to evaporate moisture in sample is generally practiced. The

test sample is first heated in the oven, and the evaporated moisture is transferred to

measuring cell by carrier gas where moisture titration is performed according to JIS

M 8211-1995 Standard Test Method by Karl Fischer titration.

The combine water termed in JIS means water evaporation from iron ore between

105°C and 950°C, however, the oven temperature is adjusted appropriate to the

sample in present test.

For indirect method, the extracting solvent ME from Riedel de Haen is used.

Test samples measured this time are as follows:

Iron ore, Manganese ore, Rock, Kaolin, Hornblende, Black mica

2.Reference

1) JIS M 8211-1995 Test Method for Iron ore -Combine water

2) JIS K 0113-2005: Standard Test Method by Potentiometric, Amperometrtic,

Coulometric and Karl Fischer Titration

3) ASTM E 203-96 Standard Test Method for Water Using Volumetric Karl Fischer

Titration

4) ISO 760:1978 Determination of Water-Karl Fischer method (General method)

5) ISO 7335:1987 Iron ores -- Determination of combined water content

-- Karl Fischer titrimetric method

6) Hydranal manual from Riedel de Haen

3.Cautions in measurement

1) In order to refrain from the effect of ambient humidity, the test must be

conducted in a well air-conditioned room.

2) Since water coexistence varies from test sample, select sample size and oven

temperature appropriate to each sample piece.

3) Obtain the factor of Karl Fischer reagent using the solvent in advance.

KVX-01551 Ver.01 1/4

4. Post-measurement care

After the reagent in flask is drained out and the electrode is cleaned, keep the

electrode in titration flask filled with extracting medium.

5.Test equipment

Main unit: Karl Fischer moisture titration volumetric system

Electrode: Twin platinum electrode for KF titration

Option : Water evaporator (for high heat, mineral ore)

6.Reagent

Reagent : Hydranal Composit 5 (Riedel de Haen)

Solvent : Extracting medium ME (for gas)(Hayashi Chemicals)

7.Measurement procedure

The following test proceeds regardless of water of adhesion or combine water in

sample.

-Preparation-

1) Prepare approximately 50mL ME solvent in the titration cell.

2) Dehydrate the measuring cell by performing pretitration in advance.

3) Set the oven to a temperature appropriate to the sample and maintain the

temperature.

4) Purge the evaporating system with carrier gas.

―Measurement―

1) Start back purge for 180 seconds and cell purge for 120 seconds manually.

2) Take approximately 0.1~1g sample with sampler.

3) Weigh the sampler on balance of which resolution is to the nearest 0.1mg.

4) After cell purge, press Start key of titrator.

5) Transfer the sample onto the boat in heating unit through sample inlet.

6) Press Start key to move the boat into the oven. Again press Start key of titrator

to start titration.

7) Weigh the sampler after the sample is discharged.

8) Enter Wt1 with the weight of above 3),and Wt2 with 7).

9) After titration, obtain water content from titration volume.

8.Formula

Water content ( % ) = (( Data × F - Blank ) / ( Wt1 - Wt2 ) ) × 0.1

Data : Titration volume ( mL )

F : Factor of titrant

Blank : Blank level ( mg )

Wt1 : Sample + sampler ( g )

Wt2 : Weight of empty sampler ( g )

KVX-01551 Ver.01 2/4

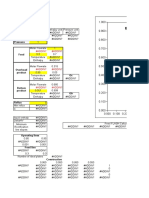

9. Example of measurement

-Titration parameter-

MKA-610 MKA-520 MKS-500

Method No. 1 [Titration] [Titration]

Method 1 Method Direct

[Titration] Titr Mode Normal Titr.Speed 3

Titr.mode Normal Titr Buret No. 1 End Time 30 s

t(stir) 0s End Time 30 s Final Vol. 0.01 mL

t(wait) 10 s Final Vol. 0.01 mL Detector Mode Normal

t(max) 1800 s Titr.Speed 3 t(stir) 0s

t(interval) 0s Detector Mode 1 t(max) 1800 s

Max.volume 10 mL t(stir) 0s Drift Titr. On

Titr.bur.No. 1 t(wait) 10 s Max.Volume 10 mL

Dose mode Off t(max) 1800 s

Drift Titr On

[Control] Start Manual

End time 30 s Max.Volume 10 mL

Final vol. 0.01 mL Dose mode Off

Titr.speed 3 Oven Off

Detect.mode 1

Drift titr. On

Start mode Manual

End level 75 mV

Samp.time 5s

Stir.speed 3

-Calculation parameter-

MKA-610 MKA-520 MKS-500

[Calculation] [Calculation] [Calculation]

Calc.type Sample Calc. 2 g->%

Blank No. 1 Unit %

Calc.No. 2 Weight Variable

Unit %

Decimal 2

Fraction Half adjust

Drift comp. Off

Evaluation Off

KVX-01551 Ver.01 3/4

-Measurement results-

Sample Oven Water content

Sample name Solvent

(g) (℃) mg %

Iron ore (Indian ore) 0.5638 ME 750 13.58 2.41

Manganese ore 0.2313 ME 750 24.29 10.50

Rock 0.4112 ME 700 22.04 5.36

Kaolin 0.1414 ME 800 19.94 14.10

Hornblende 1.0283 ME 1000 16.04 1.56

Black mica 1.1005 ME 1000 25.75 2.34

10.Summary

Mineral ores are rocks and sands which contain natural resources useful for human

economic activities. The sample test has been successfully conducted by using the

evaporator. The moisture from the sample is delivered to solvent ME in titration cell

by carrier gas. Precise and reliable water content can be obtained by Karl Fischer

moisture titration system. In order to separate water of adhesion and combine water,

it is recommended to use an oven with two heat ranges: 50~130°C heat zone, and 50

~1000°C overheat zone. Moisture of mineral ores can be measured by any of the

following Karl Fischer titration systems manufactured by Kyoto Electronics (KEM).

【MKA-610】 【MKA-520】 【MKS-500】

Awarded Product of • Compact and cost • Low cost and high

Supreme Technology from performance performance

Kyoto City • Easy dispensing of • User friendly easy to

• Easy key entry by touch extracting medium both operate

panel on 8-inch large color discharge and drain out • Titration nozzle made of

LCD • One touch change over of PTFE both anti-diffusion

• Two measurements in burette unit and regular type are

parallel at a time standard equipped

• Both potentiometric and

Karl Fischer moisture

titration (coulometric ・

volumetric ) can be

performed at a time

KVX-01551 Ver.01 4/4

You might also like

- Karl Fischer (Water Determination)Document4 pagesKarl Fischer (Water Determination)Alfonso Dominguez Gonzalez100% (1)

- Etib 99424Document4 pagesEtib 99424Curavavi MasDar SepthiadiNo ratings yet

- Isocyanate Content of U: RethaneDocument4 pagesIsocyanate Content of U: Rethaneswapon kumar shillNo ratings yet

- SN - 118 - 2013 - TKN Determination in Water and Waste Water Using Potentiometric TitrationDocument1 pageSN - 118 - 2013 - TKN Determination in Water and Waste Water Using Potentiometric TitrationSara ÖZGENNo ratings yet

- Bilal ENVIRONMENTAL Engg.Document29 pagesBilal ENVIRONMENTAL Engg.KhanBangash11No ratings yet

- ASBCUG 6 Use of Volatile Initiation Temperature of CoalsDocument25 pagesASBCUG 6 Use of Volatile Initiation Temperature of CoalsGothandaraman Muthu ManickamNo ratings yet

- EO in Sesame Seed Using TQDocument6 pagesEO in Sesame Seed Using TQMailinda Mega LorensNo ratings yet

- ETIB-99307 Saponification Oil PDFDocument4 pagesETIB-99307 Saponification Oil PDFRAFI04No ratings yet

- 5991-9254EN 8260 Lumin ApplicationDocument8 pages5991-9254EN 8260 Lumin Applicationinfinity1200No ratings yet

- No 49 Applications With Karl Fischer Oven AutosamplerDocument80 pagesNo 49 Applications With Karl Fischer Oven AutosamplerKeila ChavesNo ratings yet

- Lab ManualDocument20 pagesLab ManualNadira NadieyraNo ratings yet

- Acid-Base Titrations: The Complete Applications PackageDocument55 pagesAcid-Base Titrations: The Complete Applications PackageoldpenguinNo ratings yet

- COD203Document25 pagesCOD203rajarao001No ratings yet

- CLP301 Friday Report4 C21 Double-Effect-Evaporator G2Document9 pagesCLP301 Friday Report4 C21 Double-Effect-Evaporator G2Ojas SrivastavaNo ratings yet

- Method of Test For Determination of Total Chloride Ion in Concrete (Acid-Soluble)Document8 pagesMethod of Test For Determination of Total Chloride Ion in Concrete (Acid-Soluble)ming_zhu10No ratings yet

- TKN Determination in Water and Waste Water: Application Note No. 191/2015Document9 pagesTKN Determination in Water and Waste Water: Application Note No. 191/2015Alessandro BisbanoNo ratings yet

- Urea ManualDocument89 pagesUrea Manualabhay shuklaNo ratings yet

- Oin Ops Chem 011 Analytical Procedures For Raw MaterialDocument83 pagesOin Ops Chem 011 Analytical Procedures For Raw Materialrani100% (1)

- Bologna 2012 MatejtschukDocument53 pagesBologna 2012 MatejtschukTatenda Alfred KajauNo ratings yet

- Petroleum Testing Laboratory Manual With CalculationDocument17 pagesPetroleum Testing Laboratory Manual With CalculationKarthikeshwaran RamasamyNo ratings yet

- Etia 07010 PDFDocument4 pagesEtia 07010 PDFrbdubey2020No ratings yet

- Thenylchlor: Materials To Be Analyzed InstrumentationDocument5 pagesThenylchlor: Materials To Be Analyzed Instrumentationjuanvi.sanchoNo ratings yet

- Etib 99309 PDFDocument4 pagesEtib 99309 PDFRaja KajaNo ratings yet

- Coal and OilDocument48 pagesCoal and OilAnjaly KumariNo ratings yet

- Microcrystalline Cellulose USP MonographDocument4 pagesMicrocrystalline Cellulose USP Monographisaac_soto_12No ratings yet

- Al Farabi University College ةيلك ةعماجلا يبارافلا: ASTM D88-99Document6 pagesAl Farabi University College ةيلك ةعماجلا يبارافلا: ASTM D88-99Abbas sabbarNo ratings yet

- Mass Transfer ReportDocument89 pagesMass Transfer ReportPRALAY GEDAMNo ratings yet

- Coresta 2014Document32 pagesCoresta 2014Cristina RufenerNo ratings yet

- USP-NF Silicified Microcrystalline CelluloseDocument3 pagesUSP-NF Silicified Microcrystalline CelluloseVõ Đức TrọngNo ratings yet

- EuSalt AS016-2005 Chloride - Potentiometric MethodDocument4 pagesEuSalt AS016-2005 Chloride - Potentiometric MethodBadini ChanalNo ratings yet

- Gas ChromatographyDocument34 pagesGas ChromatographyReverse FlashNo ratings yet

- HYDROXYPROPYLMETHYL CELLULOSE SPECIFICATIONSDocument7 pagesHYDROXYPROPYLMETHYL CELLULOSE SPECIFICATIONSAndrea Sanchez AbarcaNo ratings yet

- Boiling Up Rate For Batch DistillationDocument4 pagesBoiling Up Rate For Batch DistillationKanhaiyalal PatilNo ratings yet

- Determination of Total Acid Number (TAN) According To ASTM 664Document5 pagesDetermination of Total Acid Number (TAN) According To ASTM 664sarahNo ratings yet

- Milcoside test method scope and proceduresDocument4 pagesMilcoside test method scope and procedureswilNo ratings yet

- Pki - 2000 - SDB E640010b Turbomass Sensitivity TestDocument39 pagesPki - 2000 - SDB E640010b Turbomass Sensitivity TestAdelitza StrubingerNo ratings yet

- Laboratory Testing ManualDocument70 pagesLaboratory Testing ManualToedjuNo ratings yet

- University of Nottingham Butanol Project - Design Guide 1Document6 pagesUniversity of Nottingham Butanol Project - Design Guide 1Tom HartNo ratings yet

- E102 PDFDocument3 pagesE102 PDFGovind RajNo ratings yet

- NBT 492Document4 pagesNBT 492Raja QammarNo ratings yet

- Section 10 - Medicines & Biological AnalysisDocument43 pagesSection 10 - Medicines & Biological AnalysisNguyễn Mai Thanh LộcNo ratings yet

- D6721-Standard Test Method For Determination of Chlorine in Coal by Oxidative Hydrolysis MicrocoulometryDocument4 pagesD6721-Standard Test Method For Determination of Chlorine in Coal by Oxidative Hydrolysis MicrocoulometryAyaNo ratings yet

- MAE Extraction of Triterpenoid Saponins in 30 MinutesDocument2 pagesMAE Extraction of Triterpenoid Saponins in 30 MinutesThong Tran DinhNo ratings yet

- TVB-N in Fish and ShrimpsDocument8 pagesTVB-N in Fish and ShrimpsRizal Eka NugrahaNo ratings yet

- Heat Balance Programme0Document18 pagesHeat Balance Programme0Mohamed SelimNo ratings yet

- Boiler Mainenance and Safety PDFDocument54 pagesBoiler Mainenance and Safety PDFBallu BaluNo ratings yet

- Test ProceduresDocument40 pagesTest ProceduresFarhan AkhterNo ratings yet

- Study of reducing gear teeth distortion through heat treatment process optimizationDocument9 pagesStudy of reducing gear teeth distortion through heat treatment process optimizationthai avvaiNo ratings yet

- Petro e SeminarDocument71 pagesPetro e SeminargandoupletaNo ratings yet

- Heat Transfer Analysis of Dilute Magnetorheological Fluid in Turbulator Assisted Concentric Tube Heat Exchanger AbstractDocument12 pagesHeat Transfer Analysis of Dilute Magnetorheological Fluid in Turbulator Assisted Concentric Tube Heat Exchanger AbstractAshish KNo ratings yet

- UOP291 348270 - 1 Chlore MeasurementsDocument9 pagesUOP291 348270 - 1 Chlore MeasurementsabhinavbhandariNo ratings yet

- Ab-404 1 en PDFDocument8 pagesAb-404 1 en PDFVel MuruganNo ratings yet

- Test Method: Ordering InformationDocument1 pageTest Method: Ordering InformationbenlahnecheNo ratings yet

- Cardinal Environmental Laboratories, LLC Standard Operating ProcedureDocument6 pagesCardinal Environmental Laboratories, LLC Standard Operating ProcedureAhmad RyderNo ratings yet

- 5 Shortcut Distillation Distillation ChemcadDocument25 pages5 Shortcut Distillation Distillation ChemcadGianmarco CANo ratings yet

- Working Guide to Petroleum and Natural Gas Production EngineeringFrom EverandWorking Guide to Petroleum and Natural Gas Production EngineeringRating: 5 out of 5 stars5/5 (2)

- SDS-PAGE of Protein: BT 510 Analytical Biotechnology LabDocument6 pagesSDS-PAGE of Protein: BT 510 Analytical Biotechnology LabBarish RoyNo ratings yet

- Column ChromatographyDocument9 pagesColumn ChromatographyQuratul AinNo ratings yet

- 3 - Modified Buffers Biochem Lab 1 With WorksheetDocument4 pages3 - Modified Buffers Biochem Lab 1 With WorksheetkatherinecalmaNo ratings yet

- Recommended MCQs - 123 Questions The Solid State Chemistry NEET Practice Questions, MCQS, Past Year Questions (PYQs), NCERT QuesDocument1 pageRecommended MCQs - 123 Questions The Solid State Chemistry NEET Practice Questions, MCQS, Past Year Questions (PYQs), NCERT QuesNeet 720No ratings yet

- Det KSPDocument4 pagesDet KSPsyaichurroziNo ratings yet

- Instrument Assignment 2Document17 pagesInstrument Assignment 2firaol mokonnenNo ratings yet

- Determining Concentration via Iodometric TitrationDocument5 pagesDetermining Concentration via Iodometric TitrationIzzat Arif33% (3)

- Lecture 15Document33 pagesLecture 15Anas Nasir officalNo ratings yet

- Chem - First Sem-I - PraticalDocument27 pagesChem - First Sem-I - PraticalsureshNo ratings yet

- UF HandbookDocument64 pagesUF Handbookamendelsohn1596100% (1)

- A Presentationn On FtirDocument7 pagesA Presentationn On FtirmtariqjanNo ratings yet

- Analytical Chemistry Hand-Out 1Document11 pagesAnalytical Chemistry Hand-Out 1Mark Jesson Datario100% (1)

- Che 152. Separation Processes Handout 1.1. Countercurrent Multistage Distillation With Reflux: Ponchon-Savarit Method Multiple Equilibrium StagesDocument11 pagesChe 152. Separation Processes Handout 1.1. Countercurrent Multistage Distillation With Reflux: Ponchon-Savarit Method Multiple Equilibrium StagesBor OtNo ratings yet

- Development and Validation of RP-HPLC Method For Simultaneous Estimation of Furosemide and Spironolactone in Their Combined Tablet Dosage Form PDFDocument4 pagesDevelopment and Validation of RP-HPLC Method For Simultaneous Estimation of Furosemide and Spironolactone in Their Combined Tablet Dosage Form PDFAlexandru GondorNo ratings yet

- Bio 462 Past Year Chapter 1Document1 pageBio 462 Past Year Chapter 1MamamiaNo ratings yet

- HPLC method for pantoprazole and impuritiesDocument9 pagesHPLC method for pantoprazole and impuritiesJesus Barcenas HernandezNo ratings yet

- 01 Simulis McCabe-Thiele BZ TolDocument10 pages01 Simulis McCabe-Thiele BZ TolCriveanuNNarcisNo ratings yet

- Hetero CVDocument3 pagesHetero CVPentesh NingaramainaNo ratings yet

- CrystallographyDocument17 pagesCrystallographyDolih GozaliNo ratings yet

- USP Medicines Compendium - Dihydroartemisinin and Piperaquine Phosphate Tablets - 2012-11-15 PDFDocument7 pagesUSP Medicines Compendium - Dihydroartemisinin and Piperaquine Phosphate Tablets - 2012-11-15 PDFDelano HabibieNo ratings yet

- D 6994 - 04Document27 pagesD 6994 - 04Oh No PotatoNo ratings yet

- Ultracentrifuge - Wikipedia, The Free EncyclopediaDocument3 pagesUltracentrifuge - Wikipedia, The Free EncyclopediaShailendra YadavNo ratings yet

- HPLC e PDFDocument9 pagesHPLC e PDFHassaanNo ratings yet

- Chap 04 Acids and BasesDocument22 pagesChap 04 Acids and BasesavNo ratings yet

- Chem Lab Report Oxalic AcidDocument8 pagesChem Lab Report Oxalic AcidMbee90% (20)

- Experiment 2 ChromatographyDocument3 pagesExperiment 2 ChromatographyChacha Mercado0% (1)

- 1 s2.0 S1878535213003389 MainDocument8 pages1 s2.0 S1878535213003389 Mainadolfo olmosNo ratings yet

- Standardization of NaOHDocument3 pagesStandardization of NaOHKeisha DenoloNo ratings yet

- Acids & BasesDocument4 pagesAcids & BasesGrand Meme VinesNo ratings yet

- Au XRDDocument3 pagesAu XRDAbdullah TekerNo ratings yet