Professional Documents

Culture Documents

Why Do o Rings Fail

Uploaded by

Eyob0 ratings0% found this document useful (0 votes)

38 views10 pagesOriginal Title

Why do o rings fail - Copy

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

38 views10 pagesWhy Do o Rings Fail

Uploaded by

EyobCopyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 10

Why do o rings fail?

O ring failure guide

O ring failure often occurs too soon in applications due to inadequate gland design or compound choice.

This article explain why O rings fail by supplying examples of general damage modes. In order to improve

seal execution, it is necessary to correctly and effectively identify the damage mode.

No matter how careful we are during the design phase, O rings can fail in their application for various

reasons. The number of pressures that affect O rings can be very hard to assess which is why it is extremely

important to re-test every material in its original environment and precisely examine them throughout the

installation stages.

The O ring failure guide below provides details of some of the most popular o ring failure modes.

FAILURE 1: EXTRUSION AND NIBBLING

Description and visual indications:

Extrusion is the process where high stresses force material into the clearance gap, then pulses of high

pressure cause the clearance gap to open and close, trapping the O ring between the mating surfaces which

results in physical damage to the seal surface. The edges of the O ring are nibbled, chipped or ragged

(usually on the low pressure side). In severe cases, shaving can occur and the surface may be peeled off.

Contributing factors/failure analysis:

Excessive gland clearances

Excessive system pressure

O ring material too soft

Degradation of o ring by system fluid

Irregular clearance gaps caused by eccentricity

Improper machining of o ring gland (leaving sharp edges)

O ring size too large for gland

Prevention and suggested solutions:

Increase rigidity of metal components

Decrease sharp edges of the gland to a minimum

Reduce back clearance gaps by using backup devices

Decrease clearance by reducing machining tolerance

Appropriate gland design

Compatibility of an O ring material with system fluid

Installation of adequate O ring size

Use of the harder seal material

FAILURE 2: COMPRESSION SET

Description and visual indications:

COMPRESSION SET is one of the most common O ring failures. An efficient O ring seal needs a

continuous seal line between the seal surfaces which is a function of gland design and seal cross-section. To

maintain seal integrity without excessive deformation of the seal, the seal line establishes the correct amount

of compression on the O ring. O ring becomes less circular and has flattened surfaces (flat sided oval), it has

taken the shape of the groove and it is unable to recover to its original shape.

Contributing factors/failure analysis:

Physical and chemical changes appear

Excessive compression/over tightening

Improper gland design

Excessive temperature, which caused the O rings to lose its elastic properties

Elastomer with high compression set

O ring volume swell because of system fluid

Elastomer completely cured during production

Poor compression set

Properties of material selected

Fluid incompatible with O ring material

O ring losing its elasticity due to cross-link density increase

Prevention and suggested solutions:

Selection of elastomer materials with low compression set

Confirm material compatibility with intended service conditions

Confirm the O ring is not over-squeezed

Check gland design

Use more flexible polymer structure

Lower system operating temperature

Reduce excessive frictional heat build-up at seal interface

FAILURE 3: EXPLOSIVE DECOMPRESSION

Description and visual indications:

After a period of time in service (under high pressure) the pressure is may decrease too quickly. The gas

is then absorbed and expands very fast and blisters and ruptures the elastomer surface. Excessive trapped gas

may result in total destruction of an O ring. Blisters and cracks on the surface due to absorption of gas at high

pressure and the subsequent fast drop in pressure. Surface marked with deep splits. Splits and fissures

revealed after examinations of internal structure. In severe cases, the surface is completely ruptured.

Contributing factors/failure analysis:

Rapid pressure changes

Low hardness elastomer

Absorption of gas by O rings while operating in high pressure conditions

Prevention and suggested solutions:

Slower decompression allows trapped gas to escape from seal material

Higher hardness elastomer

Reduce temperature

Choose ED-resistant material

Right selection of seal material-explosive decompression resistant

Consider using metallic O ring or C ring

FAILURE 4: ABRASION

Description and visual indications:

Abrasion is another common type of seal failure. Mostly it’s found in dynamic seals due to rotary

motion, oscillating and reciprocating. Flat area on the side of an O ring where it was touching the dynamic

surface. Grazed lines on the flat surface parallel to the direction of motion. Only one side of the seal will be

worn. Seal surface may have some loose particles and scrapes. Excessive wear – lacerations may be deeper

and there may be breaking in places.

Contributing factors/failure analysis:

Repetitive friction between O ring surface and the housing

Dynamic motion

Improper lubrication

Improper finish of the surface in dynamic contact with the O ring (the surface may be

abrasive, too smooth or too rough due to inability to hold lubricant)

Excessive temperature

Process environment containing abrasive particles

Poor elastomer surface finish

Prevention and suggested solutions:

Adequate lubrication

Use O ring sealing materials with improved abrasion resistance

Eliminate abrasive components

Use of recommended gland surface finishes

Eliminate the source of contamination

Use of wiper or scraper rings will reduce contamination of the seal

Consider use of internally lubricated O rings – this will reduce friction and wear

FAILURE 5: INSTALLATION DAMAGE

Description and visual indications:

Occurring in both static and dynamic seals, Small cuts, nicks or gashes on the seal

Contributing factors/failure analysis:

Sharp edge of glands, threads or components, which may damage O ring during

assembly

Wrong sizing of O ring

Low hardness elastomer

Improper lubrication before installation

Prevention and suggested solutions:

Remove all sharp edges

Proper gland design

Proper elastomer sizing

Ensure all components are clean before installation

Use of lubricant

Higher hardness elastomer

FAILURE 6: SPIRAL TWISTING FAILURE

Description and visual indications:

Generally found on long stoke, hydraulic piston seals, the surface of the O ring exhibits a

series of deep, spiral 45° angle cuts, spiraling pattern around its exterior with subsequent deep

cutting.

Contributing factors/failure analysis:

O ring is both sliding and rolling at the same time

Slow reciprocating speed

Improper installation

Irregular seal surface finish

Excessive gland width

Low hardness elastomer

Uneven or rough gland surface finish

Insufficient lubrication

Eccentric components

friction

Prevention and suggested solutions:

Correct installation procedures

Possible use of polymer backup rings

Higher hardness elastomer

Proper gland surface finish

Adequate gland design

Internally-lubed elastomers or properly lubricated elastomer

FAILURE 7: FAILURE WITHOUT VISIBLE EVIDENCE ON SEAL

Description and visual indications:

Of the various types of seal failure, this is among the hardest to diagnose because the

result of the problem is not visible on the O ring. There are no visual clues.

Contributing factors/failure analysis:

Insufficient compression

Tolerance stack-up

Eccentric-shaped components

Parting lines and/or flash left on the O ring from the molding process

Improper volume relationship between the seal and its gland

Prevention and suggested solutions:

Maintain recommended compression range for the application

Identify the amount of stretch as it reduces the O ring cross section with increased stretch

Determine the component tolerance stack-up as it directly affects the seal cross section

Consider maximum component shift in design to ensure that compression is still

contained within recommended compression range

Avoid parting lines in O ring grooves as they tend to be areas of flash and mismatch

Ensure that the O ring gland volume surpasses the O ring volume to allow for seal

expansion without seal detriment.

FAILURE 8: HEAT HARDENING AND OXIDATION

Description and visual indications:

Seen in both static and dynamic seals, the surface of O-ring appears pitted and/or

cracked, often accompanied by the flatness of high compression set.

Contributing factors/failure analysis:

Excessive temperature causing elastomer hardening

Evaporation of plasticizers

Cracking from oxidation

Prevention and suggested solutions:

Specify high temperature O-ring materials with antioxidants

Lower operating temperature of hydraulic system

FAILURE 9: EXCESSIVE SWELL

Description and visual indications:

Easily identified by a marked increase in seal dimensions; can occur in both static and

dynamic applications. Results in reduction of physical properties and can result in improper

sizing between seal and gland. Dynamic applications are especially prone to this problem

because friction accelerates seal failure.

Contributing factors/failure analysis:

Like a sponge, the seal absorbs the surrounding fluids and swells to the point of

malfunction because of incompatibility between seal compound and system environment

(i.e. chemical incompatibility, high humidity, etc.)

Prevention and suggested solutions:

Select an O – ring material that is chemically compatible with the fluid it will contact.

FAILURE 10: WEATHER OR OZONE CRACKING

Description and visual indications:

Occurring in both static and dynamic seals exposed to atmospheres containing ozone and

other air pollutants, this failure mode is marked by the appearance of many small surfaces cracks

perpendicular to the direction of stress.

Contributing factors/failure analysis:

Ozone attacks the polymer chains

Causing O – ring material to crack

Prevention and suggested solutions:

Substitute O – ring elastomers that are resistant to ozone attack

You might also like

- Why Do o Rings FailDocument10 pagesWhy Do o Rings Failabrham negashNo ratings yet

- O Ring Failure Analysis GuideDocument6 pagesO Ring Failure Analysis GuideSaikat Das Gupta100% (1)

- O-Ring Troubleshooting Guide O-Ring Failure Analysis PDFDocument3 pagesO-Ring Troubleshooting Guide O-Ring Failure Analysis PDFharshpatel18No ratings yet

- How To Recognize and Avoid The Common Causes of O-Ring Failure - Hydraulics & PneumaticsDocument21 pagesHow To Recognize and Avoid The Common Causes of O-Ring Failure - Hydraulics & PneumaticsrinshonsanNo ratings yet

- Common Causes of O-Ring Failure - Technical SupportDocument4 pagesCommon Causes of O-Ring Failure - Technical SupportiJordanScribdNo ratings yet

- O Ring Troubleshoothing GuideDocument1 pageO Ring Troubleshoothing GuideLylla Damasceno DamascenoNo ratings yet

- O-Ring Trouble ShootingDocument3 pagesO-Ring Trouble ShootingFrederique VerhulstNo ratings yet

- Failure Analysis John CraneDocument83 pagesFailure Analysis John CraneIulian Luncan96% (23)

- John CraneDocument83 pagesJohn CraneVj KrshkumrNo ratings yet

- O-Ring Failure Analysis GuideDocument7 pagesO-Ring Failure Analysis GuideJean Pierre CastilloNo ratings yet

- Seal FailureDocument17 pagesSeal Failurenikita100% (3)

- Injection Molding Defect OzDocument12 pagesInjection Molding Defect Oztopkaya100% (1)

- O-Ring Failure AnalysisDocument10 pagesO-Ring Failure AnalysisAnonymous XPQKHSNo ratings yet

- Common Seal FailuresDocument4 pagesCommon Seal Failuresbarry nancooNo ratings yet

- Troubleshoot Mechanical Seal FailuresDocument5 pagesTroubleshoot Mechanical Seal FailuresRené Mora-CasalNo ratings yet

- Seal Reliability and Failure AnalysisDocument41 pagesSeal Reliability and Failure Analysiskarioke mohaNo ratings yet

- Gask o Seal PDFDocument24 pagesGask o Seal PDFThang CaoNo ratings yet

- Mechanical Seal Troubleshooting GuideDocument10 pagesMechanical Seal Troubleshooting Guideempswook100% (2)

- SUBJECT: A Quick Reference Guide For Mechanical Seal Failure 4-11Document5 pagesSUBJECT: A Quick Reference Guide For Mechanical Seal Failure 4-11Liz Lynn LimNo ratings yet

- Rubber Seal - O Rings - IRIDocument35 pagesRubber Seal - O Rings - IRIGnaneshNo ratings yet

- 12 Reasons Why Bearings FailDocument7 pages12 Reasons Why Bearings FailAmirmasoudNo ratings yet

- Mechanical Seal Failure ModesDocument9 pagesMechanical Seal Failure ModesMostafa MahmoudNo ratings yet

- Mechanical Seal Failure Modes Causes and PreventionDocument9 pagesMechanical Seal Failure Modes Causes and Preventionpmdongre100% (2)

- Construction Maintenance Department: Mechanical Technician Qualification ModuleDocument109 pagesConstruction Maintenance Department: Mechanical Technician Qualification ModuleAndinata Sitepu100% (1)

- Bearing DataDocument16 pagesBearing DataCisco StarkNo ratings yet

- Hydraulics WhitepaperDocument4 pagesHydraulics WhitepaperHUERTANESTORNo ratings yet

- 4 Ways To Prevent Seal FailureDocument5 pages4 Ways To Prevent Seal FailureGlobe Star Engineers Pvt LtdNo ratings yet

- What Are Mechanical Seals?: Sap PartsDocument16 pagesWhat Are Mechanical Seals?: Sap PartsBalasubramanian MuthukumarNo ratings yet

- Seal Off Centrifugal Pump ProblemsDocument6 pagesSeal Off Centrifugal Pump ProblemsArturo Valles TerrazasNo ratings yet

- Bearing Damage AnalysisDocument12 pagesBearing Damage AnalysisZulfahmi IrhamdaniNo ratings yet

- 10 Hydraulics Tips You Need To Know: Outside Factors Are A Vital Component of Hydraulic SystemsDocument4 pages10 Hydraulics Tips You Need To Know: Outside Factors Are A Vital Component of Hydraulic SystemsGunjanNo ratings yet

- Manual HidraulicaDocument5 pagesManual HidraulicasimonsecurityNo ratings yet

- Hidráulica Sello Cilíndrico de Análisis de FallasDocument22 pagesHidráulica Sello Cilíndrico de Análisis de FallasPedro Cerna DiazNo ratings yet

- O-Rings: The Worlds Most Popular and Verstile SealDocument101 pagesO-Rings: The Worlds Most Popular and Verstile Sealaqibazizkhan100% (2)

- Understanding and Preventing Common Casting Defects Like Hot TearsDocument4 pagesUnderstanding and Preventing Common Casting Defects Like Hot TearsSachin KumbharNo ratings yet

- Fastening: Manufacturing ProcessesDocument51 pagesFastening: Manufacturing ProcessesCR MamRe GaringgingNo ratings yet

- Ultrasonic Welding Trouble Shooting Guide: Problem Probable Causes SolutionsDocument6 pagesUltrasonic Welding Trouble Shooting Guide: Problem Probable Causes SolutionsZiad Al SarrafNo ratings yet

- Mechanical Seal Reliability - What Realistically Can Be AchievedDocument11 pagesMechanical Seal Reliability - What Realistically Can Be AchievedsfontherunNo ratings yet

- TTU Metallurgical Processes LAB Exp.3: Specimen PreparationDocument9 pagesTTU Metallurgical Processes LAB Exp.3: Specimen PreparationG. Dancer GhNo ratings yet

- STLE - Basic of WearDocument17 pagesSTLE - Basic of WearGerson NevesNo ratings yet

- Sample Preparation for Metallographic ExaminationDocument83 pagesSample Preparation for Metallographic ExaminationErdi Sofyandra AdikriNo ratings yet

- 13 Ways To Kill A Mechanical Seal FINALDocument16 pages13 Ways To Kill A Mechanical Seal FINALRanjit Koshy AlexanderNo ratings yet

- Thread Sealing 101 Tech ArticleDocument4 pagesThread Sealing 101 Tech ArticleAndy ChongNo ratings yet

- Analyze O-Ring & Seal FailuresDocument5 pagesAnalyze O-Ring & Seal FailuresAmirmasoudNo ratings yet

- INSPECTION SCHEDULE AND DEFECTSDocument17 pagesINSPECTION SCHEDULE AND DEFECTSRishu GuptaNo ratings yet

- Transeals Identifying Hydraulic SealsDocument28 pagesTranseals Identifying Hydraulic Sealsvikram_007No ratings yet

- Ring Design Chapter032Document1 pageRing Design Chapter032ismail güleçNo ratings yet

- Adhesives Retain With Confidence Tech ArticleDocument4 pagesAdhesives Retain With Confidence Tech ArticlegobajasaeindiaNo ratings yet

- ObjectDocument77 pagesObjectامير بشير جوادNo ratings yet

- How To Analyze Gear FailuresDocument9 pagesHow To Analyze Gear Failuresrobertoalfaro49100% (1)

- SMT TsDocument38 pagesSMT TsGlauber AquinoNo ratings yet

- Seals: V-Ring PackingsDocument6 pagesSeals: V-Ring PackingsRtfjrjgr Xefwwxebge XsjlkzxzlsjxsjNo ratings yet

- ProjectDocument34 pagesProjectmansukhNo ratings yet

- Home About Us Software Services Training Download Pricing Bolting InfoDocument9 pagesHome About Us Software Services Training Download Pricing Bolting Infopaeg6512No ratings yet

- Assembly and Installation PVC To MEtal PipeDocument11 pagesAssembly and Installation PVC To MEtal PipevuongNo ratings yet

- Chapter 1Document23 pagesChapter 1Ricardo OrdoñezNo ratings yet

- Elastomeric Ring Seals: Static and DynamicDocument13 pagesElastomeric Ring Seals: Static and DynamicArnaldo BenitezNo ratings yet

- Plastic Injection Mold Design for Toolmakers - Volume I: Plastic Injection Mold Design for Toolmakers, #1From EverandPlastic Injection Mold Design for Toolmakers - Volume I: Plastic Injection Mold Design for Toolmakers, #1Rating: 5 out of 5 stars5/5 (2)

- XG 2 ReportDocument4 pagesXG 2 ReportEyobNo ratings yet

- Breakdown Analysis - 5 Why'S: DateDocument3 pagesBreakdown Analysis - 5 Why'S: DateEyobNo ratings yet

- Wheel Loader Lw560a 01 Missed PartsDocument1 pageWheel Loader Lw560a 01 Missed PartsEyobNo ratings yet

- How Air Brakes WorkDocument6 pagesHow Air Brakes WorkEyobNo ratings yet

- Action Plan UpdatedDocument1 pageAction Plan UpdatedEyobNo ratings yet

- National Cement Share Company 3000 TPD Auto-Garage Department Generators Inspection Report Julay 13/2020Document6 pagesNational Cement Share Company 3000 TPD Auto-Garage Department Generators Inspection Report Julay 13/2020EyobNo ratings yet

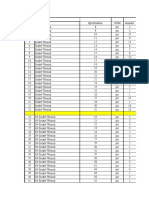

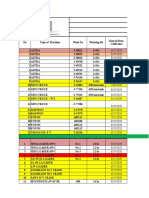

- Tools InventryDocument10 pagesTools InventryEyobNo ratings yet

- Work To Be Done in Shout DownDocument2 pagesWork To Be Done in Shout DownEyobNo ratings yet

- Action Plan UpdatedDocument1 pageAction Plan UpdatedEyobNo ratings yet

- Work To Be Done in Shout DownDocument2 pagesWork To Be Done in Shout DownEyobNo ratings yet

- XG 2 ReportDocument4 pagesXG 2 ReportEyobNo ratings yet

- National Cement Share Company 3000 TPD: Auto-Garage Department Weekly Pms Plan DataDocument11 pagesNational Cement Share Company 3000 TPD: Auto-Garage Department Weekly Pms Plan DataEyobNo ratings yet

- National Cement Share Company 3000 TPD Auto-Garage Department Generators Inspection Report Julay 13/2020Document6 pagesNational Cement Share Company 3000 TPD Auto-Garage Department Generators Inspection Report Julay 13/2020EyobNo ratings yet

- Eyasu.m (NNNDocument22 pagesEyasu.m (NNNEyobNo ratings yet

- 1 Astra 3-58021Document14 pages1 Astra 3-58021EyobNo ratings yet

- Tools InventryDocument10 pagesTools InventryEyobNo ratings yet

- How Air Brakes WorkDocument6 pagesHow Air Brakes WorkEyobNo ratings yet

- Diagnostic Fault Codes For Cummins EnginesDocument1 pageDiagnostic Fault Codes For Cummins EnginesEyobNo ratings yet

- Business Plan For:: Auto Body, Mechanical and Electrical Repairs and ServicingDocument5 pagesBusiness Plan For:: Auto Body, Mechanical and Electrical Repairs and ServicingEyob100% (1)

- Breakdown Analysis - 5 Why'S: DateDocument3 pagesBreakdown Analysis - 5 Why'S: DateEyobNo ratings yet

- Bussines Plan For Seeds200,000 EtbDocument15 pagesBussines Plan For Seeds200,000 EtbEyobNo ratings yet

- Business Plan For:: Auto Body, Mechanical and Electrical Repairs and ServicingDocument6 pagesBusiness Plan For:: Auto Body, Mechanical and Electrical Repairs and ServicingEyobNo ratings yet

- Astra D.truck ChecklistDocument9 pagesAstra D.truck ChecklistEyobNo ratings yet

- Air-Powerd Crawler Drill Roc 203 PC Missing PartsDocument2 pagesAir-Powerd Crawler Drill Roc 203 PC Missing Partsabrham negashNo ratings yet

- Plan & OrganizeDocument8 pagesPlan & OrganizeEyobNo ratings yet

- Air-Powerd Crawler Drill Roc 203 PC Missing PartsDocument2 pagesAir-Powerd Crawler Drill Roc 203 PC Missing Partsabrham negashNo ratings yet

- National Cement Share Company 3000 TPD Auto-Garage DepartmentDocument6 pagesNational Cement Share Company 3000 TPD Auto-Garage DepartmentEyobNo ratings yet

- Astra D.truck ChecklistDocument9 pagesAstra D.truck ChecklistEyobNo ratings yet

- Strategic Management and Municipal Financial ReportingDocument38 pagesStrategic Management and Municipal Financial ReportingMarius BuysNo ratings yet

- Engine Technology Course A/F Control Classroom TrainingDocument14 pagesEngine Technology Course A/F Control Classroom Traininglongtrandang5867No ratings yet

- 01 - Narmada M PhilDocument200 pages01 - Narmada M PhilafaceanNo ratings yet

- MIT LL. Target Radar Cross Section (RCS)Document45 pagesMIT LL. Target Radar Cross Section (RCS)darin koblickNo ratings yet

- Danh sách KH Biệt Thự Thảo Điền - Quận 2Document4 pagesDanh sách KH Biệt Thự Thảo Điền - Quận 2La TraNo ratings yet

- Language in UseDocument1 pageLanguage in UseEvaNo ratings yet

- Sample Resume For HRDocument2 pagesSample Resume For HRnapinnvoNo ratings yet

- SRV210 - 250TC Spare PartsDocument2 pagesSRV210 - 250TC Spare PartsEnzo SovittiNo ratings yet

- 337 686 1 SMDocument8 pages337 686 1 SMK61 ĐOÀN HỒ GIA HUYNo ratings yet

- Studentwise Final Placement DetailsLast 3 YearsDocument18 pagesStudentwise Final Placement DetailsLast 3 YearsAmitNo ratings yet

- Finite Element Analysis (FEA) Software MarketDocument3 pagesFinite Element Analysis (FEA) Software Marketsurendra choudharyNo ratings yet

- From Birth Till Palatoplasty Prosthetic.20Document5 pagesFrom Birth Till Palatoplasty Prosthetic.20Maria FernandaNo ratings yet

- New Age Int. Publication Civil EngineeringDocument28 pagesNew Age Int. Publication Civil EngineeringLove SharmaNo ratings yet

- KPW FSO Yetagun Presentation 250713Document36 pagesKPW FSO Yetagun Presentation 250713muhamadrafie1975No ratings yet

- Belotero Intense LidocaineDocument7 pagesBelotero Intense LidocaineAnnaNo ratings yet

- SKM 4 - COCU - CU2 - Child - Care - Centre - HealthDocument14 pagesSKM 4 - COCU - CU2 - Child - Care - Centre - HealthShireen TahirNo ratings yet

- Irregular Verbs Multiple ChoiceDocument2 pagesIrregular Verbs Multiple Choicecloudcatching0% (1)

- WholeDocument397 pagesWholedelbot01No ratings yet

- ISO 9000 Standards Guide Quality Systems InternationallyDocument12 pagesISO 9000 Standards Guide Quality Systems InternationallyArslan Saleem0% (1)

- (Food Engineering Series) Gustavo V Barbosa-Cánovas - Humberto Vega-Mercado - Dehydration of Foods PDFDocument339 pages(Food Engineering Series) Gustavo V Barbosa-Cánovas - Humberto Vega-Mercado - Dehydration of Foods PDFLis FernandesNo ratings yet

- DEME Offshore Brochure_2022Document16 pagesDEME Offshore Brochure_2022amin32No ratings yet

- Sunday School Lesson Activity 219 Moses Builds A Tablernacle in The Wilderness - Printable 3D Model KitDocument17 pagesSunday School Lesson Activity 219 Moses Builds A Tablernacle in The Wilderness - Printable 3D Model Kitmcontrerasseitz3193No ratings yet

- Vernacular Terms in Philippine ConstructionDocument3 pagesVernacular Terms in Philippine ConstructionFelix Albit Ogabang IiiNo ratings yet

- Clinical Presentation of Ectopic Pregnancy Turned Out to Be Ectopic PregnancyDocument33 pagesClinical Presentation of Ectopic Pregnancy Turned Out to Be Ectopic PregnancyRosiNo ratings yet

- Frogkisser! by Garth Nix (Excerpt)Document17 pagesFrogkisser! by Garth Nix (Excerpt)I Read YA0% (1)

- Beef Steaks: MethodDocument2 pagesBeef Steaks: MethodGoshigoshi AkhtarNo ratings yet

- African in The Modern WorldDocument18 pagesAfrican in The Modern WorldSally AnkomaahNo ratings yet

- Fundamentals Deep Learning Activation Functions When To Use ThemDocument15 pagesFundamentals Deep Learning Activation Functions When To Use ThemfaisalNo ratings yet

- Diosdado MacapagalDocument13 pagesDiosdado MacapagalMermie ArmentaNo ratings yet