Professional Documents

Culture Documents

Accelerated Curing Method Is Used To Get Early High Compressive Strength in Concrete

Accelerated Curing Method Is Used To Get Early High Compressive Strength in Concrete

Uploaded by

ADENH MDUOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Accelerated Curing Method Is Used To Get Early High Compressive Strength in Concrete

Accelerated Curing Method Is Used To Get Early High Compressive Strength in Concrete

Uploaded by

ADENH MDUCopyright:

Available Formats

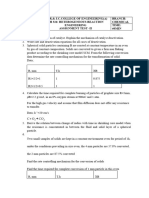

Accelerated Curing Method is used to get early high compressive strength in concrete.

This method is also used to find out 28 days compressive strength of concrete in 28

hours. (As per IS 9013-1978-Method of making, curing and determining compressive

strength of accelerated cured concrete test specimens).

Accelerated curing is useful in the prefabrication industry wherein high early age strength

enables the removal of the formwork within 24 hours thereby reducing the cycle time

resulting in cost saving benefits.The most commonly adopted curing techniques

are steam curing at atmospheric pressure, warm water curing, boiling water curing

and autoclaving.

Compressive Strength Test using Accelerated Curing

Method

1. After the test specimens (whose 28 days strength to be determined) have been made,

store it in moist air of at least 90 percent humidity for 23 hours + 15 min.

2. Cover the specimens with flat steel cover plate to avoid distortion during the use.

3. Carefully and gently lower the specimens into the curing tank and shall remain totally

immersed for a period of 3½ Hours + 15 min.

4. The temperature of water in the curing tank shall be at boiling (100 C) when the

o

specimens are placed.

5. After curing for 3 ½ hours in boil water, the specimen shall be carefully removed from

the boiling water and cooled by immersing in cooling tank at 27 +2 C for 2 hrs.

o

6. After cooling remove the specimens from the mould and tested for its accelerated

compressive strength (Ra) in N/mm . 2

7. The 28 days can be found out using following formula.

Predicted 28 days compressive strength = R28 = 8.09 + 1.64 Ra, where Ra is accelerated

compressive strength and R28 is predicted compressive strength at 28 days

You might also like

- ASTM D 6396 - 99 - Pipe Thread SealantsDocument5 pagesASTM D 6396 - 99 - Pipe Thread SealantsJoão Pedro MoreiraNo ratings yet

- Validation of Accelerated Curing Tank: Suraj T V, Dhanya KrishnanDocument13 pagesValidation of Accelerated Curing Tank: Suraj T V, Dhanya KrishnanPritha DasNo ratings yet

- Validation of Acce. Curing TankDocument13 pagesValidation of Acce. Curing TankvardhangargNo ratings yet

- Method For Making CylindersDocument3 pagesMethod For Making CylindersHumberto MorenoNo ratings yet

- ACFrOgBtG7-XmqRBRIcX2Ui RxpXk58joKN30zCs3n 0yxnx3 CsQEv3LTG7XKLGo9W9K8KmM2fJBqiJIf5sd9oD-jpz-keHTt7sh3fNoPx1J57w-GYxxn0Axbo 4OkKZMyBGV0Bt5IpKLAKNCrh PDFDocument4 pagesACFrOgBtG7-XmqRBRIcX2Ui RxpXk58joKN30zCs3n 0yxnx3 CsQEv3LTG7XKLGo9W9K8KmM2fJBqiJIf5sd9oD-jpz-keHTt7sh3fNoPx1J57w-GYxxn0Axbo 4OkKZMyBGV0Bt5IpKLAKNCrh PDFPrincess Tamani ManzanoNo ratings yet

- Effects of Non-Standard Curing On Strength of ConcreteDocument3 pagesEffects of Non-Standard Curing On Strength of ConcreteFarhanNo ratings yet

- WPT & RCPT Testing ProcedureDocument3 pagesWPT & RCPT Testing ProcedurePratik Sinha100% (1)

- Capsule Cement Data Sheet - MSDS CertificateDocument1 pageCapsule Cement Data Sheet - MSDS CertificateTom L HightNo ratings yet

- Accelerate Curing TestDocument15 pagesAccelerate Curing TestJunior CastañedaNo ratings yet

- 10.1515 - htmp-2013-0041 Performance and Life Assessment of Reformer TubesDocument14 pages10.1515 - htmp-2013-0041 Performance and Life Assessment of Reformer TubesFrancisco GonzalezNo ratings yet

- Compressive Strength of CementDocument3 pagesCompressive Strength of CementVarun AroraNo ratings yet

- Soundness of CementDocument3 pagesSoundness of CementKrishnaChaitanya100% (1)

- Final Methods and ResultsDocument13 pagesFinal Methods and ResultsRavindu ThilakarathneNo ratings yet

- Effect of Different Curing Conditions On The Mechanical Properties of UHPFCDocument5 pagesEffect of Different Curing Conditions On The Mechanical Properties of UHPFCLawend KoramarkiNo ratings yet

- Compressive Strength Test (IS: 4031 (Part 6) - 1988)Document2 pagesCompressive Strength Test (IS: 4031 (Part 6) - 1988)সন্দীপ চন্দ্রNo ratings yet

- 1 ST AndaziaranDocument8 pages1 ST Andaziaranceice2013No ratings yet

- Re-Evacuation, Repair and Revival Techniques of Cryogenic DewarsDocument6 pagesRe-Evacuation, Repair and Revival Techniques of Cryogenic DewarsOscar GarciaNo ratings yet

- 1516 1439 MR 1980 5373 MR 2017 0089Document7 pages1516 1439 MR 1980 5373 MR 2017 0089Thauan GomesNo ratings yet

- Developments in The Prediction of Potential Strength of Concrete From Results of Early TestsDocument12 pagesDevelopments in The Prediction of Potential Strength of Concrete From Results of Early TestsBalcha BinyamNo ratings yet

- Different Tests On Adobe BricksDocument4 pagesDifferent Tests On Adobe BricksMuhammad Junaid KhanNo ratings yet

- Bricks AdobeDocument4 pagesBricks AdobeMuhammad Junaid KhanNo ratings yet

- BricksDocument4 pagesBricksMuhammad Junaid KhanNo ratings yet

- C 272 - 91 R96 - Qzi3mi1sruqDocument5 pagesC 272 - 91 R96 - Qzi3mi1sruqStuartNo ratings yet

- Materials: Cure Cycle Optimization of Rapidly Cured Out-Of-Autoclave CompositesDocument15 pagesMaterials: Cure Cycle Optimization of Rapidly Cured Out-Of-Autoclave CompositesAbd BaghadNo ratings yet

- 2017 04 Dao Single Solution To The Formation of Polymer in Top of The Vacuum SeparatorDocument4 pages2017 04 Dao Single Solution To The Formation of Polymer in Top of The Vacuum Separatordorelysmarcano1No ratings yet

- Development of Mathematical Model To PredictDocument6 pagesDevelopment of Mathematical Model To PredictvardhangargNo ratings yet

- Conferance Effect of Different Curing Conditions On The Mechanical Properties of UHPFC F00408 RG. ID. 000693 Lawend K. AskarDocument6 pagesConferance Effect of Different Curing Conditions On The Mechanical Properties of UHPFC F00408 RG. ID. 000693 Lawend K. AskarLawend Koramarki100% (1)

- 11 Heat TreatmentDocument5 pages11 Heat TreatmentamokhtaNo ratings yet

- Standard Test Method For Alkali Resistance of Fiber Reinforced PolymerDocument3 pagesStandard Test Method For Alkali Resistance of Fiber Reinforced PolymerazhaniNo ratings yet

- Method To Determine Hot Permeability and Strength of Ceramic Shell MouldsDocument5 pagesMethod To Determine Hot Permeability and Strength of Ceramic Shell MouldsuzairmetallurgistNo ratings yet

- Surface Hardness and Compressive Strength of ConcreteDocument20 pagesSurface Hardness and Compressive Strength of ConcreteAmer FarkhanNo ratings yet

- Determining The Water Vapor Sorption of Unfaced Mineral Fiber InsulationDocument3 pagesDetermining The Water Vapor Sorption of Unfaced Mineral Fiber Insulationdinhtung2210100% (1)

- Experiment No: Dry Shrinkage Test For MortarDocument13 pagesExperiment No: Dry Shrinkage Test For Mortarruba.qammarNo ratings yet

- Mortar Strength TestDocument47 pagesMortar Strength TestVikas SharmaNo ratings yet

- Comparison of Methods For Determining The Water Ab PDFDocument7 pagesComparison of Methods For Determining The Water Ab PDFSivakumar Sadasivan NairNo ratings yet

- Compressive Strength of CementDocument3 pagesCompressive Strength of CementRama shankarNo ratings yet

- ResultsDocument3 pagesResultsRavindu ThilakarathneNo ratings yet

- Evolution of Precipitates During Age-Hardening of AW 6016 AlloyDocument6 pagesEvolution of Precipitates During Age-Hardening of AW 6016 AlloyPhung Tuan AnhNo ratings yet

- Masterflow 870 TdsDocument3 pagesMasterflow 870 TdsemilNo ratings yet

- EXP6 Soundness TestDocument2 pagesEXP6 Soundness TestMaterial LabNo ratings yet

- Effects of Accelerated Weathering On Elastomeric Joint SealantsDocument3 pagesEffects of Accelerated Weathering On Elastomeric Joint SealantsKelly-Moore Việt Nam0% (1)

- Shrinkage TestDocument4 pagesShrinkage TestJustin SeanNo ratings yet

- Cre Ii AssDocument2 pagesCre Ii Assashrafpatan639No ratings yet

- Compressive Strength of Cement Mortars Using 50 MM Cube Specimens T 106 & C109Document4 pagesCompressive Strength of Cement Mortars Using 50 MM Cube Specimens T 106 & C109YasirNo ratings yet

- Box Type Solar Cooker: EngineeringDocument2 pagesBox Type Solar Cooker: EngineeringR D SamNo ratings yet

- Concrete CubesDocument2 pagesConcrete CubesJonathan KeoughNo ratings yet

- Irc 85Document16 pagesIrc 85lisan2053No ratings yet

- C617 Capping Cylindrical Concrete Specimens-3Document1 pageC617 Capping Cylindrical Concrete Specimens-3Fitria RindangNo ratings yet

- Microstructural Characterization of Stainless Steel 17-4 PH Used in The Control Element of Pwr-Type Reactors Submitted To Different Heat TreatmentsDocument10 pagesMicrostructural Characterization of Stainless Steel 17-4 PH Used in The Control Element of Pwr-Type Reactors Submitted To Different Heat TreatmentsWILLIAN RICARDO DOS SANTOSNo ratings yet

- D-3137 - Standard Test Method For Rubber Property Hydrolytic StabilityDocument2 pagesD-3137 - Standard Test Method For Rubber Property Hydrolytic StabilityJak TaeNo ratings yet

- 4.4 Research Procedures: 4.4.1. Get The Volcanic Rock SampleDocument22 pages4.4 Research Procedures: 4.4.1. Get The Volcanic Rock SampleClaudio LoperaNo ratings yet

- Reliability of Accelerated Curing Techniques For Speedy Design of Concrete Mixes - An Appraisal of IS 9013:1978 CodeDocument4 pagesReliability of Accelerated Curing Techniques For Speedy Design of Concrete Mixes - An Appraisal of IS 9013:1978 CodeAnonymous BoP7nnBNo ratings yet

- Influence of Curing Regime On Strength Development of Grade C60 ConcreteDocument6 pagesInfluence of Curing Regime On Strength Development of Grade C60 ConcreteSri SrikanthNo ratings yet

- GIW WI-HQ1-012 - Titanium Dioxide, Muffle FurnaceDocument4 pagesGIW WI-HQ1-012 - Titanium Dioxide, Muffle FurnaceMohamed RashidNo ratings yet

- c3 Accelerated Aging Tests 10Document10 pagesc3 Accelerated Aging Tests 10thinker_No ratings yet

- 672CDocument3 pages672CJGD123No ratings yet

- Bitumen TestDocument6 pagesBitumen TestSayal SattarNo ratings yet

- Resistance of Concrete To Rapid Freezing and Thawing: Standard Test Method ForDocument6 pagesResistance of Concrete To Rapid Freezing and Thawing: Standard Test Method ForRam Kumar Jaiswal100% (3)

- Saso 87 Methods of Test For Concrete (Cement) Building Bricks and BlocksDocument7 pagesSaso 87 Methods of Test For Concrete (Cement) Building Bricks and BlocksMohamed AbdinNo ratings yet