Professional Documents

Culture Documents

SRT-EDL16/32: Engine Control Unit With Data Logger

Uploaded by

jlee_296737Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SRT-EDL16/32: Engine Control Unit With Data Logger

Uploaded by

jlee_296737Copyright:

Available Formats

SRT-EDL16/32

Engine Control Unit with Data Logger

SRT-EDL16/32 combines the performance of the SRT-E Engine Control Unit with an internal 16/32 Mbyte

data logger with a very high speed Ethernet connection for data download. The engine control capability of the

SRT-EDL16/32 is an evolution of the SRA Engine Control Unit with greater input/output and communications

capability in reduced package size and having more robust external connections.

Like the SRT-E, SRT-EDL16/32 is a dedicated Engine Control Unit. A single SRT-EDL16/32 can drive up to

eight injectors and six ignition coils. It is compatible with a wide range of sensors and actuators (especially F1

products) such as coils, injectors and sensors. SRT-EDL16/32 can also drive logic command coils (HW

option).

In addition to the very high speed Ethernet connection for data download, communications from the PC based

configuration tool and to other units (such as dashboard and logger) is possible by 2 CAN lines and an

asynchronous serial line.

Inside the unit there is a high performance RISC microcontroller and an FPGA for diagnostic purposes.

SRT-EDL16/32 provides analogue inputs for single-ended, differential, temperature and knock-sensor as well

as an interface for a linear wide band lambda sensor. The unit also provides 2 H-Bridge output stages for use with suitable “Drive by Wire” or Trumpet

Control actuators.

6 configurable speed sensor inputs (up to 3 inductive) provide full flexibility of configuration for engine angle detection as well as other frequency inputs

such as wheel or shaft speed.

For further information or different solution, please contact our technical department.

Technical data

Analogue inputs Mechanical/Electrical characteristics

Single-ended (0 to 5 Vcc). .............................................. 14 Power supply

Linear Lambda controller (UEGO) .................................... 2 total system operating....................................... 7 to 16 V

Knock sensor.................................................................... 2 logic core operating .......................................... 6 to 16 V

K-type thermocouple......................................................... 2 external Vref operating...................................... 7 to 16 V

NTC/PT1000 temperature sensor (selectable).................. 4 Operating temperature range (internal) ................. -20 to 85 °C

NTC internal temperature sensor...................................... 1 Vibrations range tested (30 to 1500 Hz).......................... 10 g

V battery injector............................................................... 1 EMI immunity tested (1 to 400 MHz) ............................. 300 mA

Digital inputs Protection class...........................................................IP 54

Pick-ups (engine & wheel parameters) Container ............................................machined aluminium

magnetic or Hall effect (exclusive) ............................. 3 Connectors

Hall effect.......................................................................... 3 AS218-35PA...................................................... 66 pin

Lap trigger (Pulled down (*)) ............................................. 1 AS218-35PN...................................................... 66 pin

“Code Load” enable pin .................................................... 1 Dimensions

Syncro (Iso9141) .............................................................. 1 without connectors.............................134 x 133.5 x 39 mm

with connectors.....................................134 x 146 x 39 mm

Outputs Weight .......................................................................... 700 g

On/Off injector drivers ....................................................... 8

(all with voltage feedback)

Logic core

max. current .............................................................. 4 A Microcontroller (80 MIPS RISC) ........................................ 1

clamp....................................................................... 60 V FPGA (50k gates) ............................................................. 1

Inductive or logic command ignition drivers (HW option)... 6 Flash E2PROM (microcontroller) ...................................... 1 Mbyte

(all with current feedback) RAM memory (microcontroller) ....................................... 48 Kbyte

max. charge current................................................. 20 A RAM memory................................................................ 512 Kbyte

H-Bridges.......................................................................... 2 E2PROM......................................................................... 64 Kbyte

(Full-bridge, DC-Motors control, with failure diagnosis by SPI) Time keeper...................................................................... 1

max. current .............................................................. 6 A Logging

....................................................................... (peak) 7 A Flash disk memory................................................. 16 or 32 Mbyte

On/Off Lambda heater drivers........................................... 2 Logged channels.................................................. up to 256

(with voltage feedback) Logging rate........................................................... up to 40 Kbyte/s

max. current .............................................................. 3 A Sampling rate..................................................... up to 1000 Hz

PWM................................................................................. 4

(all with current feedback) Note:

max. current .............................................................. 5 A (*) Active when high. For different solution contact our technical

Voltage references (independent)..................................... 3 department.

Communications (**) Configurable on request.

CAN line (1 Mbit/s (**))...................................................... 2

Ethernet line (100 Mbit/s).................................................. 1

Serial current loop............................................................. 1

Ordering Information

Label Description Order code

SRT-EDL16 Engine Control Unit with Data Logger 16 Mbyte 083814144300

SRT-EDL32 Engine Control Unit with Data Logger 32 Mbyte 083814152100

For further details please contact

MAGNETI MARELLI HOLDING S.p.A.

MOTORSPORT Tel: +39 02 97227478

Viale Aldo Borletti 61/63 Fax: +39 02 97227570

20011 Corbetta (MI) - ITALY

MAGNETI MARELLI CONFIDENTIAL PROPRIETARY

All rights reserved. No reproduction of this document, use and communication of its contents may be made without written authorisation.

Specification subject to change without notice.

Ver. 1.6 - 03/03/2006 1/4

Characteristics

• 14 Single-ended • Up to 40 Kbyte/s logging rate

• 3 Pick-ups or Hall effect • Sampling rates up to 1000 Hz

• 3 Hall effect • 2 CAN communication buses

• 6 Inductive or logic command ignition drivers (HW option) • 1 Ethernet line

• 8 On/Off injector drivers • Data download via standard 100BaseT Ethernet

• 2 H-Bridge: DC-Motor driver for “Drive by Wire” control • Floating point data management

• 4 PWM • Direct management of Marelli dashboard display

• 2 Linear Lambda • Pick-up inputs for wheel speed and distance measurement

• 2 Knock input for detonation control accelerometers • Requires Wintax3 analysis software (compatible Win2K/XP)

• 16 or 32 Mbyte Internal data logger • Requires Axon logging setup tool

• Up to 256 logged channels

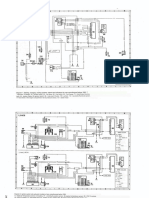

Dimensions

Dimensions in millimetres

MAGNETI MARELLI CONFIDENTIAL PROPRIETARY

All rights reserved. No reproduction of this document, use and communication of its contents may be made without written authorisation.

Specification subject to change without notice.

Ver. 1.6 - 03/03/2006 2/4

Connector Pin Out

SRT-EDL16/32 pin-out: AS218-35PA

Pin Name Descr. Pin Name Descr. Pin Name Descr.

1 RX_ETH_N RX_N Ethernet 23 IN_HALL6 Hall Effect Sensors Input 6 45 IN_TEMP4 NTC-PT1000 Input 4

10/100 Base T (Wheel Rear Left)

2 VBATT_AUX Positive Supply Aux 24 OUT_PELV2 Proportional Electrovalve Output 46 IN_LAMBDA1_ Input Vs- Lambda 1

2 VS-

3 VBATT_AUX Positive Supply Aux 25 INP_KNOCK_1P Knock 1 Input positive 47 IN_LAMBDA1_ Input Ip+ Lambda 1

IP+

4 TX_ETH_P TX_P Ethernet 26 INP_KNOCK_1N Knock 1 Input negative 48 IN_TC2P Differential input 2

10/100 Base T Positive

5 RX_ETH_P RX_P Ethernet 27 IN_AN13 Single Ended Input 13 49 IN_HALL1 Hall Effect Sensors Input

10/100 Base T (0-5 V) 1

6 VBATT_AUX Positive Supply Aux 28 IN_ENCP Enable Code Programming 50 OUT1_HB1 Output H Bridge1

7 VBATT_AUX Positive Supply Aux 29 CAN1_L CAN1 Serial Line (L) for Vision 51 EXTGNDMA3 External GNDMA

8 OUT_PELV3 Proportional 30 CAN0_L CAN0 Serial Line (L) for 52 IN_TEMP3 NTC-PT1000 Input 3

Electrovalve Output acquisition from external

3 modules and dashboard

9 OUT_PELV4 Proportional 31 IN_HALL5 Hall Effect Sensors Input 5 53 GND_POWER_ Ground Power Aux

Electrovalve Output (Wheel Rear Right) AUX (PWR3)

4

10 TX_ETH_N TX_N Ethernet 32 IN_HALL2 Hall Effect Sensors Input 2 54 IN_TC1N Differential input 1

10/100 Base T Negative

11 IN_PKUP2P Electromagnetic 33 OUT2_HB1 Output H Bridge1 55 EXTGNDMS Digital Output Ground

Pick-up Input 2

Positive

12 IN_PKUP2_3N Electromagnetic 34 IN_LAMBDA2_VS- Input Vs- Lambda 2 56 SHIELD1 Wiring Shield PK

Pick-up 4 Negative

13 I_O_SYNCRO Digital Input Iso9141 35 IN_LAMBDA2_VS+ Input Vs+ Lambda 2 57 OUT1_HB1 Output H Bridge1

14 RX RS232 loop current 36 IN_VBINJ Input Injector battery Supply 58 EXTVREF3 External Reference

RX Supply 3 (5 V)

15 IN_LAP_TRIGGER Digital Input for Lap 37 IN_AN14 Single Ended Input 14 (0 to 5 V) 59 GND_POWER_ Ground Power Aux

Trigger AUX (PWR3)

16 OUT_PELV1 Proportional 38 IN_LAMBDA1_VS+ Input Vs+ Lambda 1 60 GND_POWER_ Ground Power Aux

Electrovalve Output AUX (PWR3)

1

17 INP_KNOCK_2N Knock 2 Input 39 IN_TC2N Differential input 2 Negative 61 IN_TC1P Differential input 1

negative Positive

18 INP_KNOCK_2P Knock 2 Input 40 CAN0_H CAN0 Serial Line (H) for 62 OUT2_HB2 Output H Bridge2

positive acquisition from external

modules and dashboard

19 IN_PKUP3P Electromagnetic 41 IN_HALL3 Hall Effect Sensors Input 3 63 OUT2_HB2 Output H Bridge2

Pick-up Input 3 (Wheel Front Right)

Positive

20 TX RS232 loop current 42 OUT2_HB1 Output H Bridge1 64 GND_POWER_ Ground Power Aux

TX AUX (PWR3)

21 CAN1_H CAN1 Serial Line 43 IN_LAMBDA2_IP+ Input Ip+ Lambda 2 65 OUT1_HB2 Output H Bridge2

(H) for Vision

22 IN_HALL4 Hall Effect Sensors 44 GND_TEMP3_4 Analog Ground Temp3_4 (Vref) 66 OUT1_HB2 Output H Bridge2

Input 4 (Wheel Front

Left)

MAGNETI MARELLI CONFIDENTIAL PROPRIETARY

All rights reserved. No reproduction of this document, use and communication of its contents may be made without written authorisation.

Specification subject to change without notice.

Ver. 1.6 - 03/03/2006 3/4

SRT-EDL16/32 pin-out: AS218-35PN

Pin Name Descr. Pin Name Descr. Pin Name Descr.

1 OUT_LAMBDA1 Lambda1 Heater 23 OUT_IGN5 Ignition Output 5 45 PWR_GND_INJE Power Output Ground

Output CTOR Injector (PWR2)

2 OUT_IGN4 Ignition Output 4 24 OUT_IGN5 Ignition Output 5 46 PWR_GND_INJE Power Output Ground

CTOR Injector (PWR2)

3 OUT_IGN4 Ignition Output 4 25 OUT_INJ5 Injector Output 5 (fuel) 47 PWR_GND_INJE Power Output Ground

CTOR Injector (PWR2)

4 EXTVREF1 External Reference 26 IN_AN6 Single Ended Input 6 (0 to 5V) 48 PWR_GND_IGNI Power Output Ground

Supply 1 (5 V) TION Ignition (PWR1)

5 OUT_LAMBDA2 Lambda2 Heater 27 IN_AN4 Single Ended Input 4 (0 to 5V) 49 OUT_IGN3 Ignition Output 3

Output

6 IN_AN8 Single Ended Input 8 28 IN_AN3 Single Ended Input 3 (0 to 5V) 50 OUT_IGN3 Ignition Output 3

(0 to 5 V)

7 OUT_IGN4 Ignition Output 4 29 IN_AN9 Single Ended Input 9 (0 to 5V) 51 OUT_INJ3 Injector Output 3 (fuel)

8 OUT_IGN6 Ignition Output 6 30 GND_TEMP1_2 Analog Ground Temp1_2 (Vref) 52 PWR_GND_IGNI Power Output Ground

TION Ignition (PWR1)

9 OUT_IGN6 Ignition Output 6 31 IN_TEMP2 NTC-PT1000 Input 2 53 PWR_GND_IGNI Power Output Ground

TION Ignition (PWR1)

10 EXTGNDMA1 External GNDMA1 32 IN_AN12 Single Ended Input 12 (0 to 5V) 54 PWR_GND_IGNI Power Output Ground

TION Ignition (PWR1)

11 IN_AN10 Single Ended Input 10 33 OUT_IGN2 Ignition Output 2 55 PWR_GND_IGNI Power Output Ground

(0 to 5 V) TION Ignition (PWR1)

12 IN_AN2 Single Ended Input 2 34 OUT_INJ2 Injector Output 2 (fuel) 56 OUT_IGN1 Ignition Output 1

(0 to 5 V)

13 IN_AN7 Single Ended Input 7 35 VBATTP Positive Battery Supply 57 OUT_IGN3 Ignition Output 3

(0 to 5 V)

14 IN_PKUP1N Electromagnetic Pick- 36 VBATTP Positive Battery Supply 58 OUT_INJ8 Injector Output 8 (fuel)

up 1 Negative

15 OUT_IGN6 Ignition Output 6 37 IN_AN1 Single Ended Input 1 (0 to 5V) 59 OUT_INJ7 Injector Output 7 (fuel)

16 OUT_IGN5 Ignition Output 5 38 SHIELD2 Wiring Shield PK 60 PWR_GND_IGNI Power Output Ground

TION Ignition (PWR1)

17 EXTVREF2 External Reference 39 VBATTN Negative Battery Supply 61 GND_POWER_A Ground Power Aux

Supply 2 (5 V) UX (PWR3)

18 EXTGNDMA2 External GNDMA2 40 VBATTN Negative Battery Supply 62 OUT_IGN1 Ignition Output 1

19 IN_AN11 Single Ended Input 11 41 OUT_IGN2 Ignition Output 2 63 OUT_IGN1 Ignition Output 1

(0 to 5 V)

20 IN_AN5 Single Ended Input 5 42 OUT_IGN2 Ignition Output 2 64 OUT_INJ6 Injector Output 6 (fuel)

(0 to 5 V)

21 IN_PKUP1P Electromagnetic Pick- 43 OUT_INJ4 Injector Output 4 (fuel) 65 OUT_INJ1 Injector Output 1 (fuel)

up Input 1 Positive

22 IN_TEMP1 NTC-PT1000 Input 1 44 PWR_GND_INJE Power Output Ground Injector 66 GND_POWER_A Ground Power Aux

CTOR (PWR2) UX (PWR3)

MAGNETI MARELLI CONFIDENTIAL PROPRIETARY

All rights reserved. No reproduction of this document, use and communication of its contents may be made without written authorisation.

Specification subject to change without notice.

Ver. 1.6 - 03/03/2006 4/4

You might also like

- STM32F105xx STM32F107xxDocument103 pagesSTM32F105xx STM32F107xxQue Hara Angel TomasNo ratings yet

- STM32 F105 XX STM32 F107 XXDocument104 pagesSTM32 F105 XX STM32 F107 XXbehbehbehNo ratings yet

- STM8L001J3Document58 pagesSTM8L001J3sfleandro_67No ratings yet

- CD00191185 PDFDocument130 pagesCD00191185 PDFcoccomNo ratings yet

- Stm32F2xx DatasheetDocument163 pagesStm32F2xx DatasheetAlan Coombs0% (1)

- Stm32f4 Discovery DatasheetDocument154 pagesStm32f4 Discovery DatasheetArtur JunqueiraNo ratings yet

- DM00035129 - STM32F41xxxDocument156 pagesDM00035129 - STM32F41xxxbatrung2906No ratings yet

- Stm32f103rbt6 ManualDocument102 pagesStm32f103rbt6 ManualserlabtriesteNo ratings yet

- mXT1664T2-C2U 1v1 Datasheet DXDocument94 pagesmXT1664T2-C2U 1v1 Datasheet DXRosa María AmoneNo ratings yet

- STM8L151G4 Ufqfpn28Document124 pagesSTM8L151G4 Ufqfpn28Faisal AbdullahNo ratings yet

- HMS87C1304 (2) A HMS87C1204 (2) A HMS87C1104 (2) A: User's ManualDocument88 pagesHMS87C1304 (2) A HMS87C1204 (2) A HMS87C1104 (2) A: User's ManualBhadreshkumar SharmaNo ratings yet

- Resistive Touchscreen ControllerDocument65 pagesResistive Touchscreen ControllerencsumanNo ratings yet

- STM 32 F 103 RCDocument115 pagesSTM 32 F 103 RClnguyen_237557No ratings yet

- 4563 PDFDocument101 pages4563 PDFJoséNo ratings yet

- STM32F103V8T6 STMicroelectronicsDocument99 pagesSTM32F103V8T6 STMicroelectronicsMike SharpeNo ratings yet

- STM8L051F3: 8-Bit Ultra-Low-Power MCU, 8-Kbyte Flash Memory, 256-Byte Data EEPROM, RTC, Timers, USART, I2C, SPI, ADCDocument96 pagesSTM8L051F3: 8-Bit Ultra-Low-Power MCU, 8-Kbyte Flash Memory, 256-Byte Data EEPROM, RTC, Timers, USART, I2C, SPI, ADCSubramani KarurNo ratings yet

- TLE5012B: 1 FeaturesDocument51 pagesTLE5012B: 1 FeaturesAbdi PrasetyoNo ratings yet

- CD00251732 PDFDocument88 pagesCD00251732 PDFdavideosto3560No ratings yet

- Arm M4Document186 pagesArm M4Tôi Là Hùng AnhNo ratings yet

- Stmpe811 DatasheetDocument64 pagesStmpe811 Datasheetfivya anbalakanNo ratings yet

- PDF STR710RZDocument80 pagesPDF STR710RZDébora MenesesNo ratings yet

- STM32F4Document202 pagesSTM32F4Anonymous jeV0uyZfJ5No ratings yet

- Single Ethernet 10/100M PHY: Never Stop ThinkingDocument92 pagesSingle Ethernet 10/100M PHY: Never Stop Thinkingvsc2012No ratings yet

- STM32F103 DatasheetDocument80 pagesSTM32F103 DatasheetmikyduudeNo ratings yet

- DM 00035129Document201 pagesDM 00035129AKSHATHAVENKATESHNo ratings yet

- SPC560P44L3Document112 pagesSPC560P44L3quemasda quiensoyNo ratings yet

- ST STM8L051F3 8-Bit Microcontroller DatasheetDocument93 pagesST STM8L051F3 8-Bit Microcontroller Datasheettaj.nezami1660No ratings yet

- PEF22558EDocument90 pagesPEF22558EGabriel RacovskyNo ratings yet

- Microconverter, Multichannel 12-Bit Adc With Embedded Flash McuDocument57 pagesMicroconverter, Multichannel 12-Bit Adc With Embedded Flash McubtanmayNo ratings yet

- PLC Connection GuideDocument1,163 pagesPLC Connection GuidewarwarNo ratings yet

- Zapi Sem-X ManualDocument40 pagesZapi Sem-X ManualRicardo Gamez Ortega75% (4)

- STM8 L101 FXDocument88 pagesSTM8 L101 FXReVNo ratings yet

- Lis3Dsh: MEMS Digital Output Motion Sensor Ultra Low-Power High Performance Three-Axis "Nano" AccelerometerDocument53 pagesLis3Dsh: MEMS Digital Output Motion Sensor Ultra Low-Power High Performance Three-Axis "Nano" AccelerometerselocaNo ratings yet

- Mip 1 2008 PDFDocument94 pagesMip 1 2008 PDFlazarosNo ratings yet

- AS5055 Datasheet v1 1Document21 pagesAS5055 Datasheet v1 1mohamedsamimorsiNo ratings yet

- M 41 T 82Document64 pagesM 41 T 82Muhammad DarojadNo ratings yet

- Datasheet STM32F407Document180 pagesDatasheet STM32F407mametgonzalesNo ratings yet

- AT25SF128A 85C Data Sheet RevD 03-19-2019Document56 pagesAT25SF128A 85C Data Sheet RevD 03-19-2019Hans ClarinNo ratings yet

- Netduino (IC STM)Document233 pagesNetduino (IC STM)mars1972No ratings yet

- Gioi Thieu Stm8sDocument103 pagesGioi Thieu Stm8sVũ AnhNo ratings yet

- Data Sheet yDocument109 pagesData Sheet ypoojaraiturkarNo ratings yet

- STM32 LXXDocument131 pagesSTM32 LXXSSevNo ratings yet

- STM32F429Document91 pagesSTM32F429andresboliviaNo ratings yet

- Datasheed STM32F401xDDocument130 pagesDatasheed STM32F401xDnospherathusNo ratings yet

- STM32F429 DatasheetDocument226 pagesSTM32F429 DatasheetBhaskar SenNo ratings yet

- Nais-FP0 HWDocument372 pagesNais-FP0 HWGitha Agust0% (1)

- IS21TF16G/32G/64G/128G IS22TF16G/32G/64G/128G: 16GB/32GB/64GB/128GB eMMCDocument52 pagesIS21TF16G/32G/64G/128G IS22TF16G/32G/64G/128G: 16GB/32GB/64GB/128GB eMMCri3admNo ratings yet

- Ilidustriallc Data Book: SiemensDocument1,000 pagesIlidustriallc Data Book: SiemensTodorosss JjNo ratings yet

- ST62T53C/T60C/T63C ST62E60C: 8-Bit Otp/Eprom Mcus With A/D Converter, Safe Reset, Auto-Reload Timer, Eeprom and SpiDocument84 pagesST62T53C/T60C/T63C ST62E60C: 8-Bit Otp/Eprom Mcus With A/D Converter, Safe Reset, Auto-Reload Timer, Eeprom and SpibeciNo ratings yet

- DatasheetDocument80 pagesDatasheetselocaNo ratings yet

- DataSheet STM32F429xxDocument103 pagesDataSheet STM32F429xxfmvfmvfmvNo ratings yet

- STM32F030x4 STM32F030x6 STM32F030x8 STM32F030xCDocument93 pagesSTM32F030x4 STM32F030x6 STM32F030x8 STM32F030xCAn ŠpNo ratings yet

- STM32F 030C6 PDFDocument93 pagesSTM32F 030C6 PDFJuan P. RomanielloNo ratings yet

- Max3107 Spi/I C Uart With 128-Word Fifos: General Description Benefits and FeaturesDocument52 pagesMax3107 Spi/I C Uart With 128-Word Fifos: General Description Benefits and Featuressanthosha rkNo ratings yet

- Engine Control SystemDocument21 pagesEngine Control SystemRaúl MartínezNo ratings yet

- XC836 Data SheetDocument56 pagesXC836 Data SheetNegru AndreiNo ratings yet

- CAN and FPGA Communication Engineering: Implementation of a CAN Bus based Measurement System on an FPGA Development KitFrom EverandCAN and FPGA Communication Engineering: Implementation of a CAN Bus based Measurement System on an FPGA Development KitNo ratings yet

- Elektroshemy Ford Escort Vi enDocument23 pagesElektroshemy Ford Escort Vi enjlee_296737No ratings yet

- Product CardDocument2 pagesProduct Cardjlee_296737No ratings yet

- Leptin Signal Transduction Underlies The Differential Metabolic Response of LEW and WKY Rats To Cafeteria DietDocument10 pagesLeptin Signal Transduction Underlies The Differential Metabolic Response of LEW and WKY Rats To Cafeteria Dietjlee_296737No ratings yet

- Animals: Morphometric Study of Mus Musculus, Rattus Norvegicus, and Rattus Rattus in QatarDocument15 pagesAnimals: Morphometric Study of Mus Musculus, Rattus Norvegicus, and Rattus Rattus in Qatarjlee_296737No ratings yet

- LMDH Technical Regulations 2022.06.21Document64 pagesLMDH Technical Regulations 2022.06.21jlee_296737No ratings yet

- Product CardDocument2 pagesProduct Cardjlee_296737No ratings yet

- PDM User ManualDocument60 pagesPDM User Manualjlee_296737100% (1)

- D4FDocument97 pagesD4Fcatant86% (7)

- MR392CLIO8 - Clio 3 Echipament Electric PDFDocument434 pagesMR392CLIO8 - Clio 3 Echipament Electric PDFAndrei Sterian100% (1)

- AS0047Document2 pagesAS0047jlee_296737No ratings yet

- Clio2 Cup Rally enDocument67 pagesClio2 Cup Rally enjlee_296737No ratings yet

- Spare Parts Book: Reference: 7711150216 Date: 06/07/2015Document111 pagesSpare Parts Book: Reference: 7711150216 Date: 06/07/2015jlee_296737No ratings yet

- MR392CLIO1Document1,276 pagesMR392CLIO1cherif yahyaouiNo ratings yet

- Clio 8 Electrical Fault FindingDocument201 pagesClio 8 Electrical Fault Findingjlee_296737100% (1)

- PA10 0389 Technical Manual 911 GT3 Cup 991 MY 2019 V8 enDocument491 pagesPA10 0389 Technical Manual 911 GT3 Cup 991 MY 2019 V8 enjlee_296737No ratings yet

- Balance of PerformanceDocument6 pagesBalance of Performancejlee_296737No ratings yet

- PA10 0132 Technical Manual GT3 CUP 991 2014 v2.6 enDocument320 pagesPA10 0132 Technical Manual GT3 CUP 991 2014 v2.6 enjlee_296737No ratings yet

- Effect of Retarded Injection Timing On Knock Resistance and Cycle To Cycle Variation in GDI EngineDocument8 pagesEffect of Retarded Injection Timing On Knock Resistance and Cycle To Cycle Variation in GDI Enginejlee_296737No ratings yet

- 911 GT3 CupDocument25 pages911 GT3 Cupjlee_296737No ratings yet

- Experimental Study of The Impact of Port and Direct Fuel Injection Strategies On The Efficiency, Performance and Emissions of A Downsized Gdi EngineDocument416 pagesExperimental Study of The Impact of Port and Direct Fuel Injection Strategies On The Efficiency, Performance and Emissions of A Downsized Gdi Enginejlee_296737No ratings yet

- 2016 991 Cup Technical Manual V1 PDFDocument326 pages2016 991 Cup Technical Manual V1 PDFJaviJi9No ratings yet

- Effect of Ethanol On Engine PerformanceDocument17 pagesEffect of Ethanol On Engine PerformancelatshareNo ratings yet

- TCR Lambda Monitoring MethodDocument4 pagesTCR Lambda Monitoring Methodjlee_296737No ratings yet

- Balance of Performance IGTC Tracks BDocument5 pagesBalance of Performance IGTC Tracks Bjlee_296737No ratings yet

- Balance of Performance Blancpain GT Series Asia Tracks B 04042019Document4 pagesBalance of Performance Blancpain GT Series Asia Tracks B 04042019jlee_296737No ratings yet

- Decision of The Endurance Committee: Article: 7.4.3 2018-2019 FIA World Endurance Championship Sporting RegulationsDocument2 pagesDecision of The Endurance Committee: Article: 7.4.3 2018-2019 FIA World Endurance Championship Sporting Regulationsjlee_296737No ratings yet

- TB Iwsc 19-21 Bop Tables 040319Document4 pagesTB Iwsc 19-21 Bop Tables 040319jlee_296737No ratings yet

- TB Iwsc 19-18 Sebring Bop Tables 022719Document6 pagesTB Iwsc 19-18 Sebring Bop Tables 022719jlee_296737No ratings yet

- TB IWSC 20 12 Daytona 240 BoP Tables 06252020Document7 pagesTB IWSC 20 12 Daytona 240 BoP Tables 06252020jlee_296737No ratings yet

- TribologyTransactions2008 PeggyDocument16 pagesTribologyTransactions2008 Peggyjlee_296737No ratings yet

- Mcu Installation+Manual Db68-06903a-05 221122-d07 English+and+FrenchDocument32 pagesMcu Installation+Manual Db68-06903a-05 221122-d07 English+and+FrenchNicolae RoNo ratings yet

- Catalog - UPS - Delta-1Phase-LongTime VSHDocument7 pagesCatalog - UPS - Delta-1Phase-LongTime VSHnhungtruongNo ratings yet

- Sony HCD-GNZ55D Service Manual v1.1Document100 pagesSony HCD-GNZ55D Service Manual v1.1Alver Tuiza75% (4)

- Ierg3820 Lab Report1 Teamc03Document8 pagesIerg3820 Lab Report1 Teamc03Iii猫一No ratings yet

- Schematic Circuits: Section C - ElectricsDocument1 pageSchematic Circuits: Section C - ElectricsIonut GrozaNo ratings yet

- DS9637A Dual Differential Line Receiver: Features DescriptionDocument7 pagesDS9637A Dual Differential Line Receiver: Features DescriptionBrahim RebaouiNo ratings yet

- Abeba DebruDocument90 pagesAbeba Debruabera alemayehuNo ratings yet

- OMNI - LT Automation Installation ManualDocument48 pagesOMNI - LT Automation Installation ManualRajo AmehNo ratings yet

- OTDR TRAINING 83 SlideDocument83 pagesOTDR TRAINING 83 SlideFerry Kurniawan80% (5)

- LPC2478 PDFDocument93 pagesLPC2478 PDFdecosat2012No ratings yet

- Bollet Point To Lodha LetterDocument3 pagesBollet Point To Lodha Letterchief engineer CommercialNo ratings yet

- PLX 7200Document3 pagesPLX 7200ismailNo ratings yet

- Chapt.3 DiodesDocument30 pagesChapt.3 Diodesjeabum324No ratings yet

- BigJoe S22Document162 pagesBigJoe S22martinNo ratings yet

- Datasheet Tellabs 6325 EDGE NodeDocument2 pagesDatasheet Tellabs 6325 EDGE NodeBoby Rahmadi100% (1)

- Semiconductor QBDocument9 pagesSemiconductor QBdheeraj rajNo ratings yet

- Interactive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768Document39 pagesInteractive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768Andy Sanchez GamarraNo ratings yet

- Selection and Installation of Aircraft Electric Equipment 飞机电气设备的选择和安装MIL-STD-7080Document26 pagesSelection and Installation of Aircraft Electric Equipment 飞机电气设备的选择和安装MIL-STD-7080qingtaoNo ratings yet

- Details Make The Difference: Xlpe Insulated Heavy Duty Cables 650/1100VDocument25 pagesDetails Make The Difference: Xlpe Insulated Heavy Duty Cables 650/1100VlogixNo ratings yet

- SKF Static Motor Analyzer Baker DX: DX Capabilities and Added FlexibilityDocument4 pagesSKF Static Motor Analyzer Baker DX: DX Capabilities and Added FlexibilityPablo Marcelo Garnica TejerinaNo ratings yet

- Novatek NT96650 PDFDocument35 pagesNovatek NT96650 PDFRenatoNo ratings yet

- 1 - Installation Manual - OTS3-PigtailsDocument8 pages1 - Installation Manual - OTS3-PigtailsJavier LeónNo ratings yet

- Irwin, Engineering Circuit Analysis, 11e ISV Chapter 13Document92 pagesIrwin, Engineering Circuit Analysis, 11e ISV Chapter 13이잉No ratings yet

- NITROX 12152025KW 3Ph 5G Updated SmallDocument24 pagesNITROX 12152025KW 3Ph 5G Updated SmallAbdulrehman SoomroNo ratings yet

- Workshop Manual W3024EN2.pdf Workshop Manual W3024EN2 PDFDocument64 pagesWorkshop Manual W3024EN2.pdf Workshop Manual W3024EN2 PDFAlexander LopezNo ratings yet

- Generalised Cockcroft-Walton Voltage MultipliersDocument2 pagesGeneralised Cockcroft-Walton Voltage MultipliersfeelblastNo ratings yet

- Power Transmission and Distribution SummaryDocument20 pagesPower Transmission and Distribution SummaryScott Saw0% (1)

- Alex0718 PDUDocument17 pagesAlex0718 PDUDwiki KurniaNo ratings yet

- Beckwith-Generator Protection 1Document188 pagesBeckwith-Generator Protection 1Catrina FedericoNo ratings yet

- Saep 350 PDFDocument15 pagesSaep 350 PDFRami Elloumi100% (1)