Professional Documents

Culture Documents

LL0220AA Linear Low Density Polyethylene Film Properties

Uploaded by

Xuân Giang NguyễnOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

LL0220AA Linear Low Density Polyethylene Film Properties

Uploaded by

Xuân Giang NguyễnCopyright:

Available Formats

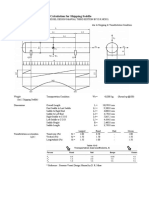

Linear Low Density Polyethylene

LL0220AA

Test method

Typical properties Unit Value

(ASTM)

Resin

MFI@190°C,2.16 kg D1238 gr/10min 2 - 2.5

Density D2839 gr/ml 0.917-0.920

Film *

Tensile Strength@Yield ,MD/TD D638 Mpa 10/9

Elongation@Break,MD/TD D638 % 600/810

Tensile Strength@Break,MD/TD D688 Mpa 40/31

Tear Strength,MD/TD D1922 gr/25mic 90/280

Haze D1003 % 13

°

Gloss(45 ) D2457 Rating 50

¾ Values shown are averages & are not to be considered as product specifications.

* 38 microns, 2:1 Blow ratio / MD=Machine Direction, TD=Transverse Direction

Main application & Characteristics:

LL0220AA is a linear low density polyethylene copolymer containing butene-1 as

a co-monomer.

Address:

No. 3, Taban St.

LL0220AA has been specially developed for production of hand wrap and other

Vali-e-Asr Ave. cast stretch films such as oriented tapes. It can also be used as a blending

Tehran - IRAN partner in LDPE or LLDPE in both cast and blown film applications.

LL0220AA offers the following advantages when it processed by the cast

extrusion process:

Tel: − Good balance of mechanical properties.

(+98 21)82122700

− Good optical properties.

− Good cling performance.

Fax:

(+98 21)8867 4126-27

LL0220AA also can be used as compounds for low voltage power cable

insulation or fibre optic jacketing.

LL0220AA should be processed in machinery designed for LLDPE.

Web-site: Melt temperature range in the cast process are normally 240°C-280°C and in

www.arpc.ir lean blends for blown film are 165°C-215°C.

LL0220AA should be stored in the dry condition below the 50°C and avoided

from the exposure of direct sunlight.

E-mail:

Sales@arpc-ir.net

* LL0220AA is suitable for food contact.

1 Of 1

You might also like

- LL0209 AA-shazand PDFDocument1 pageLL0209 AA-shazand PDFmohamad mostafaviNo ratings yet

- Q2018 Series: Linear Low Density Polyethylene (LLDPE)Document2 pagesQ2018 Series: Linear Low Density Polyethylene (LLDPE)lyesNo ratings yet

- LL 22402 Linear Low Density Polyethylene Properties and ApplicationsDocument1 pageLL 22402 Linear Low Density Polyethylene Properties and ApplicationsJaime222No ratings yet

- Q1018 Series: Linear Low Density Polyethylene (LLDPE)Document2 pagesQ1018 Series: Linear Low Density Polyethylene (LLDPE)lyesNo ratings yet

- LDF201FG R01Document1 pageLDF201FG R01Oscar Tan IIINo ratings yet

- Qatofin Lotrene Q2018Document2 pagesQatofin Lotrene Q2018HichamSalamaNo ratings yet

- Product Data: Titanlene Ldf200GgDocument1 pageProduct Data: Titanlene Ldf200GgchinchotarngNo ratings yet

- SABIC® LDPE - HP2023JN - Global - Technical - Data - SheetDocument2 pagesSABIC® LDPE - HP2023JN - Global - Technical - Data - SheetSarvesh SinghNo ratings yet

- SABIC® LDPE - HP0322N - Global - Technical - Data - SheetDocument2 pagesSABIC® LDPE - HP0322N - Global - Technical - Data - SheetThamimNo ratings yet

- Lotrene LLDPE Datasheet PDFDocument6 pagesLotrene LLDPE Datasheet PDFThụy Thảo LinhNo ratings yet

- LLDPE - Lotrene Q1018N PDFDocument2 pagesLLDPE - Lotrene Q1018N PDFNilay TanrıverNo ratings yet

- Sabicr Ldpe Hp4023wnDocument2 pagesSabicr Ldpe Hp4023wnFarah bennourNo ratings yet

- 1695012734-2058787459-h-t-nh-a-ldpe-hp0724nn-tdsDocument2 pages1695012734-2058787459-h-t-nh-a-ldpe-hp0724nn-tdsChu ChuNo ratings yet

- Riblene FF20Document2 pagesRiblene FF20Stefan PopaNo ratings yet

- Ldpe L07920Document1 pageLdpe L07920Luis Fernando Camacho VargasNo ratings yet

- SABIC® LDPE - HP0323NN - Global - Technical - Data - SheetDocument2 pagesSABIC® LDPE - HP0323NN - Global - Technical - Data - SheetRubenMurguiaNo ratings yet

- Lldpe 22501aa22501kjDocument2 pagesLldpe 22501aa22501kj李万福No ratings yet

- Product Data: Titanlene Ldf250YzDocument1 pageProduct Data: Titanlene Ldf250YzchinchotarngNo ratings yet

- SABIC® LDPE - HP2022NN - Global - Technical - Data - SheetDocument2 pagesSABIC® LDPE - HP2022NN - Global - Technical - Data - Sheetselman gürbüzNo ratings yet

- LDPE L2AS Data SheetDocument1 pageLDPE L2AS Data SheetGabriela Lopez MunozNo ratings yet

- SABIC® LDPE - HP4024WN - Global - Technical - Data - SheetDocument2 pagesSABIC® LDPE - HP4024WN - Global - Technical - Data - SheetTOMALO FREENo ratings yet

- FR2375CDocument1 pageFR2375CDanitsa Fiorella Silvestre BautistaNo ratings yet

- Sabic® Ldpe Hp0322Nn: Low Density PolyethyleneDocument2 pagesSabic® Ldpe Hp0322Nn: Low Density PolyethyleneGabriela Lopez MunozNo ratings yet

- Formolene fl2202c 1Document1 pageFormolene fl2202c 1armandoestavanquitoNo ratings yet

- Hdpe HHM TR 144Document1 pageHdpe HHM TR 144JagrutNo ratings yet

- LDPE-HP0723JNDocument2 pagesLDPE-HP0723JNChu ChuNo ratings yet

- LLDPE Film Product Data SheetDocument2 pagesLLDPE Film Product Data SheetManufaktur Sinar JoyoboyoNo ratings yet

- Novapol TF 0338 e NovaDocument2 pagesNovapol TF 0338 e NovaJulio GarcíaNo ratings yet

- Low Density Polyethylene LD7000A: DescriptionDocument1 pageLow Density Polyethylene LD7000A: DescriptionJaime222No ratings yet

- TechnicalDataSheet 4032D Films PDFDocument3 pagesTechnicalDataSheet 4032D Films PDFP StuartNo ratings yet

- Leaflet BJ300 enDocument2 pagesLeaflet BJ300 enVu TranNo ratings yet

- LL7420D Linear Low Density Polyethylene ResinDocument1 pageLL7420D Linear Low Density Polyethylene ResinFahad MohamedNo ratings yet

- Low Density Polyethylene: DescriptionDocument2 pagesLow Density Polyethylene: DescriptionlyesNo ratings yet

- Sabic Lldpe 118Wsj: Linear Low Density PolyethyleneDocument2 pagesSabic Lldpe 118Wsj: Linear Low Density PolyethyleneFahad MohamedNo ratings yet

- Lldpe Ll0209Aa Linear Low Density Polyethylene: 3) Typical Data Test Method Typical Value Unit Property PhysicalDocument2 pagesLldpe Ll0209Aa Linear Low Density Polyethylene: 3) Typical Data Test Method Typical Value Unit Property PhysicalĐỗ Ngọc TúNo ratings yet

- Lldpe - Sabic® Lldpe - 118NJ PDFDocument2 pagesLldpe - Sabic® Lldpe - 118NJ PDFNilay TanrıverNo ratings yet

- SABIC® LLDPE - 118NJA - Americas - Technical - Data - SheetDocument2 pagesSABIC® LLDPE - 118NJA - Americas - Technical - Data - Sheetdiana sarmientoNo ratings yet

- SABIC® LLDPE - 118WJA - Americas - Technical - Data - SheetDocument2 pagesSABIC® LLDPE - 118WJA - Americas - Technical - Data - SheetDiana SarmientoNo ratings yet

- LF410 (영문)Document1 pageLF410 (영문)coordinador.comercialNo ratings yet

- 1661ff33-51be - ZA - LF2103 Film - EN-ZADocument2 pages1661ff33-51be - ZA - LF2103 Film - EN-ZApepeNo ratings yet

- SABIC® LLDPE - 218WJA - Americas - Technical - Data - SheetDocument2 pagesSABIC® LLDPE - 218WJA - Americas - Technical - Data - Sheetdiana sarmientoNo ratings yet

- FORMOLENE LB1810E2 Homotipo Venelene 11pg4Document1 pageFORMOLENE LB1810E2 Homotipo Venelene 11pg4Luis Eduardo Julio MovillaNo ratings yet

- Product DatasheetDocument1 pageProduct Datasheetأبو أميرNo ratings yet

- Product Data: Titanex Hf0961Document1 pageProduct Data: Titanex Hf0961chinchotarngNo ratings yet

- Sabic FJ00952Document2 pagesSabic FJ00952Yemane FekadeNo ratings yet

- BandarImam 0200Document2 pagesBandarImam 0200art72 talNo ratings yet

- Low Density Polyethylene: Lamination Film ApplicationsDocument1 pageLow Density Polyethylene: Lamination Film ApplicationsMahadi Bachar MahamatNo ratings yet

- Linear Low Density Polyethylene Injection MoldingDocument2 pagesLinear Low Density Polyethylene Injection MoldingakshayNo ratings yet

- LLDPE Sabic 118WJADocument2 pagesLLDPE Sabic 118WJAGustavo DiazNo ratings yet

- Luban DFDA-7047: Linear Low Density PolyethyleneDocument2 pagesLuban DFDA-7047: Linear Low Density PolyethyleneNazmul - Polymet SANo ratings yet

- Formolene FC2304E: Clarity LDPE Resin With 900 PPM Slip and 1200 PPM AntiblockDocument1 pageFormolene FC2304E: Clarity LDPE Resin With 900 PPM Slip and 1200 PPM AntiblockHichamSalamaNo ratings yet

- Luban DFDA-7047: Linear Low Density PolyethyleneDocument2 pagesLuban DFDA-7047: Linear Low Density PolyethyleneJasmine leNo ratings yet

- Low Density Polyethylene: Extrusion Coating and Film ApplicationsDocument1 pageLow Density Polyethylene: Extrusion Coating and Film ApplicationsMahadi Bachar MahamatNo ratings yet

- TDS - LD 2023 CC PDFDocument1 pageTDS - LD 2023 CC PDFYasir SiddiquiNo ratings yet

- Innoplus (GC Marketing) LL7835ADocument1 pageInnoplus (GC Marketing) LL7835AOscar Tan IIINo ratings yet

- Linear Low Density Polyethylene Film PropertiesDocument2 pagesLinear Low Density Polyethylene Film PropertiesOsamah JoubsenNo ratings yet

- Hdpe SP360Document1 pageHdpe SP360Alejandra Paz San MartínNo ratings yet

- Linear Low Density Polyethylene Resin Special CharacteristicsDocument1 pageLinear Low Density Polyethylene Resin Special CharacteristicsFahad MohamedNo ratings yet

- MS 571 - TDS-2023Document1 pageMS 571 - TDS-2023Xuân Giang NguyễnNo ratings yet

- Wanchem Light Stabilizer 783Document1 pageWanchem Light Stabilizer 783Xuân Giang NguyễnNo ratings yet

- Light Stabilizer 2020Document1 pageLight Stabilizer 2020Xuân Giang NguyễnNo ratings yet

- A Guide To Polyolefin Extrusion CoatingDocument61 pagesA Guide To Polyolefin Extrusion CoatingAriane Victoria DantesNo ratings yet

- Wanchem Light Stabilizer 944Document1 pageWanchem Light Stabilizer 944Xuân Giang NguyễnNo ratings yet

- Uvasorb® HA-88FDDocument2 pagesUvasorb® HA-88FDXuân Giang NguyễnNo ratings yet

- Sinobase HALS 783Document1 pageSinobase HALS 783Xuân Giang NguyễnNo ratings yet

- Shanghai Sunwise Chemical Co., LTD.: Product Name: HALS 622Document1 pageShanghai Sunwise Chemical Co., LTD.: Product Name: HALS 622Xuân Giang NguyễnNo ratings yet

- Yantai Suny Chem International Co.,Ltd: SUNOXY-330Document2 pagesYantai Suny Chem International Co.,Ltd: SUNOXY-330Xuân Giang NguyễnNo ratings yet

- Chimassorb 2020: Technical Information Plastic AdditivesDocument3 pagesChimassorb 2020: Technical Information Plastic AdditivesXuân Giang Nguyễn100% (2)

- Omnistab AN 1330: Antioxidant, Polymer AdditivesDocument3 pagesOmnistab AN 1330: Antioxidant, Polymer AdditivesXuân Giang NguyễnNo ratings yet

- Yantai Suny Chem International Co.,Ltd: SUNOXY 3114Document1 pageYantai Suny Chem International Co.,Ltd: SUNOXY 3114Xuân Giang NguyễnNo ratings yet

- Shanghai Sunwise Chemical Co., LTD.: Product Name: HALS 944Document2 pagesShanghai Sunwise Chemical Co., LTD.: Product Name: HALS 944Xuân Giang NguyễnNo ratings yet

- ISO9001 Certified HALS 783 Technical Data SheetDocument2 pagesISO9001 Certified HALS 783 Technical Data SheetXuân Giang NguyễnNo ratings yet

- Dragonox-1098: Pine Chemicals Polymer Additives Petrochemicals ProductsDocument2 pagesDragonox-1098: Pine Chemicals Polymer Additives Petrochemicals ProductsXuân Giang NguyễnNo ratings yet

- GUARD DOG™ UV119 Light StabilizerDocument2 pagesGUARD DOG™ UV119 Light StabilizerXuân Giang NguyễnNo ratings yet

- Dragonox-1098: Pine Chemicals Polymer Additives Petrochemicals ProductsDocument2 pagesDragonox-1098: Pine Chemicals Polymer Additives Petrochemicals ProductsXuân Giang NguyễnNo ratings yet

- Technical Data Sheet: Anti-OxidantDocument1 pageTechnical Data Sheet: Anti-OxidantXuân Giang NguyễnNo ratings yet

- Antioxidant 1076 protects polymersDocument1 pageAntioxidant 1076 protects polymersXuân Giang NguyễnNo ratings yet

- Evernox - 1330 Evernox - 1330GF: EverspringDocument2 pagesEvernox - 1330 Evernox - 1330GF: EverspringXuân Giang NguyễnNo ratings yet

- ANTI-OXIDANT TECH DATA BIONOX 565Document1 pageANTI-OXIDANT TECH DATA BIONOX 565Xuân Giang NguyễnNo ratings yet

- Nov 24th 2014 Monday: Products DetailsDocument1 pageNov 24th 2014 Monday: Products DetailsXuân Giang NguyễnNo ratings yet

- Byk® Max or 4206Document2 pagesByk® Max or 4206Xuân Giang NguyễnNo ratings yet

- Byk® Max or 4206Document2 pagesByk® Max or 4206Xuân Giang NguyễnNo ratings yet

- Byk® Max or 4206Document2 pagesByk® Max or 4206Xuân Giang NguyễnNo ratings yet

- Nov 21st 2014 Friday: Products DetailsDocument1 pageNov 21st 2014 Friday: Products DetailsXuân Giang NguyễnNo ratings yet

- Byk® Max or 4206Document2 pagesByk® Max or 4206Xuân Giang NguyễnNo ratings yet

- Nov 24th 2014 Monday: Products DetailsDocument1 pageNov 24th 2014 Monday: Products DetailsXuân Giang NguyễnNo ratings yet

- Polymer Additives: Product Solutions From CorbionDocument8 pagesPolymer Additives: Product Solutions From CorbionXuân Giang NguyễnNo ratings yet

- Degradation of Pollutants Using PhotocatalysisDocument13 pagesDegradation of Pollutants Using Photocatalysisprateek kumarNo ratings yet

- Unconsolidated Undrained Test Lab ManualDocument6 pagesUnconsolidated Undrained Test Lab ManualmmNo ratings yet

- Curriculum Vitae: Academic QualificationsDocument3 pagesCurriculum Vitae: Academic QualificationswongsosoegaliNo ratings yet

- Experiment 9: Viscosity of WaterDocument8 pagesExperiment 9: Viscosity of Waterwallace kitoNo ratings yet

- % Steel RCC STRDocument9 pages% Steel RCC STRVenkata Raju KalidindiNo ratings yet

- Improved Steel Beam-Column Connections in Industrial StructuresDocument6 pagesImproved Steel Beam-Column Connections in Industrial StructuresSufyan Berinyuy WiysahnyuyNo ratings yet

- ANODIZING (Autosaved)Document17 pagesANODIZING (Autosaved)Sonu JajamNo ratings yet

- Compact Blue-Green Lasers for OEM ApplicationsDocument41 pagesCompact Blue-Green Lasers for OEM Applicationsdpiehler@alphion.comNo ratings yet

- Chap2 (B) Fits and TolerancesDocument20 pagesChap2 (B) Fits and TolerancesjojoNo ratings yet

- Fracture Mechanics, Schreus, 2012 PDFDocument162 pagesFracture Mechanics, Schreus, 2012 PDFCarlos HernandezNo ratings yet

- Adsorption Isotherms of Acetic Acid on Activated CharcoalDocument5 pagesAdsorption Isotherms of Acetic Acid on Activated CharcoalNauman KhalidNo ratings yet

- Assignment 1Document2 pagesAssignment 1Alwarsamy Ramasamy100% (1)

- Atif Tahir (2017086)Document4 pagesAtif Tahir (2017086)AtifNo ratings yet

- Properties of Matter QuizDocument55 pagesProperties of Matter QuizLemuel Glenn BautistaNo ratings yet

- PE Pipe Design and Engineering Guide (Polypipe)Document78 pagesPE Pipe Design and Engineering Guide (Polypipe)1zorro1100% (1)

- Group - 2 - Design of RC T Girder BridgeDocument229 pagesGroup - 2 - Design of RC T Girder BridgesubodhstudymaterialsNo ratings yet

- Topic SP025Document1 pageTopic SP025HafizahNo ratings yet

- Operation Manual 950 PagesDocument950 pagesOperation Manual 950 Pageskatibra67% (3)

- Type 101 Sealing Glass: Standard Specification ForDocument3 pagesType 101 Sealing Glass: Standard Specification ForRob GridleyNo ratings yet

- The TRIP Effect and Its Application in Cold Formable Sheet SteelsDocument21 pagesThe TRIP Effect and Its Application in Cold Formable Sheet SteelsFernandoNo ratings yet

- Reinforced Concrete Beam Design ProblemsDocument5 pagesReinforced Concrete Beam Design ProblemsCeyn Lumabad0% (1)

- Hydrotest Saddle - 2 Saddle Tail Gas DRMDocument13 pagesHydrotest Saddle - 2 Saddle Tail Gas DRMSu Kil SungNo ratings yet

- An Introduction To The Finite Element Method 123Document2 pagesAn Introduction To The Finite Element Method 123Likhon BiswasNo ratings yet

- Chapter 15: Composites: Many Engineering Components Are CompositesDocument31 pagesChapter 15: Composites: Many Engineering Components Are CompositesbadaboyNo ratings yet

- Weather Report TranscriptsDocument3 pagesWeather Report TranscriptsJun-Mar Sabenorio100% (1)

- Determine Material Property (PSG Data Book Page No 1.9 & 1.5)Document28 pagesDetermine Material Property (PSG Data Book Page No 1.9 & 1.5)Sagarias Albus100% (1)

- Pile Bearing Capacily (Beta Method) (By Mujab)Document19 pagesPile Bearing Capacily (Beta Method) (By Mujab)Mujab Abd ElganiNo ratings yet

- Strength of Materials Lab EquipmentsDocument12 pagesStrength of Materials Lab EquipmentslabtekindiaNo ratings yet

- Revision Worksheet - Chemical Bonding and Molecular Structure-2022-23Document2 pagesRevision Worksheet - Chemical Bonding and Molecular Structure-2022-23Malolan SriramNo ratings yet

- Periodic Tales: A Cultural History of the Elements, from Arsenic to ZincFrom EverandPeriodic Tales: A Cultural History of the Elements, from Arsenic to ZincRating: 3.5 out of 5 stars3.5/5 (137)

- Is That a Fact?: Frauds, Quacks, and the Real Science of Everyday LifeFrom EverandIs That a Fact?: Frauds, Quacks, and the Real Science of Everyday LifeRating: 4.5 out of 5 stars4.5/5 (3)

- The Disappearing Spoon: And Other True Tales of Madness, Love, and the History of the World from the Periodic Table of the ElementsFrom EverandThe Disappearing Spoon: And Other True Tales of Madness, Love, and the History of the World from the Periodic Table of the ElementsRating: 4 out of 5 stars4/5 (146)

- Organic Chemistry for Schools: Advanced Level and Senior High SchoolFrom EverandOrganic Chemistry for Schools: Advanced Level and Senior High SchoolNo ratings yet

- Guidelines for Asset Integrity ManagementFrom EverandGuidelines for Asset Integrity ManagementRating: 5 out of 5 stars5/5 (1)

- Meltdown: Nuclear disaster and the human cost of going criticalFrom EverandMeltdown: Nuclear disaster and the human cost of going criticalRating: 5 out of 5 stars5/5 (5)

- The Periodic Table of Elements - Post-Transition Metals, Metalloids and Nonmetals | Children's Chemistry BookFrom EverandThe Periodic Table of Elements - Post-Transition Metals, Metalloids and Nonmetals | Children's Chemistry BookNo ratings yet

- Chemistry: a QuickStudy Laminated Reference GuideFrom EverandChemistry: a QuickStudy Laminated Reference GuideRating: 5 out of 5 stars5/5 (1)

- Chemistry at Home - A Collection of Experiments and Formulas for the Chemistry EnthusiastFrom EverandChemistry at Home - A Collection of Experiments and Formulas for the Chemistry EnthusiastNo ratings yet

- Essential Oil Chemistry Formulating Essential Oil Blends that Heal - Aldehyde - Ketone - Lactone: Healing with Essential OilFrom EverandEssential Oil Chemistry Formulating Essential Oil Blends that Heal - Aldehyde - Ketone - Lactone: Healing with Essential OilRating: 5 out of 5 stars5/5 (1)

- Chemistry for Breakfast: The Amazing Science of Everyday LifeFrom EverandChemistry for Breakfast: The Amazing Science of Everyday LifeRating: 4.5 out of 5 stars4.5/5 (14)

- An Introduction to the Periodic Table of Elements : Chemistry Textbook Grade 8 | Children's Chemistry BooksFrom EverandAn Introduction to the Periodic Table of Elements : Chemistry Textbook Grade 8 | Children's Chemistry BooksRating: 5 out of 5 stars5/5 (1)

- Coating and Drying Defects: Troubleshooting Operating ProblemsFrom EverandCoating and Drying Defects: Troubleshooting Operating ProblemsRating: 5 out of 5 stars5/5 (1)

- Science Goes Viral: Captivating Accounts of Science in Everyday LifeFrom EverandScience Goes Viral: Captivating Accounts of Science in Everyday LifeRating: 5 out of 5 stars5/5 (1)

- The Elements We Live By: How Iron Helps Us Breathe, Potassium Lets Us See, and Other Surprising Superpowers of the Periodic TableFrom EverandThe Elements We Live By: How Iron Helps Us Breathe, Potassium Lets Us See, and Other Surprising Superpowers of the Periodic TableRating: 3.5 out of 5 stars3.5/5 (22)

- The Regenerative Grower's Guide to Garden Amendments: Using Locally Sourced Materials to Make Mineral and Biological Extracts and FermentsFrom EverandThe Regenerative Grower's Guide to Garden Amendments: Using Locally Sourced Materials to Make Mineral and Biological Extracts and FermentsRating: 5 out of 5 stars5/5 (3)

- Gas-Liquid And Liquid-Liquid SeparatorsFrom EverandGas-Liquid And Liquid-Liquid SeparatorsRating: 3.5 out of 5 stars3.5/5 (3)

- Monkeys, Myths, and Molecules: Separating Fact from Fiction in the Science of Everyday LifeFrom EverandMonkeys, Myths, and Molecules: Separating Fact from Fiction in the Science of Everyday LifeRating: 4 out of 5 stars4/5 (9)

- Stuff Matters: Exploring the Marvelous Materials That Shape Our Man-Made WorldFrom EverandStuff Matters: Exploring the Marvelous Materials That Shape Our Man-Made WorldRating: 4 out of 5 stars4/5 (289)

- The Periodic Table: A Very Short IntroductionFrom EverandThe Periodic Table: A Very Short IntroductionRating: 4.5 out of 5 stars4.5/5 (3)

- Guidelines for Integrating Process Safety into Engineering ProjectsFrom EverandGuidelines for Integrating Process Safety into Engineering ProjectsNo ratings yet

- Chemical Elements Pocket Guide: Detailed Summary of the Periodic TableFrom EverandChemical Elements Pocket Guide: Detailed Summary of the Periodic TableNo ratings yet