Professional Documents

Culture Documents

40 45 PDF

Uploaded by

Desalegn TamirOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

40 45 PDF

Uploaded by

Desalegn TamirCopyright:

Available Formats

MATHEMATICAL MODELLING OF FLOW THROUGH POROUS

MEDIA AND DETERMINATION OF VELOCITY POTENTIAL

Dakheel Abdulla M.M1, Jacob V James2, Jesna Francis K3 , Kavya Jose4 , Sunith John David5

1

U.G. Student, Department of Civil Engineering, MITS Ernakulam

2

U.G. Student, Department of Civil Engineering

3

U.G. Student, Department of Civil Engineering, MITS Ernakulam

4

U.G. Student, Department of Civil Engineering, MITS Ernakulam

5

Assistant Professor, Department of Civil Engineering, MITS Ernakulam

Email: dakheel456@gmail.com1, jacobjamesvallimala@gmail.com2, jesnafrancy123@gmail.com3,

kavyajoss@gmail.com4, sunithjohndavid@mgits.ac.in5

Abstract points. Another cause of water movement in

Seepage is one of the important factors to be soils is the existence of excess pore water

considered in proper design of earthen pressure due to external loading. This type of

embankments as it pertains to the estimation water flow is usually not referred to as seepage,

of quantity of water seeping through the but the fundamental mathematical equations

medium in consideration and resulting pore describing the water movement are essentially

pressure developed due to it. Seepage can identical. Thus, the term seepage can be used to

occur beneath the foundation and also describe all movement of water through soil

through the body of the hydraulic structure. regardless of the creation or source of the driving

Excessive seepage could result in scouring force or whether the flow is through saturated or

and piping thereby leading to the ultimate unsaturated soils. Seepage can occur in both

failure of the structure. Since analytical foundations of an engineering structure or

solution is quiet difficult to find velocity sometimes through the structure itself as the case

potential and governing seepage equation, its of earthen dams. A failure of earth dam is

determination requires an iterative attributed to the following: hydraulic failure,

procedure. In the present work, a numerical seepage failure, piping through dam body and

code in MATLAB software has been structural failure due to earthquake. Seepage

developed using FEM to find out the potential analysis pertains to the estimation of quantity of

head in a flow domain under a sheet pile. The water seeping through the medium in

work can be extended to find the velocity consideration and resulting uplift pressure

potential through anisotropic soil condition. developed due to it and the exit gradients.

Index Terms: Seepage, Velocity potential, Excessive seepage could result in scouring and

anisotropic soil. piping and the ultimate failure of the foundation

I. INTRODUCTION and the structure accompanying it. The design

Seepage analysis in an important factor to be and construction of an earth-fill dam is one of the

considered in the proper design of any civil key challenges because of the unavoidable

engineering structures. The term ‘seepage’ variation in foundation condition and the

usually refers to situations where the primary properties of the available construction materials.

driving force is gravity controlled, such as A homogeneous earth-fill dam should be

establishing seepage losses from a reservoir, designed with relatively flat slopes to reduce the

where the driving force is the total hydraulic risk of failure. The practical seepage problems

head difference between the entrance and exit are not easily convertible into an equivalent

ISSN (PRINT): 2393-8374, (ONLINE): 2394-0697, VOLUME-4, ISSUE-2, 2017

40

INTERNATIONAL JOURNAL OF CURRENT ENGINEERING AND SCIENTIFIC RESEARCH (IJCESR)

numerical counterpart because of the regions are when subdivided into triangles. The

heterogeneity of the natural soils and the varying subdivision between regions should be located

boundary conditions. Even though the solution where there is a change in geometry, applied

of governing equation seems tedious, the load or material properties or both. A triangular

solution which is more close to the analytical region is most easily divided into elements by

solution can be derived using finite element specifying the same number of nodes along each

formulation. The analysis of seepage can be side and then connecting the appropriate nodes

done by the discharge computation from flownet. by straight lines and placing nodes at the

A flow net is a graphical solution to the intersecting points.

equations of steady groundwater flow. A flow Figure1 shows a typical triangular element

net consists of two sets of lines which must having nodes1, 2 and 3

always be orthogonal (perpendicular to each

other): flow lines, which show the direction of

groundwater flow, and equipotential (lines of

constant head), which show the distribution of

potential energy. Flow nets are usually

constructed through trial-and-error sketching.

II. METHODOLOGY

Modelling the flow of water through soil with a

numerical solution can be very complex. Natural

soil deposits are generally highly heterogeneous

and anisotropic. In addition, boundary

conditions often change with time and cannot Figure1. Triangular element

always be defined with certainty at the beginning

of an analysis; in fact, the correct boundary At each node, let the value of potential be φ1, φ2,

condition can sometimes be part of the solution. φ3 and coordinates (Xi ,Yi), (Xj, Yj), (Xk, Yk)

When a soil becomes unsaturated, the coefficient respectively. Then the value of potential within

of permeability or hydraulic conductivity the triangular mesh can be expressed as

becomes a function of the negative pore water (1)

pressure in the soil. The pore water pressure is This can be expressed in matrix form as

the primary unknown and needs to be

determined, so iterative numerical techniques (2)

are required to match the computed seepage

pressure and the material property, which makes Where N is called the interpolation function,

the solution highly nonlinear. These given by

complexities make it necessary to use some form (3)

of numerical analysis to analyze seepage (4)

problems for all, but the simplest cases. A (5)

common approach is to use finite element Where

formulations

A. Triangular Element and Shape Function

The division of a two dimensional body into

linear triangles is emphasized because this B. Formulation of finite element equation

element is analytically the simplest of the two The governing equation for steady state flow

dimensional elements. This simplicity of the through porous media

element requires that a large number of elements

(6)

be used to model a region; therefore the division

of a domain into linear triangles probably Where and are coefficients of permeability

represents the finest subdivision that would be Considering the weighted residual formulation

used.

The division of any two dimensional domain into Where w is the weighing function

elements should star with the division of body

into quadrilateral and triangular regions. These

ISSN (PRINT): 2393-8374, (ONLINE): 2394-0697, VOLUME-4, ISSUE-2, 2017

41

INTERNATIONAL JOURNAL OF CURRENT ENGINEERING AND SCIENTIFIC RESEARCH (IJCESR)

On integration by parts, Flow lines should always be parallel to an

impermeable boundary, and

equipotential lines are always

perpendicular to it.

Since we have Flow lines should always be perpendicular

to a constant head boundary, and

equipotential lines are always parallel to

it.

For drawing flow nets the suggested procedure is

as follows:

This equation can be converted into the general The boundary conditions should be firstly

form identified, e.g. boundaries which are

(7) impermeable and which are constant

(8) head.

Where K is called the stiffness matrix and Then, regions where the water is entering

Q is the boundary condition. the system and regions where it can it

For isotropic soil the stiffness matrix K is given should be identified.

by Any symmetry in the boundary conditions

should always be looked for.

The number of flow channels to be used

should be decided.

By trial and error sketching, a first trial

Where

flow line must be drawn and then other

flow lines must be drawn in to define all

flow channels.

Where flow channels squeeze, more

Where A is the area of one triangular mesh

closely spaced equipotential lines (higher

C. Algorithm in FEM

head gradients) are required to transfer

A general program to determine the total

the same quantity of water through the

potential within an earthen dam was developed

flow channel.

in MATLAB software. Algorithm for the

Finally, the curvilinear squares should be

determination of velocity potential is written as:

fitted together by drawing in the

Discretize into finite elements.

equipotential lines. In this process, the

Identify nodes & elements

positions of certain flow lines may be

Develop element stiffness matrices [Ke]

revised, making a trial and error

for all elements

procedure.

Assemble element stiffness matrices to

III. NUMERICAL CODE FORMULATION

get the global stiffness matrix

AND ITS VERIFICATION

Apply boundary conditions

In order to validate the finite element

Solve for velocity potential

formulation, we consider an example of flow

field with known potential having analytical

With the potential values at each nodes, the

solution

equipotential lines were drawn by interpolation

A. Flow field with known potential

method. The stream lines were drawn based on

The problem is to find out the velocity potential

literature survey.

for a rectangular flow field, when the flow is in

According to Casagrande (Casagrande, 1940),

the X-direction. The boundary is assumed to be

the following rules should be obeyed in drawing

impermeable and there is no flow in Y-direction.

flow nets:

The velocities in the X-direction and the field

Flow lines and equipotential lines should

dimensions are known. The boundary conditions

always be perpendicular to each other, in

are formulated for all the four sides of field. The

a homogeneous isotropic system, and

flow grid is shown in Figure2. Domain for

form curvilinear “squares”.

known potential

ISSN (PRINT): 2393-8374, (ONLINE): 2394-0697, VOLUME-4, ISSUE-2, 2017

42

INTERNATIONAL JOURNAL OF CURRENT ENGINEERING AND SCIENTIFIC RESEARCH (IJCESR)

Number of nodes=25

Number of elements=32

Since the analytical solution is available for the

problem, the developed program ‘potential.m’

was used to find the finite element solution of the

same problem in MATLAB software. The

results from the MATLAB software comprising

of both analytical and finite element software is

given by

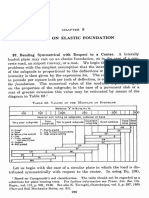

Table1. Comparison of FEM and Analytical

solution

Node FEM Analytica Absolute Relative

no. Solution l Solution Error Error

1 0 0 0 0

Figure2. Domain for known potential 2 0 0 0 0

The governing equation for the problem is 3 0 0 0 0

4 0 0 0 0

The flow grid used is a size of 5x10 5 0 0 0 0

Potential distribution= 6 0 0 0 0

Analytical 7

3.05158

2.882226 0.169359 5.549867

solution= 5

5.63859

8 5.324463 0.31413 5.571079

B. Discretization 3

To solve the partial differential equation 9

7.36717

6.953889 0.413288 5.609854

governing the seepage problem using FEM, first 7

7.97417

the domain is discretized to elements and nodes 10 7.521764 0.452411 5.673457

5

and then the approximation function is

11 0 0 0 0

systematically derived over the given domain.

7.96147

Then, the Galerkin type approximation of the 12 7.635645 0.325828 4.092563

3

governing equation is derived over each 14.7108

13 14.10566 0.605222 4.114107

element. Finally, the equations over all elements 9

of the collection are converted by the continuity 14 19.2207 18.42237 0.798328 4.153482

of primary variables, the boundary conditions of 15

20.8043

19.92679 0.877541 4.218066

the problem are imposed, and the connection set 3

of equations is solved. 16 0 0 0 0

Since we know the upstream and downstream 17.7196

17 17.34626 0.373343 2.106948

1

head, the nodes 1, 2, 3, 4, 5, 6, 11, 16, 21, 22, 23,

32.7415

24 and 25 are considered as constrained nodes. 18

7

32.04452 0.697055 2.128959

42.7789

19 41.85099 0.927941 2.169154

3

46.3035

20 45.26866 1.034917 2.23507

8

21 0 0 0 0

22 38.2683 38.31839 0.050093 0.130899

23 70.7107 70.78726 0.076558 0.108269

24 92.388 92.45003 0.062032 0.067143

25 100 99.99977 0.000235 0.000235

From the above table, It is observed that, there is

no much variation between analytical solution

Figure3. Discretization of flow field with known and FEM solution. Also, it is inferred that the

potential relative error between finite element solution

and analytical solution is considerably small and

ISSN (PRINT): 2393-8374, (ONLINE): 2394-0697, VOLUME-4, ISSUE-2, 2017

43

INTERNATIONAL JOURNAL OF CURRENT ENGINEERING AND SCIENTIFIC RESEARCH (IJCESR)

so the program potential.m can be used to find N

potential value under any flow domain for NO O NO

POTENT POTENT

specified boundary condition. DE POTENTIAL D

IAL

DE

IAL

IV. APPLICATION OF MATLAB no E no

no

PROGRAMME UNDER A FLOW DOMAIN

Consider a flow field of length 36 m, depth 12 m 1 5.9944584 23 6.5705933 45 7.0851237

having unit thickness under a hydraulic structure. 2 5.8199957 24 6.4071261 46 7.0182092

The upstream water level is 7.5 m and the 3 5.3117132 25 5.7181447 47 6.8380372

downstream water level is 1m. The flow field is

4 5.2348195 26 5.3915447 48 4.8156857

discretized using Finite Element Method. Figure

5 shows flow domain with a sheet pile of depth 5 4.6297403 27 4.5815779 49 4.4552327

40% of total depth and Figure 6 shows the 6 3.9361162 28 3.8757894 50 3.8332537

discretized flow field. The node number 56, 57, 7 3.2773441 29 3.1880072 51 3.139658

58, 64, 65 and 66 are considered as the

8 2.6797809 30 2.5007786 52 2.3711327

constrained nodes.

9 2.1970653 31 1.8695303 53 1.4749889

10 1.9024212 32 1.5770085 54 1.269625

11 1.8055752 33 1.4947507 55 1.2238468

12 6.168921 34 6.7037048 56 7.5

13 5.9869057 35 6.5647327 57 7.5

14 5.4067063 36 6.0859884 58 7.5

15 5.3111888 37 5.1483177 59 4.7184516

16 4.6308629 38 4.545802 60 4.4206721

17 3.9186902 39 3.8632635 61 3.8211482

18 3.2467397 40 3.1732687 62 3.1247796

19 2.6223571 41 2.4647859 63 2.3093841

20 2.1030295 42 1.7772829 64 1

Figure5. Flow domain

21 1.8035221 43 1.4993536 65 1

Total number of nodes = 66 22 1.7087292 44 1.4248045 66 1

Governing equation

Total number of elements = 94 V. RESULTS AND ANALYSIS

Flow grid size 36m x 12m Using the MATLAB program shhet40.m, the

value of potential under the flow field is

determined and tabulated and furnished in

following table. With the potential values from

the above table, the equipotential lines were

drawn by interpolation. Stream lines

perpendicular to the equipotential lines were

drawn with the guide lines and the flow net was

constructed.

Figure6. Discretized flow domain

Figure 7. Flow net under flow domain

ISSN (PRINT): 2393-8374, (ONLINE): 2394-0697, VOLUME-4, ISSUE-2, 2017

44

INTERNATIONAL JOURNAL OF CURRENT ENGINEERING AND SCIENTIFIC RESEARCH (IJCESR)

Since we obtain the flow net under a flow Computing in civil engineering, Vol 3, No 3.

domain, the discharge through the flow field can July 1989.

be calculated with the help of flow net [5] Li, G.C. and Desai, C.S, “Stress and Seepage

constructed. The discharge through the flow net Analysis of Earthen Dam”, Journal of

is given by Geotechnical Engineering, ASCE 109,

946-960. 1983.

[6] S. Rajasekaran, “Finite Element Analysis in

(8) Engineering Design”, S. Chand Publications,

2015.

k = Coefficient of permeability = 4.5 x 10-6 m/s

(Assumed)

H = u/s head – d/s head = 7.5 – 1 = 6.5 m

Nf = Number of flow field = 4

Nd = Number of potential drop= 13

As the flow domain is considered in the two

dimensional direction the discharge obtained

will be discharge per unit width and discharge,

Q=0.7776m3/day

VI. CONCLUSION

From the present work of determination of

potential using finite element method, the

following conclusions are derived:

Mathematical modelling of flow through

porous media has been studied.

A program in MATLAB software has

been developed to solve the governing

equation of seepage through porous

media, which is Laplace equation.

Using MATLAB Program developed, the

velocity potential under a flow domain

has been determined under specified

boundary conditions.

Flow net under the flow domain has been

constructed and analysed to determine

the discharge value.

Discharge Q=0.7776m3/day

REFERENCES

[1] Alam Singh and B.C. Punmia, “Seepage

below horizontal apron with downstream

cutoff, founded on anisotropic pervious

medium of finite depth”, Indian

Geotechnical Journal, vol. 3, Number 3, July

1973

[2] C.S Desai, “Finite element residual schemes

for unconfined flow”, International Journal

for numerical methods in engineering 1976.

[3] D.V. Griffith and I.M. Smith, “Programming

the Finite Element Method”, IIIrd Edition,

John Wiley and Sons, West Sussex, England

1996.

[4] F.T. Tracy and N. Radhakrishnan,

“Automatic generation of seepage flow nets

by finite element method”, Journal of

ISSN (PRINT): 2393-8374, (ONLINE): 2394-0697, VOLUME-4, ISSUE-2, 2017

45

You might also like

- Three Dimensional CFD Modeling of Flow Structure in Compound ChannelsDocument12 pagesThree Dimensional CFD Modeling of Flow Structure in Compound ChannelsLuay Kadhum AlwailiNo ratings yet

- France (1974)Document18 pagesFrance (1974)julianaNo ratings yet

- Orbital Mechanics and Genetic Algorithm Applied in Civil EngineeringDocument6 pagesOrbital Mechanics and Genetic Algorithm Applied in Civil EngineeringDebayan BoseNo ratings yet

- Soil Mechanics Assighnment 1Document3 pagesSoil Mechanics Assighnment 1EVANS KIPNGETICHNo ratings yet

- A New Method For Computing Hydrostatic PDocument7 pagesA New Method For Computing Hydrostatic PMikhail Roy Dela CruzNo ratings yet

- FSIDocument11 pagesFSIpiyushNo ratings yet

- Numerical analysis of seepage in embankment damsDocument11 pagesNumerical analysis of seepage in embankment damsEndless LoveNo ratings yet

- Energies: An Investigation of Parallel Post-Laminar Flow Through Coarse Granular Porous Media With The Wilkins EquationDocument19 pagesEnergies: An Investigation of Parallel Post-Laminar Flow Through Coarse Granular Porous Media With The Wilkins EquationNasser93No ratings yet

- Spe 125043 Pa PDFDocument14 pagesSpe 125043 Pa PDFFABIANNo ratings yet

- U3 - L15 Flow Nets Characteristics of Flow Nets and Guidelines For Drawing Flow NetsDocument5 pagesU3 - L15 Flow Nets Characteristics of Flow Nets and Guidelines For Drawing Flow NetsJoe Njore100% (1)

- Finite Difference Method of Modelling Groundwater FlowDocument7 pagesFinite Difference Method of Modelling Groundwater FlowVenegasNo ratings yet

- Stochastic Methods for Flow in Porous Media: Coping with UncertaintiesFrom EverandStochastic Methods for Flow in Porous Media: Coping with UncertaintiesNo ratings yet

- Development of Volume of Fluid (VOF) and Level Set (LS) Method CodeDocument110 pagesDevelopment of Volume of Fluid (VOF) and Level Set (LS) Method CodeVinesh H Gada50% (2)

- 2019 Correlation of Joint Roughness Coefficient and Permeability of A FractureDocument13 pages2019 Correlation of Joint Roughness Coefficient and Permeability of A FractureJhan DNo ratings yet

- Solving Groundwater Flow Equations Using Gradually: Varied FunctionsDocument12 pagesSolving Groundwater Flow Equations Using Gradually: Varied FunctionsAna Beatriz Rubio ArellanoNo ratings yet

- Reference Manual - Macra - R7 - 04Document23 pagesReference Manual - Macra - R7 - 04Jeric Dela Cruz QuiminalesNo ratings yet

- Hall 1982Document28 pagesHall 1982Otoma OrkaidoNo ratings yet

- Theory of Groundwater FlowDocument33 pagesTheory of Groundwater FlowSudharsananPRSNo ratings yet

- Deep-water Mooring Study Analyzes Effects of Water Depth VariationDocument14 pagesDeep-water Mooring Study Analyzes Effects of Water Depth VariationkometmayorNo ratings yet

- Fluid Flow Modeling in FracturesDocument41 pagesFluid Flow Modeling in FracturesAlberto RomanNo ratings yet

- Boundary layer adaptivity for turbulent flowsDocument21 pagesBoundary layer adaptivity for turbulent flowsHariharan RamanathanNo ratings yet

- Distribution of Pore Water Pressure in An EarthenDocument6 pagesDistribution of Pore Water Pressure in An EarthenSHNo ratings yet

- Hird 1992Document13 pagesHird 1992yutubpremiummmm01No ratings yet

- Nelder-Mead Simplex Method for Unconfined SeepageDocument10 pagesNelder-Mead Simplex Method for Unconfined SeepageEndless LoveNo ratings yet

- Modal Behavior of Dam Reservoir Foundati PDFDocument13 pagesModal Behavior of Dam Reservoir Foundati PDFdce_40No ratings yet

- Numerical Study of Dam-Break Flow - Omid SeyedashrafDocument9 pagesNumerical Study of Dam-Break Flow - Omid SeyedashrafseyedashrafNo ratings yet

- Application of Time Domain Methods For Marine Hydrodynamic and Hydroelasticity Analyses of Floating SystemsDocument19 pagesApplication of Time Domain Methods For Marine Hydrodynamic and Hydroelasticity Analyses of Floating Systemstran phamNo ratings yet

- Comparative Study OF ONE Dimensional AND TWO Dimensional Steady Surface Flow AnalysisDocument16 pagesComparative Study OF ONE Dimensional AND TWO Dimensional Steady Surface Flow AnalysisPankaj pacharNo ratings yet

- A Continuum Method For Modeling Surface Tension PDFDocument20 pagesA Continuum Method For Modeling Surface Tension PDFaryamesaNo ratings yet

- Gradual Variation Analysis For Groundwater Flow: Lchen@udc - EduDocument12 pagesGradual Variation Analysis For Groundwater Flow: Lchen@udc - EduAna Beatriz Rubio ArellanoNo ratings yet

- New Equation for Reservoir Area-Capacity CalculationsDocument9 pagesNew Equation for Reservoir Area-Capacity CalculationsIshit DhadaNo ratings yet

- Lid Driven Cavity CFD Simulation Report by S N TopannavarDocument127 pagesLid Driven Cavity CFD Simulation Report by S N TopannavarAkshay PatilNo ratings yet

- Seepage Through Earth Dams With Horizontal FiltersDocument15 pagesSeepage Through Earth Dams With Horizontal FiltersSandeep BandipallyNo ratings yet

- Numerical and Experimental Study of Classical Hydraulic JumpDocument16 pagesNumerical and Experimental Study of Classical Hydraulic JumpM A AbdulrazaqNo ratings yet

- Applied Mathematical Modelling: S.M. Seyedpoor, J. Salajegheh, E. SalajeghehDocument15 pagesApplied Mathematical Modelling: S.M. Seyedpoor, J. Salajegheh, E. SalajeghehDaniel WorkuNo ratings yet

- Estimation of The Coefficient of Consolidation by Used CPT and His Verification With Numerical ModelDocument8 pagesEstimation of The Coefficient of Consolidation by Used CPT and His Verification With Numerical ModelGEOLINKS International Conference 2019No ratings yet

- Fluid-Structure Interaction in Morison's Equation For The Design of Offshore StructuresDocument12 pagesFluid-Structure Interaction in Morison's Equation For The Design of Offshore StructuresSuzon IkramNo ratings yet

- Mesh ShipDocument7 pagesMesh ShipPranshu MalikNo ratings yet

- ACFrOgAhFbiyYPelIiyOI-D3Vp6Bk5hqs0vz3B2JavNSJCsN1H5bx5P2mcatw 8ojy xDeWw6uLXzl H0wgry9Z3MQc-NFw4WQ6o5rKERm Nh6hgcOysonQWrCj2OZt hmfLO4lMBM0uUiMRFxd6Document10 pagesACFrOgAhFbiyYPelIiyOI-D3Vp6Bk5hqs0vz3B2JavNSJCsN1H5bx5P2mcatw 8ojy xDeWw6uLXzl H0wgry9Z3MQc-NFw4WQ6o5rKERm Nh6hgcOysonQWrCj2OZt hmfLO4lMBM0uUiMRFxd6Natália SantosNo ratings yet

- Seepage beneath water retaining structures on random soilDocument17 pagesSeepage beneath water retaining structures on random soilThishaniNo ratings yet

- Fundamentals of Fluid MechanicsDocument90 pagesFundamentals of Fluid MechanicsSurendar MechNo ratings yet

- Lisa - KingDocument6 pagesLisa - KingamirNo ratings yet

- Full Report HecRasDocument25 pagesFull Report HecRasHafizul ZaidanNo ratings yet

- Seepage Tank Model: Instructions ManualDocument9 pagesSeepage Tank Model: Instructions ManualRenalyn AndradeNo ratings yet

- CFD Simulation of Hydraulic Jump in Triangular Channel Seminar ReportDocument19 pagesCFD Simulation of Hydraulic Jump in Triangular Channel Seminar ReportRanjitDesaiNo ratings yet

- CFD Letters2Document20 pagesCFD Letters2Eswaran MuthaiahNo ratings yet

- Calculations of Stratified Wavy Two-Phase Ow in Pipes: Petter Andreas Berthelsen, Tor YtrehusDocument22 pagesCalculations of Stratified Wavy Two-Phase Ow in Pipes: Petter Andreas Berthelsen, Tor YtrehusOmar SaeedNo ratings yet

- Fundamentals of Fluid Mechanics ExplainedDocument89 pagesFundamentals of Fluid Mechanics Explainedpraveen_01236No ratings yet

- Greg Melling, Justin Dix, Stephen Turnock, University of Southampton - Gjm1v07@noc - Soton.ac - Uk Richard Whitehouse, HR WallingfordDocument6 pagesGreg Melling, Justin Dix, Stephen Turnock, University of Southampton - Gjm1v07@noc - Soton.ac - Uk Richard Whitehouse, HR WallingfordMahmoud Abd El LateefNo ratings yet

- Steady Flow - Water Surface Profiles: EM 1110-2-1416 15 Oct 93Document27 pagesSteady Flow - Water Surface Profiles: EM 1110-2-1416 15 Oct 93Natasha GybzyNo ratings yet

- Numerical Analysis of Free Flow Past A Sluice GateDocument6 pagesNumerical Analysis of Free Flow Past A Sluice GateBabak mahmoudiNo ratings yet

- Numerical Methods in Geotechnical Engineering: All Functions Active Only With Adobe Reader Version 6.0Document7 pagesNumerical Methods in Geotechnical Engineering: All Functions Active Only With Adobe Reader Version 6.0Snezana VulovicNo ratings yet

- ReportDocument26 pagesReportahnednaeem312No ratings yet

- Castelliz 1974Document8 pagesCastelliz 1974Soledad AceitunoNo ratings yet

- Finite Element Analysis of Confined SeepageDocument13 pagesFinite Element Analysis of Confined SeepageMoiz Khan YousufzaiNo ratings yet

- Mathematical Hydraulics of Surface IrrigationDocument105 pagesMathematical Hydraulics of Surface IrrigationMahmoud YasserNo ratings yet

- Mathematical Models for Oil Reservoir SimulationDocument9 pagesMathematical Models for Oil Reservoir SimulationSeptianjefryCNNo ratings yet

- Y K Wong - Comparison of Drainage Line Elements in PLAXIS 2D and 3D Applied in Consolidating Marine Clay DepositsDocument8 pagesY K Wong - Comparison of Drainage Line Elements in PLAXIS 2D and 3D Applied in Consolidating Marine Clay DepositsGoh Kay YunNo ratings yet

- Study On Hydraulic Characteristic of The Tube Settler: Yonghai Yu, Dong Liu and Xiaofeng CuiDocument4 pagesStudy On Hydraulic Characteristic of The Tube Settler: Yonghai Yu, Dong Liu and Xiaofeng CuiMuhammad IkhrarNo ratings yet

- Chapter 1 Part 2Document66 pagesChapter 1 Part 2Desalegn TamirNo ratings yet

- Bearing CapacityDocument8 pagesBearing CapacityDesalegn TamirNo ratings yet

- Chapter 1Document16 pagesChapter 1Desalegn TamirNo ratings yet

- Foundation Engineering Ii - Ceng 4142 Assignment On Pile FoundationDocument1 pageFoundation Engineering Ii - Ceng 4142 Assignment On Pile Foundationabdu yimerNo ratings yet

- Earth Loads on Steel PipeDocument37 pagesEarth Loads on Steel PipeDesalegn TamirNo ratings yet

- Dam Failures: C. Deangeli, G.P. Giani, B. Chiaia & A.P. FantilliDocument50 pagesDam Failures: C. Deangeli, G.P. Giani, B. Chiaia & A.P. FantilliDesalegn TamirNo ratings yet

- Research ArticleDocument22 pagesResearch ArticleDesalegn TamirNo ratings yet

- Research Article: Theoretical and Case Studies of Interval Nonprobabilistic Reliability For Tailing Dam StabilityDocument12 pagesResearch Article: Theoretical and Case Studies of Interval Nonprobabilistic Reliability For Tailing Dam StabilityDesalegn TamirNo ratings yet

- Seepage Analysis of Rock-Fill Dam Subjected To Water Level Fluctuation: A Case Study On Gotvand-Olya DamDocument6 pagesSeepage Analysis of Rock-Fill Dam Subjected To Water Level Fluctuation: A Case Study On Gotvand-Olya DamDesalegn TamirNo ratings yet

- Foundations On Expansive SoilsDocument31 pagesFoundations On Expansive Soilsbini100% (1)

- Time For Development of Internal Erosion and Piping in Embankment DamsDocument8 pagesTime For Development of Internal Erosion and Piping in Embankment DamsDesalegn TamirNo ratings yet

- Seepage and Stability Analyses of Earth Dam Using Finite Element MethodDocument8 pagesSeepage and Stability Analyses of Earth Dam Using Finite Element MethodVishakha PatelNo ratings yet

- 5 Mohr Coulomb ModelDocument4 pages5 Mohr Coulomb ModelKTMONo ratings yet

- Mohr-Coulomb and Hardening Soil Model Comparison of The Settlement of An Embankment DamDocument5 pagesMohr-Coulomb and Hardening Soil Model Comparison of The Settlement of An Embankment DamDesalegn TamirNo ratings yet

- Numerical analysis of seepage in embankment damsDocument11 pagesNumerical analysis of seepage in embankment damsEndless LoveNo ratings yet

- 2D2012 0 Gen InfoDocument0 pages2D2012 0 Gen InfomrloadmovieNo ratings yet

- What Is Embankment Dam - Its Types and ComponentsDocument7 pagesWhat Is Embankment Dam - Its Types and ComponentsDesalegn TamirNo ratings yet

- Stress Due To Surface LoadDocument7 pagesStress Due To Surface LoadDesalegn TamirNo ratings yet

- Handbook of Dam Engineering (Ebook pdfDocument1 pageHandbook of Dam Engineering (Ebook pdfDesalegn TamirNo ratings yet

- Algebra IiDocument2 pagesAlgebra IiFumiServi GuayaquilNo ratings yet

- Economical Operation of Nuclear PlantsDocument10 pagesEconomical Operation of Nuclear PlantsArun PatilNo ratings yet

- Hot and Cold CorrosionDocument6 pagesHot and Cold CorrosioniceburnerNo ratings yet

- Sistem Informasi Geografis Pemetaan Lahan PertaniaDocument12 pagesSistem Informasi Geografis Pemetaan Lahan PertaniaRizal Nurrahman HabibNo ratings yet

- Autonomy Necessity and Love by Harry FrankfurtDocument14 pagesAutonomy Necessity and Love by Harry FrankfurtjamesdigNo ratings yet

- A Socio-Cultural Dimension of Local Batik Industry Development in IndoneisaDocument28 pagesA Socio-Cultural Dimension of Local Batik Industry Development in Indoneisaprihadi nugrohoNo ratings yet

- Supply Chain Management 5th Edition Chopra Solutions ManualDocument3 pagesSupply Chain Management 5th Edition Chopra Solutions Manualdammar.jealousgvg6100% (18)

- Guidelines For Synopsis & Dissertation-DefenseDocument10 pagesGuidelines For Synopsis & Dissertation-DefenseRajni KumariNo ratings yet

- CMO Olympiad Book For Class 3Document13 pagesCMO Olympiad Book For Class 3Srividya BaiNo ratings yet

- M-2 AIS Installation Manual ContentDocument57 pagesM-2 AIS Installation Manual ContentAdi PrasetyoNo ratings yet

- Danica Seleskovitch-Mariann A Lederer: Interpréter Pour TraduireDocument17 pagesDanica Seleskovitch-Mariann A Lederer: Interpréter Pour TraduireGarima KukrejaNo ratings yet

- Mass TransportationDocument20 pagesMass Transportationyoyo_8998No ratings yet

- DIK 18A Intan Suhariani 218112100 CJR Research MethodologyDocument9 pagesDIK 18A Intan Suhariani 218112100 CJR Research MethodologyFadli RafiNo ratings yet

- Presentation 5 1Document76 pagesPresentation 5 1Anshul SinghNo ratings yet

- Civil Engineering Materials CE-115 by Dr. Muhammad Salik JavaidDocument32 pagesCivil Engineering Materials CE-115 by Dr. Muhammad Salik Javaidfaizankhan23No ratings yet

- Solid Solution For Catalytic Ammonia Synthesis FromDocument8 pagesSolid Solution For Catalytic Ammonia Synthesis FromAhmad AlShahrourNo ratings yet

- 11 - Leo Vega Bolt Failure AnalysisDocument35 pages11 - Leo Vega Bolt Failure AnalysissymkimonNo ratings yet

- Liquefaction of Soil in KathmanduDocument9 pagesLiquefaction of Soil in Kathmanduajay shresthaNo ratings yet

- Babylonian Mathematics (Also Known As Assyro-BabylonianDocument10 pagesBabylonian Mathematics (Also Known As Assyro-BabylonianNirmal BhowmickNo ratings yet

- Atma Bodha of Shri SankaracharyaDocument1 pageAtma Bodha of Shri SankaracharyaMerike TazaNo ratings yet

- Simha Lagna: First House Ruled by The Planet Sun (LEO) : The 1st House Known As The Ascendant orDocument3 pagesSimha Lagna: First House Ruled by The Planet Sun (LEO) : The 1st House Known As The Ascendant orRahulshah1984No ratings yet

- Quality OrientationDocument2 pagesQuality OrientationResearcherNo ratings yet

- 722.6 Transmission Conductor Plate Replacement DIYDocument3 pages722.6 Transmission Conductor Plate Replacement DIYcamaro67427100% (1)

- International Journal of Information Technology, Control and Automation (IJITCA)Document2 pagesInternational Journal of Information Technology, Control and Automation (IJITCA)ijitcajournalNo ratings yet

- GCSE Combined Science PDFDocument198 pagesGCSE Combined Science PDFMpumelelo Langalethu MoyoNo ratings yet

- Is BN 9789526041957Document72 pagesIs BN 9789526041957supriya rakshitNo ratings yet

- Testing Methods for Selectivity Bias in Panel Data ModelsDocument24 pagesTesting Methods for Selectivity Bias in Panel Data Modelsstehta16529No ratings yet

- Coolit SystemsDocument5 pagesCoolit SystemsUsama NaseemNo ratings yet

- Oracle Property Manager System OptionsDocument6 pagesOracle Property Manager System OptionsAhmadShuaibiNo ratings yet

- OPM - Assignment 2Document12 pagesOPM - Assignment 2Nima IraniNo ratings yet