Professional Documents

Culture Documents

Νέο - Έγγραφο του Microsoft Word

Νέο - Έγγραφο του Microsoft Word

Uploaded by

greekpapariaOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Νέο - Έγγραφο του Microsoft Word

Νέο - Έγγραφο του Microsoft Word

Uploaded by

greekpapariaCopyright:

Available Formats

Nitrous oxide can be used as an oxidizer in a rocket motor.

This has the advantages

over other oxidizers in that it is non-toxic and, due to its stability at room temperature,

easy to store and relatively safe to carry on a flight. As a secondary benefit it can be

readily decomposed to form breathing air. Its high density and low storage pressure

enable it to be highly competitive with stored high-pressure gas systems.

In a 1914 patent, American rocket pioneer Robert Goddard suggested nitrous oxide

and gasoline as possible propellants for a liquid-fueled rocket. Nitrous oxide has been

the oxidizer of choice in several hybrid rocket designs (using solid fuel with a liquid

or gaseous oxidizer). The combination of nitrous oxide with hydroxyl-terminated

polybutadiene fuel has been used by SpaceShipOne and others. It is also notably used

in amateur and high power rocketry with various plastics as the fuel.

Nitrous oxide can also be used in a monopropellant rocket. In the presence of a heated

catalyst, N2O will decompose exothermically into nitrogen and oxygen, at a

temperature of approximately 1300 °C. Because of the large heat release, the catalytic

action rapidly becomes secondary as thermal autodecomposition becomes dominant.

In a vacuum thruster, this can provide a monopropellant specific impulse (Isp) of as

much as 180 s. While noticeably less than the Isp available from hydrazine thrusters

(monopropellant or bipropellant with nitrogen tetroxide), the decreased toxicity

makes nitrous oxide an option worth investigating.

Specific impulse (Isp) can be improved by blending a hydrocarbon fuel with the

nitrous oxide inside the same storage tank, becoming a nitrous oxide fuel blend

(NOFB) monopropellant. This storage mixture does not incur the danger of

spontaneous ignition, since N2O is chemically stable. When the nitrous oxide

decomposes by a heated catalyst, high temperature oxygen is released and rapidly

ignites the hydrocarbon fuel-blend. NOFB monopropellants are capable of I

sp greater than 300 seconds, while avoiding the toxicity associated with hypergolic

propulsion systems.[18][19] The low freezing point of NOFB eases thermal management

compared to hydrazine and dinitrogen tetroxide—a valuable property for space

storable propellants.

[edit] Internal combustion engine

Main article: Nitrous

In vehicle racing, nitrous oxide (often referred to as just "nitrous" or "NOS") allows

the engine to burn more fuel and air, resulting in a more powerful combustion. The

gas itself is not flammable, but it delivers more oxygen than atmospheric air by

breaking down at elevated temperatures.

Nitrous oxide is stored as a compressed liquid; the evaporation and expansion of

liquid nitrous oxide in the intake manifold causes a large drop in intake charge

temperature, resulting in a denser charge, further allowing more air/fuel mixture to

enter the cylinder. Nitrous oxide is sometimes injected into (or prior to) the intake

manifold, whereas other systems directly inject right before the cylinder (direct port

injection) to increase power.

The technique was used during World War II by Luftwaffe aircraft with the GM-1

system to boost the power output of aircraft engines. Originally meant to provide the

Luftwaffe standard aircraft with superior high-altitude performance, technological

considerations limited its use to extremely high altitudes. Accordingly, it was only

used by specialized planes like high-altitude reconnaissance aircraft, high-speed

bombers, and high-altitude interceptor aircraft.

One of the major problems of using nitrous oxide in a reciprocating engine is that it

can produce enough power to damage or destroy the engine. Very large power

increases are possible, and if the mechanical structure of the engine is not properly

reinforced, the engine may be severely damaged or destroyed during this kind of

operation. It is very important with nitrous oxide augmentation of internal combustion

engines to maintain proper operating temperatures and fuel levels to prevent

"preignition", or "detonation" (sometimes referred to as "knocking" or "pinging").

Most problems that are associated with nitrous do not come from mechanical failure

due to the power increases. Since nitrous allows a much denser charge into the

cylinder it dramatically increases cylinder pressures. The increased pressure and

temperature can cause problems such as melting the piston or valves. It may also

crack or warp the piston or head and cause preignition due to uneven heating.

Automotive-grade liquid nitrous oxide differs slightly from medical-grade nitrous

oxide. A small amount of sulfur dioxide is added to prevent substance abuse.[20]

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5819)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- 5.0&5.7 Engine A-FDocument250 pages5.0&5.7 Engine A-FTracy Waalewyn71% (7)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Onan L317 Diesel Engine Parts ManualDocument42 pagesOnan L317 Diesel Engine Parts ManualCosta Amanatidis100% (3)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Caterpillar Acert Engine Diagnostic CodesDocument6 pagesCaterpillar Acert Engine Diagnostic CodesNoel Salazar100% (2)

- BorgWarner 2018 07 02Document82 pagesBorgWarner 2018 07 02Eng Moh100% (2)

- SDLG L953F L956F L958F Wheel Loader Parts CatalogDocument151 pagesSDLG L953F L956F L958F Wheel Loader Parts CatalogWILLIAM100% (4)

- Error Codes PDFDocument22 pagesError Codes PDFcristian93% (15)

- 1hz 1hd-t EngineDocument10 pages1hz 1hd-t EngineWalid Wahyudi67% (3)

- 4000 Series PM SchedulesDocument3 pages4000 Series PM SchedulesSoubhik MishraNo ratings yet

- C13 Oil SystemDocument6 pagesC13 Oil Systemjeddo2005100% (1)

- Servicemanual Peugeot Euro 4 PDFDocument16 pagesServicemanual Peugeot Euro 4 PDFsky100% (2)

- 220Document1 page220fahmi wibowoNo ratings yet

- Anatomy of A Valve FailureDocument1 pageAnatomy of A Valve FailureJesseNo ratings yet

- Part Catalogue Mitsubishi Engine L3E SeriesDocument130 pagesPart Catalogue Mitsubishi Engine L3E SeriesDesta 77No ratings yet

- Altronics A2 BLLTN 08-1987 PDFDocument4 pagesAltronics A2 BLLTN 08-1987 PDFSMcNo ratings yet

- Part Book Motor GD655-5 - SAA6D107E 1CC S N 26540705 UPDocument159 pagesPart Book Motor GD655-5 - SAA6D107E 1CC S N 26540705 UPkit101No ratings yet

- Agriculture EngineeringDocument10 pagesAgriculture EngineeringChan RoNo ratings yet

- Tensora D5HDocument2 pagesTensora D5Hjorge Diaz RodriguezNo ratings yet

- PN CircuitsDocument7 pagesPN CircuitsJap IbeNo ratings yet

- ME221 Software Tuning ManualDocument72 pagesME221 Software Tuning Manualtlxv04No ratings yet

- Mnit001 Meter Manual PDFDocument9 pagesMnit001 Meter Manual PDFSergio Andres Rivera JaramilloNo ratings yet

- Seminar Report On FadecDocument17 pagesSeminar Report On FadecMithil Pandey100% (2)

- Electric Motors - Energy Efficiency Reference Guide - CEATI PDFDocument166 pagesElectric Motors - Energy Efficiency Reference Guide - CEATI PDFjwsmith60No ratings yet

- 3408E 3412E INDUSTRIAL ENGINES - ELECTRICAL SCHEMATIC CAT Machines ElectricalDocument2 pages3408E 3412E INDUSTRIAL ENGINES - ELECTRICAL SCHEMATIC CAT Machines ElectricalurakovicNo ratings yet

- (SELD0179-11) 3500 Engines and Short Blocks (Peso Motores CAT)Document4 pages(SELD0179-11) 3500 Engines and Short Blocks (Peso Motores CAT)victor.cipriani100% (1)

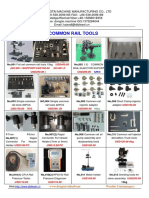

- CR Tools and Spare Parts NEWDocument21 pagesCR Tools and Spare Parts NEWeber granadosNo ratings yet

- Soul 2010 1.6LDocument71 pagesSoul 2010 1.6LIsmael RodriguezNo ratings yet

- PDF Kta19m PDFDocument2 pagesPDF Kta19m PDFFelipe Antonio Aurolo Moraga100% (2)

- Schulz Piston Machine CatalogDocument6 pagesSchulz Piston Machine CatalogjerrNo ratings yet

- Manual CaterpillarDocument308 pagesManual CaterpillarMaria Quiroga92% (13)

- PWC Cylinder Block - With PTO Sleeve (Spark Series) - Shop Manual Supplement smr2016-114Document24 pagesPWC Cylinder Block - With PTO Sleeve (Spark Series) - Shop Manual Supplement smr2016-114Théo GousseyNo ratings yet