Professional Documents

Culture Documents

Aeroshell Fluid 41: Main Applications Specifications, Approvals & Recommendations

Uploaded by

abdul rehmanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Aeroshell Fluid 41: Main Applications Specifications, Approvals & Recommendations

Uploaded by

abdul rehmanCopyright:

Available Formats

Technical Data Sheet

AeroShell Fluid 41

AeroShell Fluid 41 is a mineral hydraulic oil manufactured to a very high level of cleanliness, and possesses improved

fluid properties. AeroShell Fluid 41 contains additives which provide excellent low temperature fluidity as well as

exceptional anti-wear, oxidation - corrosion inhibition and shear stability. In addition metal de-activators and foam

inhibitors are included in this high viscosity index fluid to enhance performance in hydraulic applications. AeroShell

Fluid 41 is capable of wide temperature range operation.

AeroShell Fluid 41 is dyed red.

Main Applications Specifications, Approvals & Recommendations

· AeroShell Fluid 41 is intended as an hydraulic fluid in all · Approved MIL-PRF-5606H* (both U.S. and European

modern aircraft applications requiring a mineral hydraulic production)

fluid. AeroShell Fluid 41 is particularly recommended where

use of a "superclean" fluid can contribute to improvements in

· Approved DEF STAN 91-48 Grade Superclean* (European

production only)

component reliability, and can be used in aircraft systems

operating unpressurised between –54°C to 90°C and

· Meets DEF STAN 91-48 Grade Normal (European production

only) Equivalent to DEF STAN 91-48 Grades Superclean* &

pressurised between –54°C to 135°C.

Normal (U.S. production only)

· AeroShell Fluid 41 should be used in systems with synthetic

· Approved DCSEA 415/A (French)

rubber components and must not be used in systems

incorporating natural rubber. · Analogue to AMG-10 (Russian)

· AeroShell Fluid 41 is compatible with AeroShell Fluids 4, 31, · NATO Code H-515* (equivalent H-520)

51, 61 and 71 and SSF/LGF. · Joint Service Designation OM-15* (equivalent OM-18)

· Chlorinated solvents should not be used for cleaning hydraulic For a full listing of equipment approvals and recommendations,

please consult your local Shell Technical Helpdesk, or the OEM

components which use AeroShell Fluid 41. The residual solvent

contaminates the hydraulic fluid and may lead to corrosion. Approvals website.

Typical Physical Characteristics

Properties MIL-PRF-5606H Typical US Typical European

Production Production

Oil Type Mineral Mineral Mineral

Kinematic viscosity @100°C mm²/s 4.90 min 6.13 5.30

Kinematic viscosity @40°C mm²/s 13.2 min 15.68 14.1

Kinematic viscosity @–40°C mm²/s 600 max 384 491

Kinematic viscosity @–54°C mm²/s 2500 max 1450 2300

Viscosity index – 214 Over 200

Flashpoint (Pensky Martin Closed Cup) °C 82 min 104 105

Autoignition temperature °C – 230 230

Pour point °C –60 max <–60 <–60

Total acid number mgKOH/g 0.20 max 0 0.01

Evaporation loss 6 hrs @71°C %m 20 max 16.5 10

Water content ppm 100 max 55 <100

Relative density @15.6/15.6°C Report 0.874 0.87

Page 1 of 2 - AeroShell Fluid 41, v 1

Properties MIL-PRF-5606H Typical US Typical European

Production Production

Colour Red Red Red

Particulate contamination, number of particles per 5 to 15 µm 10000 max 1200 808

100 ml in size range

Particulate contamination, number of particles per 15 to 25 µm 1000 max 550 116

100 ml in size range

Particulate contamination, number of particles per 25 to 50 µm 150 max 70 44

100 ml in size range

Particulate contamination, number of particles per 50 to 100 µm 20 max 5 10

100 ml in size range

Particulate contamination, number of particles per over 100 µm 5 max 0 1

100 ml in size range

Copper corrosion 2e max 1b 2b

Steel on steel wear, scar diam mm 1.0 max 0.65 0.95

Rubber swell, L rubber % 19 to 30 22 25.4

Corrosiveness & oxidation, 168 hrs @135°C - Must Pass Passes Passes

metal weight change

Corrosiveness & oxidation, 168 hrs @ 135°C - @40°C % –5 to +20 8.08 +0.1

viscosity change

Corrosiveness & oxidation, 168 hrs @135°C - acid mgKOH/g 0.20 max 0.02 +0.1

number change

Low temperature stability 72 hrs @–54°C Must Pass Passes Passes

Shear stability - viscosity change @40°C Must Pass Passes Passes

Shear stability - acid number change 0.2 max Less than 0.2 Less than 0.2

Gravimetric filtration mg/100m 0.3 max 0.1 Less than 0.3

filtration time min 15 max 10 Less than 15

Foaming tendency Must Pass Passes Passes

Barium content ppm 10 max Nil Nil

These characteristics are typical of current production. Whilst future production will conform to Shell's specification, variations in these characteristics

may occur.

Health, Safety & Environment

· Health and Safety

Guidance on Health and Safety is available on the appropriate Material Safety Data Sheet, which can be obtained from

http://www.epc.shell.com/

· Protect the Environment

Take used oil to an authorised collection point. Do not discharge into drains, soil or water.

Additional Information

· Advice

Advice on applications not covered here may be obtained from your Shell representative.

· *Superclean grades

The British specification DEF STAN 91-48 covers two grades (normal and superclean) of mineral hydraulic fluid which differ only

in their cleanliness limits. AeroShell Fluid 41 is manufactured to meet the superclean requirements and thus it also meets the

requirements of the normal grade.

Page 2 of 2 - AeroShell Fluid 41, v 1

You might also like

- Aeroshell Fluid 41: Main Applications Specifications, Approvals & RecommendationsDocument2 pagesAeroshell Fluid 41: Main Applications Specifications, Approvals & Recommendationsmanish mishraNo ratings yet

- GPCDOC X Cbe 24855 Key 140008284476 201504141143 PDFDocument2 pagesGPCDOC X Cbe 24855 Key 140008284476 201504141143 PDFCesar Estrada Estrada MataNo ratings yet

- Aeroshell Fluid 41Document2 pagesAeroshell Fluid 41S. MadaniNo ratings yet

- Technical Data Sheet for AeroShell Fluid 41 (IndiaDocument3 pagesTechnical Data Sheet for AeroShell Fluid 41 (IndiaAaron ChanNo ratings yet

- Aeroshell Fluid 41: Main Applications Specifications, Approvals & RecommendationsDocument2 pagesAeroshell Fluid 41: Main Applications Specifications, Approvals & Recommendationsmg kaungNo ratings yet

- AeroShell Fluid 4 Technical Datasheet - SCLDocument3 pagesAeroShell Fluid 4 Technical Datasheet - SCLabdul rehmanNo ratings yet

- Aeroshell Fluid 71Document2 pagesAeroshell Fluid 71mertaktayNo ratings yet

- AeroShell Fluid 41 Technical Data SheetDocument2 pagesAeroShell Fluid 41 Technical Data SheetFarid SaadNo ratings yet

- AeroShell Fluid 41 Technical Data SheetDocument2 pagesAeroShell Fluid 41 Technical Data SheetHarry NuryantoNo ratings yet

- PassportDocument2 pagesPassportAzat ZaripovNo ratings yet

- AeroShell Fluid 41 Technical Data SheetDocument2 pagesAeroShell Fluid 41 Technical Data SheetPawang SingaNo ratings yet

- Aeroshell Fluid 41: Specifications U.SDocument2 pagesAeroshell Fluid 41: Specifications U.Sapi-133947076No ratings yet

- Aeroshell Fluid 41Document2 pagesAeroshell Fluid 41Anonymous oAbjbl4HNo ratings yet

- Renolin Ac Compressor Oils: Product InformationDocument2 pagesRenolin Ac Compressor Oils: Product InformationSoporte Técnico RyRNo ratings yet

- Priolube 3970Document2 pagesPriolube 3970Agenk VambudyNo ratings yet

- NC 2017 Anexa 1Document5 pagesNC 2017 Anexa 1mayaNo ratings yet

- Aerospec 100 TdsDocument2 pagesAerospec 100 TdsHasnain ZaidiNo ratings yet

- Aeroshell Fluid 12: Main Applications Specifications, Approvals & RecommendationsDocument2 pagesAeroshell Fluid 12: Main Applications Specifications, Approvals & RecommendationsThái NgọcNo ratings yet

- Aeroshell Grease 4Document1 pageAeroshell Grease 4Anonymous oAbjbl4HNo ratings yet

- Aeroshell Fluid 61Document2 pagesAeroshell Fluid 61Jorge MartinsNo ratings yet

- Thermaline 450 EP PDSDocument3 pagesThermaline 450 EP PDSdgambhavaNo ratings yet

- 2401-00 Simacover EP UnicoatDocument3 pages2401-00 Simacover EP UnicoatSAEFUDDIN SAEFUDDINNo ratings yet

- AeroShell Fluid 1 (en-GB) TDSDocument1 pageAeroShell Fluid 1 (en-GB) TDSjaganNo ratings yet

- Interline 850+ds+eng PDFDocument4 pagesInterline 850+ds+eng PDFMohamed NouzerNo ratings yet

- Chevron Base OilDocument3 pagesChevron Base OilNeha AntimonyNo ratings yet

- Helix Ultra 5W-40 PDFDocument2 pagesHelix Ultra 5W-40 PDFEzraGoenadiNo ratings yet

- Shell Helix Ultra 5W-40 Technical Data SheetDocument2 pagesShell Helix Ultra 5W-40 Technical Data Sheetbanditman2013No ratings yet

- Interline 955: Product DescriptionDocument4 pagesInterline 955: Product DescriptionArun PadmanNo ratings yet

- 0901d196800634a7 PDF Preview MediumDocument2 pages0901d196800634a7 PDF Preview Mediummgamal1080No ratings yet

- 2915 8275 00 - Fluids and Lubricants - 2017Document20 pages2915 8275 00 - Fluids and Lubricants - 2017GuptaNo ratings yet

- Hempadur 15130Document2 pagesHempadur 15130MuthuKumarNo ratings yet

- Mobil Aero HF Series (PDS)Document3 pagesMobil Aero HF Series (PDS)Vikram SinghNo ratings yet

- Interline 850 PDFDocument4 pagesInterline 850 PDFaqeelNo ratings yet

- Ecoalube642TDS PDFDocument2 pagesEcoalube642TDS PDFDkC gunsNo ratings yet

- Technical Data Sheet for Shell Helix Ultra 0W-40Document2 pagesTechnical Data Sheet for Shell Helix Ultra 0W-40Franz LehnerNo ratings yet

- Shell Helix Ultra 0W-40: Performance, Features & Benefits Main ApplicationsDocument2 pagesShell Helix Ultra 0W-40: Performance, Features & Benefits Main ApplicationsFranz LehnerNo ratings yet

- Hydrolub HmaxDocument1 pageHydrolub HmaxOlivier DupNo ratings yet

- Rocol Sapphire® Hi-Power Range 22Document7 pagesRocol Sapphire® Hi-Power Range 22Luz Angela GuerreroNo ratings yet

- SKF LGHP 2 GreaseDocument2 pagesSKF LGHP 2 GreaseANILNo ratings yet

- SKF LGMT-2 Data SheetDocument2 pagesSKF LGMT-2 Data SheetRahul SharmaNo ratings yet

- Valvoline Long Life RTUDocument3 pagesValvoline Long Life RTUThein Lin HtunNo ratings yet

- Lgep 2: SKF High Load, Extreme Pressure Bearing GreaseDocument2 pagesLgep 2: SKF High Load, Extreme Pressure Bearing GreaseStanislavNo ratings yet

- 135Document2 pages135Abdullah SahlyNo ratings yet

- Interzone954TdsEng PDFDocument4 pagesInterzone954TdsEng PDFÖzgür TuştaşNo ratings yet

- Helix Hx5 15w 40 TdsDocument2 pagesHelix Hx5 15w 40 TdsMark John BeduralNo ratings yet

- Interzone 505: Glass Flake EpoxyDocument4 pagesInterzone 505: Glass Flake EpoxyAidil Luthfansyah PutraNo ratings yet

- Everlube 9002 TDSDocument2 pagesEverlube 9002 TDSValentinNo ratings yet

- Rix Turbine: Premium Turbine Oil With AdditivesDocument2 pagesRix Turbine: Premium Turbine Oil With AdditivesiceburnerNo ratings yet

- Enviroline 405HT+ds+eng PDFDocument4 pagesEnviroline 405HT+ds+eng PDFMohamed NouzerNo ratings yet

- AeroShell Grease 14 Technical Data SheetDocument2 pagesAeroShell Grease 14 Technical Data SheetTaher HriziNo ratings yet

- Macropoxy 646 - 2023Document2 pagesMacropoxy 646 - 2023nellyNo ratings yet

- Statoil Hydraulic Oil 131Document2 pagesStatoil Hydraulic Oil 131RZW RNo ratings yet

- Intercure 99Document4 pagesIntercure 99Doby YuniardiNo ratings yet

- n25 ManualDocument12 pagesn25 ManualRikshita Agarwal100% (1)

- Interline 982+ds+eng PDFDocument4 pagesInterline 982+ds+eng PDFMohamed NouzerNo ratings yet

- Enviroline 2405: Hybrid EpoxyDocument4 pagesEnviroline 2405: Hybrid EpoxyMuthuKumarNo ratings yet

- Shell Caprinus HPD 40 (en-GB) TDSDocument2 pagesShell Caprinus HPD 40 (en-GB) TDSMahmoud YosriNo ratings yet

- 2015 Synfluid BroDocument8 pages2015 Synfluid BromarcelhidajatNo ratings yet

- IGS-NT Communication Guide 02-2016 PDFDocument141 pagesIGS-NT Communication Guide 02-2016 PDFabdul rehmanNo ratings yet

- IM-NT-FDR-3.1.0 Reference Guide r2 PDFDocument302 pagesIM-NT-FDR-3.1.0 Reference Guide r2 PDFabdul rehmanNo ratings yet

- Dia-Flo & Pure-Flo Diaphragm Valves Instruction Manual With Dia-Flo ActuatorDocument16 pagesDia-Flo & Pure-Flo Diaphragm Valves Instruction Manual With Dia-Flo Actuatorabdul rehmanNo ratings yet

- EntisXL OperationDocument174 pagesEntisXL OperationnknicoNo ratings yet

- Users Guide Entis XLDocument87 pagesUsers Guide Entis XLnknicoNo ratings yet

- Product Specification: Premierlink™ Retrofit Rooftop ControllerDocument4 pagesProduct Specification: Premierlink™ Retrofit Rooftop Controllerabdul rehmanNo ratings yet

- WDG IV O2 AnalyserDocument4 pagesWDG IV O2 Analyserabdul rehmanNo ratings yet

- AeroShell Fluid 4 Technical Datasheet - SCLDocument3 pagesAeroShell Fluid 4 Technical Datasheet - SCLabdul rehmanNo ratings yet

- OG Bi131B TPAmmeter 1109101Document2 pagesOG Bi131B TPAmmeter 1109101Rick JordanNo ratings yet

- Reliance Probe Iom R500 E189 A 3 2012 08Document2 pagesReliance Probe Iom R500 E189 A 3 2012 08abdul rehmanNo ratings yet

- Simplex ManualDocument68 pagesSimplex Manualabdul rehmanNo ratings yet

- A Guide To Transformer Oil Analysis: BY I.A.R. GRAY Transformer Chemistry ServicesDocument12 pagesA Guide To Transformer Oil Analysis: BY I.A.R. GRAY Transformer Chemistry ServicesAnonymous OCDJg17Z100% (1)

- Manual 167d 167da 167ds 167das Switching Valves Fisher en 127606Document12 pagesManual 167d 167da 167ds 167das Switching Valves Fisher en 127606arif fadhillahNo ratings yet

- Silica Analyzer - HACHDocument136 pagesSilica Analyzer - HACHSheikh ZakirNo ratings yet

- Warud ExpoDocument6 pagesWarud Exponikhil indoreinfolineNo ratings yet

- Analytical Chem Week 5Document37 pagesAnalytical Chem Week 5ANGELICA FRANSCINE GOMEZNo ratings yet

- Glysantin g48 BG PgsDocument15 pagesGlysantin g48 BG PgsSam MalikNo ratings yet

- HPLC Columns For Carbohydrates: Product SpecificationDocument2 pagesHPLC Columns For Carbohydrates: Product SpecificationSandip BasuNo ratings yet

- Inorganic Application NoteDocument3 pagesInorganic Application NoteHarry HuangNo ratings yet

- Hinged 45 MMDocument134 pagesHinged 45 MMMuraleedharanNo ratings yet

- Introduction To Refrigeration SystemsDocument27 pagesIntroduction To Refrigeration SystemsChristian Breth BurgosNo ratings yet

- 07 - Chapter 4 Methodology For MuehlenbeckiaDocument42 pages07 - Chapter 4 Methodology For Muehlenbeckiaprabhakar beeravelliNo ratings yet

- Introduction of CarbohydratesDocument28 pagesIntroduction of CarbohydratesShahzad BashirNo ratings yet

- Assignment AnswersDocument2 pagesAssignment Answersxewoj59015No ratings yet

- PHR-224L (Pharmaceutical Analysis Lab) - IDocument22 pagesPHR-224L (Pharmaceutical Analysis Lab) - ISanjida Khandoker 1911009049No ratings yet

- 80005302enDocument134 pages80005302enUlfahanny RachsetyaNo ratings yet

- General Chemistry Module 20 GENCHEM1-12-Q1-MELC20-MOD-Areola, Marissa - Marissa AreolaDocument16 pagesGeneral Chemistry Module 20 GENCHEM1-12-Q1-MELC20-MOD-Areola, Marissa - Marissa AreolaJunelle Ramos AquinoNo ratings yet

- D 6666 - 01 Rdy2njytmde - PDFDocument14 pagesD 6666 - 01 Rdy2njytmde - PDFNORMANo ratings yet

- CellStructureWorksheet1watermark 230214 101313 MergedDocument84 pagesCellStructureWorksheet1watermark 230214 101313 MergedManojna Raj OjhaNo ratings yet

- Guide To Apparel and Textile Care Symbols - Canadian StandardsDocument6 pagesGuide To Apparel and Textile Care Symbols - Canadian StandardspraknithNo ratings yet

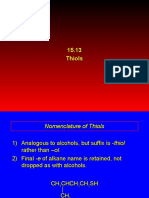

- 15.13 ThiolsDocument19 pages15.13 ThiolsSNo ratings yet

- A Level Chemistry Paper 1 Set 1Document20 pagesA Level Chemistry Paper 1 Set 1RUBANGAKENE DENISNo ratings yet

- Astm A 143 PDFDocument3 pagesAstm A 143 PDFdoni zamroni100% (1)

- Life Cycle Assessment of Fertilizer Manufacturing and Impacts (39Document31 pagesLife Cycle Assessment of Fertilizer Manufacturing and Impacts (39Vijay SinghNo ratings yet

- Development of An Internationally Competitive Australian Saffron IndustryDocument37 pagesDevelopment of An Internationally Competitive Australian Saffron IndustryNemanja NikolicNo ratings yet

- FP-J30M: Air Purifier Operation ManualDocument16 pagesFP-J30M: Air Purifier Operation ManualHari Singh ChauhanNo ratings yet

- TDS-Maha Glycerine USP 99.7Document1 pageTDS-Maha Glycerine USP 99.7mehongnhamnhiNo ratings yet

- KarnatakaDocument8 pagesKarnatakaMain Sanatani Hun0% (1)

- Chemical Performance of PE: Chemical Formula Temp. Conc. Resistance (C) (%) Mdpe/Hdpe Ldpe AcetaldehydeDocument25 pagesChemical Performance of PE: Chemical Formula Temp. Conc. Resistance (C) (%) Mdpe/Hdpe Ldpe AcetaldehydeBobdNo ratings yet

- Tropical SoilsDocument88 pagesTropical SoilsBernard Kipng'eno100% (1)

- Second Periodical Test in Science 9Document2 pagesSecond Periodical Test in Science 9tolisNo ratings yet

- Industrial Training Performed at Piramal Pharma Solutions, Mahad, Dist-RaigadDocument32 pagesIndustrial Training Performed at Piramal Pharma Solutions, Mahad, Dist-RaigadChandan A. Wagh100% (1)

- Physical Chemistry JEE Main 2023 Chapterwise PYQs PDFDocument22 pagesPhysical Chemistry JEE Main 2023 Chapterwise PYQs PDFSrishant KumarNo ratings yet

- Alora Night Glowing Cream DHM 2033Document4 pagesAlora Night Glowing Cream DHM 2033Muhammad ImranNo ratings yet