Professional Documents

Culture Documents

A Review On Seven S (7S) As A Tool of Workplace Organization

Uploaded by

jS132Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

A Review On Seven S (7S) As A Tool of Workplace Organization

Uploaded by

jS132Copyright:

Available Formats

International Journal of Innovations in Engineering and Technology (IJIET)

A Review on Seven S (7S) as a tool of

Workplace Organization

Ajay Anantrao Joshi

M. Tech Student, Department of Industrial Engineering

RCOEM, Nagpur, Maharashtra, India

Abstract- The workplace organization is a foundation stone for the productivity improvement that eliminates

or reduces the muda, mura and muri. Visual Management and 5S/5C are the basic tools of workplace

organization. The visual management focuses on the placing an item, component or machine at specific

location with proper labeling and colour coding. While, 5S continually improves the workplace by sorting &

placing Gembutsu at proper location, cleaning the Gemba, standardization and sustaining the 4S by training

and education to the employees. 7S is the new terminology consists of the seven phases namely Sort, Set in

order, Shine, Standardize, Sustain or Self Discipline, Safety and Spirit. The paper explains the methodology,

action steps, resources required and target outcomes for the implementation of 7S as a tool of organizing

workplace scenario.

Keywords – 7S, 5S, Visual Management, Workplace Organization

I. INTRODUCTION

The introduction discusses the concepts of Workplace organization, Visual management and 5S/5C.

A. Workplace organization:

The workplace organization is one of the simplest means of determining an organizational approach to its business

to evaluate its housekeeping and visual management. When things look right, they often are. The workplace

organization consists of visual management and Gemba Kanri or 5S/5C technique. (The Lean Group).

B. Visual Management:

Visual Management is a workplace where all associates understand and manage their own work in a safe, clean,

organized environment that fosters open communication, pride, and continuous improvement. The Visual

Management provides real-time information on work place status by a combination of simple, effective visual

information aids. These allow employees to understand their influence as well as improve the organizational

performance. Visual Management implementation consists of six phases viz. Visual control board, Andon

(Lantern=Signals), Footprints, Signage (Graphical display), Obeya (Innovation=Automation) and Hansei (Self

reflection). (iCAM) The six phases of Visual Management is shown in figure 1.

Figure 1 Phases of Visual Management

Volume 6 Issue 2 December 2015 19 ISSN: 2319 – 1058

International Journal of Innovations in Engineering and Technology (IJIET)

C.5S/5C or Gemba Kanri:

Gemba Kanri or 5S/5C is a systemized and methodical approach allowing teams to organize their workplace in the

safest and most efficient manner. The initial stage involves removing all unnecessary items from the workplace.

Leftover is then placed in a permanent location depending on the frequency of used. 5S is a process for implementing

and maintaining a clean, safe and organized work area. 5S provides a way for organizations to operate efficiently and

effectively. 5S/5C consists of Seiri = Sort (Clean out), Seiton = Set in order (Configure), Seiso = Shine (Clean &

Check), Seiketsu = Standardize (Conformity), Shitsuke = Sustain or Self discipline (Custom & Practice) as shown in

figure 2.

Figure 2 Phases of 5S (5C)

II. LITERATURE REVIEW

R. S. Agrahari et al (2015) explains the 5S implementation methodology and guidelines to improve performance

of the small scale industries. The qualitative form of results obtained in the safety, productivity, efficiency and

housekeeping practices. The results after implementation and before implementations are shown by using

photographs.

S. R. Dulange (2013) implemented 5S principles in textile industries in order to improve the organization

performance. The inventory cost reduction is achieved from approx. 3500 INR to approx. 3000 INR after 5S

implementation in the organization.

Marion, S C et al (2010) describes the major problems faced by industries particularly of USA manufacturing

industries and the indispensable tools such as Lean Manufacturing and 6S to tackle with the problems. This paper

shares some success stories that motivate industries to implement these tools to achieve their set goals.

Lista International Corporation (2011) discusses the 5S implementation methodology for manufacturing industries

to organize their workplaces. The importance and benefits of 5S are described in detail with the help of photographs.

K. Chandrasekar (2011) explains the role of workplace environment to motivate and encourage the employees of

an organization in order to enhance the efficiency and effectiveness of employees. Paper describes the only good pay

is not sufficient to motivate the employees. Interesting work, opportunity to develop special abilities, enough

authority, friendly and helpful coworker, competent supervision and clearly defined responsibilities requires

motivating them.

Vipulkumar C. Patel et al (2014) describe the methodology of 5S implementation, components of 5S and benefits

of 5S implementation. This review paper shows the improvements possible by 5S implementations such as process

improvement, reduction in breakdowns, reduction in the wastages and pollution and enhance working environment.

J. Michalska et al (2007) explain the Total Quality Management (TQM) can be achieved through lean principles

such as 5S. The paper discusses the 5S methodology and implementation strategies in order to enhance the quality of

the product with proper training, guiding and educating the employees.

Volume 6 Issue 2 December 2015 20 ISSN: 2319 – 1058

International Journal of Innovations in Engineering and Technology (IJIET)

Production Automation Corporation (PAC) (2009) has published the handbook providing detailed 5S

methodology with the help of illustrations and photographs. This handbook describes the action steps, resources

required, target outcomes and audit form for continuous monitoring for the improvisation of 5S methodology.

Y. C. Ennin et al (2012) illustrates the 5S is the good housekeeping technique for enhancing the productivity,

quality and safety at the workplace. This paper describes the meaning, methods and benefits of 5S implementation

with the help of photographs and 5S checklists.

International College of Automotive (iCAM) (2010) explains the meaning, importance, principles such as safety,

productivity & quality, steps for VM and benefits of the Visual Management for the development of the organization.

Conard Robertson (2002) explains the Visual Management, 5S and 5S supporting strategies with the help of

illustrations. Various templates, diagrams and checklists are provided to measure, monitor, analyze, improve and

maintain the workplace environment clean, safe and healthy.

III. METHODOLOGY

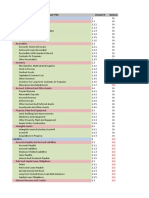

Seven S (7S) methodology adopted for the workplace organization by eliminating or reducing muda (Waste),

Mura (Inconsistency) and Muri (Physical strain). The 7S implementation consists of seven phases shown in Figure 3

viz. Sort, Set in order, Shine, Standardize, Sustain or Self Discipline, Safety and Spirit.

Each phase continuously improves the performance of an organization by eliminating wastages of searching,

waiting, transportation, motion, work in progress inventory etc. 7S also makes the working environment clean and

safe that improves the morale of the employees. The improvement in the form of the morale is a qualitative form that

is responsible for the reduction in the Manufacturing Lead Time (MLT). So, the 7S helps to reduce MLT in

quantitative form as well as in qualitative form. The quantifiable variables are searching, move, waiting time, cycle

time, lead time, production rate, productivity, quality, profit and client network and the qualitative variables are

working environment, communication and morale.

Figure 3 Phases of 7S

The description of each phase of 7S implementation is as follows-

(1S) Sort:

This means distinguishing or sort out between wanted (Value Added) and unwanted (Non Value Added) items at

place of work and removal of unwanted (NVA) items.

Action Steps:

• Identify a 5S-project area and take "before" pictures

• Review sorting criteria

• Create a local red tag area

• Tag, record, and move red tagged items

• Take "after" pictures

Resources required:

Volume 6 Issue 2 December 2015 21 ISSN: 2319 – 1058

International Journal of Innovations in Engineering and Technology (IJIET)

• Red Tags

• Red Tag Record Forms

• Camera for “before” and “after” pictures

Target Outcomes:

• Increase in floor space utilization.

• Searching time of tools, materials, and papers is reduced.

• Better flow of work.

• Inventory cost of unnecessary items is reduced.

(2S) Set in order:

Arranging and labeling items in such a manner that they are easy to find and use.

Action Steps:

• Take “before” pictures

• Implement workplace changes

• Mark locations by creating addresses and applying labeling, marking, and color-coding

• Take “after” pictures

Resources required:

• Existing plant standards for labeling, marking, and color-coding

• Labeling supplies

• Tape for creating borders on work surfaces and floors

• Paint and painting supplies

Target Outcomes:

• Take things out and keep things back easily.

• Make lesser mistakes.

• Reduce searching time.

• Work environment becomes safe

(3S) Shine:

This means removing dirt, strain, filth, soot and dust from the work area. This includes cleaning and care for

equipment and facilities and also inspecting them for abnormalities. In a way it also includes primary maintenance

of equipment.

Action Steps:

• Define "clean"

• Get cleaning supplies

• Take "before" pictures

• Clean the work area

• Identify contamination sources

• Fix small imperfections

• Take "after" pictures

Resources required:

• Cleaning supplies such as brooms, dust pans, rags, degreasers, and floor cleaner.

Volume 6 Issue 2 December 2015 22 ISSN: 2319 – 1058

International Journal of Innovations in Engineering and Technology (IJIET)

• Personal protective equipment such as gloves and eye protection.

Target Outcomes:

• Work place becomes free of dirt and stains which is the starting point for quality.

• Equipment lifespan will be prolonged and breakdowns will be less.

• Creates a pleasant environment.

• Prevents accidents.

(4S) Standardize:

This call for systematizing the above 4S practices. This means ensuring that whatever cleanliness and orderliness

is achieved should be maintained. This should develop a work structure that will support the new practices and

turn them into habits.

The purpose of standardization is to make sure that everyone in the company follows the same procedure, the

same names of items, the same size of signalization/floor marking, shapes, colours, etc. Standardize also helps to

do the right thing the right way every time.

Action Steps:

• Brainstorm ideas for making the 5S changes standard operating procedure

• Update documentation to reflect changes

• Make sure all stakeholders are aware of the new standards - inform and educate

Resources required:

• Support from those who can create documentation, job aids, and visual aids

• Information and approval from those responsible for maintaining company procedures

• Poster-making supplies for posting new standards in work areas

Target Outcomes:

• Activities will be simplified.

• Consistency in the work practices.

• Avoid mistakes.

• Better visual and transparency management work efficiency will improve.

(5S) Sustain or Self Discipline:

Sustain also means ‘Discipline’. It denotes commitment to maintain orderliness and to practice first 3S as a way of

life.

Action Steps:

• Monitor processes established during S4 -Standardize

• Expand 5S efforts to other work areas

• Evaluate 5S effectiveness and continuously improve

• Recognize and reward strong efforts

Resources required:

• Management audit forms

• Resources for communication and recognizing successes (newsletters, displays, awards)

Volume 6 Issue 2 December 2015 23 ISSN: 2319 – 1058

International Journal of Innovations in Engineering and Technology (IJIET)

• Presentation tools for sharing best practices with other work areas

• Management commitment and focus on maintaining the new standards

Target Outcomes:

• Promotes habit for complying with workplace rules and procedures.

• Creates healthy atmosphere and a good work place.

• Helps you to develop team work.

• Provides you with data for improving 5S.

(6S) Safety:

Safety is the condition of being protected against physical, social, spiritual, financial, political, emotional,

occupational, psychological, educational, or other types or consequences of failure, damage, error, accident, harm,

or any other event that could be considered non-desirable.

Action Steps:

• Error Proofing (Poka-yoke)

• Safety related instructions & symbols

• Alert, Warning, Hazard area identification and labeling with proper symbols

• Safety trainings to employees

Resources required:

• Safety related instruction and Symbols

• Personal Protective Equipments (PPE)

• Safety Trainer or Expert

Target Outcomes:

• Avoid errors or mistakes

• Reduces accidents

• Safer working environment

(7S) Spirit (Team Spirit):

Team spirit is a willingness to cooperate as part of a team.

Action Steps:

• Formation of 7S team with a team leader

• Regular meetings to set benchmark and strategies for achievement

• Motivational and co-operational speeches or trainings for each 7S team on regular basis

Resources required:

• 7S team manual for the conclusion or solutions obtained after brainstorming session or meetings

• Leader with knowledge, abilities, experience, good understanding and cooperating skills

• Questionnaire survey at regular basis for measuring and analyzing the team spirit

• 7S Audit form for checking overall performance

Target Outcomes:

• Better communication

• Higher confidence to do work

Volume 6 Issue 2 December 2015 24 ISSN: 2319 – 1058

International Journal of Innovations in Engineering and Technology (IJIET)

• Better Understanding & Analysis on problems

• Creates healthy working environment

• Reduces boredom approach toward the job

IV. DISCUSSION

The general concept of the 7S is that they are intended to eliminate Muda (waste). The Lean Manufacturing (LM)

focuses on the reduction of the wastages and the foundation tool of LM is Workplace organization. Working in

disorder is neither productive, nor safe. 7S is a simple and practical method to build a quality culture at the work

place. It is relatively easy to undertake, and requires minimal additional resources. The first and small investment

made in time and effort pays off in a much bigger manner when the results are realized and maintained.

Only implementation of the 7S or Workplace organization is not sufficient. Continuous monitoring and

controlling the all 7S activities is also important and it can be monitored by conducting the questionnaire survey at

regular interval. If the responses by the respondents are poor then it reflects the degradation of the workplace

organization.

Benefits of implementing 7S are as follows-

• Workplace becomes cleaner, safer, well-organized and more pleasant;

• Floor space utilization is improved;

• Workflow becomes smoother and more systematic and non-value added activities are reduced;

• Time for searching tools, materials and document is minimized;

• Machine breakdowns are reduced since clean and well-maintained equipment breaks down less frequently and it

also becomes easier to diagnose and repair before breakdowns occur, therefore extending equipment life;

• Errors are minimized leading to making defect-free products;

• Consumables and material wastage are minimized;

• Morale and satisfaction of employees improve;

• Productivity of the organization improves together with the quality of products and services.

V. CONCLUSION

Workplace Organization is a simple and basic tool to organize the Gemba (workplace) in systematic manner so that

each and every item is at proper place or location provided with labeling and colour coding. Visual Management and

5S methodologies implemented for the improvisation of workplace. 7S is the extension of 5S with additional 2S i.e.

Safety and Spirit (Team Spirit). Safety practices and safety trainings are helpful for the reduction of accidents in the

industry. Team spirit encourages and motivates the team members to work in better way. So, it increases the

efficiency of the production operations or process.

The 7s activities should continuously monitored using questionnaire survey and improved if degrades. The 7S

improves organizations performance in terms of higher productivity, better quality, less accidents, clean, safe and

healthier working environment.

REFERENCES

[1] R. S. Agrahari, P.A. Dangle, K.V.Chandratre, “Implementation of 5S Methodology in the Small Scale Industry: A Case Study”,

International Journal of Scientific & Technology Research Volume 4, Issue 04, pp. 180-187, April 2015..

[2] S. R. Dulange, “A Study on Power looms by Management Intervention: 5S Philosophy”, Industrial Engineering Letters, Vol.3, No.12, pp.

37-41, 2013.

[3] Marion, S C, Sharon McKittrick, “Lean manufacturing, 6S program are indispensable tools for Beneteau USA”, SCMEP Success Stories

Helping South Carolina Companies Grow, pp.1-2, 2010.

Volume 6 Issue 2 December 2015 25 ISSN: 2319 – 1058

International Journal of Innovations in Engineering and Technology (IJIET)

[4] “Implementing 5S Workplace Organization Methodology Programs in Manufacturing Facilities”, Lista International Corporation, pp. 1-5,

2011.

[5] Dr. K. Chandrasekar, “Workplace Environment and its Impact on Organizational Performance in Public Sector Organizations”,

International Journal of Enterprise Computing and Business Systems, Vol. 1 Issue 1, pp. 1-19, January 2011.

[6] Vipulkumar C. Patel, Dr. Hemant Thakkar, “Review on Implementation of 5S in Various Organization”, Journal of Engineering Research

and Applications, Vol. 4, Issue 3 (Version 1), pp.774-779, March 2014.

[7] J. Michalska, D. Szewieczek, “The 5S methodology as a tool for improving the organization”, Journal of Achievements in Materials and

Manufacturing Engineering, Volume 24 Issue 2, pp. 211-214, October 2007.

[8] “5S / Visual Workplace Handbook Building the foundation for continuous improvement”, Production Automation Corporation (PAC), pp.

1-20, 2009.

[9] Y. C. Ennin and D. Obi, K. Ramful, “5S: Good Housekeeping Techniques for Enhancing Productivity, Quality and Safety at the

Workplace”, International Trade Centre (ITC), No 89/2012, pp. 1-17, 2012

[10] “Instruction Notes on Visual Management”, International College of Automotive (iCAM), 2010.

[11] Conard Robertson, “Visual Management”, 2002.

Volume 6 Issue 2 December 2015 26 ISSN: 2319 – 1058

You might also like

- 5S Case StudyDocument7 pages5S Case StudyYASH BHAVSARNo ratings yet

- Da2d PDFDocument6 pagesDa2d PDFCyron Elden Senarillos-Talita Bangis-BodegasNo ratings yet

- 1-Ijbgm - Effects of 5s Implementation On Performance of OrganizationDocument14 pages1-Ijbgm - Effects of 5s Implementation On Performance of Organizationiaset123No ratings yet

- Implementation of The 5S System As A Factor For Improving The Quality Management PDFDocument6 pagesImplementation of The 5S System As A Factor For Improving The Quality Management PDFEva Eh GiàNo ratings yet

- Format. Hum - Implementation of 5s Methodology in The Banking SectorDocument10 pagesFormat. Hum - Implementation of 5s Methodology in The Banking SectorImpact JournalsNo ratings yet

- 5s 3Document6 pages5s 3Chirag SuleNo ratings yet

- 5S System As A Manner For Improving Working ConditDocument12 pages5S System As A Manner For Improving Working ConditDrRasha Abo ShoShaNo ratings yet

- 5SDocument23 pages5SReetu Sri100% (1)

- B. For Students - Session 67 PDFDocument35 pagesB. For Students - Session 67 PDFSairah Camille ArandiaNo ratings yet

- Project ReportDocument32 pagesProject ReportShilp VachhaniNo ratings yet

- Jurnal InternasionalDocument6 pagesJurnal InternasionalNadila MutiahNo ratings yet

- QRE Micro ProjectDocument12 pagesQRE Micro Projectviveksrivastava1213No ratings yet

- Enhancement in Productivity by Integration of 5S Methodology and Time and Motion StudyDocument10 pagesEnhancement in Productivity by Integration of 5S Methodology and Time and Motion StudyJN RJNo ratings yet

- Importance of The 5S Methodology To Occupational Safety and Health: A Case Study in A Branch of The Asia Commercial Bank in VietnamDocument8 pagesImportance of The 5S Methodology To Occupational Safety and Health: A Case Study in A Branch of The Asia Commercial Bank in VietnamRafeyTahirNo ratings yet

- 5SDocument7 pages5SKlunskyNo ratings yet

- Productivity Improvement Tools 7TH MECH RAJDocument34 pagesProductivity Improvement Tools 7TH MECH RAJRaj VadhavanaNo ratings yet

- Rater-Reliability of A 5S Audit ChecklistDocument1 pageRater-Reliability of A 5S Audit ChecklistAizz D'Tech AbeNo ratings yet

- An Integrated Framework For The Implementation and Continuous Improvement of Spatial Data InfrastructuresDocument14 pagesAn Integrated Framework For The Implementation and Continuous Improvement of Spatial Data Infrastructuresvisanu91No ratings yet

- Online Library of Quality, Service Improvement and Redesign ToolsDocument5 pagesOnline Library of Quality, Service Improvement and Redesign ToolsAntonio TiradoNo ratings yet

- Apply 5S ProcedureDocument14 pagesApply 5S ProcedurehailuNo ratings yet

- Read Me 1Document12 pagesRead Me 1kachkach zakNo ratings yet

- Production & Operation ManagementDocument13 pagesProduction & Operation Managementmadhvendra99No ratings yet

- Monodzukuri Test Monodzukuri Test: Learning Textbook Learning TextbookDocument31 pagesMonodzukuri Test Monodzukuri Test: Learning Textbook Learning TextbookMani Rathinam Rajamani0% (2)

- N266 IjstmDocument7 pagesN266 IjstmEr Aftab ShaikhNo ratings yet

- Implementing 5S Methodology: AbstractDocument4 pagesImplementing 5S Methodology: AbstractPrathmesh MahajaniNo ratings yet

- Performance Management Method For Construction Companies: Namho Kim Moonseo ParkDocument6 pagesPerformance Management Method For Construction Companies: Namho Kim Moonseo ParkAhmadElTebiNo ratings yet

- Toyota Standard Work: The Foundation of KaizenFrom EverandToyota Standard Work: The Foundation of KaizenRating: 5 out of 5 stars5/5 (1)

- The "5S" Strategy by Using PDCA Cycle For Continuous Improvement of The Manufacturing Processes in Agriculture IndustryDocument14 pagesThe "5S" Strategy by Using PDCA Cycle For Continuous Improvement of The Manufacturing Processes in Agriculture IndustryDrRasha Abo ShoShaNo ratings yet

- Kaizen: Kaizen (Japanese For "Improvement" or "Change For The Better") Refers To Philosophy or Practices ThatDocument7 pagesKaizen: Kaizen (Japanese For "Improvement" or "Change For The Better") Refers To Philosophy or Practices ThatGhanshyam BarhateNo ratings yet

- KPI in SMEDocument15 pagesKPI in SMEsachinrajkv100% (1)

- KAIZENDocument17 pagesKAIZENK.s. RameshNo ratings yet

- Study Performance AppricalDocument7 pagesStudy Performance AppricalSourav DharaNo ratings yet

- Center?" or "Where Is The Best Location To Build An Ambulance Station?". Also, One of TheDocument2 pagesCenter?" or "Where Is The Best Location To Build An Ambulance Station?". Also, One of TheMounicha AmbayecNo ratings yet

- 17ME664 TQM Module 4Document31 pages17ME664 TQM Module 4Mohsin MominNo ratings yet

- Critical Success Factors For The Implementation of Enterprise Resource Planning (Erp) : Empirical ValidationDocument10 pagesCritical Success Factors For The Implementation of Enterprise Resource Planning (Erp) : Empirical ValidationiacikgozNo ratings yet

- Total Productive Maintenance (TPM) & It S ImplementationDocument46 pagesTotal Productive Maintenance (TPM) & It S ImplementationDeep DaveNo ratings yet

- LM - Jury DocumentDocument21 pagesLM - Jury DocumentMuskan GuptaNo ratings yet

- New Wordpad DocumentDocument20 pagesNew Wordpad DocumentRupa SharmaNo ratings yet

- The 5S Lean Method As A Tool of Industrial Management PerformancesDocument7 pagesThe 5S Lean Method As A Tool of Industrial Management PerformancesMarizelle EscobarNo ratings yet

- Design and Implementation of Hotel Operations Platform: A Study On Selected Hotels in PhuketDocument13 pagesDesign and Implementation of Hotel Operations Platform: A Study On Selected Hotels in Phuketmithashakarkera3272No ratings yet

- Lean ManufacturingDocument21 pagesLean ManufacturingJithesh S.RNo ratings yet

- EBQCI4A Chapter 2Document32 pagesEBQCI4A Chapter 2therealmutshidziNo ratings yet

- IA - Satrio Wibowo Wicaksono - 2ADocument6 pagesIA - Satrio Wibowo Wicaksono - 2Aikam sansNo ratings yet

- Descriptives of MisDocument19 pagesDescriptives of MisMr BeenNo ratings yet

- IETEBanglore509Document10 pagesIETEBanglore509Muthu KumarNo ratings yet

- Technology & Operational StrategyDocument10 pagesTechnology & Operational StrategyAnonymous uxd1ydNo ratings yet

- What Is 5S Philosophy?: Quality Glossary Definition: Five S's (5S)Document8 pagesWhat Is 5S Philosophy?: Quality Glossary Definition: Five S's (5S)MudassarNo ratings yet

- The Role of Artificial Intelligence Applications in Managing The Employee Performance Evaluation An Iraqi Case StudyDocument11 pagesThe Role of Artificial Intelligence Applications in Managing The Employee Performance Evaluation An Iraqi Case StudyEditor IJTSRDNo ratings yet

- Implementation of 5S Practices A ReviewDocument9 pagesImplementation of 5S Practices A ReviewChetan ParaskarNo ratings yet

- The 5S" Strategy For Continuous Improvement of The Manufacturing Processes in Autocar Exhaust Gheorghe DULHAIDocument6 pagesThe 5S" Strategy For Continuous Improvement of The Manufacturing Processes in Autocar Exhaust Gheorghe DULHAIAnllelo VazquezNo ratings yet

- Process Efficiency Improvement in Small Organization Through Lean Supply Chain ApproachDocument8 pagesProcess Efficiency Improvement in Small Organization Through Lean Supply Chain ApproachGautam MishraNo ratings yet

- 2 Mark and 8 Mark (Notes)Document156 pages2 Mark and 8 Mark (Notes)IfiifNo ratings yet

- 5S (Methodology)Document9 pages5S (Methodology)thuyayehtut454No ratings yet

- Business Processes QuizDocument6 pagesBusiness Processes QuizGilbert KiprotichNo ratings yet

- Total Quality MangementDocument8 pagesTotal Quality MangementMohinderSinghNo ratings yet

- 5S DetailsDocument10 pages5S DetailsHemalakshmiNo ratings yet

- MGT613 Short Answers QuestionsDocument12 pagesMGT613 Short Answers QuestionsHilew TSegayeNo ratings yet

- Attaining Agility at The Enterprise LevelDocument5 pagesAttaining Agility at The Enterprise LevelramptechNo ratings yet

- Enterprise Resource Planning: Fundamentals of Design and ImplementationFrom EverandEnterprise Resource Planning: Fundamentals of Design and ImplementationNo ratings yet

- Gaap Chart Basic Function NatureDocument3 pagesGaap Chart Basic Function NaturearifuddinkNo ratings yet

- Configuration Basics of Discrete ManufacturingDocument6 pagesConfiguration Basics of Discrete ManufacturinggvlaxmipathiNo ratings yet

- Operation Mangament CH15Document22 pagesOperation Mangament CH15Moe Alnaim100% (2)

- Gujarat Activity ReportDocument15 pagesGujarat Activity ReportgandhiannexNo ratings yet

- Comparitive Study Between Digital and Trditional MarketingDocument72 pagesComparitive Study Between Digital and Trditional MarketingYOGITA50% (2)

- Personnel Psychology Winter 1995 48, 4 ABI/INFORM GlobalDocument28 pagesPersonnel Psychology Winter 1995 48, 4 ABI/INFORM GlobalUm'e HabibaNo ratings yet

- Cold StorageDocument22 pagesCold Storagedineshjain11100% (1)

- Industrial RelationsDocument3 pagesIndustrial RelationsPankaj KhindriaNo ratings yet

- KEY Cuadernillo Nivel 4Document112 pagesKEY Cuadernillo Nivel 4Cami NogueraNo ratings yet

- Chapter 1 Business Combination - Statutory Merger and Statutory Consolidation - As of 7.13Document4 pagesChapter 1 Business Combination - Statutory Merger and Statutory Consolidation - As of 7.13EyngelNo ratings yet

- Ch3 ACCA BPP F1 SlideDocument25 pagesCh3 ACCA BPP F1 SlideIskandar BudionoNo ratings yet

- Grandteq Industrial Steel Products Vs MargalloDocument1 pageGrandteq Industrial Steel Products Vs MargalloJoe CuraNo ratings yet

- December 28,2009 PN Vijay Financial Services PVT LTD: Company Update: Aurobindo Pharma LTDDocument4 pagesDecember 28,2009 PN Vijay Financial Services PVT LTD: Company Update: Aurobindo Pharma LTDvinay.prabhuNo ratings yet

- The Subsidiary-Level StrategyDocument11 pagesThe Subsidiary-Level Strategyoureducation.in100% (4)

- 13 Macroeconomic Analysis of India's Inclusive Growth - Sunil Bhardwaj - GM012Document9 pages13 Macroeconomic Analysis of India's Inclusive Growth - Sunil Bhardwaj - GM012Muhammad Sohail100% (1)

- 5b3b0c0283739 BPI IR 2017 Senior Management and Corporate Governance 6Document20 pages5b3b0c0283739 BPI IR 2017 Senior Management and Corporate Governance 6John Karlo CamineroNo ratings yet

- Trust Receipts LawDocument26 pagesTrust Receipts LawFrancis Paolo TiopiancoNo ratings yet

- SAP TablesDocument14 pagesSAP TablesCorey Acevedo100% (2)

- Case Goli Vada PavDocument2 pagesCase Goli Vada PavAPNo ratings yet

- ExxxxxxDocument2 pagesExxxxxxGuiness DeguzmanNo ratings yet

- Week 10 Books of AcctsDocument6 pagesWeek 10 Books of AcctsKirsten BentingananNo ratings yet

- Contacts JPGDocument96 pagesContacts JPGYassine ZemmouriNo ratings yet

- Inventories Cost ApproachDocument56 pagesInventories Cost ApproachJD DLNo ratings yet

- PMP Case Study 1Document9 pagesPMP Case Study 1Khyle Laurenz DuroNo ratings yet

- HSE Manual: DesignDocument134 pagesHSE Manual: DesignpasungiliiNo ratings yet

- MOSL Subros 201809 Initiating CoverageDocument18 pagesMOSL Subros 201809 Initiating Coveragerchawdhry123No ratings yet

- PESTLE AnalysisDocument4 pagesPESTLE Analysiserarun22100% (1)

- MBA 113 - Reaction Paper 7Document6 pagesMBA 113 - Reaction Paper 7Denise Katrina PerezNo ratings yet

- CourseOutline 1201 HOSP1320Document3 pagesCourseOutline 1201 HOSP1320uknowgaryNo ratings yet

- Merchant and Investment BankingDocument55 pagesMerchant and Investment BankingShafiq SumonNo ratings yet