Professional Documents

Culture Documents

Heat Fusion Joining of Polyolefin Pipe and Fittings: Standard Practice For

Uploaded by

Arnold Ochochoque ArcosOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Heat Fusion Joining of Polyolefin Pipe and Fittings: Standard Practice For

Uploaded by

Arnold Ochochoque ArcosCopyright:

Available Formats

An American National Standard

Designation: D 2657 – 07

Standard Practice for

Heat Fusion Joining of Polyolefin Pipe and Fittings1

This standard is issued under the fixed designation D 2657; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

m

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

co

1. Scope 2. Referenced Documents

1.1 This practice describes general procedures for making 2.1 ASTM Standards: 2

.

joints with polyolefin pipe and fittings (excluding polyethylene F 1056 Specification for Socket Fusion Tools for Use in

sh

pipe and fittings) by means of heat fusion joining techniques in Socket Fusion Joining Polyethylene Pipe or Tubing and

either a shop or field environment. These procedures are Fittings

general ones. Specific instructions for heat fusion joining are F 2620 Practice for Heat Fusion Joining of Polyethylene

ki

obtained from product manufacturers. See Practice F 2620 for Pipe and Fittings

heat fusion joining of polyethylene pipe and fittings.

1.2 The techniques covered are applicable only to joining 3. Summary of Practice

polyolefin pipe and fittings of related polymer chemistry, for

example, polypropylenes to polypropylenes, or polybutylenes

e-

3.1 Heat-fusion joining uses a combination of heat and force

resulting in two melted surfaces flowing together to produce a

en

to polybutylenes. Material, density, and flow rate shall be taken joint. Fusion bonding occurs when the joint cools below the

into consideration in order to develop uniform melt viscosities melt temperature of the material. There is a temperature range

and formation of a good fusion bond when joining the same within which any particular material is satisfactorily joined.

material to itself or to other materials of related polymer The specific temperature used requires consideration of the

yl

chemistry. properties of the specific material, and the joining environment.

1.3 Parts that are within the dimensional tolerances given in With Techniques II or III (3.3.2 or 3.3.3), there is also an

th

present ASTM specifications are required to produce sound appropriate force to be applied which depends upon the

joints between polyolefin pipe and fittings when using the material, the fusion equipment being used, and fusion tempera-

joining techniques described in this practice. ture. See Practice F 2620 for heat fusion procedure for poly-

se

1.4 The values stated in inch-pound units are to be regarded ethylene pipe and fittings.

as the standard. The values given in parentheses are for 3.1.1 Electrically powered heat fusion tools and equipment

information only. are usually not explosion proof. When performing heat fusion

ar

1.5 The text of this practice references notes, footnotes, and in a potentially combustible atmosphere such as in an excava-

appendixes which provide explanatory material. These notes tion where gas is present, all electrically powered tools and

and footnotes (excluding those in tables and figures) shall not equipment that will be used in the combustible atmosphere

.p

be considered as requirements of the practice. shall be disconnected from the electrical power source and

1.6 This standard does not purport to address all of the operated manually to prevent explosion and fire. For the

w

safety concerns, if any, associated with its use. It is the heating tool, this requires bringing the heating tool up to or

responsibility of the user of this standard to establish appro- slightly above temperature in a safe area, then disconnecting it

priate safety and health practices and determine the applica- from electrical power immediately before use. This procedure

w

bility of regulatory limitations prior to use. See specific safety is limited to smaller sizes where heating is accomplished

precautions in 3.1.1, 5.2, 8.2.3.1, Note 8 and Note 9, and A1.1. before the heating tool drops below acceptable temperature.

w

1 2

This practice is under the jurisdiction of ASTM Committee F17 on Plastic For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Piping Systems and is the direct responsibility of Subcommittee F17.20 on Joining. contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Current edition approved May 1, 2007. Published May 2007. Originally Standards volume information, refer to the standard’s Document Summary page on

approved in 1967. Last previous edition approved in 2003 as D 2657 – 03. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

--`,,```,,,,````-`-`,,`,,`,`,,`---

You might also like

- Astm D2657Document7 pagesAstm D2657Romeo Ramos MéndezNo ratings yet

- Heat Fusion Joining of Polyolefin Pipe and Fittings: Standard Practice ForDocument7 pagesHeat Fusion Joining of Polyolefin Pipe and Fittings: Standard Practice ForSergio TapiaNo ratings yet

- Astm D2657 07 2023Document5 pagesAstm D2657 07 2023luisNo ratings yet

- D 2657 - 03 Rdi2ntcDocument7 pagesD 2657 - 03 Rdi2ntcHumberto GutierrezNo ratings yet

- Astm F 1290Document3 pagesAstm F 1290محمود أبو الحسنNo ratings yet

- Astm D 2657 - 97Document9 pagesAstm D 2657 - 97Walther LaricoNo ratings yet

- Astm F2620-13 PDFDocument25 pagesAstm F2620-13 PDFAdamDunn0372566No ratings yet

- ASTM D2657 - 07 Heat Fusion Joning HDPEDocument7 pagesASTM D2657 - 07 Heat Fusion Joning HDPEMarlon TurnerNo ratings yet

- ASTM F1290.11564 Electro FusionDocument3 pagesASTM F1290.11564 Electro Fusionjoe jackNo ratings yet

- Astm F2620-13 PDFDocument25 pagesAstm F2620-13 PDFJORGENo ratings yet

- Astm F2620-13Document25 pagesAstm F2620-13Najib100% (3)

- Astm D2657 - 07Document7 pagesAstm D2657 - 07dsalguero_2100% (2)

- F2620 PDFDocument19 pagesF2620 PDFAhmad Zubair RasulyNo ratings yet

- f2620 - Standar Practce For Heat Fusion Joining of Polyethylene PipeDocument21 pagesf2620 - Standar Practce For Heat Fusion Joining of Polyethylene PipeDeyvi Vasquez PittmanNo ratings yet

- Heat Fusion Joining of Polyethylene Pipe and Fittings: Standard Practice ForDocument19 pagesHeat Fusion Joining of Polyethylene Pipe and Fittings: Standard Practice FordnavarroNo ratings yet

- Design and Installation of Underground Thermoplastic Irrigation Systems With Maximum Working Pressure of 125 PsiDocument8 pagesDesign and Installation of Underground Thermoplastic Irrigation Systems With Maximum Working Pressure of 125 PsidgkmurtiNo ratings yet

- Astm F2620-11Document21 pagesAstm F2620-11Gianfranco Niquín100% (3)

- Astm F2620Document22 pagesAstm F2620Ricardo Peralta100% (1)

- F1056-04 (Reapproved 2011)Document4 pagesF1056-04 (Reapproved 2011)Deepak AryaNo ratings yet

- Adhesive Bonding of Aluminum Facings in Foam and Beam Type SheltersDocument4 pagesAdhesive Bonding of Aluminum Facings in Foam and Beam Type SheltersEric GozzerNo ratings yet

- Astm F2620 20Document11 pagesAstm F2620 20CarolinaNo ratings yet

- Astm F3190-16 PDFDocument6 pagesAstm F3190-16 PDFdiego andres100% (1)

- Astm D3895 19Document3 pagesAstm D3895 19Samer MohamedNo ratings yet

- Electrofusion Type Polyethylene Fittings For Outside Diameter Controlled Polyethylene Pipe and TubingDocument8 pagesElectrofusion Type Polyethylene Fittings For Outside Diameter Controlled Polyethylene Pipe and TubingSergio TapiaNo ratings yet

- Astm e 136Document10 pagesAstm e 136Zahoor Ahmed MohsanNo ratings yet

- F 1055 - 98 RjewntutotgDocument9 pagesF 1055 - 98 RjewntutotgMMNo ratings yet

- Astm F2620Document25 pagesAstm F2620Romeo Ramos MéndezNo ratings yet

- E 1794 - 13Document3 pagesE 1794 - 13Eric GozzerNo ratings yet

- F 2620 Fig. 3: 4. Significance and UseDocument1 pageF 2620 Fig. 3: 4. Significance and UseArnold Ochochoque ArcosNo ratings yet

- Astm d1857 (m) -2010 Aft 灰熔融Document5 pagesAstm d1857 (m) -2010 Aft 灰熔融Winnjone YinNo ratings yet

- Determining The Short Term Tensile Weld Strength of Chemical-Resistant ThermoplasticsDocument4 pagesDetermining The Short Term Tensile Weld Strength of Chemical-Resistant ThermoplasticsKristian EspinozaNo ratings yet

- Heat Treatment of Magnesium Alloys: Standard Practice ForDocument7 pagesHeat Treatment of Magnesium Alloys: Standard Practice ForJordanNo ratings yet

- Determining The Short Term Tensile Weld Strength of Chemical-Resistant ThermoplasticsDocument4 pagesDetermining The Short Term Tensile Weld Strength of Chemical-Resistant ThermoplasticsFernando Da RosNo ratings yet

- Astm D 5207Document4 pagesAstm D 5207Boris AguilarNo ratings yet

- F2600 PDFDocument10 pagesF2600 PDFAhmad Zubair RasulyNo ratings yet

- AstmDocument3 pagesAstmMuhammad NaumanNo ratings yet

- D 3012 - 04 - Rdmwmti - PDFDocument6 pagesD 3012 - 04 - Rdmwmti - PDFsusanaNo ratings yet

- Astm C1397-13Document9 pagesAstm C1397-13Boz Van DuynNo ratings yet

- E 3134 - 17Document12 pagesE 3134 - 17Jacky LeongNo ratings yet

- Astm e 648 Rev A 2006 PDFDocument14 pagesAstm e 648 Rev A 2006 PDFJORGE ARTURO TORIBIO HUERTANo ratings yet

- ASTM C547 - 11e1 (Jan. 2012)Document7 pagesASTM C547 - 11e1 (Jan. 2012)Melih SENTURKNo ratings yet

- Socket Fusion Tools For Use in Socket Fusion Joining Polyethylene Pipe or Tubing and FittingsDocument4 pagesSocket Fusion Tools For Use in Socket Fusion Joining Polyethylene Pipe or Tubing and FittingsakhmadmarufnurNo ratings yet

- Application of Class PB Exterior Insulation and Finish SystemsDocument8 pagesApplication of Class PB Exterior Insulation and Finish SystemsTarek FennicheNo ratings yet

- D3574 11 PDFDocument149 pagesD3574 11 PDFAkash YadavNo ratings yet

- Astm F2620 2019 PDFDocument25 pagesAstm F2620 2019 PDFNassim Ben AbdeddayemNo ratings yet

- Behavior of Materials in A Vertical Tube Furnace at 750°C: Standard Test Method ForDocument10 pagesBehavior of Materials in A Vertical Tube Furnace at 750°C: Standard Test Method ForPYDNo ratings yet

- Selecting Temperatures For Evaluating and Reporting Thermal Properties of Thermal InsulationDocument3 pagesSelecting Temperatures For Evaluating and Reporting Thermal Properties of Thermal InsulationAsmaa RamadanNo ratings yet

- E 1800 - 00 Rte4mdatmdaDocument3 pagesE 1800 - 00 Rte4mdatmdaHoward Gallegos MontenegroNo ratings yet

- E582-07 (2013) E1 Standard Test Method For MinimumDocument6 pagesE582-07 (2013) E1 Standard Test Method For Minimumouari.ouariNo ratings yet

- Installation of Gypsum Products in Concealed Radiant Ceiling Heating SystemsDocument2 pagesInstallation of Gypsum Products in Concealed Radiant Ceiling Heating SystemsINARQ1979No ratings yet

- Astm E1529Document15 pagesAstm E1529archwilfredNo ratings yet

- Astm C656Document3 pagesAstm C656alokjha_03No ratings yet

- ASTM D618 08 Conditioning Plastics For Testing PDFDocument4 pagesASTM D618 08 Conditioning Plastics For Testing PDFmtnguyennsNo ratings yet

- Fusibility of Coal and Coke Ash: Standard Test Method ForDocument5 pagesFusibility of Coal and Coke Ash: Standard Test Method Forravi kumarNo ratings yet

- Thermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesFrom EverandThermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesRating: 3.5 out of 5 stars3.5/5 (3)

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsFrom Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsRating: 4 out of 5 stars4/5 (1)

- Case Studies of Material Corrosion Prevention for Oil and Gas ValvesFrom EverandCase Studies of Material Corrosion Prevention for Oil and Gas ValvesNo ratings yet

- The IEE Wiring Regulations Explained and IllustratedFrom EverandThe IEE Wiring Regulations Explained and IllustratedRating: 4 out of 5 stars4/5 (14)

- Section 2: Schedule 80 CPVC Piping System Serviced by GF Little RockDocument28 pagesSection 2: Schedule 80 CPVC Piping System Serviced by GF Little RockArnold Ochochoque ArcosNo ratings yet

- Tal-Ox-Png-Iso-1zs001401 - 3-Zs-Ox-20312-A3c1f-NDocument1 pageTal-Ox-Png-Iso-1zs001401 - 3-Zs-Ox-20312-A3c1f-NArnold Ochochoque ArcosNo ratings yet

- Section 2: Schedule 80 CPVC Piping System Serviced by GF Little RockDocument28 pagesSection 2: Schedule 80 CPVC Piping System Serviced by GF Little RockArnold Ochochoque ArcosNo ratings yet

- Procedure 1-Socket FusionDocument1 pageProcedure 1-Socket FusionArnold Ochochoque ArcosNo ratings yet

- FIG. 2 Typical Butt Fusion OperationDocument1 pageFIG. 2 Typical Butt Fusion OperationArnold Ochochoque ArcosNo ratings yet

- FIG. 4 Bent Strap Test SpecimenDocument1 pageFIG. 4 Bent Strap Test SpecimenArnold Ochochoque ArcosNo ratings yet

- SJGXNVDocument1 pageSJGXNVArnold Ochochoque ArcosNo ratings yet

- Slurry Transport Using Centrifugal Pumps (1) - 006 PDFDocument1 pageSlurry Transport Using Centrifugal Pumps (1) - 006 PDFArnold Ochochoque ArcosNo ratings yet

- Slurry Transport Using Centrifugal Pumps (1) - 004 PDFDocument1 pageSlurry Transport Using Centrifugal Pumps (1) - 004 PDFArnold Ochochoque ArcosNo ratings yet

- F 2620 Fig. 3: 4. Significance and UseDocument1 pageF 2620 Fig. 3: 4. Significance and UseArnold Ochochoque ArcosNo ratings yet

- Slurry Transport Using Centrifugal Pumps: Third EditionDocument1 pageSlurry Transport Using Centrifugal Pumps: Third EditionArnold Ochochoque ArcosNo ratings yet

- Slurry TDocument1 pageSlurry TArnold Ochochoque ArcosNo ratings yet

- Slurry Transport Using Centrifugal Pumps (1) - 004 PDFDocument1 pageSlurry Transport Using Centrifugal Pumps (1) - 004 PDFArnold Ochochoque ArcosNo ratings yet

- Impulse 4.0 Users Guide SI PDFDocument554 pagesImpulse 4.0 Users Guide SI PDFalberto fuentealbaNo ratings yet

- Slurry Transport Using Centrifugal Pumps (1) - 005 PDFDocument1 pageSlurry Transport Using Centrifugal Pumps (1) - 005 PDFArnold Ochochoque ArcosNo ratings yet

- Slurry Transport Using Centrifugal Pumps (1) - 004 PDFDocument1 pageSlurry Transport Using Centrifugal Pumps (1) - 004 PDFArnold Ochochoque ArcosNo ratings yet

- Slurry Transport Using Centrifugal Pumps: Third EditionDocument1 pageSlurry Transport Using Centrifugal Pumps: Third EditionArnold Ochochoque Arcos0% (1)

- Slurry Transport Using Centrifugal Pumps (1) - 005 PDFDocument1 pageSlurry Transport Using Centrifugal Pumps (1) - 005 PDFArnold Ochochoque ArcosNo ratings yet

- Slurry Transport Using Centrifugal Pumps: Third EditionDocument1 pageSlurry Transport Using Centrifugal Pumps: Third EditionArnold Ochochoque ArcosNo ratings yet

- Slurry Transport Using Centrifugal Pumps (1) - 003 PDFDocument1 pageSlurry Transport Using Centrifugal Pumps (1) - 003 PDFArnold Ochochoque ArcosNo ratings yet

- Slurry Transport Using Centrifugal Pumps (1) - 006 PDFDocument1 pageSlurry Transport Using Centrifugal Pumps (1) - 006 PDFArnold Ochochoque ArcosNo ratings yet

- Slurry Transport Using Centrifugal Pumps (1) - 007 PDFDocument1 pageSlurry Transport Using Centrifugal Pumps (1) - 007 PDFArnold Ochochoque Arcos0% (1)

- Slurry Transport Using Centrifugal Pumps (1) - 002Document1 pageSlurry Transport Using Centrifugal Pumps (1) - 002Arnold Ochochoque ArcosNo ratings yet

- Slurry Transport Using Centrifugal Pumps (1) - 040Document1 pageSlurry Transport Using Centrifugal Pumps (1) - 040Arnold Ochochoque ArcosNo ratings yet

- Astm D2657-2007Document7 pagesAstm D2657-2007Arnold Ochochoque ArcosNo ratings yet

- Slurry TDocument1 pageSlurry TArnold Ochochoque ArcosNo ratings yet

- Slurry Transport Using Centrifugal Pumps (1) - 021Document1 pageSlurry Transport Using Centrifugal Pumps (1) - 021Arnold Ochochoque ArcosNo ratings yet

- Slurry Transport Using Centrifugal Pumps (1) - 003Document1 pageSlurry Transport Using Centrifugal Pumps (1) - 003Arnold Ochochoque ArcosNo ratings yet

- Guia de Autoevaluacion AmbientalDocument6 pagesGuia de Autoevaluacion AmbientalSergio LorenzoNo ratings yet

- MDS Report Substances of Assemblies and Materials: 1. Company and Product NameDocument3 pagesMDS Report Substances of Assemblies and Materials: 1. Company and Product NameMohamed HarisNo ratings yet

- H.T BRAUTEK LITHIUM EP SeriesDocument2 pagesH.T BRAUTEK LITHIUM EP SeriesALFREDO CANTOS CORNEJONo ratings yet

- Costamix-200m 20201Document2 pagesCostamix-200m 20201Moyinoluwa Bukola EbitighaNo ratings yet

- Potential and Electric Field Distribution Associated With HVDC Insulators Under Different Pollution ConditionsDocument121 pagesPotential and Electric Field Distribution Associated With HVDC Insulators Under Different Pollution ConditionsFaridah HassanNo ratings yet

- Irc 121 2017Document37 pagesIrc 121 2017Anil SuryawanshiNo ratings yet

- Little Panda: Crochet Toy PatternDocument16 pagesLittle Panda: Crochet Toy PatternMonica Guarnieri100% (1)

- Bombas Bredel en 13Document11 pagesBombas Bredel en 13Felipe MelgarejoNo ratings yet

- Untitled Diagram CepsaDocument2 pagesUntitled Diagram CepsaJon HermozaNo ratings yet

- What Is Tungsten DisulfideDocument3 pagesWhat Is Tungsten DisulfidePrathyusha RamadurgamNo ratings yet

- Impact of Cotton Parameters On Yarn QualityDocument4 pagesImpact of Cotton Parameters On Yarn Qualityغلام جیلانی100% (6)

- List Column HPLC Agilent PDFDocument5 pagesList Column HPLC Agilent PDFYulis AdrianaNo ratings yet

- Compressed Jayna Price List 01.04.2021Document88 pagesCompressed Jayna Price List 01.04.2021DESIGN85No ratings yet

- Casein PDFDocument3 pagesCasein PDFEasy ways2017No ratings yet

- Bikreta Biniyamawali 2075 PDFDocument74 pagesBikreta Biniyamawali 2075 PDFGsUpretiNo ratings yet

- Block 91 Roorkee - SoR - MORTHDocument71 pagesBlock 91 Roorkee - SoR - MORTHsmithNo ratings yet

- Biogeochemical CyclesDocument31 pagesBiogeochemical Cyclesd gNo ratings yet

- Aeroshell Fluid 41: Main Applications Specifications, Approvals & RecommendationsDocument2 pagesAeroshell Fluid 41: Main Applications Specifications, Approvals & Recommendationsabdul rehmanNo ratings yet

- Databook of Hvac Load CalculationDocument46 pagesDatabook of Hvac Load CalculationASHNA K NAVADNo ratings yet

- Laboratory ManualDocument0 pagesLaboratory ManualsuryavigneNo ratings yet

- Apavisa Catalogo General 16Document438 pagesApavisa Catalogo General 16ggestrudesNo ratings yet

- Year 13 Amount of Substance PPQsDocument49 pagesYear 13 Amount of Substance PPQsNotes NotesNo ratings yet

- Installation of Marble and Granite Tiles On FloorDocument7 pagesInstallation of Marble and Granite Tiles On FloorAleen Gamal Al-Dinji100% (2)

- Chemical Bonding ExerciseDocument6 pagesChemical Bonding Exerciseapi-386303659No ratings yet

- 1 WB-0673 - FinalDocument4 pages1 WB-0673 - FinalSrikanth SikhaNo ratings yet

- Sabic DirectoryDocument9 pagesSabic DirectoryPranabesh MallickNo ratings yet

- Cajas y Tapas TOPAZ F.T.Document28 pagesCajas y Tapas TOPAZ F.T.Brayan CJNo ratings yet

- AISC-ASD-Anchor Bolt CapacityDocument1 pageAISC-ASD-Anchor Bolt CapacityUmar FarooqueNo ratings yet

- Issue/Rev Details of Changes Date: Name Designation Signature Date LevelDocument6 pagesIssue/Rev Details of Changes Date: Name Designation Signature Date LevelAbhey DograNo ratings yet

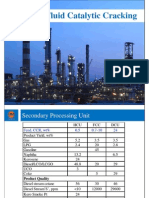

- V FCCDocument38 pagesV FCCpipe_boyNo ratings yet

- Introduction To Metal Forming: by Prof. Jigar V. Patel U V Patel College of Engineering, KhervaDocument22 pagesIntroduction To Metal Forming: by Prof. Jigar V. Patel U V Patel College of Engineering, KhervaNishithNo ratings yet