Professional Documents

Culture Documents

General Concrete Requirements-Waterproofing

Uploaded by

Cire Lop CastroOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

General Concrete Requirements-Waterproofing

Uploaded by

Cire Lop CastroCopyright:

Available Formats

CONSULTANT PROCEDURES & DESIGN GUIDELINES UNIVERSITY OF MISSOURI

336354 General Concrete Requirements - Waterproofing

GENERAL:

The scope of this document is to provide instruction for the installation of waterproofing of

concrete steam chases, tunnels and manholes.

DESIGN GUIDELINES:

A. General

1. Outside surfaces of all subgrade floors, walls and lids of new utility chase and walk

tunnels, and subgrade walls, roof and risers of new manholes shall be waterproofed.

2. New concrete lids installed on existing chase or tunnel shall be waterproofed.

3. Included in this document is an Alternate Waterproofing System that should be

considered in cases where the manholes, tunnels or pipe chases are located in very

wet locations, such as near or below the water table.

B. Materials

1. Concrete Repair Materials -As recommended by waterproofing manufacturer.

2. Waterstops

2.1. Waterstops for use in manholes and at base of utility chase/tunnel walls, and

expansion joints shall be 6", PVC, serrated with center bulb. Waterstop to be

Style 703 as manufactured by Greenstreak, St. Louis MO or approved equal.

2.2. Waterstops for locations where the chase/tunnel abuts structures shall be a Split

Flange - 6", PVC serrated with center bulb for new to new installations.

Waterstop to be Style 723 as manufactured by Greenstreak, St. Louis MO or

approved equal. For new to existing installations waterstop shall be a Style 609

as manufactured by Greenstreak, St. Louis MO or approved equal.

2.3. Waterstops for construction joints shall be 6", PVC, serrated. Waterstop to be

Style 782 as manufactured by Greenstreak, St. Louis MO or approved equal.

2.4. Waterstops for the precast lid to wall connection shall be Butyl-Rubber sealant.

Waterstop to be Conseal CS-102 or approved equal.

3. Pre Applied sheet Waterproofing

3.1. Provide Preprufe 300R membrane by Grace Construction Products or approved

equal. Pre-applied integrally bonded sheet waterproofing membrane: 1.2 mm

nominal thickness composite sheet membrane comprising .8 mm of high

density polyethylene film, and layers of specially formulated synthetic adhesive

layers. The membrane shall form an integral and permanent bond to poured

concrete to prevent water migration at the interface of the membrane and

structural concrete. Tape and other accessories specified or acceptable to

manufacturer of pre-applied waterproofing membrane.

4. Self-Adhesive Waterproofing Membrane

4.1. Self-adhesive waterproofing membrane for use to transition from pre-applied

sheet waterproofing to hot applied rubberized asphalt waterproofing. Provide

sheet applied, self-adhered waterproofing membrane Blueskin WP200 by

Revised 6/20/2014 Page 1 of 5 336354

CONSULTANT PROCEDURES & DESIGN GUIDELINES UNIVERSITY OF MISSOURI

336354 General Concrete Requirements - Waterproofing

Henry Company or approved equal. Self-adhesive waterproofing membrane

shall have the following physical properties:

4.1.1. Thickness: 1.5 mm (60 mils) min.

4.1.2. Flexibility: Pass @ -40 degrees C to ASTM D1970

4.1.3. Vapour permeance: 2.8 ng/Pa.s.m^2 (.05 perms) to ASTM E96,

4.1.4. Tensile strength (membrane): 2.24 MPa to ASTM D412,

4.1.5. Tensile strength (film): 34.5 MPa to ASTM D882,

4.1.6. Elongation: 300% to ASTM D412,

4.1.7. Puncture resistance: 222 N min. to ASTM E154.

5. Hot Applied Rubberized Asphalt Waterproofing

5.1. Components and membrane materials must be obtained as a single source from

the membrane manufacturer to ensure total system compatibility and integrity.

Provide Henry Company 790-11 SBS modified hot applied rubberized asphalt

or approved equal. Rubberized asphalt waterproofing shall have the following

qualities:

5.1.1. Solids Content: 100%;

5.1.2. Low Temperature Flexibility and Adhesion: No cracking, delamination

or loss of adhesion @ 13 degrees F in accordance with CGSB 37-GP-

50-M89;

5.1.3. Flow (1/8 inch film on 75% angle for 5 hours @ 140 degrees F): No

flow in accordance with ASTM D1191;

5.1.4. Cone Penetration: More than 10 @ 32 degrees F, less than 110 @ 77

degrees F, less than 200 @ 122 degrees F in accordance with ASTM

D1191;

5.1.5. Water Absorption: Gain of 0.09g in accordance with CGSB 37-GP-50-

M89;

5.1.6. Flash Point (Open Cup): 545 degrees F in accordance with ASTM D92;

5.1.7. Water Vapor Permeance (3mm Film): 0.01 perms in accordance with

ASTM E96 Procedure A and 0.02 perms in accordance with ASTM

E96 Procedure E.

5.1.8. Ratio of Toughness to Peak Load: 0.04 min. in accordance with CGSB

37-GP-50-M89.

5.1.9. Toughness: 9.2J in accordance with CGSB 37-GP-50-M89.

5.1.10. Crack Bridging Capability: No cracking, splitting or loss of adhesion in

accordance with CGSB 37-GP-50-M89.

5.1.11. Heat Stability (5 hours @ 390 degrees F): Meets flow, penetration and

low temperature flexibility in accordance with CGSB 37-GP-50-M89.

6. Hot Rubberized Asphalt Primer

6.1. Solvent based, synthetic rubber adhesive for hot applied rubberized asphalt

membranes. Henry HE93018 polymer modified adhesive or approved equal.

7. Self adhered waterproofing primer

7.1. Polymer emulsion based primer for self-adhesive membranes. Henry Aquatac

primer or approved equal. Self-adhesive waterproofing primer shall have the

following physical properties:

7.1.1. Color: Aqua

7.1.2. Solids by Volume: 53%

7.1.3. Weight: 8.3 lbs/gal

7.1.4. Application Temperature: 25F to 104F

7.1.5. Maximum VOC: 100 g/L

7.1.6. Service temperature -40F to 150F

Revised 6/20/2014 Page 2 of 5 336354

CONSULTANT PROCEDURES & DESIGN GUIDELINES UNIVERSITY OF MISSOURI

336354 General Concrete Requirements - Waterproofing

8. Neoprene Flashing

8.1. Neoprene flashing sheets is used with 790-11 hot rubberized asphalt membrane

at expansion joints and exposed flashing details. Neoprene flashing shall be

Henry HE850AA or approved equal and shall have the following physical

properties:

8.1.1. Brittleness Point: -40F

8.1.2. Color: Black

8.1.3. Elongation (Initial) ASTM D412 – 300%

8.1.4. Tear Resistance (ASTM D624 Die C) 125 lbs/in min

8.1.5. Tensile strength, membrane: (ASTM D412 Die C) 1800 psi min

8.1.6. Thickness: 60 mils

9. Fabric Reinforcement

9.1. Polyester fabric reinforcement sheet as supplied by Henry, an inorganic spun

bonded polyester fabric sheet with sufficient porosity to allow good interplay

bonding between layers of waterproofing membrane.

10. Termination Sealant

10.1. Termination sealant shall be Henry HE925 BES moisture cure sealant for

construction joints.

11. Drainage Pipe

11.1. 6”, schedule 80, perforated PVC piping with filter sock.

12. Drainage Board

12.1. Provide Henry DB520 drainage board or approved equal. Drainage board shall

have the following properties:

12.1.1. Thickness: 7/16” thick

12.1.2. Compressive strength: 15,000 lb/sq.ft.

12.1.3. Flow rate: 150 gpm/sq.ft.

12.1.4. Backing sheet: Polymeric backing film for contact with softer

waterproofing membranes.

C. Installation

1. Delivery, Storage, and Handling

1.1. Deliver materials and products in labeled packages. Store and handle in strict

compliance with manufacturer's instructions, recommendations and material

safety data sheets. Protect from damage from sunlight, weather, excessive

temperatures and construction operations. Remove damaged material from the

site and dispose of in accordance with applicable regulations.

1.2. Protect primer, mastic and adhesive from moisture and potential sources of

ignition.

1.3. Store protection board flat and off the ground. Provide cover on top and all

sides.

1.4. Sequence deliveries to avoid delays and minimize on-site storage.

2. Typical waterproofing installation includes concrete repairs, joint caulking,

waterstops, preapplied sheet waterproofing, hot applied waterproofing and protection

board. Refer to manufacturer's literature for instructions on installation.

3. Primer - Apply primer as recommended by manufacturer and allow to dry prior to

the application of the primary waterproofing membrane or membrane flashings.

4. Joint Treatment for Precast Concrete Trench Lids - Reinforce all joints between

precast lids and between lids and wall with a strip of 12 inch wide Polyester Fabric

set in an 18 inch wide, 1/8 inch thick coat of membrane.

Revised 6/20/2014 Page 3 of 5 336354

CONSULTANT PROCEDURES & DESIGN GUIDELINES UNIVERSITY OF MISSOURI

336354 General Concrete Requirements - Waterproofing

5. Crack Treatment

5.1. Fill cracks with sealants per joint sealant construction standards.

5.2. Seal cracks and joints 1/16 inch to 1/8 inch in width with a 12 inch wide, 1/8

inch thick coat of hot rubberized asphalt membrane and a 6 inch wide strip of

fabric reinforcement, centered over joint.

5.3. Seal cracks and joints 1/8 inch to ½” inch in width with a 12 inch wide, 1/8

inch thick coat of hot rubberized asphalt membrane and a 6 inch wide strip of

neoprene flashing centered over joint.

6. Application of Hot Rubberized Asphalt Membrane

6.1. Ensure concrete is ready to receive hot applied rubberized asphalt membrane.

6.2. Apply membrane smooth, free from air pockets, wrinkles or tears and to

manufacturer’s instructions. Ensure full bond of membrane to substrate

6.3. Apply first layer of hot rubberized asphalt membrane evenly to a minimum

thickness of 90 mils to form a continuous monolithic coating over horizontal

and vertical surfaces including previously reinforced areas.

6.4. Apply fabric reinforcing sheet and firmly press into first layer of hot

membrane. Overlap fabric approximately ¼ inch ensuring that a layer of

membrane is present between overlaps. Apply second layer of membrane over

the fabric to a minimum thickness of 1/8 inches providing a total thickness of

215 mils.

7. Installation of Protection Course/Separation Sheet

7.1. Protection shall be rolled onto hot applied rubberized asphalt membrane while

still warm and tacky.

7.2. Lap protection course 2 inches on side laps and 6 inches on end laps.

7.3. Starting at the low points or drains lay the protection course membrane in full

continuous sheets in a shingle pattern. Stager all end laps.

8. Cast-in-place Concrete Substrates

8.1. Do not proceed with installation until concrete has properly cured and dried. If

recommended by the manufacturer, special primers may be used to allow

priming and installation of hot applied waterproofing sooner than 7 days.

Priming may begin as soon as the concrete will maintain structural integrity.

8.2. Fill form tie rod holes with concrete and finish flush with surrounding surface.

8.3. Repair bugholes over 13 mm (0.5 in.) in length and 6 mm (0.25 in.) deep and

finish flush with surrounding surface.

8.4. Remove scaling to sound, unaffected concrete and repair exposed area.

8.5. Grind irregular construction joint to suitable flush surface.

8.6. Treat joints and install flashing as recommended by waterproofing

manufacturer.

9. Waterstops

9.1. Waterstops shall be installed in strict accordance with manufacturer's

recommendations with particular care being given to properly setting in

adhesive and maintaining the required 2" minimum concrete coverage.

10. Cleaning and Protection

10.1. Remove any masking materials after installation. Clean any stains on materials

which would be exposed in the completed work.

10.2. Protect completed membrane waterproofing from subsequent construction

activities as recommended by manufacturer.

10.3. Butt joint between precast lids shall be sealed immediately after placing lids in

order to minimize water infiltration prior to applying waterproofing. Seal with

horizontal joint sealant as specified.

Revised 6/20/2014 Page 4 of 5 336354

CONSULTANT PROCEDURES & DESIGN GUIDELINES UNIVERSITY OF MISSOURI

336354 General Concrete Requirements - Waterproofing

11. Quality Assurance

11.1. Installer shall be firm which has at least 3 years of experience in work of the

type required by these Construction Standards.

11.2. For each type of material required for the work of this section, provide primary

materials which are the products of one manufacturer to the extent possible.

12. Project Conditions

12.1. Perform work only when existing and forecasted weather conditions are within

the limits established by the manufacturer of the materials and products used.

12.2. Proceed with installation only when substrate construction and preparation

work is complete and in condition to receive sheet membrane waterproofing.

13. Execution

13.1. Refer to manufacturer's literature for requirements for preparation of substrates.

Surfaces shall be structurally sound and free of voids, spalled area, loose

aggregate and sharp protrusions. Remove contaminates such as grease, oil and

wax from exposed surfaces. Remove dust, dirt, loose stone and debris. Use

repair materials and methods which are acceptable to membrane manufacturer.

14. Alternate Waterproofing System

In extremely wet locations drain piping shall be added to the waterproofing

design. Refer to the construction standard drawings. The piping shall be routed

to the nearest storm sewer utilizing a separate sump pump manhole when

required.

15. Warranty: Provide written five (5) year material warranty for sheet membrane

waterproofing issued by the membrane manufacturer upon completion of the work.

REFERENCES

Revised 6/20/2014 Page 5 of 5 336354

You might also like

- Thermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesFrom EverandThermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesRating: 3.5 out of 5 stars3.5/5 (3)

- Section 07131 Self-Adhering Sheet Waterproofing Part 1Document72 pagesSection 07131 Self-Adhering Sheet Waterproofing Part 1jacksondcplNo ratings yet

- Sealfl Ex: Description Method of UseDocument4 pagesSealfl Ex: Description Method of UseramiNo ratings yet

- Green RoofingDocument9 pagesGreen RoofingSolomon MehariNo ratings yet

- D6950D6950M-04 (2012) E1 Standard Practice For Application of Heat Weldable Atactic Polypropylene (APP) Modified Bituminous Waterproofing Membranes Systems For New Building DecksDocument4 pagesD6950D6950M-04 (2012) E1 Standard Practice For Application of Heat Weldable Atactic Polypropylene (APP) Modified Bituminous Waterproofing Membranes Systems For New Building DecksSatya kaliprasad vangaraNo ratings yet

- Specification Blindside Waterproofing With BentoniteDocument9 pagesSpecification Blindside Waterproofing With BentoniteBaugh Graphic DesignNo ratings yet

- Sikaproof A - Suggested Master SpecificationsDocument7 pagesSikaproof A - Suggested Master SpecificationsSindayiheba PatrickNo ratings yet

- Water Proof SpecDocument2 pagesWater Proof SpecdjgiumixNo ratings yet

- Specifications Dampproofing (Ecodamp)Document7 pagesSpecifications Dampproofing (Ecodamp)Baugh Graphic DesignNo ratings yet

- Tunnel Segment Gasket Design - Solutions and Innovations: Bakhshi, Mehdi and Nasri, VeryaDocument10 pagesTunnel Segment Gasket Design - Solutions and Innovations: Bakhshi, Mehdi and Nasri, VeryaMehdi BakhshiNo ratings yet

- 134Document5 pages134ali razaNo ratings yet

- Specification Concrete and Cmu WallsDocument6 pagesSpecification Concrete and Cmu WallsBaugh Graphic DesignNo ratings yet

- Certificate 062 99Document6 pagesCertificate 062 99ferdinandbataraNo ratings yet

- Fosroc Waterproofing B2R-BOQ (Revised 24th)Document38 pagesFosroc Waterproofing B2R-BOQ (Revised 24th)폴로 쥰 차67% (3)

- Section 07141 Cold Fluid Applied WaterproofingDocument6 pagesSection 07141 Cold Fluid Applied WaterproofingMØhãmmed ØwięsNo ratings yet

- University of Houston Master Construction Specifications Insert Project NameDocument5 pagesUniversity of Houston Master Construction Specifications Insert Project NameTaher AmmarNo ratings yet

- Gasket DesignDocument10 pagesGasket Designnikita saleNo ratings yet

- Guide Specification: NeoflexDocument4 pagesGuide Specification: NeoflexruloNo ratings yet

- Cold-Applied Tape Coating - Rev 3-17Document19 pagesCold-Applied Tape Coating - Rev 3-17AhmedNo ratings yet

- Foamglas Insulation SpecificationsDocument7 pagesFoamglas Insulation Specificationsjohn_p47No ratings yet

- Self Adhering Sheet Waterproofing Bituthene 3000 and Bituthene Low Temperature GSWP 003A v2Document5 pagesSelf Adhering Sheet Waterproofing Bituthene 3000 and Bituthene Low Temperature GSWP 003A v2200365530No ratings yet

- Specification Concrete and Cmu Walls (Reinforced)Document6 pagesSpecification Concrete and Cmu Walls (Reinforced)Baugh Graphic Design100% (1)

- GRP Enclosures For PAckage SubstationDocument12 pagesGRP Enclosures For PAckage SubstationjoseNo ratings yet

- The Wet-Seal System Waterproofing Membrane: ProductDocument4 pagesThe Wet-Seal System Waterproofing Membrane: ProductmagdyamdbNo ratings yet

- Cafco Sprayfilm WB3 - DSDocument6 pagesCafco Sprayfilm WB3 - DSSiva GsNo ratings yet

- Afico Faceed InsulationDocument4 pagesAfico Faceed Insulationhello1230No ratings yet

- ITCC in Riyadh Residential Complex J10-13300 07100-1 WaterproofingDocument5 pagesITCC in Riyadh Residential Complex J10-13300 07100-1 WaterproofinguddinnadeemNo ratings yet

- Technical Project Proposal #537/19: PVC (V01/2019)Document8 pagesTechnical Project Proposal #537/19: PVC (V01/2019)karendiaz1No ratings yet

- 3 LayerDocument4 pages3 LayerArya Raditya100% (1)

- Division 7 Thermal and Moisture ProtectionDocument17 pagesDivision 7 Thermal and Moisture ProtectionSajjadAhmadNo ratings yet

- FLORPRUFE120Document2 pagesFLORPRUFE120Walter PattiNo ratings yet

- Pittsburgh Corning Foamglass Cold Process Piping Installation GuidelineDocument7 pagesPittsburgh Corning Foamglass Cold Process Piping Installation Guidelinenaseema1No ratings yet

- Methodology For TERRACE Waterproofing NITOPROOF 600 PDFDocument7 pagesMethodology For TERRACE Waterproofing NITOPROOF 600 PDF폴로 쥰 차100% (1)

- HBR XL - Crosslink Closed Cell PDSDocument2 pagesHBR XL - Crosslink Closed Cell PDSHuy ThaiNo ratings yet

- Typical Specification Fiberglass Pressure Sewer or Water PipeDocument4 pagesTypical Specification Fiberglass Pressure Sewer or Water PipeLuana CarolNo ratings yet

- Klambon Steel PipingDocument5 pagesKlambon Steel PipingshaunswanbyNo ratings yet

- Sodium Hypo FRP SpecDocument6 pagesSodium Hypo FRP SpecZeroRecoNo ratings yet

- Specification Concrete and Cmu Walls With BentoniteDocument8 pagesSpecification Concrete and Cmu Walls With BentoniteBaugh Graphic DesignNo ratings yet

- Suggested Specifications For PVC and Hydrotite Waterstop System (OK) PDFDocument3 pagesSuggested Specifications For PVC and Hydrotite Waterstop System (OK) PDFjunaid112No ratings yet

- HDPE Membrane Water Proofing Under Basement RaftDocument2 pagesHDPE Membrane Water Proofing Under Basement RaftAmulyaRajbharNo ratings yet

- Rubber Wheelstop or Parking Curb SpecificationsDocument5 pagesRubber Wheelstop or Parking Curb Specificationstlctrafficsafety100% (2)

- Client: Jacobs: Waterproofing System For BASEMENT - HIGH WATER TABLEDocument2 pagesClient: Jacobs: Waterproofing System For BASEMENT - HIGH WATER TABLEShakil AkhterNo ratings yet

- Tender Specification - Sea WaterDocument12 pagesTender Specification - Sea WaterSuhas NatuNo ratings yet

- Specification Concrete Deck/Between Slab (Reinforced)Document6 pagesSpecification Concrete Deck/Between Slab (Reinforced)Baugh Graphic DesignNo ratings yet

- Specification For SealantsDocument17 pagesSpecification For SealantsMalak HindiNo ratings yet

- Tender Specification - Potable WaterDocument12 pagesTender Specification - Potable WaterSuhas NatuNo ratings yet

- 1 RoofingDocument6 pages1 RoofingEfz EfzNo ratings yet

- Styrofoam (English)Document21 pagesStyrofoam (English)Krish DoodnauthNo ratings yet

- Proofex Engage PDFDocument2 pagesProofex Engage PDFmilanbrasinaNo ratings yet

- Proofex GPDocument2 pagesProofex GPSyed ShahbazNo ratings yet

- Bauder Thermofolbrochure May2010Document12 pagesBauder Thermofolbrochure May2010Deana WhiteNo ratings yet

- Specification Beneath Slab Moisture BarrierDocument5 pagesSpecification Beneath Slab Moisture BarrierBaugh Graphic DesignNo ratings yet

- Aquafin-2K/M Two-Component Cement-Based Acrylic-Based Waterproofing Guide Aquafin, Inc. SpecificationDocument5 pagesAquafin-2K/M Two-Component Cement-Based Acrylic-Based Waterproofing Guide Aquafin, Inc. SpecificationalpegambarliNo ratings yet

- Boscoseal Torch OnDocument3 pagesBoscoseal Torch OnjbonvierNo ratings yet

- 60ac024587f24dd6bf133ade - 07 56 00.02 - Fluid-Applied Roofing (Metal)Document3 pages60ac024587f24dd6bf133ade - 07 56 00.02 - Fluid-Applied Roofing (Metal)Eng Victor FidelisNo ratings yet

- Index Fidia P - Mineral Roof Deck Plant Room Acciona W2E Kwinana 03-2019Document6 pagesIndex Fidia P - Mineral Roof Deck Plant Room Acciona W2E Kwinana 03-2019Biju_PottayilNo ratings yet

- 07131Document11 pages07131bravo deltafoxNo ratings yet

- Kingdom of Saudi Arabia Royal Commission For Jubail and Yanbu Directorate General For Royal Commission at Jubail Jubail Industrial CityDocument11 pagesKingdom of Saudi Arabia Royal Commission For Jubail and Yanbu Directorate General For Royal Commission at Jubail Jubail Industrial CityJett SorianoNo ratings yet

- SECTION 15081: Duct Insulation 15081Document5 pagesSECTION 15081: Duct Insulation 15081fatREVITNo ratings yet

- Part 5 - 5.12 WaterproofingDocument6 pagesPart 5 - 5.12 WaterproofingAbdul Wahab JamilNo ratings yet

- KPI GuideDocument64 pagesKPI GuideCire Lop CastroNo ratings yet

- Opms Discharge Permit: ApplicationDocument47 pagesOpms Discharge Permit: ApplicationCire Lop CastroNo ratings yet

- Tundishes TUND-004-0419 v3Document2 pagesTundishes TUND-004-0419 v3Cire Lop CastroNo ratings yet

- AD 22 FuelOilSystemsDocument4 pagesAD 22 FuelOilSystemsCire Lop CastroNo ratings yet

- Polyethylene, Carbon Steel, Brass, Ductile Iron, Epdm: Materials of ConstructionDocument21 pagesPolyethylene, Carbon Steel, Brass, Ductile Iron, Epdm: Materials of ConstructionCire Lop CastroNo ratings yet

- Simplex Oil PumpDocument8 pagesSimplex Oil PumpCire Lop CastroNo ratings yet

- 58 Lpg-Aaa A2016 SrreportDocument122 pages58 Lpg-Aaa A2016 SrreportCire Lop CastroNo ratings yet

- Thesis Ebe 2010 Fahy GDocument82 pagesThesis Ebe 2010 Fahy GCire Lop CastroNo ratings yet

- Standard Practice For The Design and Construction of High Density Polyethylene Pipe (Hdpe)Document56 pagesStandard Practice For The Design and Construction of High Density Polyethylene Pipe (Hdpe)Cire Lop CastroNo ratings yet

- Pipe Freeze Protection Design/Install Guide: Page 1 of 16Document16 pagesPipe Freeze Protection Design/Install Guide: Page 1 of 16Cire Lop CastroNo ratings yet

- Controllable Reduced Pressure Zone Backflow Preventer, BA TypeDocument8 pagesControllable Reduced Pressure Zone Backflow Preventer, BA TypeCire Lop CastroNo ratings yet

- DG Immersion Heaters Over The SideDocument3 pagesDG Immersion Heaters Over The SideCire Lop CastroNo ratings yet

- Installation Instructions / Operating & Maintenance Manual Reduced Pressure Zone (RPZ) Valves Type "BA" DevicesDocument3 pagesInstallation Instructions / Operating & Maintenance Manual Reduced Pressure Zone (RPZ) Valves Type "BA" DevicesCire Lop CastroNo ratings yet

- Highland Tank: Highdro Water TanksDocument4 pagesHighland Tank: Highdro Water TanksCire Lop CastroNo ratings yet

- DHM 6 Set: Mini Instantaneous Water Heater PRODUCT-NO.: 236452Document4 pagesDHM 6 Set: Mini Instantaneous Water Heater PRODUCT-NO.: 236452Cire Lop CastroNo ratings yet

- B - V E D P P: ALL Alve With Xtensions AND UAL Urge ORTDocument2 pagesB - V E D P P: ALL Alve With Xtensions AND UAL Urge ORTCire Lop CastroNo ratings yet

- Hydraulic Filtration Product Guide PDFDocument286 pagesHydraulic Filtration Product Guide PDFCire Lop CastroNo ratings yet

- Data Sheet: The Configuration Is Inconsistent This Printout Is Possibly IncorrectDocument5 pagesData Sheet: The Configuration Is Inconsistent This Printout Is Possibly IncorrectCire Lop CastroNo ratings yet

- Hangers PDFDocument31 pagesHangers PDFCire Lop CastroNo ratings yet

- Modusat TP Technical Manual 2551124EDocument63 pagesModusat TP Technical Manual 2551124ECire Lop CastroNo ratings yet

- Position Qty. Description Sololift2 D-2: Note! Product Picture May Differ From Actual ProductDocument4 pagesPosition Qty. Description Sololift2 D-2: Note! Product Picture May Differ From Actual ProductCire Lop CastroNo ratings yet

- Polypipe Details PDFDocument1 pagePolypipe Details PDFCire Lop CastroNo ratings yet

- University of Mauritius: Potential of Using Locally Available Natural Plant Fibres in Engineering ApplicationsDocument28 pagesUniversity of Mauritius: Potential of Using Locally Available Natural Plant Fibres in Engineering ApplicationsVinitJoryNo ratings yet

- BV Calculation Sheet - RADocument6 pagesBV Calculation Sheet - RAKrishnamoorthyNo ratings yet

- 5th Grade - Week 2 Mixing SubstancesDocument12 pages5th Grade - Week 2 Mixing Substancesapi-254428474100% (1)

- Viscosity TablesDocument3 pagesViscosity TablesKhafid Al Na'imNo ratings yet

- Energetics I (Multiple Choice) QPDocument15 pagesEnergetics I (Multiple Choice) QPSalmantt SalmanlohussaNo ratings yet

- Properties of Epoxy-Asphalt Pavement Mixture For Bridge DecksDocument8 pagesProperties of Epoxy-Asphalt Pavement Mixture For Bridge DecksAhmed Al-mohammdiNo ratings yet

- EN - Panlube S 37Document4 pagesEN - Panlube S 37Vinodh Kanna100% (1)

- Types of RockDocument21 pagesTypes of RockFain AloyanNo ratings yet

- (I) Chemistry of Soap: Main IngredientsDocument2 pages(I) Chemistry of Soap: Main IngredientsMayvic BaňagaNo ratings yet

- Purchase List of SuppliersDocument11 pagesPurchase List of SuppliersHanamantappa dhanojiNo ratings yet

- 12 Tig WeldingDocument8 pages12 Tig WeldingSampath KumarNo ratings yet

- Ldpe 2420H PDFDocument1 pageLdpe 2420H PDFjavadmohammadiNo ratings yet

- DatasheetDocument74 pagesDatasheetagustin bautistaNo ratings yet

- Straightness of Stainless Steel PipeDocument3 pagesStraightness of Stainless Steel PipeGonzalo MazaNo ratings yet

- EPS Test 2 April 2022Document10 pagesEPS Test 2 April 2022Nyoka DunnNo ratings yet

- Bergerlac Aluminium Finish PDFDocument2 pagesBergerlac Aluminium Finish PDFMuthuKumarNo ratings yet

- Spesifikasi Cat JotunDocument3 pagesSpesifikasi Cat JotunTeknoGayaNo ratings yet

- Carbon180 - A Review of Global and U.S. Total Available Markets For CarbontechDocument11 pagesCarbon180 - A Review of Global and U.S. Total Available Markets For CarbontechTito JankowskiNo ratings yet

- CIS SAFE د ماجد البنا مقارنة الحل اليدوي والحل في برنامج 2Document7 pagesCIS SAFE د ماجد البنا مقارنة الحل اليدوي والحل في برنامج 2bassam1911992No ratings yet

- IDS 302 1001 002 General Purpose MEK BlackDocument3 pagesIDS 302 1001 002 General Purpose MEK BlackFarid DiazNo ratings yet

- Service Manual: Charge 2 PlusDocument49 pagesService Manual: Charge 2 PlusAconatic tvhomeNo ratings yet

- Bottom Ash ReportDocument30 pagesBottom Ash ReportmhdsolehNo ratings yet

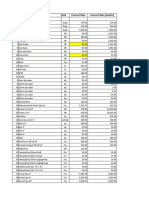

- S.N. Description Unit Current Rate Current Rate (Metric) A Civil MaterialDocument25 pagesS.N. Description Unit Current Rate Current Rate (Metric) A Civil MaterialNishan GajurelNo ratings yet

- Riodin XEDocument2 pagesRiodin XEAntónio NôroNo ratings yet

- Strength of Materials University Question PaperDocument2 pagesStrength of Materials University Question PaperSaravanan KumarNo ratings yet

- Porosity, Permeability & Skin FactorDocument27 pagesPorosity, Permeability & Skin FactorPratick Tibrewala100% (1)

- Nitoseal MS50Document2 pagesNitoseal MS50shanon33No ratings yet

- 2017 - Ink Jet Printing of Capacitive Touch SensorDocument7 pages2017 - Ink Jet Printing of Capacitive Touch SensorsamikhereNo ratings yet

- Lesson 9.3 ElectromagnetismDocument32 pagesLesson 9.3 ElectromagnetismJericho JacaNo ratings yet

- Proracun - Example Cold Formed SteelDocument10 pagesProracun - Example Cold Formed SteelpedjaNo ratings yet