Professional Documents

Culture Documents

Weldabilty Flow Chart

Uploaded by

bassamOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Weldabilty Flow Chart

Uploaded by

bassamCopyright:

Available Formats

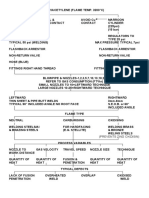

CARBON/LOW ALLOY STEELS

WELDABILITY

“GOOD” “LIMITED”

LAMELLAR

LOW RISK OF HICC TEARING MAY RISK

BUT SOLIDIFICATION HARDENING EFFECTS

WELD METAL CRACKING THROUGH WELDING/CUTTING

“POOR THROUGH

DUE TO THICKNESS DUCTILITY” HYDROGEN INDUCED

POOR GRAIN STRUCTURE + DEFECTS COLD CRACKING

(HICC)

WELD PREPERATION AVOID BY

(DEEP & NARROW) PREVENTION

THROUGH BUTTERING CHANGE

THICKNESS WITH OF

TESTING “SOFT” WELD JOINT REDUCE

METAL DESIGN HARDNESS

CAUSED BY PRE-HEAT HEAT INPUT

CONTROL

SULPHUR OR REDUCE

PHOSPHOROUS HYDROGEN LEVEL OR BOTH

IN MATERIAL

OR

P.W.H.T.

INCREASING AVOID BY CONSUMABLE H2 LEVEL PROCESS

INCLUDED ADDING Mn SELECTION LOW EB/LASER TEMPERS REMOVES REDUCES

ANGLE AND REDUCE TIG HARD HYDROGEN STRESS

/OR GAP SIZE DILUTION/ LOW HYDROGEN MIG H.A.Z.

WELD SIZE & CONTOL MMA BASIC

MAG

BAKING FREEDOM SUB ARC

OF BASIC FROM MOISTURE MAG/CO2

ELECTRODE/FLUX HIGH OXY-GAS

“ACCEPTABLE”

WELD

You might also like

- Heat Treatment Process: By: Jagdish PampaniaDocument67 pagesHeat Treatment Process: By: Jagdish PampaniabassamNo ratings yet

- Oxy - Acetylene Flow ChartDocument1 pageOxy - Acetylene Flow ChartbassamNo ratings yet

- Mam Flow ChartDocument1 pageMam Flow ChartbassamNo ratings yet

- Duties of A Weld InspDocument1 pageDuties of A Weld InspbassamNo ratings yet

- Oxy Fuel Cutting Flow ChartDocument1 pageOxy Fuel Cutting Flow ChartbassamNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5795)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Bank Reconcialiation ProblemDocument10 pagesBank Reconcialiation ProblemChatlyn Kaye MediavilloNo ratings yet

- Business Intelligence ConstituenciesDocument4 pagesBusiness Intelligence ConstituenciesJesy Parsadela100% (1)

- Solution Practice 1 Share CapitalDocument2 pagesSolution Practice 1 Share CapitalMya Hmuu KhinNo ratings yet

- Does China S Going Out Strategy Prefigure A New Food RegimeDocument40 pagesDoes China S Going Out Strategy Prefigure A New Food RegimeAgostina CostantinoNo ratings yet

- Presentation ON Tata Docomo: By: Abhishek Kumar JainDocument12 pagesPresentation ON Tata Docomo: By: Abhishek Kumar JainAbhishek JainNo ratings yet

- Audit & Assurance 2012Document13 pagesAudit & Assurance 2012S M Wadud TuhinNo ratings yet

- Finance Department: Government Order No. - F of 2021 Dated: .01.2021Document5 pagesFinance Department: Government Order No. - F of 2021 Dated: .01.2021KhalilNo ratings yet

- Idoc - Pub - Method Statement For Air Leak Test For Hvac Duct System Light Test PDFDocument18 pagesIdoc - Pub - Method Statement For Air Leak Test For Hvac Duct System Light Test PDFIbrahim SirpiNo ratings yet

- Banking RegulationsDocument5 pagesBanking RegulationsManuella RyanNo ratings yet

- Iso Astm 52901 2017Document9 pagesIso Astm 52901 2017FantasticNo ratings yet

- Nguyen Quang HuyDocument60 pagesNguyen Quang HuyThao NguyenNo ratings yet

- Fire Safety: ManualDocument16 pagesFire Safety: ManualTanvirNo ratings yet

- THE CONTEMPORARY WORLD Midterm ExamDocument3 pagesTHE CONTEMPORARY WORLD Midterm ExamNikki DedomingoNo ratings yet

- Executing Strategy With BSCDocument7 pagesExecuting Strategy With BSCAndrés RedondoNo ratings yet

- Universiti Teknologi Mara Common Test 1 Answer Scheme: Confidential AC/OCT2018/FAR320Document5 pagesUniversiti Teknologi Mara Common Test 1 Answer Scheme: Confidential AC/OCT2018/FAR320iqbalhakim123No ratings yet

- Chromite Mining ProcessDocument2 pagesChromite Mining ProcessAndika Rizal90% (10)

- Vans Skating On AirDocument8 pagesVans Skating On AirAnand Shankar50% (2)

- Assignment 1 - Written ReportDocument7 pagesAssignment 1 - Written ReporttiqahNo ratings yet

- Affinda Parser JdMyIWPODocument19 pagesAffinda Parser JdMyIWPOsavan kalakarNo ratings yet

- Management of Business: Teacher: Miss. GardnerDocument33 pagesManagement of Business: Teacher: Miss. GardnerOckouri BarnesNo ratings yet

- Chapter 5: Production Production TheoryDocument7 pagesChapter 5: Production Production TheoryPoudel SathiNo ratings yet

- 実用ビジネス日本語―成功への10章 (アルクの日本語テキスト) (Practical Business Japanese) (PDFDrive)Document203 pages実用ビジネス日本語―成功への10章 (アルクの日本語テキスト) (Practical Business Japanese) (PDFDrive)AsmitaNo ratings yet

- Brochure - 6th Annual Treasury Management India Summit 2022Document13 pagesBrochure - 6th Annual Treasury Management India Summit 2022Finogent AdvisoryNo ratings yet

- Fundamental & Technical AnalysisDocument19 pagesFundamental & Technical AnalysisShahzad SaifNo ratings yet

- Lesson 1 Prepare Construction Materials and ToolsDocument38 pagesLesson 1 Prepare Construction Materials and ToolsJenneth Bondoc RapistaNo ratings yet

- Event List Use Case Diagram Activity Diagram For The "Pickup A Package" Use Case System Sequence Diagram For The "Pickup A Package" Use CaseDocument8 pagesEvent List Use Case Diagram Activity Diagram For The "Pickup A Package" Use Case System Sequence Diagram For The "Pickup A Package" Use CaseAkshaya LakshminarasimhanNo ratings yet

- HSE PlanDocument55 pagesHSE PlanPlanning - Pappu ConstructionNo ratings yet

- R.A. 9520-Salient Points - Cooperative Development CodeDocument37 pagesR.A. 9520-Salient Points - Cooperative Development CodeMakoy BixenmanNo ratings yet

- 249 Enterpreneurship Lesson 4Document15 pages249 Enterpreneurship Lesson 4Koushik D.R.No ratings yet

- Intermediate Accounting 9th Edition Spiceland Solutions ManualDocument37 pagesIntermediate Accounting 9th Edition Spiceland Solutions Manualensampleruskw3ob100% (12)