Professional Documents

Culture Documents

Six Sigma Project Guideline: Relevance of Topic: Suitable For: Own Contribution

Uploaded by

Arun KangeyanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Six Sigma Project Guideline: Relevance of Topic: Suitable For: Own Contribution

Uploaded by

Arun KangeyanCopyright:

Available Formats

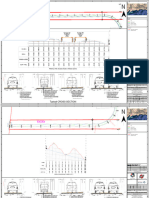

Six Sigma Project Guideline Technische Universität München

P a r e to C ha r t o f F e hl e r ty p Summary Report for Y

De

Analyse

10 0 Anderson-Darling Normality Test

20

Graphical Analysis of Data

A-Squared 0,22

Relevance of Topic: 36% Identify Project

80 P-Value 0,828

15

Mean 0,021 45

Percent

60

Count

StDev 0,97241

10

40 Variance 0,94559

Skewness -0,1 24656

5 20 Kurtosis -0,003328

N 1 000

0 0 Minimum -3,571 37

collect Topics a) Pareto-Diagram

F e h le r t y p is en N r r d e

P re m n- V -N Co

1 st Quartile -0,6331 6

i: Na r te CV i: Median 0,00431

be i: Ka i: e

r e be r b 3rd Quartile 0,65294

h le rb be

i:

h le

ab

le r

Fe r le Maximum 2,67709

F eh h le eh Fe

fine

F

Fe 95% Confidence Interval for Mean

C ou nt 8 ,4 2 4 ,8 1 3,61 2,41 1,80 -0,03889 0,081 79

Suitable for: Six Sigma

P erce nt 4 0,0 2 2,9 1 7 ,1 1 1 ,4 8 ,6 95% Confidence Interval for Median

evaluate Topics b) Histogram

C um % 4 0,0 6 2,9 8 0 ,0 9 1 ,4 1 0 0 ,0 -3 -2 -1 -0 1 2 -0,04487 0,1 1 464

4 ,0

B o x pl o t o f S tim m u n g b y Z e it

cd

prioritize Topics c) Boxplot

3 ,5

3 ,0

Stimmung

2 ,5

Own contribution: 80%

2 ,0

select Project 1 ,5

1 ,0

1 2 3

d) Time Series Plot

Z e it

Process-Capability Process-Control

Define Project Process Capability Report for Yt1 _Cookie-Weight I-MR Chart of Y_Consumption_per_Day

Summary Report

Process-Capability/ -Control

Process and Output Yield%/ DPU/ DPMO

Is the process mean stable? Comments

Evaluate the % of out-of-control points.

LSL Target USL The process mean may not be stable. 5 (15,6%) data points are out of control

0% > 5% on the I chart. Keep in mind that you may see 0,7% out-of-control points by

Process Data Overall chance, even when the process is stable.

LSL 18 Within

Target 20 Yes No

USL 22 Overall Capability 15,6%

Sample Mean 20,9507 Z.Bench 0,1 8

Z.LSL 1 ,26

Zbench (Sigma Level) )/ cp/ cpk …

Sample N 60

StDev(Overall) 2,3331 5 Z.USL 0,45

Problem

StDev(Within) 2,04775 Ppk 0,1 5

Cpm 0,26

Potential (Within) Capability Individual and Moving Range Charts

Investigate any out-of-control points.

Z.Bench 0,31

25

Z.LSL 1 ,44 UCL=23,92

Z.USL 0,51

Individual Value

Cpk 0,1 7

I-MR/ xbar-R/ xbar-S/ P-/ U-Chart

10

_

Effect

X=5,89

-5

LCL=-12,13

UCL=22,14

20

Moving Range

Solution ideas (if present) as baseline of the Process

10

1 5,0 1 6,5 1 8,0 1 9,5 21 ,0 22,5 24,0 25,5 __

MR=6,78

Performance

Observed Expected Overall Expected Within 0 LCL=0

PPM < LSL 1 00000,00 1 02992,26 74799,56 1 4 7 10 13 16 19 22 25 28 31

PPM > USL 266666,67 326450,62 3041 79,60

PPM Total 366666,67 429442,89 378979,1 5 N: 32 Mean: 5,8947 StDev(within): 6,0087 StDev(overall): 4,0946

Control limits are estimated using the StDev(within).

SIPOC (Supplier-Input-Process-Output-Customer) Difference Relationship

Test Hypothesis

Input Process Output structure Process into main the Boxplot of Y_Cookie_Weight Scatterplot of Y_Brightness_of_Cookie vs x_Baking_Time

27,5 22

Difference-Hypothesis:

main process steps 25,0

20

Ya =/≠ Yb

Y _Brigh tness_of_Cook ie

18

Y_C ookie_W eight

22,5

assign Inputs and 16

Relationship-Hypothesis:

20,0

14

Input Process Output (intermediate) Outputs 1 7,5 12

1 5,0

10

Y =/≠ f(x)

assign Supplier and Customer

t_1 t_2 10 12 14 16 18 20

time_of_measurement x_Baking_Time

Voice of Customer & Business

VoC/ VoB > CCR/ CBR > CtQ

Root-Cause-Analysis

interview Customer/ Manager

derive requirements for Outputs

Requirements and Deviations identify Root-Causes x´

and evaluate their deviations

of the negative influences x on

derive severity of Problems Y of

Severity of Problems of Outputs the Problems Y

the Output

Project-Charter Project-Charter Solution-Ideas

Improve

Business

Problem focus on critical Problems Y develop Solutions to eliminate,

Relevance Cause Problem

specify their business relevance (x´)

Solution

(Y)

circumvent or adjust parameter

Scope/ Experts of the Root-Causes x´

Belt-Team define scope and objectives

Objectives

Management build a team prioritize Solutions

Input Input-Analysis

M

Design of Experiments (DoE)

identify necessary Inputs

easure

Requirements and deviations specify the requirements Y= f(x) adjust the parameter

specify negative Influences xi on

of Solutions optimally

negative Influences on Problems the Problems of the Output Y

Process-Steps > Activities Process-Mapping & -Analysis

map Process-Steps into Activities

Measure 8

Action-List

Measure 3

Input, Output, Methods & Resources assign Inputs and Outputs

specify Methods & Resources specify Solutions as Measures

Measure 4

(Who?/ What?/ until When?)

negative Influences on Problems specify negative Influences xp

FMEA

Problems (Y)

(Failure Mode and Effects Analysis)

Cause & Effect-Matrix (C&E)

Risk-Analysis Improvement new Risk-Analysis

Probabili ty of

Probabili ty of

the Probl em

the Probl em

Det ection of

Det ection of

Severity of

Severity of

R R

the Effect

the Effect

Y1 Y2 Y3 Yn

Cause

Cause

actual controls to detect the Failures/

potential Failures/ Problems

Problems

potential Effects of the Failures/ Problems potential Causes of the Failure/ Problem P Countermeasures P

N N

Measure-No.

3

evaluate impact strength of the

Measure (What has to be done?)

FMEA (Failure Mode and Effects Analysis)

10= catast rophic

10= catast rophic

Xi1

Risk-Prior ity-

Risk-Prior ity-

1= always -

1= always -

10= always

10= always

1= never -

1= never -

10= never

10= never

Input

Number

Number

1= no -

1= no -

Rating:

Rating:

Rating:

Rating:

Rating:

Rating:

Which Failures/ Problems can result from the By which existing Controls could the Failure/ How could the trigger of the Failure/ Problem, i.e.

1

Measures? Problem be detected, before it occurs? What is the Effect of the Failure/ Problem? Which Influence triggers the Failure/ Problem? their Root-Causes be eliminated

(Xi) Xi2 ...? ...? ...? ...? ...? ...?

Xin 4 negative Influences of Inputs xi 1.

Let the Chef weigh 10 g of chocolate for her

special Chocolate Check

can cause caries periodic dental prophylaxis 5

...?

tooth loss 7

...?

sugar/ bacterial plaque 10

...?

350

immediate brushing of teeth after check of

chocolate

7

...?

2

...?

5

...?

70

minimize Risks of Measures

...? ...? ...? ...? ...? ...?

Process-Steps

Xp1 2 and Activities of the Process xp ...?

...?

...?

...?

...?

...?

...?

...?

...?

...?

...?

...?

Xp2 5 ...? ...? ...? ...? ...? ...?

(Xp)

Xpn 7

on Problems of the Outputs Y ...?

...?

...?

...?

...?

...?

...?

...?

...?

...?

...?

...?

...?

...?

...?

...?

...?

...?

Operationalisation Graphical Display

Data Collection Plan

Y1

implement Implementation

Problems

Y2 operationalize Influences xi, xp

(Y)

Yn qualify decide on Measures

and Problems Y as measurands inform &

Input

Xi1

motivate inform and motivate

(Xi) Xi2

determine scale level

Xin

decide qualify (if necessary)

Process- Xp1

determine conditions and

Steps Xp2 implement Measures

(Xp) Xpn procedure of measurement

Hypothesis Process-Capability Process-Control

Process-Capability/ -Control

Co

Risk: 14%

There is a/ no Difference

automatically generated with:

Process Capability Report for Yt1 _Cookie-Weight I-MR Chart of Y_Consumption_per_Day

Summary Report

Yield%/ DPU/ DPMO

Is the process mean stable? Comments

Evaluate the % of out-of-control points.

in: the degree of: (Y) …

LSL Target USL The process mean may not be stable. 5 (15,6%) data points are out of control

0% > 5% on the I chart. Keep in mind that you may see 0,7% out-of-control points by

Process Data Overall chance, even when the process is stable.

LSL 18 Within

Target 20 Yes No

USL 22 Overall Capability 15,6%

- type of Hypothesis

Sample Mean 20,9507 Z.Bench 0,1 8

Z.LSL 1 ,26

Zbench (Sigma Level)/ cp/ cpk …

Sample N 60

between: Levels of (x)

StDev(Overall) 2,3331 5 Z.USL 0,45

Ppk 0,1 5

ntrol

StDev(Within) 2,04775

Cpm 0,26

Potential (Within) Capability Individual and Moving Range Charts

Investigate any out-of-control points.

Z.Bench 0,31

25

Z.LSL 1 ,44 UCL=23,92

(Difference/ Relationship)

Z.USL 0,51

Individual Value

Cpk 0,1 7

I-MR/ xbar-R/ xbar-S/ P-/ U-Chart

10

_

X=5,89

-5

- relevance of Hypothesis (Risk)

LCL=-12,13

UCL=22,14

20

Moving Range

Test: ANOVA for the improved Process

10

1 5,0 1 6,5 1 8,0 1 9,5 21 ,0 22,5 24,0 25,5 __

MR=6,78

Performance

- appropriate statistical test

Observed Expected Overall Expected Within 0 LCL=0

PPM < LSL 1 00000,00 1 02992,26 74799,56 1 4 7 10 13 16 19 22 25 28 31

PPM > USL 266666,67 326450,62 3041 79,60

PPM Total 366666,67 429442,89 378979,1 5 N: 32 Mean: 5,8947 StDev(within): 6,0087 StDev(overall): 4,0946

Control limits are estimated using the StDev(within).

Difference Relationship

Measurement-System-Analysis Boxplot of Y_Cookie_Weight Scatterplot of Y_Brightness_of_Cookie vs x_Baking_Time

Test Hypothesis

check repeatability, reproduci- 27,5

25,0

22

20

Difference-Hypothesis:

bility, stability and linearity of the Ya =/≠ Yb

Y_Brightn ess_of_C ookie

18

Y_C ookie_W eight

22,5

16

Relationship-Hypothesis:

20,0

measurement system 1 7,5

14

12

Gage R&R 1 5,0

t_1

time_of_measurement

t_2

10

10 12 14

x_Baking_Time

16 18 20 Y =/≠ f(x)

12 011011102200801 Collect Data Plan Process

Monitoring and Out

Document

Project and present

Define Standards

for the new Process

Handover and close Project

110114051978101 of Control Measures Results

9 3 101501195801001

collect existing data Start Continuous Continue checking Continue checking Storyboard of Project

010100101010101 Improvement (CIP) Target Achievement Process Capability

measure actual data Process-Management-Plan

001110100110011

6

Management (Sponsor, Accountable) / Role: monitor, decide, support Project sigmaGuide©

Project Team: Belt (Black-Belt/ Green-Belt) / Role: lead Project Tools: Copyright: reiner.hutwelker@softLogik.de

Experts / Role: support Project Minitab©

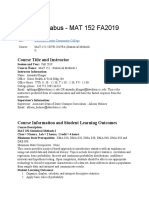

Six Sigma Projekt Leitfaden Technische Universität München

P a r e to C ha r t o f F e hl e r ty p Summary Report for Y

De

Analyse

10 0 Anderson-Darling Normality Test

20

graphische Analyse der Daten

A-Squared 0,22

Relevanz des Themas: 36% Projekt identifizieren

80 P-Value 0,828

15

Mean 0,021 45

Percent

60

Count

StDev 0,97241

10

40 Variance 0,94559

Skewness -0,1 24656

5 20 Kurtosis -0,003328

N 1 000

0 0 Minimum -3,571 37

Themen einsammeln a) Pareto-Diagramm

F e h le r t y p is en N r r d e

P re m n- V -N Co

1 st Quartile -0,6331 6

i: Na r te CV i: Median 0,00431

be i: Ka i: e

r e be r b 3rd Quartile 0,65294

h le rb be

i:

h le

ab

le r

Fe r le Maximum 2,67709

F eh h le eh Fe

fine

F

Fe 95% Confidence Interval for Mean

C ou nt 8 ,4 2 4 ,8 1 3,61 2,41 1,80 -0,03889 0,081 79

Tauglichkeit für: Six Sigma

P erce nt 4 0,0 2 2,9 1 7 ,1 1 1 ,4 8 ,6 95% Confidence Interval for Median

Themen bewerten b) Histogramm

C um % 4 0,0 6 2,9 8 0 ,0 9 1 ,4 1 0 0 ,0 -3 -2 -1 -0 1 2 -0,04487 0,1 1 464

4 ,0

B o x pl o t o f S tim m u n g b y Z e it

cd

Themen priorisieren c) Boxplot

3 ,5

3 ,0

Stimmung

2 ,5

eigener Beitrag: 80%

2 ,0

Projekte auswählen 1 ,5

1 ,0

1 2 3

d) Zeitreihen-Diagramm

Z e it

Prozess-Fähigkeit Prozess-Monitoring

Projekt definieren Process Capability Report for Yt1 _Cookie-Weight I-MR Chart of Y_Consumption_per_Day

Summary Report

Prozess-Fähigkeit/-Monitoring

Prozess und Output Yield%/ DPU/ DPMO

Is the process mean stable? Comments

Evaluate the % of out-of-control points.

LSL Target USL The process mean may not be stable. 5 (15,6%) data points are out of control

0% > 5% on the I chart. Keep in mind that you may see 0,7% out-of-control points by

Process Data Overall chance, even when the process is stable.

LSL 18 Within

Target 20 Yes No

USL 22 Overall Capability 15,6%

Sample Mean 20,9507 Z.Bench 0,1 8

Z.LSL 1 ,26

Zbench (Sigma Level) )/ cp/ cpk …

Sample N 60

StDev(Overall) 2,3331 5 Z.USL 0,45

Problem

StDev(Within) 2,04775 Ppk 0,1 5

Cpm 0,26

Potential (Within) Capability Individual and Moving Range Charts

Investigate any out-of-control points.

Z.Bench 0,31

25

Z.LSL 1 ,44 UCL=23,92

Z.USL 0,51

Individual Value

Cpk 0,1 7

I-MR/ xbar-R/ xbar-S/ P-/ U-Chart

10

_

Wirkung

X=5,89

-5

LCL=-12,13

UCL=22,14

20

Moving Range

Lösungs-Ideen (falls vorhanden) als Baseline des Prozesses

10

1 5,0 1 6,5 1 8,0 1 9,5 21 ,0 22,5 24,0 25,5 __

MR=6,78

Performance

Observed Expected Overall Expected Within 0 LCL=0

PPM < LSL 1 00000,00 1 02992,26 74799,56 1 4 7 10 13 16 19 22 25 28 31

PPM > USL 266666,67 326450,62 3041 79,60

PPM Total 366666,67 429442,89 378979,1 5 N: 32 Mean: 5,8947 StDev(within): 6,0087 StDev(overall): 4,0946

Control limits are estimated using the StDev(within).

SIPOC (Supplier-Input-Process-Output-Customer) Unterschied Zusammenhang

Hypothesentests

Input Process Output Prozess in die wichtigen Boxplot of Y_Cookie_Weight Scatterplot of Y_Brightness_of_Cookie vs x_Baking_Time

27,5 22

Unterschieds-Hypothese:

Prozess-Schritte gliedern 25,0

20

Ya =/≠ Yb

Y _Brigh tness_of_Cook ie

18

Y_C ookie_W eight

Inputs und (Zwischen-) Outputs

22,5

16

Zusammenhangs-Hypothese:

20,0

14

Input Process Output zuordnen, ebenso wie 1 7,5 12

1 5,0

10

Y =/≠ f(x)

Lieferanten und Kunden

t_1 t_2 10 12 14 16 18 20

time_of_measurement x_Baking_Time

Voice of Customer & Business

VoC/ VoB > CCR/ CBR > CtQ

Ursache-Wirkungs-Analyse

Kunden/ Manager befragen

Anforderungen an Outputs und

Anforderungen und Abweichungen Basis-Ursachen x´

deren Abweichungen ableiten

der negativen Einflüsse x auf

Abweichungen bewerten und

Schwere der Probleme des Outputs die Probleme Y identifizieren

Schwere der Probleme Y ableiten

Project-Charter Project-Charter Lösungs-Ideen

Improve

Lösungs-Ideen entwickeln, mit

Business-

Problem kritische Probleme Y fokussieren Ursache Problem denen die Basis-Ursachen x´

Relevanz Lösung

Business-Relevanz ableiten (x´) (Y) eliminiert, umgangen oder

Scope/ Experten

Belt-Team Scope und Ziele definieren optimal justiert werden können

Ziele

Management Team zusammenstellen Lösungsideen priorisieren

Input

Input-Analyse

M

notwendige Inputs identifizieren Design of Experiments (DoE)

Anforderungen an Inputs

easure

Anforderungen und Abweichungen

konkretisieren Y= f(x) Parameter der Lösung

negative Einflüsse xi auf optimal justieren

negative Einflüsse auf Probleme

Probleme der Outputs Y ableiten

Prozess-Schritte > Aktivitäten

Prozess-Mapping & -Analyse

Prozess-Schritte in Aktivitäten Maßnahme 8

Maßnahmen-Liste

Input, Output, Methoden & Ressourcen

gliedern Maßnahme 3

Inputs & Outputs, Methoden & Lösungen in konkrete

Ressourcen zuordnen Maßnahme 4 Maßnahmen überführen

negative Einflüsse auf Probleme (Wer?/ Was?/ bis Wann?)

negative Einflüsse xp ableiten

FMEA

Problems (Y)

(Failure Mode and Effects Analysis)

Cause & Effect-Matrix (C&E)

Risk-Analysis Improvement new Risk-Analysis

Probabili ty of

Probabili ty of

the Probl em

the Probl em

Det ection of

Det ection of

Severity of

Severity of

R R

the Effect

the Effect

Y1 Y2 Y3 Yn

FMEA (Failure Mode and Effects Analysis)

Cause

Cause

actual controls to detect the Failures/

potential Failures/ Problems

Problems

potential Effects of the Failures/ Problems potential Causes of the Failure/ Problem P Countermeasures P

N N

Measure-No.

Stärke der negativen Einflüsse

Measure (What has to be done?)

3

10= catast rophic

10= catast rophic

Xi1

Risk-Prior ity-

Risk-Prior ity-

1= always -

1= always -

10= always

10= always

1= never -

1= never -

10= never

10= never

Input

Number

Number

1= no -

1= no -

Rating:

Rating:

Rating:

Rating:

Rating:

Rating:

Which Failures/ Problems can result from the By which existing Controls could the Failure/ How could the trigger of the Failure/ Problem, i.e.

1

Measures? Problem be detected, before it occurs? What is the Effect of the Failure/ Problem? Which Influence triggers the Failure/ Problem? their Root-Causes be eliminated

(Xi) Xi2 ...? ...? ...? ...? ...? ...?

4 der Inputs xi und Aktivitäten im 1.

Let the Chef weigh 10 g of chocolate for her

special Chocolate Check

can cause caries periodic dental prophylaxis 5 tooth loss 7 sugar/ bacterial plaque 10 350

immediate brushing of teeth after check of

chocolate

7 2 5 70

Xin

Risiken der Maßnahmen

...? ...? ...? ...? ...? ...?

...? ...? ...? ...? ...? ...?

Process-Steps

Xp1 2 Prozess xp auf die Probleme des ...?

...?

...?

...?

...?

...?

...?

...?

...?

...?

...?

...?

Xp2 5 ...? ...? ...? ...? ...? ...?

minimieren

(Xp)

Xpn 7

Outputs Y bewerten ...?

...?

...?

...?

...?

...?

...?

...?

...?

...?

...?

...?

...?

...?

...?

...?

...?

...?

Operationalisation Graphical Display

Problems

Y1 Daten-Erhebungs-Plan umsetzen Umsetzung

Y2

(Y)

Yn Einflüsse x und Probleme Y als qualifizieren Entscheide über Maßnahmen

informieren

Input

(Xi)

Xi1

Xi2 Messgrößen operationalisieren & motivieren informieren & motivieren

Process-

Xin

Xp1

Bedingungen und Prozedur der entscheiden qualifizieren (wenn notwendig)

Steps

(Xp)

Xp2

Xpn

Messung konkretisieren setze Maßnahmen um

Hypothesen Prozess-Fähigkeit Prozess-Monitoring

Prozess-Fähigkeit/-Monitoring

Risiko: 14%

Co

Es gibt (k)einen Unterschied

automatisch erzeugt mit:

Process Capability Report for Yt1 _Cookie-Weight I-MR Chart of Y_Consumption_per_Day

Summary Report

Yield%/ DPU/ DPMO

Is the process mean stable? Comments

in: Ausmaß von (Y) …

Evaluate the % of out-of-control points.

LSL Target USL The process mean may not be stable. 5 (15,6%) data points are out of control

0% > 5% on the I chart. Keep in mind that you may see 0,7% out-of-control points by

Process Data Overall chance, even when the process is stable.

LSL 18 Within

Target 20 Yes No

USL 22 Overall Capability

- Typ der Hypothese

15,6%

Sample Mean 20,9507 Z.Bench 0,1 8

Z.LSL 1 ,26

zwischen: Stufen von (x) Zbench (Sigma Level) )/ cp/ cpk …

Sample N 60

StDev(Overall) 2,3331 5 Z.USL 0,45

ntrol

StDev(Within) 2,04775 Ppk 0,1 5

Cpm 0,26

Potential (Within) Capability Individual and Moving Range Charts

Investigate any out-of-control points.

Z.Bench 0,31

25

Z.LSL 1 ,44 UCL=23,92

(Unterschied/ Zusammenhang) Z.USL 0,51

Individual Value

Cpk 0,1 7

I-MR/ xbar-R/ xbar-S/ P-/ U-Chart

10

_

X=5,89

-5

- Relevanz der Hypothese (Risiko) 20

LCL=-12,13

UCL=22,14

Moving Range

Test: ANOVA zur verbesserten Prozess-Leistung

10

1 5,0 1 6,5 1 8,0 1 9,5 21 ,0 22,5 24,0 25,5 __

MR=6,78

- angemessener statistischer Test

Performance

Observed Expected Overall Expected Within 0 LCL=0

PPM < LSL 1 00000,00 1 02992,26 74799,56 1 4 7 10 13 16 19 22 25 28 31

PPM > USL 266666,67 326450,62 3041 79,60

PPM Total 366666,67 429442,89 378979,1 5 N: 32 Mean: 5,8947 StDev(within): 6,0087 StDev(overall): 4,0946

Control limits are estimated using the StDev(within).

Unterschied Zusammenhang

Mess-System-Analyse Boxplot of Y_Cookie_Weight Scatterplot of Y_Brightness_of_Cookie vs x_Baking_Time

Hypothesentests

Wiederholbarkeit und Reprodu- 27,5

25,0

22

20

Unterschieds-Hypothese:

zierbarkeit, Stabilität & Linearität Ya =/≠ Yb

Y_Brightn ess_of_C ookie

18

Y_C ookie_W eight

22,5

16

Zusammenhangs-Hypothese:

20,0

des Mess-Systems prüfen 1 7,5

14

12

Gage R&R 1 5,0

t_1

time_of_measurement

t_2

10

10 12 14

x_Baking_Time

16 18 20 Y =/≠ f(x)

12 011011102200801 Plan für das

Storyboard zum

Daten erheben Prozess-Monitoring

und Notfall-

Projekt abschließen

Definiere Standards

für den neuen Projekt abschließen

110114051978101 Maßnahmen

und Ergebnisse

Prozess

erstellen

präsentieren

Storyboard abschließen

9 3 101501195801001

vorhandene Daten abrufen Beginne mit dem

Kontinuierlichen

Setze die Setze die Prozess-Management-Plan

010100101010101 Verbesserungs-

Überprüfung der

Zielerreichung fort

Überprüfung der

Prozessfähigkeit fort

aktuelle Daten messen Prozess (KVP)

übergeben

001110100110011

6

Management (Sponsor, Accountable) / Rolle: überwachen, entscheiden, unterstützen sigmaGuide©

Projekt Team: Belt (Black-Belt/ Green-Belt) / Rolle: Projekt leiten Tools: Copyright: reiner.hutwelker@softLogik.de

Experten / Rolle: Projekt unterstützen Minitab©

You might also like

- Pianoforte Puccini Turandot Nessun Dorma GCDocument2 pagesPianoforte Puccini Turandot Nessun Dorma GCRobertoNo ratings yet

- Instant Assessments for Data Tracking, Grade 1: MathFrom EverandInstant Assessments for Data Tracking, Grade 1: MathRating: 4 out of 5 stars4/5 (1)

- Instant Assessments for Data Tracking, Grade 5: Language ArtsFrom EverandInstant Assessments for Data Tracking, Grade 5: Language ArtsNo ratings yet

- Nothing Else Matters: Metalica arr.M.Thorkildsen 50Document3 pagesNothing Else Matters: Metalica arr.M.Thorkildsen 50Raquel Kaffee100% (1)

- Study Guide and How To Crack Exam On Asq Certified Quality Engineer (Cqe)Document5 pagesStudy Guide and How To Crack Exam On Asq Certified Quality Engineer (Cqe)Arun KangeyanNo ratings yet

- All You Need Is Love-PianoDocument3 pagesAll You Need Is Love-PianoCristina Serra De TorresNo ratings yet

- Amazing Grace - String Quartet-VioloncelloDocument1 pageAmazing Grace - String Quartet-VioloncelloBernardo LourençoNo ratings yet

- Statistics in ValidationDocument71 pagesStatistics in ValidationPhani KrishnaNo ratings yet

- Julia Ben VersionDocument3 pagesJulia Ben VersionNico E MartinezNo ratings yet

- Half Girlfriend Free PDFDocument5 pagesHalf Girlfriend Free PDFRANE SWAPNEEL73% (59)

- The Butterfly Lovers - Adapted by Richard ClaydermanDocument4 pagesThe Butterfly Lovers - Adapted by Richard ClaydermanjmcyangNo ratings yet

- Balanced ScorecardDocument15 pagesBalanced ScorecardVVNAGESWAR100% (2)

- ChatGPT As An Academic Support Tool On The AcademiDocument13 pagesChatGPT As An Academic Support Tool On The Academijovanejapalali2005No ratings yet

- Projeto Estrutural Academia Layout1.PDF 9 10Document1 pageProjeto Estrutural Academia Layout1.PDF 9 10João PauloNo ratings yet

- asset-v1-TUMx QPLS1x 2T2018 Type@asset block@SixSigma - Project-GuidelineDocument2 pagesasset-v1-TUMx QPLS1x 2T2018 Type@asset block@SixSigma - Project-Guidelineravapu345No ratings yet

- Outils - 6 Sigma Project GuidelineDocument1 pageOutils - 6 Sigma Project GuidelineCar YamooNo ratings yet

- Staaloverzicht TWDocument1 pageStaaloverzicht TWCristi CapetisNo ratings yet

- 感謝妳 趙傳Document2 pages感謝妳 趙傳rachealNo ratings yet

- Power Supply CEF286ADocument3 pagesPower Supply CEF286AElextro AlanNo ratings yet

- Rivers Flow in You-PianoDocument3 pagesRivers Flow in You-PianoYurena Darias SánchezNo ratings yet

- 0320289-TE-DAD-6410-006-00 SEPARATOR 10HHA30AT001-ModelDocument1 page0320289-TE-DAD-6410-006-00 SEPARATOR 10HHA30AT001-ModelVivek VinayakumarNo ratings yet

- X0231 PDW Eut DG 20007 AaDocument1 pageX0231 PDW Eut DG 20007 AajianranrenNo ratings yet

- S. Cileungsi: Rencana Teknis BendungDocument1 pageS. Cileungsi: Rencana Teknis BendungTirta SigmaNo ratings yet

- TaifDocument1 pageTaifsalemNo ratings yet

- True North Project North: BOD BOD BOD BOD SHDocument8 pagesTrue North Project North: BOD BOD BOD BOD SHEbin NakarmiNo ratings yet

- CA LLE ILO: Rtivo ESDocument1 pageCA LLE ILO: Rtivo ESdoctor psiquiatraNo ratings yet

- Rice Field - Jay Chou Piano SheetDocument4 pagesRice Field - Jay Chou Piano SheetAnhNo ratings yet

- Sparkle (B) : RadwimpsDocument2 pagesSparkle (B) : RadwimpsLuis TrilloNo ratings yet

- Si Me Dejas No Vale - Clarinet in EbDocument2 pagesSi Me Dejas No Vale - Clarinet in EbJorge Luis Guevara MoraNo ratings yet

- Plano Bquilla-SoledadDocument1 pagePlano Bquilla-SoledadzexnicNo ratings yet

- Miscelnea Legio Urbana TubaDocument3 pagesMiscelnea Legio Urbana Tubaacpnog0110No ratings yet

- Uno Emn Mil QuinientosDocument1 pageUno Emn Mil QuinientosPercy HNNo ratings yet

- Ofr97470a Sheet1 PlotterDocument1 pageOfr97470a Sheet1 PlotterHəʌɽtləss ʌlcoholıc Ethph LaverNo ratings yet

- AdagioDocument2 pagesAdagioDeyan DenchevNo ratings yet

- 535 (Fá) - Tu És Fiel, SenhorDocument1 page535 (Fá) - Tu És Fiel, SenhorSérgioNo ratings yet

- Dancing in The Moonlight - Saxophone Quartet-Alto SaxophoneDocument2 pagesDancing in The Moonlight - Saxophone Quartet-Alto SaxophoneJoão SalcedasNo ratings yet

- Data Extraction and Multileaders Sample-Layout2Document1 pageData Extraction and Multileaders Sample-Layout2Sunem Rios YañacNo ratings yet

- 18 606000 1100001344 Asb Civ SHD 115069 - 01Document4 pages18 606000 1100001344 Asb Civ SHD 115069 - 01Mahmudul Alam kanakNo ratings yet

- CANTEN SEÑORES - Re-si-PianoDocument2 pagesCANTEN SEÑORES - Re-si-PianoAlbin.NelsonNo ratings yet

- Hours in C MajorDocument4 pagesHours in C MajorweweNo ratings yet

- Puccini - Turandot - Nessun DormaDocument2 pagesPuccini - Turandot - Nessun DormaGiosafatteLombardiNo ratings yet

- Marcha Nupcial WagnerDocument2 pagesMarcha Nupcial WagnerVictoria AcostaNo ratings yet

- Taif السطحDocument1 pageTaif السطحsalemNo ratings yet

- Me Gusta - AnittaDocument5 pagesMe Gusta - Anittale.tucheNo ratings yet

- 426-5051-00 - Turck Breakout & BoxRemote ModuleDocument6 pages426-5051-00 - Turck Breakout & BoxRemote ModulejNo ratings yet

- LooooooooooooooouiDocument1 pageLooooooooooooooouirim deNo ratings yet

- MX-140 Electric SystemDocument16 pagesMX-140 Electric SystemDedi Sii JendralNo ratings yet

- Sunnyside Solo GuitarDocument2 pagesSunnyside Solo GuitarAlexander KorkkaNo ratings yet

- Gambar 2222Document1 pageGambar 2222Bagas HilmiNo ratings yet

- TMX5BP Electrical SchematicsDocument16 pagesTMX5BP Electrical SchematicsSergioNo ratings yet

- Oriental: Enrique Granados 104Document3 pagesOriental: Enrique Granados 104pedrotmartinezNo ratings yet

- Omori (Duet) - Easy VersionDocument2 pagesOmori (Duet) - Easy VersionHesty F. P.No ratings yet

- 18-606000-1100001344-Asb-Civ-Shd-115152 - 01 - 1Document1 page18-606000-1100001344-Asb-Civ-Shd-115152 - 01 - 1Mahmudul Alam kanakNo ratings yet

- 18 606000 1100001344 Asb Civ SHD 115152 - 01Document2 pages18 606000 1100001344 Asb Civ SHD 115152 - 01Mahmudul Alam kanakNo ratings yet

- Abs Altis 2549Document1 pageAbs Altis 2549สนั่น วิริยะเจริญกุลNo ratings yet

- A Winter Story RemediosDocument3 pagesA Winter Story RemediosMaxim KoreshevNo ratings yet

- SP0793-6186-15-0020 - PVDC EXPANSION PROJECT LIME STONE MILLING BALL OFFLOADING CONCRETE LAYOUT AND DETAILS Rev.1Document1 pageSP0793-6186-15-0020 - PVDC EXPANSION PROJECT LIME STONE MILLING BALL OFFLOADING CONCRETE LAYOUT AND DETAILS Rev.1Hector HernandezNo ratings yet

- SWR UpdatedDocument1 pageSWR Updatedram prasad meenaNo ratings yet

- To Lalganj: Typical Section at Abut Pier A1Document1 pageTo Lalganj: Typical Section at Abut Pier A1bijendraNo ratings yet

- Pos. Descripción / DescriptionDocument4 pagesPos. Descripción / DescriptionomarNo ratings yet

- alliWantforChristmasisyou SaxaltoaDocument1 pagealliWantforChristmasisyou Saxaltoabergerault LamarNo ratings yet

- 1 6 Out of The GravityDocument7 pages1 6 Out of The GravityTaufik HidayatNo ratings yet

- The Great Gate of Kiev and Hopak-Violonchelo - 1Document2 pagesThe Great Gate of Kiev and Hopak-Violonchelo - 1David RomanovskyNo ratings yet

- Module 4 Week 2, Logistic Regression, ANA 500Document11 pagesModule 4 Week 2, Logistic Regression, ANA 500Arun KangeyanNo ratings yet

- In Supplier Quality Management: Best PracticesDocument6 pagesIn Supplier Quality Management: Best PracticesArun KangeyanNo ratings yet

- Saint Gba334 Unit 1 Quiz (25 Questions) All CorrectDocument5 pagesSaint Gba334 Unit 1 Quiz (25 Questions) All Correctteacher.theacestudNo ratings yet

- Effect of Training, Work Discipline, and Leadership League To Employees Performance at Pt. Sinarmas Rendranusa PekanbaruDocument14 pagesEffect of Training, Work Discipline, and Leadership League To Employees Performance at Pt. Sinarmas Rendranusa PekanbaruLanggengNo ratings yet

- NP000396 Aq010 3 1 MCFC 1Document5 pagesNP000396 Aq010 3 1 MCFC 1Janam PandeyNo ratings yet

- Agricultural Tourism For Sustainable Rural DevelopmentDocument7 pagesAgricultural Tourism For Sustainable Rural DevelopmentSilene VenessaNo ratings yet

- Dsur I Chapter 15 Nonparametric StatsDocument44 pagesDsur I Chapter 15 Nonparametric StatsDannyNo ratings yet

- Econometrics LecturesDocument240 pagesEconometrics LecturesDevin-KonulRichmondNo ratings yet

- 11.1 Uncertainties and Errors in Measurement and ResultsDocument4 pages11.1 Uncertainties and Errors in Measurement and Results灭霸No ratings yet

- Project: ©great Learning. Proprietary Content. All Rights Reserved. Unauthorised Use or Distribution ProhibitedDocument8 pagesProject: ©great Learning. Proprietary Content. All Rights Reserved. Unauthorised Use or Distribution ProhibitedPramod R BidveNo ratings yet

- Chapter 14 - Nonparametric TestsDocument10 pagesChapter 14 - Nonparametric TestsHoa Vu PhuongNo ratings yet

- A Project Report On Buiding ConstructionDocument31 pagesA Project Report On Buiding Constructionmanny ansariNo ratings yet

- Mat 152 Course Syllabus - Fa2019Document4 pagesMat 152 Course Syllabus - Fa2019api-488084761No ratings yet

- Compiled NotesDocument12 pagesCompiled Notescreacion impresionesNo ratings yet

- Mathematics Research Paper - Binomial Distribution With The Galton BoardDocument13 pagesMathematics Research Paper - Binomial Distribution With The Galton BoardNidhiNo ratings yet

- Quantitative Research Group 5 Chapter 1 5Document65 pagesQuantitative Research Group 5 Chapter 1 5Cedrex VillegasNo ratings yet

- 2014-3-MEL-GB Section A (45 Marks)Document3 pages2014-3-MEL-GB Section A (45 Marks)tingkiongNo ratings yet

- Ee 769 Assignment 1 PDFDocument11 pagesEe 769 Assignment 1 PDFSachin BisenNo ratings yet

- CoTM Thesis - Engida EjiguDocument125 pagesCoTM Thesis - Engida EjiguAddis GetahunNo ratings yet

- MCA Using Stata PDFDocument22 pagesMCA Using Stata PDFAbdoulkarimNo ratings yet

- Estimation and HypothesisDocument32 pagesEstimation and HypothesisAtul KashyapNo ratings yet

- ChebyshevDocument3 pagesChebyshevMajid Khammas NeamahNo ratings yet

- El-BAHITH REVIEW Number 08 - University of Ouargla AlgeriaDocument258 pagesEl-BAHITH REVIEW Number 08 - University of Ouargla Algeriarcogx2013No ratings yet

- UKTAG Phosphorus Standards For Rivers - Final 130906 - 0Document13 pagesUKTAG Phosphorus Standards For Rivers - Final 130906 - 0Jeremy DudleyNo ratings yet

- SeminarDocument34 pagesSeminarsreya.sreejith2211No ratings yet

- BASIC GUIDELINES FOR RESEARCH: An Introductory Approach For All DisciplinesDocument14 pagesBASIC GUIDELINES FOR RESEARCH: An Introductory Approach For All DisciplinesGRACIELA GUERRERO IDROVO100% (1)

- Interpreting The Data: Inquiries, Investigation and Immersion Week 3 and 4/ Finals Grade 11 ReadingsDocument4 pagesInterpreting The Data: Inquiries, Investigation and Immersion Week 3 and 4/ Finals Grade 11 ReadingsVANESSA JABAGATNo ratings yet

- Source Free Domain Adaptation With Image Translation: Preprint. Under ReviewDocument11 pagesSource Free Domain Adaptation With Image Translation: Preprint. Under Reviewaleposada7No ratings yet

- Decision TreeDocument57 pagesDecision TreeArjun KhoslaNo ratings yet