Professional Documents

Culture Documents

Technical Service Information: Dodge Ram Trucks 68rfe Transmission

Technical Service Information: Dodge Ram Trucks 68rfe Transmission

Uploaded by

UlloaEliasOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Technical Service Information: Dodge Ram Trucks 68rfe Transmission

Technical Service Information: Dodge Ram Trucks 68rfe Transmission

Uploaded by

UlloaEliasCopyright:

Available Formats

Technical Service Information

DODGE RAM TRUCKS 68RFE TRANSMISSION

FOUND BEHIND 5.9L (L6) and 6.7L Diesel Engines

Bar Code Label TITTJ177720548 14:10:44

704

P52119704AB RFE

ID Numbers Also Etched Into

Case Pan Rail Here

1777 20548 P52119704AB

{

{

{

Build Serial Part

0:44

Date Number Number

14:1

548 704

720

177

TITTJ

RFE

B

197

04A

4AB

P521 970

P5 211

548

720

177

Fluid Requirements

6 = Six Forward Speeds

"Mopar® ATF+4"

8 = Relative Torque Capacity

R = Rear Wheel Drive

FE = Fully Electronic

Copyright © 2011 ATSG

Figure 1

AUTOMATIC TRANSMISSION SERVICE GROUP 3

Technical Service Information

CLUTCH APPLICATION CHART

SELECTOR LO/REV UD SECOND OD FOURTH REVERSE LOW SPRAG GEAR

POSITION CLUTCH CLUTCH CLUTCH CLUTCH CLUTCH CLUTCH CLUTCH RATIO

PARK ON

REVERSE ON ON 4.44:1

NEUTRAL ON

OD-1ST ON * ON HOLD 3.23:1

OD-2ND ON ON 1.83:1

OD-3RD ON ON 1.41:1

OD-4TH ON ON 1.00:1

OD-5TH ON ON 0.81:1

OD-6TH ON ON 0.62:1

OD-LIMP ON ON 1.00:1

(2)-1ST ON * ON HOLD 3.23:1

(2)-2ND ON ON 1.83:1

(2)-LIMP ON ON 1.83:1

(1)-1ST ON ON HOLD 3.23:1

* L/R Clutch is on only with the output shaft speed below 150 RPM.

COMPONENT LOCATIONS

Underdrive

Clutch Overdrive Low/Reverse

Clutch Second Clutch Low Sprag

Reverse Clutch Clutch

Clutch Fourth

Clutch

Copyright © 2011 ATSG

Figure 2

4 AUTOMATIC TRANSMISSION SERVICE GROUP

Technical Service Information

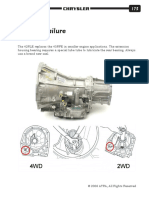

MECHANICAL OPERATION

The operation of the 68RFE is very similar to the Chrysler 45RFE. Drive range provides reduction 1st, 2nd,

and 3rd gear, direct 4th gear and overdrive 5th and 6th gears. The shift into 5th and 6th gear occurs only after the

transmission has completed the shift into 4th gear. Upshifts into 5th and 6th gear will be delayed when the fluid

temperature is below 4.5°C (40°F) or above 115°C (240°F). The Input Clutch Housing retains the "single-

sided" underdrive clutch, "single-sided" overdrive clutch and the reverse clutch. It is set up almost identical to

the 41TE transaxle, except much larger. The 68RFE also contains seperate holding clutches, such as the 2nd

clutch, 4th clutch and the "single-sided" low/reverse clutch. This unit also uses one freewheel device called the

low sprag.

To achieve its different gear ratios, the 68RFE applies different combinations of two clutch packs at a time, as

shown in Figure 2. In Park and Neutral, only the low/reverse clutch is applied. Refer to the chart in Figure 2 for

the clutches that are applied for each shift lever (gear) position.

Another feature of the 68RFE is the three planetary gear sets, as shown in Figure 2, that are all equipped with 6

pinion carriers to accommodate the Diesel engine. These planetary gear sets also provide a deeper 1st and

reverse ratio. All gear ratios are also shown in the chart in Figure 2.

SOLENOID OPERATION

Solenoids are used to control the L/R, 2C, 4C, UD and OD friction elements. The Reverse clutch is controlled

by the manual valve in the valve body and line pressure. The Multi-Select solenoid is used primarily to provide

3rd gear and reverse "limp-in" operation. The TCM energizes or operates the solenoids individually by

grounding the return wire of the solenoid as necessary. When a solenoid is energized, a fluid passage is opened

or closed (vented or applied), depending on its default operating state. The result is an apply or release of a

friction element. Refer to the chart in Figure 3.

SOLENOID APPLICATION CHART

N.V. N.A. N.V. N.V. N.V. N.A. N.V.

SELECTOR LR/CC UD OD 2nd CLUT 4th CLUT Multi-Select Line Pressure

POSITION SOLENOID SOLENOID SOLENOID SOLENOID SOLENOID SOLENOID SOLENOID

Park/ ON ON Modulating

Neutral

Park/ ON ON Modulating

Neutral

REVERSE ON ***OFF Modulating

OD-1ST *ON ON ON Modulating

OD-2ND ** ON ON ON Modulating

OD-3RD ** ON ON ON Modulating

OD-4TH ** ON ON OFF Modulating

OD-5TH ** ON ON OFF Modulating

OD-6TH ** ON ON ON Modulating

(1)-1ST Or ON ON ON Modulating

Autostick

FAILSAFE OFF OFF OFF OFF OFF OFF OFF

* L/R Clutch is on only with the output shaft speed below 150 RPM. N.V. = Normally Vented

**Modulating (EMCC) if the Converter Clutch has been signaled. N.A. = Normally Applied

***Off Below 8 MPH, On Above 8 MPH.

Copyright © 2011 ATSG

Figure 3

AUTOMATIC TRANSMISSION SERVICE GROUP 5

Technical Service Information

ELECTRICAL OPERATION

Transmission Control Module (TCM)

Vehicles equipped with the 68RFE and a 6.7L Diesel engine use a Transmission Control Module (TCM) housed in

the New Generation Controller (NGC) utilizing only the C1 and C4 connectors. The TCM controls all of the

transmission functions. The controller is located at the rear of the engine compartment, near the right inner fender, as

shown in Figure 12. The Powertrain Control Module (PCM) does not control the transmission. The electronic

components of the 68RFE transmission consist of various sensors and switches as input information to the TCM,

that the TCM uses to determine the appropriate gear ratio and shift schedule points. There is also the associated

wiring, fuses, relays, connectors, splices and grounds for the transmission to function as designed. A complete

transmission wiring schematic has been provided for you in Figure 10.

The final output from the TCM is to the six shift solenoids and the line pressure control solenoid located in the

Solenoid Body/Transmission Range Sensor assembly and bolted on the valve body as shown in Figure 9. The

solenoids in this transmission are unique in that some are normally vented and some are normally applied and this is

also illustrated in Figure 9. The TCM also communicates with other control modules, such as the PCM, and the

New Generation Controller (NGC) modules currently use PCI or CAN C bus.

The TCM recieves power from two sources, fused battery power to pin 18 (C4 connector) and fused ignition switch

input to pin 30 (C1 connector). The TCM also has several grounds to complete its electrical circuit, as shown in

Figure 10.

ADAPTIVE LEARNING

The 68RFE transmission uses an "Adaptive Learning" feature which allows the TCM to modify the clutch apply

rate to maintain consistant shift quality. This is done based on the amount of wear on the friction elements. The

TCM then adjusts the duty cycle of the shift solenoids to achieve the smoothest possible upshifts and downshifts.

The TCM adjusts the "Clutch Volume Index" when a shift change takes place to optimize clutch to clutch timing.

Clutch Volume Index is described on Page 16, along with proper clutch volumes and clutch clearances for the

68RFE transmission shown in Figure 15.

LIMP-IN MODE OPERATION

The TCM has the ability to monitor all transmission related electrical components and if it detects a problem, takes

appropriate action, and most of the time results in the TCM setting a Diagnostic Trouble Code (DTC). Whether this

results in MIL illumination, or Limp-in Mode operation, depends on the type of DTC that was set.

If the TCM determines that transmission damage may result from the DTC type that was set, the TCM will shut off

the ground signal to the transmission control relay which will shut off all power to the transmission and the vehicle

will be in Limp-in Mode Operation.

When in Limp-in Mode Operation, with the shift lever in the "Drive" position the transmission will be in 4th gear,

and if the shift lever is moved to "2" or "L" position the transmission will be in 2nd gear. This will allow the driver to

manually shift the transmission to Limp home.

Note: Vehicles equipped with Electronic Range Select (ERS) do not provide 2nd gear limp-in, because the shift

lever has no "2" or "1" shift lever positions.

The hydraulic control system design, without any electronic assist, provides the 68RFE transmission with PARK,

REVERSE, NEUTRAL, and FOURTH gears based solely on driver selection. This design allows the vehicle to be

driven in "limp-in" mode (4th gear) in the event of a total electronic control system failure, or a situation that the

TCM recognizes as potentially damaging to the transmission (DTC Stored).

Copyright © 2011 ATSG

6 AUTOMATIC TRANSMISSION SERVICE GROUP

Technical Service Information

INPUTS TO THE TCM

Input and Output Shaft Speed Sensors - are located

on the left side of the transmission and are illustrated in

Figure 5. The input shaft speed sensor reads input shaft

speed off of a tone wheel on the input clutch housing.

As the teeth of the tone wheel pass the sensor coil, an

AC voltage is generated and sent to the TCM. The

TCM interprets this information as input shaft rpm.

The output speed sensor generates an AC signal in a

similar fashion, though its coil is excited by rotation of 14:1

0:44

48

the parking gear teeth. The TCM interprets this

205 04 7

177

TITTJ7

RFE

B B

04A

1197 04A

P52

197

P 521

548

information as output shaft rpm. 177

720

OUTPUT SPEED

The TCM compares the input and output speed signals SENSOR

to determine the following: INPUT SPEED

Transmission gear ratio. SENSOR

Speed ratio error detection.

Clutch Volume Index calulation.

Torque Converter Clutch slippage.

Both speed sensors are the same and will interchange.

New speed sensors, when checked for resistance, read

535 ohms at room temperature.

Pressure Switches - are located inside the solenoid and

pressure switch assembly and are only serviced by

replacing the complete solenoid/TRS assembly. The Input Output

Speed Speed

TCM relies on five pressure switches to monitor Sensor Sensor

pressure in the Low/Rev, 2nd Clutch, 4th Clutch,

Underdrive, and Overdrive hydraulic circuits. The Twisted Dk Green/Violet Twisted

Pair Pair

primary function of these switches is to help the TCM

detect when clutch circuit hydraulic failures occur. The

Dk Green/Orange

switches close at 23 psi and open at 11 psi, and indicate

Dk Green/Brown

Dk Green/Violet

whether or not pressure exists. The switches are

continuously monitored by the TCM for the proper

states (Open or Closed) in each gear, shown in the chart

in Figure 4. C4 C4 C4

33 34 32

TCM

68RFE PRESSURE SWITCH CHART

Low/Rev 2nd Clut 4th Clut Underdrive Overdrive Copyright © 2011 ATSG

Park/Neut Closed Open Open Open Open Figure 5

Reverse Open Open Open Open Open

First Closed* Open Open Closed Open

Second Open Closed Open Closed Open Inputs To The TCM

Third Open Open Closed Closed Open Continued on Page 8

Fourth Open Open Open Closed Closed

Fifth Open Open Closed Open Closed

Sixth Open Closed Open Closed Closed

* L/R is closed if output speed is below 150 RPM in Drive and Manual 2.

L/R is open in Manual 1.

Copyright © 2011 ATSG

Figure 4

AUTOMATIC TRANSMISSION SERVICE GROUP 7

You might also like

- Aode 4R70WDocument113 pagesAode 4R70Wcustm196% (28)

- AUTOMATIC TRANSMISSION AS69RC - Service Information - Ram Pickup PDFDocument292 pagesAUTOMATIC TRANSMISSION AS69RC - Service Information - Ram Pickup PDFcharles91% (11)

- How to Rebuild & Modify Ford C4 & C6 Automatic TransmissionsFrom EverandHow to Rebuild & Modify Ford C4 & C6 Automatic TransmissionsRating: 5 out of 5 stars5/5 (5)

- THM 4l60 e Atsg Automatic Transmission Service GroupDocument112 pagesTHM 4l60 e Atsg Automatic Transmission Service Grouperick alexander hernandez100% (4)

- OPERATORS MANUAL - 544G - EnglishDocument336 pagesOPERATORS MANUAL - 544G - EnglishRaul E. Soli100% (2)

- How to Rebuild & Modify Rochester Quadrajet CarburetorsFrom EverandHow to Rebuild & Modify Rochester Quadrajet CarburetorsRating: 5 out of 5 stars5/5 (2)

- 4r75 Transmision PDFDocument10 pages4r75 Transmision PDFCarlos Arturo de Dios100% (2)

- How to Use and Upgrade to GM Gen III LS-Series Powertrain Control SystemsFrom EverandHow to Use and Upgrade to GM Gen III LS-Series Powertrain Control SystemsRating: 3.5 out of 5 stars3.5/5 (4)

- Ford AOD Transmissions: Rebuilding and Modifying the AOD, AODE and 4R70WFrom EverandFord AOD Transmissions: Rebuilding and Modifying the AOD, AODE and 4R70WRating: 4.5 out of 5 stars4.5/5 (6)

- GM 6T70/75 and Ford 6F50/55: 2007 6T70 (MH2) FWD 2007 6T75 (MY9) FWD/ (MH6) AWD Six Speed Automatic TransaxleDocument60 pagesGM 6T70/75 and Ford 6F50/55: 2007 6T70 (MH2) FWD 2007 6T75 (MY9) FWD/ (MH6) AWD Six Speed Automatic TransaxleRepuestos Maceira100% (4)

- FORD 4R100: IndexDocument120 pagesFORD 4R100: Indexjohnatan chui100% (9)

- 6l80e DiagramDocument5 pages6l80e Diagramhighvoltkv100% (2)

- GM 4L80E Transmissions: How to Rebuild & Modify: How to Rebuild & ModifyFrom EverandGM 4L80E Transmissions: How to Rebuild & Modify: How to Rebuild & ModifyRating: 5 out of 5 stars5/5 (1)

- GM Automatic Overdrive Transmission Builder's and Swapper's GuideFrom EverandGM Automatic Overdrive Transmission Builder's and Swapper's GuideRating: 4.5 out of 5 stars4.5/5 (8)

- Caja Mazda 6 Fnr5Document54 pagesCaja Mazda 6 Fnr5Allison VR100% (6)

- CHECKBALL BOOK Domestic Volume I PDFDocument120 pagesCHECKBALL BOOK Domestic Volume I PDFAlberto Del Rio Mejia100% (5)

- Chrysler TorqueFlite A-904 and A-727 Transmissions: How to RebuildFrom EverandChrysler TorqueFlite A-904 and A-727 Transmissions: How to RebuildRating: 5 out of 5 stars5/5 (1)

- Chevy Differentials: How to Rebuild the 10- and 12-BoltFrom EverandChevy Differentials: How to Rebuild the 10- and 12-BoltRating: 5 out of 5 stars5/5 (17)

- 01m ValvebodyDocument2 pages01m Valvebodyadaylite100% (2)

- Hitachi ZAXIS 130W Wheeled Excavator Operator's Manual SN 001001 and Up PDFDocument12 pagesHitachi ZAXIS 130W Wheeled Excavator Operator's Manual SN 001001 and Up PDFfjkskemdmme50% (2)

- NH Telehandler LM1340 1343 1345 1443 1445 1743 SM PDFDocument502 pagesNH Telehandler LM1340 1343 1345 1443 1445 1743 SM PDFanzor100% (3)

- Quick Reference: 68RFE Component Location and I.DDocument8 pagesQuick Reference: 68RFE Component Location and I.DAyhan Ümit100% (2)

- 4L80 eDocument120 pages4L80 eAlexey Shvatsky100% (5)

- Atra Seminar 1990-2011 PDFDocument5,067 pagesAtra Seminar 1990-2011 PDFJosé Luis100% (14)

- 4r70w Technical InformationDocument4 pages4r70w Technical InformationRay Falconi100% (5)

- Critical Wear Areas & Vacuum Test Locations: Lower Control Body - 4R100 Non-PTO ShownDocument5 pagesCritical Wear Areas & Vacuum Test Locations: Lower Control Body - 4R100 Non-PTO Shownbelchior100% (1)

- NAG 1 - 42RLE 2005 300 Hemi TransDocument836 pagesNAG 1 - 42RLE 2005 300 Hemi Transanon_158071697No ratings yet

- 5r55 OverheatingDocument46 pages5r55 OverheatingAhmed Ali100% (3)

- C68RCDocument67 pagesC68RCYovani Gamaliel100% (5)

- Muncie 4-Speed Transmissions: How to Rebuild & ModifyFrom EverandMuncie 4-Speed Transmissions: How to Rebuild & ModifyRating: 5 out of 5 stars5/5 (7)

- How to Rebuild Ford Power Stroke Diesel Engines 1994-2007From EverandHow to Rebuild Ford Power Stroke Diesel Engines 1994-2007Rating: 4 out of 5 stars4/5 (2)

- SSP.390-DSG-7 Gearbox 0AM PDFDocument0 pagesSSP.390-DSG-7 Gearbox 0AM PDFspiros23100% (8)

- 295HR - Operator's Manual PDFDocument96 pages295HR - Operator's Manual PDFHarry Wart Wart100% (1)

- Allison 8600Document2 pagesAllison 8600George Buitrago100% (1)

- An Introduction To The 68RFE: Sponsored byDocument71 pagesAn Introduction To The 68RFE: Sponsored byossoski100% (3)

- Ford E4Od: Automatic Transmission Service Group 18635 S.W. 107 AVENUE Cutler Bay, Florida 33157 (305) 670-4161Document108 pagesFord E4Od: Automatic Transmission Service Group 18635 S.W. 107 AVENUE Cutler Bay, Florida 33157 (305) 670-4161julio montenegro100% (1)

- Quick Reference: 4L60 / 4L60-E / 4L65-E / 4L70-E Component Location and I.DDocument10 pagesQuick Reference: 4L60 / 4L60-E / 4L65-E / 4L70-E Component Location and I.DAyhan Ümit100% (4)

- 6 L 80Document8 pages6 L 80Transmisiones Guero75% (4)

- 2001 ATRA Seminar Manual Contents PDFDocument218 pages2001 ATRA Seminar Manual Contents PDFchoco84No ratings yet

- 68rfe IntroductionDocument71 pages68rfe IntroductionThePokeOne86% (7)

- 2005 ATRA Seminar ManualDocument372 pages2005 ATRA Seminar Manualtambache69100% (12)

- 42REDocument104 pages42REAlberto Torres100% (2)

- E4od PDFDocument2 pagesE4od PDFmilerkNo ratings yet

- ATRA 2003 Seminar ManualDocument311 pagesATRA 2003 Seminar Manualdboo100% (9)

- Critical Wear Areas & Vacuum Test Locations: Valve Body - 45RFE ShownDocument4 pagesCritical Wear Areas & Vacuum Test Locations: Valve Body - 45RFE Shownalfredop71No ratings yet

- Atra SeminarsDocument2,631 pagesAtra SeminarsSarah Davis100% (8)

- Technical Documentation GM THM 4L60-EDocument108 pagesTechnical Documentation GM THM 4L60-Ecyber_nautica100% (3)

- GM 6t70 UpdatesDocument45 pagesGM 6t70 UpdatesThePokeOne100% (10)

- Sonnax HP 4L60E Catalog v1Document12 pagesSonnax HP 4L60E Catalog v1Brad Franc100% (2)

- 4L60 eDocument112 pages4L60 eThePokeOne100% (10)

- 4R44EDocument120 pages4R44EGaby Zam100% (4)

- 42REDocument120 pages42RETomas Delgado Montiel100% (3)

- Index: T H M 4 L 8 0 - EDocument120 pagesIndex: T H M 4 L 8 0 - EAnonymous eExWojLx100% (2)

- 2006 174 PDFDocument14 pages2006 174 PDFSantiago EscobarNo ratings yet

- 2001-2003 4L60-E Transmission OverhaulDocument104 pages2001-2003 4L60-E Transmission Overhaulbullfly71% (7)

- 2004 ATRA Seminar Manual ContentsDocument316 pages2004 ATRA Seminar Manual Contentschoco84100% (3)

- 6T70/6T75: The Future Is The Future Is Now, Part 1 Now, Part 1Document10 pages6T70/6T75: The Future Is The Future Is Now, Part 1 Now, Part 1robertorres585850% (2)

- Jatco Tranny Part 3 of 3 2007-04-40Document5 pagesJatco Tranny Part 3 of 3 2007-04-40cec985458100% (1)

- Auto Transmission TroubleshootDocument26 pagesAuto Transmission Troubleshootwei foo100% (4)

- Allison Transmissions: How to Rebuild & Modify: How to Rebuild & ModifyFrom EverandAllison Transmissions: How to Rebuild & Modify: How to Rebuild & ModifyRating: 5 out of 5 stars5/5 (1)

- Camaro 5th Gen 2010-2015: How to Build and ModifyFrom EverandCamaro 5th Gen 2010-2015: How to Build and ModifyRating: 4.5 out of 5 stars4.5/5 (3)

- 4N71B PDFDocument94 pages4N71B PDFUlloaEliasNo ratings yet

- 3N71B PDFDocument52 pages3N71B PDFUlloaEliasNo ratings yet

- Attention: 6L80 & 6L90 Installation GuideDocument4 pagesAttention: 6L80 & 6L90 Installation GuideUlloaEliasNo ratings yet

- Vdocuments - MX - A130 Manual Atsgpdf PDFDocument89 pagesVdocuments - MX - A130 Manual Atsgpdf PDFUlloaEliasNo ratings yet

- The Automotive TM, HEV & EV Drives Magazine by CTIDocument32 pagesThe Automotive TM, HEV & EV Drives Magazine by CTIUlloaEliasNo ratings yet

- p1811-p0748 Impala PDFDocument5 pagesp1811-p0748 Impala PDFUlloaEliasNo ratings yet

- Spare Parts List Catalogo Parti Di RicambioDocument15 pagesSpare Parts List Catalogo Parti Di RicambioUlloaEliasNo ratings yet

- 6T40ManualPg101 PDFDocument1 page6T40ManualPg101 PDFUlloaEliasNo ratings yet

- Slips in Reverse, 3rd, 5th P0776 Possibly Set: General MotorsDocument2 pagesSlips in Reverse, 3rd, 5th P0776 Possibly Set: General MotorsUlloaEliasNo ratings yet

- Soft Starter For ConveyorDocument8 pagesSoft Starter For ConveyoranjnaNo ratings yet

- 5501 F FS For Gas Turbine0582642418Document55 pages5501 F FS For Gas Turbine0582642418pramodtryNo ratings yet

- E4nb71 PDFDocument99 pagesE4nb71 PDFtambache69100% (1)

- Ladle TypesDocument16 pagesLadle Typessteelage100% (1)

- Cat Electronic Technician 2015A v1.0 Product Status ReportDocument7 pagesCat Electronic Technician 2015A v1.0 Product Status Reportikperha jomafuvweNo ratings yet

- Pto Aplication ChelseaDocument23 pagesPto Aplication Chelseaturciosc93100% (1)

- Hydraulic Swing Drive: Service and Maintenance ManualDocument16 pagesHydraulic Swing Drive: Service and Maintenance ManualmasakpNo ratings yet

- Thakur Institute of Aviation TechnologyDocument10 pagesThakur Institute of Aviation TechnologyAshwini ChaurasiaNo ratings yet

- Agnee - Bevel Helical Geared Motor Type AKDocument105 pagesAgnee - Bevel Helical Geared Motor Type AKEdy WijayaNo ratings yet

- Myford ML7 Lubrication ChartDocument6 pagesMyford ML7 Lubrication Chartjimxxx100% (3)

- Transmission ErrorDocument7 pagesTransmission ErrorTapas JenaNo ratings yet

- Intimidator Utv Owners ManualDocument104 pagesIntimidator Utv Owners ManualClyde FairbanksNo ratings yet

- Mazda RX-8 2009 Service HighlightsDocument299 pagesMazda RX-8 2009 Service HighlightsMarin EniNo ratings yet

- ElectricalDocument20 pagesElectricalmohanNo ratings yet

- ASE AutoGuide 2011 WEB PDFDocument84 pagesASE AutoGuide 2011 WEB PDFKen Hull100% (2)

- RC 10 Team CarDocument8 pagesRC 10 Team Carvintagerccar100% (1)

- A370 - Manual Servicio UT13-20PTEDocument29 pagesA370 - Manual Servicio UT13-20PTEanon_391259710No ratings yet

- LT 4041 Aam Deere BrochureDocument28 pagesLT 4041 Aam Deere Brochurechristian vergaray gonzalesNo ratings yet

- Kalmar DCG90-180 Lift Trucks 9 - 18 Tonnes: Technical Information, Stage IIIB/Tier 4iDocument7 pagesKalmar DCG90-180 Lift Trucks 9 - 18 Tonnes: Technical Information, Stage IIIB/Tier 4iJuan Amanqui GarciaNo ratings yet

- List of Existing Plant & Machineries of TSM Project: S.No Description Quantity A Milling PlantDocument3 pagesList of Existing Plant & Machineries of TSM Project: S.No Description Quantity A Milling Plantruhul01No ratings yet

- Diagrama Electrico de Camion Volquete-Www - Mineriacapma.blogspotDocument2 pagesDiagrama Electrico de Camion Volquete-Www - Mineriacapma.blogspotJose Luis Tairo Vega - Tave100% (2)

- SSP 283 - Part1 - 6-Speed Automatic Gearbox 09E in The Audi A8-03 - Part 1 PDFDocument24 pagesSSP 283 - Part1 - 6-Speed Automatic Gearbox 09E in The Audi A8-03 - Part 1 PDFfulltransmission100% (1)

- 12. Động Cơ Xoay Chiều 3 Pha GONGJI-GDocument27 pages12. Động Cơ Xoay Chiều 3 Pha GONGJI-GPhương NguyênNo ratings yet