Professional Documents

Culture Documents

09 - Bale Compactor PDF

Uploaded by

ImmorthalOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

09 - Bale Compactor PDF

Uploaded by

ImmorthalCopyright:

Available Formats

09 Bale Compactor

Deerberg-Systems GmbH – Moltkestraße 6a – 26122 Oldenburg – Germany

Phone: + 49 441 973 57 0 – Fax: + 49 441 777 33 7 – E-Mail: info@deerberg-systems.de

OPERATING INSTRUCTIONS

VERTICAL BALER

DBP V 605

valid for

machine no.: 6112P02468

Keep this instructions for future use!

03/2009 6.110.999.220_en P02468 1

V-PRESS 605

Contents

1 Notes on safety ............................................................................. 3

1.1 Safety symbols .......................................................................................... 4

1.1.1 "Work safety" symbol ............................................................................................................... 4

1.1.2 "Note" symbol ........................................................................................................................... 4

1.2 Classification of hazards ........................................................................... 4

1.2.1 Danger ..................................................................................................................................... 4

1.2.2 Warning .................................................................................................................................... 4

1.2.3 Caution ..................................................................................................................................... 4

1.3 Checking the safety devices ..................................................................... 5

1.4 Checklist .................................................................................................... 6

2 Use according to instructions ........................................................ 7

3 Technical data ............................................................................... 8

4 Operation of the baler ................................................................... 9

4.1 Machine overview ..................................................................................... 9

4.2 Operating elements / indicating elements ............................................... 10

4.2.1 Malfunctions ........................................................................................................................... 13

4.2.2 Reset of the control ................................................................................................................ 13

4.3 Transporting and setting up the baler ...................................................... 14

4.4 Inserting the strapping tapes ................................................................... 15

4.5 Starting and loading the baler ................................................................. 17

4.6 Strapping the bale ................................................................................... 21

4.7 Ejecting the bale ...................................................................................... 23

4.8 Shutting down the baler .......................................................................... 26

4.9 Operation outdoors ................................................................................. 26

4.10 Maintenance .......................................................................................... 27

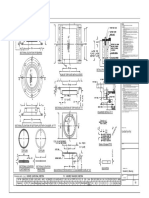

5 Dimensional drawing ...................................................................29

6 Hydraulic diagram ....................................................................... 30

7 Wiring diagrams ....................................................................................... 31

7.1 DBP V 605 - 3 x 400V / 50 Hz ............................................................... 31

7.2 Transformer DAWN-G 6.0 (3 x 690V >> 3 x 400V) ................................. 32

2 6.110.999.220_en P02468 03/2009

V-PRESS 605

1 Notes on safety

– The baler DBP V 605 employs state-of-the-art technology . However, this

machine can become hazardous if used incorrectly by the instructed staff or for

purposes other than those for which it was designed.

– Always follow local safety and accident prevention regulations when operating the

baler.

– The employer has to observe and to keep the „Minimum safety and health

requirements for use of the work equipment by workers at work“. (89/655/CEE)

– The baler may not be operated by persons under 16 years of age.

– Each person given duties of the baler must have read and fully understood the

entire Operating Manual, in particular the "Safety" section.

– The baler may only be operated, serviced and repaired by authorized, trained and

instructed personnel. Such personnel must have received special instructions

about potential dangers.

– The drive and additional devices must be secured against unintentional switching-

on before performing work on the baler. Set the main switch to "0" and secure it.

Pull out mains plug.

– Do not perform any work which may impair your safety while operating the

machine.

– Immediately report any changes which impair your safety to the person responsible.

Shut the machine down until such damage has been resolved.

– Before putting the machine into operation, ensure that it is in perfect working

condition.

– Ensure that the workplace on the baler is always clean and safe.

– All connecting cables must be laid in such a way that they cannot be tripped over.

– The user must not make any conversions or changes on his own initiative which

impair the safety of the baler. Protective devices must not be removed or rendered

inoperative.

– Only persons with specialist knowledge and experience with hydraulics may work

on the hydraulic equipment.

03/2009 6.110.999.220_en P02468 3

DBP V 605

1.1 Safety symbols

1.1.1 "Work safety" symbol

This symbol marks all work safety notes in this Operating Manual which

endanger the health or life of people. Please pay attention to this

symbol and exercise particular care in such cases. Please also forward

all work safety notes to other users.

Apart from the instructions in this manual, you must also follow

generally applicable safety and accident prevention regulations.

1.1.2 "Note" symbol

This symbol marks information in this manual which requires particular

attention so that guidelines, regulations, instructions and correct working

procedures are followed and damage to or ruin of the machine and/or

other equipment prevented.

1.2 Classification of hazards

1.2.1 Danger

identifies an immediate danger. If not avoided, it will result in death or

severe injuries (crippling).

1.2.2 Warning

identifies a possibly dangerous situation. If not avoided, it could result

in death or severe injuries.

1.2.3 Caution

identifies a possibly dangerous situation. If not avoided, it could result

in light or minor injuries. Is also used for warnings concerning damage

to material.

4 6.110.999.220_en P02468 03/2009

DBP V 605

1.3 Checking the safety devices

Check the safety devices:

• at the start of every work shift (when operation was interrupted)

• at least once a week when the operation is interrupted

• after each maintenance or repair

Check the safety devices for:

• specified condition

• specified position

• safe attachment

• specified function

Perform a check using the following checklist. Eliminate the faults before putting

the machine into operation!

If faults occur during operation the machine must be stopped immediately and the

faults eliminated.

Do not change or remove protective devices. Do not hinder protective devices by

modifications of the machine.

The machine must not be modified, for safety reasons!

03/2009 6.110.999.220_en P02468 5

DBP V 605

1.4 Checklist

Copy this list for your regular checks.

Check off the individual points when they are in order.

Operate the baler only when all points have been check and are in order.

8 7 Both control cabinets (1) must be

closed and the warning sign with

flash must be attached at the

control cabinet.

1

Check the function of the safety

switch (2) for the loading door (3)

resp. the bale ejection door (4).

2 In normal operating mode it must be

impossible to start the baler if one of

the doors is open.

Check the function of the door

3 locking mechanism of the loading

1

door (3). If you close the loading

door the locking lever (5) must snap

in automatically.

The bale ejection mechanism (6)

4 should move smoothly.

5

The label (7) "Caution! One-man

operation" (6.116.999.090) and the

label (8)"Bale strapping "

(6.110.999.100) must be attached at

the indicated position.

checked

6 Date ……………………………

Signature ………………………

6 6.110.999.220_en P02468 03/2009

D B P V 605

2 Use according to instructions

The vertical baler DS V-PRESS 605 is intended only for compacting empty

cartons, paper (Condition: dry / solvent free) andsingle-ply plastic foil as well as

any other materials agreed upon in the contract.

Material which greatly expands, such as bubble wrap or foam, may only be

compacted after consulting D S .

No cardboard cores! (thickwalled cardboard

rolls)

No stacks!

No plastic bottles/tins!

P re miu m

PET

0,33 l

Paper Cardboard Foil

03/2009 6.110.999.220_en P02468 7

DBP V 605

3 Technical data

Total machine weight ~ 644 kg

Strapping tape WG 30 / WG 40

WG 30 (8 mm) 6.205.993.010 (cardboard / foil)

WG 40 (11,5 mm) 6.212.993.010

Machine dimensions see dimensional drawings (chapter 5)

Press data

Pressing power 57 kN

Press cylinder ø 50/40 x 620 mm

Compression time with return stroke ~ 21 s

Bale size (WxDxH) 800 mm x 600 mm x max. 600 mm

Bale weight (cardbord) up to 70 kg

Motor data

Rated power 1.5 kW

Operating voltage 400 V/ 50 Hz

Rated current 3.6 A

Output RPM 1720 min-1

Protection mode IP55

Plug CEE 4x16A/5H (3P+PE)

Transformer

Power 6000 VA

Voltage Vpri = 3 x 690 V >> Vsec = 3 x 400V

Current sec Ipri = 3 x 5.5 A >> Isec = 3 x 8.67A

Frequency 50 / 60 Hz

Protection mode IP55

Isolation class T40 / F

Total fuse protection 3 x 16 A (K, C-characteristics)

Pump

Discharge Q1 4.9 l/min

Oil tank

Oil volume 5 l (3,5 l)

Oil type Multigrade oil to DIN 51524-T3

ISO viscosity class HVI 22

Noise emission values

The sound pressure level according to DIN 45635 Part 27, does not exceed the value

of 80 dB (A).

8 6.110.999.220_en P02468 03/2009

DBP V 605

4 Operation of the baler

4.1 Machine overview

16

3 10

12

11

2

13

17

5

9

8

15 7

14

1 Press chamber 10 Hydraulic unit

2 Control cabinet 11 Tape station

3 Press cylinder 12 Press ram

4 Locking lever for loading door 13 Lever for bale ejector

5 Loading door 14 Bale ejector

6 Safety switch 15 Guide profiles for tape/wire

7 Retaining claw 16 Tape insertion needle

8 Bale ejection door 17 Transformer 690V > 400V

9 Handwheel door lock device

03/2009 6.110.999.220_en P02468 9

DBP V 605

4.2 Operating elements / indicating elements

ELECTRONIC

10

2

8

4 3

9 7

1 Main switch when bale ejection door is open:

2 Selector switch cardboard / foil

3 Light symbol Foil 7 + 10 Two-handed operation: Raise press ram

4 Standby (Ready for operation) 5 + 10 Two-handed operation: Lower press ram

5 Lower press ram

6 Press ram stop

7 Raise press ram

8 Bale finished

9 Malfunction

10 Second key for two-handed operation

10 6.110.999.220_en P02468 03/2009

DBP V 605

Main switch

When turned 90° clockwise, the main switch is on.

The main switch can be locked in the "Off" position with a padlock.

Selector key "Cardboard / Foil"

Pressing this key you can switch over from compacting "Foil" to "Cardboard".

Light symbol "Foil"

This yellow symbol lights up, when the compacting material "foil" has been selected.

Light symbol "Standby"

This green symbol lights up, when the main switch is switched on and under power.

This green symbol is flashing when the loading door is open and goes off if there is

any malfunction.

"Lower press ram" key

Pressing this soft-key while the door is closed starts the compression. The press ram

moves down, compresses the material and returns automatically into its starting

position. The motor stops automatically.

"Press ram stop" key

With this soft-key the press ram can be stopped in any position.

The movement can be continued by pressing the "Raise/lower press ram" soft-key.

"Raise press ram" key

When this soft-key is pressed, the press ram returns into its starting position with the

door closed.

03/2009 6.110.999.220_en P02468 11

DBP V 605

Light symbol "Bale finished"

This message is displayed when a bale has reached a certain size. The press ram

stops automatically in extended position on the pressed material.

This symbol is flashing, if the press ramis not in bale ejection position. The ejection

postion is reached, when the blue symbol is displayed continuously.

Light symbol "Malfunction"

This red symbol lights up, when there is any malfunction on the baler. The baler is

switched off immediately . (-> see section "Malfunctions")

Key for two-handed operation for the functions:

• Raise press ram >> door is open (press 7 + 10 key simultaneously)

• Lower press ram >> door is open (press 5 + 10 key simultaneously)

Note

Works only in manual operation mode or at bale ejection.

Two-handed operation: Raise press ram (keys 7 + 10)

By simultaneous pressing of both soft-keys (within 0,5 seconds) the press ram can

be moved upwards. If one of the both soft-keys is released the press ram stops.

Two-handed operation: Lower press ram (keys 5 + 10)

By simultaneous pressing of both soft-keys (within 0,5 seconds) the press ram can

be moved downwards. If one of the both soft-keys is released the press ram stops.

12 6.110.999.220_en P02468 03/2009

DBP V 605

4.2.1 Malfunctions

Indicators Malfunction Remedy

LED 1 to 4 are blinking Wrong direct. of rotation, phase is missing Contact DESYS

LED 1 is blinking Inductive switch press ram in starting Contact DESYS

position resp. function inductive switch,

time monitoring of the press ram

LED 1 is shining Motor temperature, oil temperature, Let baler cool down

temperature sensor defective

LED 1 and 2 blinking Machine protective switch defective Contact DESYS

LED 1 and 4 blinking System error on the board, Contact DESYS

short circuit at an output of the board

LED 1, 2, 3, 4 are Machine in setup mode Reset control

blinking successively

ELECTRONIC

LED 3

LED 2 LED 4

LED 1

4.2.2 Reset of the control

– Switch the red main switch off

– Press simultaneously: and hold them pressed

– Switch main switch on while the 3 keys are pressed

– Release the 3 keys

– Switch the red main switch off and on again

• Now the baler is in normal working mode again

03/2009 6.110.999.220_en P02468 13

DBP V 605

4.3 Transporting and setting up the baler

Warning!

The baler may be transported only with the press ram lowered and

the door locked. If this is not observed, the baler kan tip over.

– For transporting on a lorry the baler must be fastened with tightening straps on

both sides.

Here tightening straps

for transport or straps

for unloading by crane

Here tightening straps

for transport or straps

for unloading by crane

– The pick-up points for unloading from a lorry by means of a forklift truck must be

observed.

– A hand forklift truck can also be used for transport to the installation site.(Carrying

capacity 500 kg!!!)

– Position the baler on a flat floor at the installation site (level out possible

unevenness of the floor with pieces of metal)

– Screw the baler with 8 screws onto the prepared floor

– Remove the packaging foil and dispose of it in an environmentally friendly manner

– Open the doors and take out the remaining accessories

– Insert the plug in the on-site socket and switch the main switch on

• If there are blinking one or more indicators -> consult an electrician! (see

section"Malfunctions")

– Observe that the baler is only operated under dry and clean operating conditions.

14 6.110.999.220_en P02468 03/2009

DBP V 605

4.4 Inserting the strapping tapes

– Put the three rolls of strapping tape onto the tape holder

– Open the hand wheel door lock device and the bale ejection door

– Swivel the tape brake to the left (tape brake is open)

– Push the tape end from top down into the corresponding hole in the brake shaft

– Push the strapping tape through the opening in the press frame and following pull

it through the eyelet at the rear of the press ram

– Pull the strapping tape in front of the fixing hook and wind it around it several times

– Position the strapping tape into the guide profiles on the floor and in the

channels of the rear panel.

03/2009 6.110.999.220_en P02468 15

DBP V 605

– Perform these steps for the 3 strapping tapes

– Swivel the bale ejection door against the baler and latch the locking bolt.

– Swivel the tape brake to the right (tape brake is closed)

– Close the bale ejection door by turning the handwheel

Note

Only tighten the handwheel slightly so that you can easily open it

after compression. Pressure is applied to the bale ejection door and

its locking mechanism by the compressed material.

The baler is now ready for operation.

16 6.110.999.220_en P02468 03/2009

DBP V 605

4.5 Starting and loading the baler

– Connect the switch cabinet of the transformer (1) to the main power supply 690V.

– Insert the red CEE-plug of the baler (2) into the socket of the transformer (3)

– Switch the black main switch of the transformer (4) on

03/2009 6.110.999.220_en P02468 17

DBP V 605

To load the baler, the bale ejection door must be closed and the press ram must

be in its starting position.

– Switch the red main switch of the baler (5) on

• symbol lights up

Note

The baler is ready for operation when the press ram is in its starting position.

If the press ram is not in its starting position, press the button until the

press ram stops.

Depending on material which should be compacted, you can switch over from "Foil"

to "Cardboard" by repeated pressing of the selection key.

Cardboard >> light symbol "Foil" is off.

Foil >> light symbol "Foil" lights.

ELECTRONIC

18 6.110.999.220_en P02468 03/2009

D B P V 605

– Open the loading door

– Fill the press chamber evenly with pressing material until it is completely full.

Caution!

If the baler is loaded unevenly e.g. with stacks at one side, the press ram

will incline while compacting the material.

This will damage press ram and press cylinder.

Note

We recommend to feed large pieces of cardboard for the first and

last compression. This prevents small pieces of material from

separating from the top and bottom of the bale and you will obtain a

better bale.

– Close the loading door

Load press

chamber

evenly!

P re miu m

PET

0,33 l

03/2009 6.110.999.220_en P02468 19

DBP V 605

As soon as the loading door is closed, the compression cycle starts automatically.

The first compression cycle after bale ejection however must be started by pressing

the "Lower press ram" soft-key.

Note

The press ram moves downwards and compresses the material. After

having reached the bottom limit position, the press ram automatically

moves back into starting position. The motor is switched off automatically.

– Repeat the loading and compression procedure several times until the

"Bale finished" light symbol comes up

The baler then switches off automatically and the press ram remains standing on the

compacted material.

Note

When the "Bale finished" symbol appears, it is possible to move the

press ram upwards forseveral times to proceed a further compression

cycle. (e.g. to put a cardboard as a cover on the top of the bale).

– You can start strapping now.

Note

The bale can be strapped even before the light symbol "Bale finsihed"

appears, e.g. if the compression material shall be changed.

20 6.110.999.220_en P02468 03/2009

DBP V 605

4.6 Strapping the bale

You can start strapping when the "Bale finished" symbol lights up.

– Turn the handwheel towards yourself as long as you can unlatch the locking bolt.

– Open the bale ejection door completely.

(Opening angle more than 90°)

> 90°

– Loosen the tape brake by swivelling it towards the left

03/2009 6.110.999.220_en P02468 21

DBP V 605

– Push the tape insertion needle (14) through the respective channel in the press

ram up to the rear panel

Note

The hook of the tape insertion needle must show upwards.

– Turn tape insertion needle (14) counter-clockwise until the tape hooks in

14

– Pull out strapping tape with the tape insertion needle

– Cut the tape loop

Note

Do not change the tape ends (12) and (13) of the cut tape loop,

otherwise strapping is not possible.

– Loosen tape end from fixing hook and tightly knot tape end (11) with strapping tape

(12) (on top of bale)

– Perform these steps for all 3 strapping tapes

✂ 13

12 11

22 6.110.999.220_en P02468 03/2009

DBP V 605

4.7 Ejecting the bale

Warning!

Make sure that no further persons are standing at the baler when the

bale is ejected.

Observe safety area!

Achtung ! Einmannbedienung

Caution ! One-man operation

Attention ! Commande à un seul opérateur

Atención ! Manejo unipersonal

Attentie ! Eenman-bediening

Gefahr ! • Danger !

Danger ! • ¡ Peligro !

Gevaar !

;

;;;

; Sicherheitsbereich

;;;

; ;

einhalten !

o.k. Observe

safety area !

No ! Respecter la

zone de sécurité

¡ Observar el

área de seguridad !

Veiligheidsafstand

bewaren!

6.116.999.090 - 03/2001

03/2009 6.110.999.220_en P02468 23

DBP V 605

Note

The opening angle of the door must be more than °90

, otherwise the bale

ejector does not work.

– Place a sufficiently large pallet in front of the baler to facilitate transport. (e.g.

EURO-pallet 1,20 x 0,80 m)

– Pull the bale ejector lever towards you

– Press both "Raise press ram" soft-keys (within 0,5 seconds) and keep

them pressed as long as the bale is ejected and the motor has switched off.

• The press ram moves upwards and pulls up the bale ejection device. The bale

ejection device tilts the bale forwards out of the press and then automatically

falls back to its initial position

ELECTRONIC

24 6.110.999.220_en P02468 03/2009

DBP V 605

– Carry away the ejected bale.

– Re-insert the strapping tapes

– Lock the tape brake by swivelling it to the right (tape brake is closed)

– Swivel the bale ejection door against the baler and latch the locking bolt.

– Close the bale ejection door by turning the handwheel

Note

Only tighten the handwheel slightly so that you can easily open it

after compression. Pressure is applied to the bale ejection door and

its locking mechanism by the compressed material.

– Close the loading door

Note

As soon as the loading door is closed again, the bale ejector falls

back into its initial position.

The baler is now ready for operation.

03/2009 6.110.999.220_en P02468 25

DBP V 605

4.8 Shutting down the baler

The baler can be put out of operation for longer interruptions of work, end of work or

for maintenance and installation work and can be secured against unauthorized use.

– Move press ram into starting position.

– Close the loading door and the bale ejection door

– Switch off the main switch and secure it.

– Unplug the baler

4.9 Operation outdoors

Warning!

Put into operation only under supervision.

The operator must ensure that unauthorized persons do not have

access to the baler.

When the baler is not operated it must be shut down and secured against

unauthorized use.

– The baler must not be directly exposed to rain.

– The maintenance intervals must be reduced.

– If the temperature drops below 0°C, use hydraulic oil with a suitable viscosity,

if required.

26 6.110.999.220_en P02468 03/2009

DBP V 605

4.10 Maintenance

Note

When using detergents and solvents, observe applicable accident

prevention regulations of the vocational cooperative society.

Observe environmental legislation when disposing of used oil.

Never mix mixtures of hydraulic oil and detergents with used oil.

Always collect these substances in separate containers and dispose

of them correctly!

Change the hydraulic oil every two years:

– Move the press ram into its starting position

– Unplug the baler

– Remove the cover(s)

– Unscrew the venting filter (with dipstick)

– Suck off oil with an oil suction aggregate

– Clean the hydraulic oil tank if it is severely soiled

– Fill the tank with the specified oil volume and check the oil level by means of

the dipstick

• The filling volume of the oil tank is 3.5 l

Oil type: Multigrade oil DIN 51524-T3 / ISO viscosity grade HVLP 22

ISO-

Viskositäts- ESSO DEA SHELL ARAL BP FINA

klasse

Mineralöle ISO VG 22 UNIVIS Astron Tellus Öl Aral Vitam Bartran HYDRAN

Mineral oils HVLP N 22 ZHLP 22 T 22 HF 22 HV 22 HV 22

– Screw in a new venting filter (35)

– Insert the plug in the on-site socket and switch the main switch on

– Move the press ram up and down several times and check the oil level again with

the press ram in the upper position.

– Top up oil as necessary.

– Screw on the cover(s)

V-Press 605

35

03/2009 6.110.999.220_en P02468 27

DBP V 605

Note

Lubricate all moving parts and hinges on demand, in particular the door

hinges as well as the bearings of the door lock with multi-purpose grease

/ multi-purpose oil.

every month every three months

JY

ÖL JA

OL IE

OL EO

ÓL ITE

E

AC LIO

O ILE

HU IL

O

ÖL

every three months

28 6.110.999.220_en P02468 03/2009

DBP V 605

5 Dimensional drawing

03/2009 6.110.999.220_en P02468 29

DBP V 605

6 Hydraulic diagram

30 6.110.999.220_en P02468 03/2009

DBP V 605

7 Wiring diagrams

7.1 DBP V 605 - 3 x 400V / 50 Hz

Wiring diagram 100000069888

see appendix

03/2009 6.110.999.220_en P02468 31

DBP V 605

7.2 Transformer DAWN-G 6.0 (3 x 690V >> 3 x 400V)

Construction drawing

32 6.110.999.220_en P02468 03/2009

You might also like

- Chainsaw Operator's Manual: Chainsaw Safety, Maintenance and Cross-cutting TechniquesFrom EverandChainsaw Operator's Manual: Chainsaw Safety, Maintenance and Cross-cutting TechniquesRating: 5 out of 5 stars5/5 (1)

- NL Pro II 50 and 60Hz Operator Manual With Cover (2016-103402 Rev B)Document92 pagesNL Pro II 50 and 60Hz Operator Manual With Cover (2016-103402 Rev B)sllanesNo ratings yet

- 5245f en PDFDocument28 pages5245f en PDFdinhvuNo ratings yet

- LSA44.3 ManualDocument24 pagesLSA44.3 ManualDaniel ArdilaNo ratings yet

- Vision LF CNCDocument98 pagesVision LF CNCwilly1234512No ratings yet

- Wilo 31895Document30 pagesWilo 31895Titi FiliNo ratings yet

- Instruction Manual: Frequency Response AnalyzerDocument145 pagesInstruction Manual: Frequency Response AnalyzerWuzekNo ratings yet

- Low Voltage Alternator - 4 Pole: Installation and MaintenanceDocument32 pagesLow Voltage Alternator - 4 Pole: Installation and MaintenanceAllen AnyayahanNo ratings yet

- Tal 044Document32 pagesTal 044محمود المستكاويNo ratings yet

- Low Voltage Alternator - 4 Pole: Installation and MaintenanceDocument32 pagesLow Voltage Alternator - 4 Pole: Installation and Maintenanceabdo elsayedNo ratings yet

- Low Voltage Alternator - 4 Pole: Installation and MaintenanceDocument28 pagesLow Voltage Alternator - 4 Pole: Installation and MaintenanceYANETH ALCANTARANo ratings yet

- Leroy SOmer TAL042 Installation and Maintenance ManualDocument32 pagesLeroy SOmer TAL042 Installation and Maintenance ManualAhmed Mohammed TahounNo ratings yet

- LSA44.3 - Maintenance ManualDocument28 pagesLSA44.3 - Maintenance ManualMuhammad HaekalNo ratings yet

- TAL 044 5226e - enDocument24 pagesTAL 044 5226e - enMd ShNo ratings yet

- Low Voltage Alternator - 4 Pole: Installation and MaintenanceDocument28 pagesLow Voltage Alternator - 4 Pole: Installation and Maintenanceamir amirNo ratings yet

- Low Voltage Alternators - 4 Pole: Three-Phase 12-Wire Dedicated Single-Phase 4-WireDocument28 pagesLow Voltage Alternators - 4 Pole: Three-Phase 12-Wire Dedicated Single-Phase 4-WireJesús MartínezNo ratings yet

- Lsa 49.3Document28 pagesLsa 49.3Rafki ChandraNo ratings yet

- Extruder-Die Head Connection HX 50/90º: Operating ManualDocument21 pagesExtruder-Die Head Connection HX 50/90º: Operating ManualFelipe Cappato Da CostaNo ratings yet

- Lauda Ecoline Immersion ThermostatDocument39 pagesLauda Ecoline Immersion ThermostatMustafa SariNo ratings yet

- Low Voltage Alternator - 4 Pole: Installation and MaintenanceDocument28 pagesLow Voltage Alternator - 4 Pole: Installation and MaintenanceAllen AnyayahanNo ratings yet

- Manual 1234Document48 pagesManual 1234Topa MarinNo ratings yet

- Instruction Manual: Model: IRMA11 IRMA12 IRMA13Document50 pagesInstruction Manual: Model: IRMA11 IRMA12 IRMA13Ramu RamuNo ratings yet

- Leroy Somer Generator ManualDocument28 pagesLeroy Somer Generator ManualLeo Burns100% (1)

- PRESENTATION 5278k - en (2021-09)Document28 pagesPRESENTATION 5278k - en (2021-09)neksfyrisNo ratings yet

- Wilo-Star RS, RSD: Pioneering For YouDocument136 pagesWilo-Star RS, RSD: Pioneering For YouKirill KNo ratings yet

- Canon FPD-400D FPM-420D ManualDocument25 pagesCanon FPD-400D FPM-420D ManualsonytechoNo ratings yet

- BA 3576-00-01-05-01-00-EnDocument9 pagesBA 3576-00-01-05-01-00-EnengineerstechNo ratings yet

- PRESENTATION 5278h - en (2019-04)Document28 pagesPRESENTATION 5278h - en (2019-04)neksfyrisNo ratings yet

- LSA47 3-Install&MaintenDocument28 pagesLSA47 3-Install&MaintenCao HieuNo ratings yet

- STP User Manual GP EN - Revb (Current)Document32 pagesSTP User Manual GP EN - Revb (Current)BambangIrawan48No ratings yet

- B-85314EN-1 01 (Alpha-DiA5 Custom PMC) PDFDocument242 pagesB-85314EN-1 01 (Alpha-DiA5 Custom PMC) PDFmastorres87No ratings yet

- Low Voltage Alternators - 6 Pole: Installation and MaintenanceDocument28 pagesLow Voltage Alternators - 6 Pole: Installation and Maintenancealeenmalek2024No ratings yet

- 4099h en PDFDocument28 pages4099h en PDFdinhvuNo ratings yet

- Product Manual 26099 (Revision C) : Servlink and EGCP-2 HMIDocument46 pagesProduct Manual 26099 (Revision C) : Servlink and EGCP-2 HMILibyanManNo ratings yet

- Chapter 02Document24 pagesChapter 02Ubeimar Rivera OspinaNo ratings yet

- Safety Precautions: SK210LC/SK250LC-6E Dynamic Acera OM, 11/02 Rev. 0Document26 pagesSafety Precautions: SK210LC/SK250LC-6E Dynamic Acera OM, 11/02 Rev. 0Ronal MoraNo ratings yet

- SECM112 Digital Control: Product Manual 26634 (Revision B, 4/2019)Document20 pagesSECM112 Digital Control: Product Manual 26634 (Revision B, 4/2019)Kaleem KhanNo ratings yet

- Video Processor Vep-2100fDocument18 pagesVideo Processor Vep-2100fVictor BlancoNo ratings yet

- LS ManualDocument28 pagesLS ManualMd Sh100% (1)

- NVC DCP551B Um CP SP 1032e 18Document220 pagesNVC DCP551B Um CP SP 1032e 18johnductamNo ratings yet

- Win713en 00Document34 pagesWin713en 00MohamedAbdelnasserNo ratings yet

- Manual de Usuario de PLC XGT SeriesDocument97 pagesManual de Usuario de PLC XGT SeriesMarios ClubsNo ratings yet

- Low Voltage Alternator - 4 Pole: Installation and MaintenanceDocument28 pagesLow Voltage Alternator - 4 Pole: Installation and MaintenanceAllen AnyayahanNo ratings yet

- Manual LeroyDocument28 pagesManual LeroyManuel Alberto Ortiz GalánNo ratings yet

- 35 - DF135 ManualDocument222 pages35 - DF135 Manualussama abdo100% (2)

- LSA46.3 ManualDocument24 pagesLSA46.3 ManualDaniel ArdilaNo ratings yet

- Wilo - 2 PDFDocument28 pagesWilo - 2 PDFAlexandru BocoșNo ratings yet

- Instacion TAL A42Document28 pagesInstacion TAL A42Roberto StepankowskyNo ratings yet

- l13892 Towerdryer Quadratouchpro PDFDocument192 pagesl13892 Towerdryer Quadratouchpro PDFKukuh Tak TergoyahkanNo ratings yet

- Maintenance B 64485ENDocument1,024 pagesMaintenance B 64485ENMichael Kenna100% (1)

- Manual Leroy Somer Generator Lsa 50 l8Document28 pagesManual Leroy Somer Generator Lsa 50 l8Carlos Andre Sante MancillaNo ratings yet

- DX200 Options Instructions For Cc-Link Communications FunctionDocument49 pagesDX200 Options Instructions For Cc-Link Communications Functioninyong baik100% (1)

- TCFD Controller Instruction Manual Controller Maintenance: 2nd EditionDocument24 pagesTCFD Controller Instruction Manual Controller Maintenance: 2nd Editionพงษ์พันธ์ คําป๊อกNo ratings yet

- Fuel Conditioning SystemDocument10 pagesFuel Conditioning SystemMERTAL JAYA ABADINo ratings yet

- Aib NG7-81 20703404Document42 pagesAib NG7-81 20703404DanielrcruzNo ratings yet

- Product Manual 36693 (Revision D, 5/2015) : PG Base AssembliesDocument10 pagesProduct Manual 36693 (Revision D, 5/2015) : PG Base AssemblieslmarcheboutNo ratings yet

- Installation and Operation Manual: Proact™ Itb Integrated Actuator and Throttle BodyDocument26 pagesInstallation and Operation Manual: Proact™ Itb Integrated Actuator and Throttle BodyNimNo ratings yet

- Fronius IG Series User ManualDocument92 pagesFronius IG Series User ManualPE TruNo ratings yet

- Preliminary: Each Relay, in Case of Heavier Loads Use A Suitable External Relay. 4.1 Probes ConnectionDocument6 pagesPreliminary: Each Relay, in Case of Heavier Loads Use A Suitable External Relay. 4.1 Probes ConnectionImmorthalNo ratings yet

- XR30CX: Installing and Operating InstructionsDocument4 pagesXR30CX: Installing and Operating InstructionsImmorthalNo ratings yet

- Deno Air Dryer Manual SD210 16757Document58 pagesDeno Air Dryer Manual SD210 16757ImmorthalNo ratings yet

- Danfoss VLT HVAC FC 102 Manual PDFDocument74 pagesDanfoss VLT HVAC FC 102 Manual PDFFernando QueirozNo ratings yet

- Indermediate Shaft Bearing Svenska BearingDocument17 pagesIndermediate Shaft Bearing Svenska BearingImmorthalNo ratings yet

- Manuale LX2500R Inglese STANDARDDocument49 pagesManuale LX2500R Inglese STANDARDImmorthalNo ratings yet

- Filter Solutions For: Danfoss PAH, APP and CLP PumpsDocument12 pagesFilter Solutions For: Danfoss PAH, APP and CLP PumpsImmorthalNo ratings yet

- Restoring IP Streams On Cisco D9824Document4 pagesRestoring IP Streams On Cisco D9824ImmorthalNo ratings yet

- L3 2019-10-30 13:28:24 Cinterface - Fc::Slot - Handshake - TCP - Connecttopms: Failed To Connect. Connecting Again In: 60 SecondsDocument5 pagesL3 2019-10-30 13:28:24 Cinterface - Fc::Slot - Handshake - TCP - Connecttopms: Failed To Connect. Connecting Again In: 60 SecondsImmorthalNo ratings yet

- Mute Configuration and Testing: 1. Setting FileDocument4 pagesMute Configuration and Testing: 1. Setting FileImmorthalNo ratings yet

- To Add or Remove Channels From Different Groups, You Must Go To Services, TV Groups and Select The Stations That They Want To WatchDocument1 pageTo Add or Remove Channels From Different Groups, You Must Go To Services, TV Groups and Select The Stations That They Want To WatchImmorthalNo ratings yet

- Check FirmwareDocument1 pageCheck FirmwareImmorthalNo ratings yet

- ContentDocument3 pagesContentImmorthalNo ratings yet

- 140 BARS: Accomodation Sections Plant-12 SectionsDocument1 page140 BARS: Accomodation Sections Plant-12 SectionsImmorthalNo ratings yet

- Em'Cy 014 Safety MessageDocument1 pageEm'Cy 014 Safety MessageImmorthalNo ratings yet

- Manual A PDFDocument49 pagesManual A PDFImmorthalNo ratings yet

- 2015 OR Guidebook PDFDocument140 pages2015 OR Guidebook PDFImmorthalNo ratings yet

- UK - Speedfit Oct2012Document66 pagesUK - Speedfit Oct2012ImmorthalNo ratings yet

- Blue Rose Q88Document7 pagesBlue Rose Q88ImmorthalNo ratings yet

- Basic Outline: Vacuum Pump 1+2Document1 pageBasic Outline: Vacuum Pump 1+2ImmorthalNo ratings yet

- Operator VDR Svdrdbs00328 30Document42 pagesOperator VDR Svdrdbs00328 30mikeNo ratings yet

- Maregas Q88Document6 pagesMaregas Q88ImmorthalNo ratings yet

- Fittings - ManuliDocument128 pagesFittings - ManuliImmorthalNo ratings yet

- Katerina-M Q88-Ship's PartDocument7 pagesKaterina-M Q88-Ship's PartImmorthal100% (1)

- Ecole Sigtto QuestionareDocument18 pagesEcole Sigtto QuestionareImmorthalNo ratings yet

- Osman Bey Vsls PartsDocument10 pagesOsman Bey Vsls PartsImmorthalNo ratings yet

- Puli Q88Document7 pagesPuli Q88ImmorthalNo ratings yet

- Peonia Q88Document7 pagesPeonia Q88Immorthal100% (1)

- Leonora Kosan Ship's ParticularsDocument1 pageLeonora Kosan Ship's ParticularsImmorthalNo ratings yet

- Guided (L) Bearing DrawingDocument1 pageGuided (L) Bearing Drawingtrichandra maharjanNo ratings yet

- BS 7121-3-2017+a1-2019 PDFDocument74 pagesBS 7121-3-2017+a1-2019 PDFAsh Turner100% (12)

- Project Management Principle AsDocument17 pagesProject Management Principle Asisaac lakiNo ratings yet

- PT-03 JSA Dismantling of Slip Form (22-05-09)Document10 pagesPT-03 JSA Dismantling of Slip Form (22-05-09)M Waqas HabibNo ratings yet

- 16mm Down Stone ChipsDocument4 pages16mm Down Stone ChipsMojammel HaqueNo ratings yet

- OCW ACT BY KAK Tax PDFDocument57 pagesOCW ACT BY KAK Tax PDFzakir84md3639No ratings yet

- Failure of Space Frame in Turkey PDFDocument13 pagesFailure of Space Frame in Turkey PDFZeeshan AhmedNo ratings yet

- LTC 443-2022 6701 Collins Avenue - Deauville Demolition UpdateDocument3 pagesLTC 443-2022 6701 Collins Avenue - Deauville Demolition Updatethe next miamiNo ratings yet

- Seminar On Mivan Technology The Aluminium FormworkDocument36 pagesSeminar On Mivan Technology The Aluminium FormworkCivilTY09Aditya GavaliNo ratings yet

- SS 595-1-2014 - PreviewDocument11 pagesSS 595-1-2014 - PreviewpierreguessNo ratings yet

- Book 2Document80 pagesBook 2Pratik GuptaNo ratings yet

- Appendix 1 - Max Forni - S Proof of Evidence Construction Noise and Vibration Management PlanDocument15 pagesAppendix 1 - Max Forni - S Proof of Evidence Construction Noise and Vibration Management PlanCory WashingtonNo ratings yet

- Offline Schedule-Siioc2023 Version2Document5 pagesOffline Schedule-Siioc2023 Version2Shah Ayushiben Vineshkumar SVNITNo ratings yet

- Revisd QTN - Ot No.1 PDFDocument4 pagesRevisd QTN - Ot No.1 PDFMUNINo ratings yet

- Formworks (Lecture & Sample Problems) : Quantity Surveying Professor: Engr. Shane Francis B. GarciaDocument28 pagesFormworks (Lecture & Sample Problems) : Quantity Surveying Professor: Engr. Shane Francis B. GarciaJohn AbandoNo ratings yet

- MaterialsDocument1 pageMaterialsPoorna28No ratings yet

- HFT SafetyFirst Export Dietzel 1901Document24 pagesHFT SafetyFirst Export Dietzel 1901Jorge UrbinaNo ratings yet

- Dique Flotante RepairDocument110 pagesDique Flotante RepairIsmael ColinaNo ratings yet

- Dar-Cv-Ahsan MahmoodDocument4 pagesDar-Cv-Ahsan MahmoodAhsan MahmoodNo ratings yet

- Understanding Hadrians WallDocument5 pagesUnderstanding Hadrians WallBernardo Milazzo0% (1)

- Building and Other Construction Workers Act 1996Document151 pagesBuilding and Other Construction Workers Act 1996Rajesh KodavatiNo ratings yet

- Ubgmsw 20 M - 2Document3 pagesUbgmsw 20 M - 2abdullah_23320666No ratings yet

- SRB Session2 EofsDocument3 pagesSRB Session2 EofsFullo Flores MarviloneNo ratings yet

- Quite Pavement System in EuropeDocument50 pagesQuite Pavement System in Europesenoln5No ratings yet

- Essentials Quality Control Plan SampleDocument11 pagesEssentials Quality Control Plan SampleSakhawat HossainNo ratings yet

- Naseer PariyantavidaDocument4 pagesNaseer PariyantavidaNaseer PariyanNo ratings yet

- 23opt17682-001-A1L DWGDocument1 page23opt17682-001-A1L DWGJames Hampton GreenieNo ratings yet

- Take A Chance With MeDocument5 pagesTake A Chance With MeOsidhdosodjNo ratings yet

- Spare Parts List: Hydraulic BreakersDocument36 pagesSpare Parts List: Hydraulic BreakersJean MoralesNo ratings yet

- Naukri Hemantkumarsharma (29y 0m)Document2 pagesNaukri Hemantkumarsharma (29y 0m)sushil.tripathiNo ratings yet