Professional Documents

Culture Documents

General

Uploaded by

alankar dhamgayeOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

General

Uploaded by

alankar dhamgayeCopyright:

Available Formats

WAGON MAINTENANCE MANUAL Page 1 of 12

CHAPTER 1

INTRODUCTION

101. GENERAL

a) For ensuring optimum performance of wagon fleet, it is necessary that:

Preventive maintenance is given timely to avoid occurrence of defects

Defects are attended effectively and well in time so that the wagons

remain fit for traffic use till the next schedule falls due

Detention during examination and repairs is kept to minimum

Frequent failures of similar nature are studied and necessary

modifications/ design changes are effected to eliminate the cause of such

failure.

In course of time and based on experience, various procedures/schedules for

maintenance of wagons have been prepared. The schedules and procedures have been

largely standardized and issued by Railway Board, RDSO, IRCA etc. However, in many

cases, instructions have been issued piecemeal. This manual consolidates various

standing instructions issued on wagon maintenance and lays down guidelines for

ensuring uniformity in the practices to be followed on various railways. The important

aspects of wagon maintenance have been covered and wherever necessary, the references

are indicated so that the reader can refer these, if necessary, for detailed instructions and

procedures not contained in this manual. In addition, the Workshop Orders, Carriage and

Wagon circulars, important letters and Technical Standing Orders issued by Zonal

Railways; taking into account the particular requirements and conditions existing on the

railways; must be read in conjunction with this manual.

b) This manual does not deal with the special stock or ODCs for which separate

instructions are issued by RDSO/manufacturers. It also doesn’t cover non-pooled

stock, used only on one or two zonal Railways.

c) At the end of this chapter, the list of important instructions and references have

been given. Throughout this manual, wherever IRCA Part III has been mentioned,

it refers to IRCA Part-III, 2000 edition.

d) While proper maintenance plays a vital role in ensuring effectiveness of the

CHAPTER 1- INTRODUCTION Ver. 2.0

WAGON MAINTENANCE MANUAL Page 2 of 12

rolling stock, an equally crucial role is played by proper handling and careful

operation of the wagon fleet so as to minimise the incidences of damage and

subsequent need for repairs. Care must be taken to avoid bumping of wagons

having CBC Knuckles in closed position. Proper release of brakes must be

ensured. Cleaning of wagon interiors after unloading of corrosive, hygroscopic or

other harmful consignments is necessary by unloading party and to be ensured by

the commercial staff. Place free end of hose pipes on dummy carriers and

couplings on suspension hooks.

102. IMPORTANT DIMENSIONS OF WAGONS

The important dimensions and sketches of main type of wagons have been given

below.

TABLE 1.1 UIC BOGIE WAGONS – VACUUM BRAKE

Type of wagons BOXT BOXC BCXT

Length over Head stock (mm) 12800 12800 14500

Length over Buffers (mm) 14070 N.A. 15770

Length over Couplers (mm) 14082 13729 15782

Length inside/ Length of wall (mm) 12792 12790 14494

Width inside (mm) 2852 2852 2944

Inside height/ Height of wall (mm) 1880 1880 2446

Wheel Base (mm) 2000 2000 2000

Bogie Centre (mm) 8800 8800 10,000

Journal Size (mm) RB 130 RB 130 RB 130

Journal Centre (mm) 2240 2240 2240

Wheel dia on tread (mm) 1000 1000 1000

Max. Axle load (t) 20.32 20.32 20.32

Tare (t) 26.23 25.0 28.5

Pay load (t) 55.05 56.28 52.8

Gross load (Pay + Tare) (t) 81.28 81.28 81.3

Ratio Gross Load/Tare 3.1 3.24 2.85

Loading density (t/m) 5.77 5.92 5.16

Floor Area (Sq. m) 36.5 36.5 42.7

Cubic Capacity (Cu. m) 68.58 68.58 104

Total Brake power- Empty (Kg) 19339 19339 18618

Total Brake power – Loaded (Kg) 34913 34913 34192

CHAPTER 1- INTRODUCTION Ver. 2.0

WAGON MAINTENANCE MANUAL Page 3 of 12

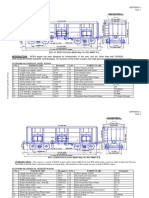

Fig. 1.1 BOXC WAGON (Ref: RDSO SK.101-626010)

CHAPTER 1- INTRODUCTION Ver. 2.0

WAGON MAINTENANCE MANUAL Page 4 of 12

Fig. 1.2 BCXT WAGON (Ref: RDSO SK 701-83901)

CHAPTER 1- INTRODUCTION Ver. 2.0

WAGON MAINTENANCE MANUAL Page 5 of 12

TABLE 1.2 CASNUB BOGIE WAGONS – AIR BRAKE

Type of wagons BOXN BCN BRN

Length over Head stock (mm) 9784 14500 13716

Length over Buffers (mm) 14986

Length over Couplers (mm) 10713 15429 14645

Length inside/ Length of wall (mm) 9784 14494 13716

Width/Dia inside (mm) 2950 2944 2845

Inside height/ Height of wall (mm) 1950 2446

Wheel Base (mm) 2000 2000 2000

Bogie Centre (mm) 6524 10,000 9144

Journal Size (mm) CTRB 144.5 144.5 144.5

Journal Centre (mm) 2260 2260 2240

Wheel dia on tread (mm) 1000 1000 1000

Max. Axle load (t) 20.32 20.32 20.32

Tare (t) 22.47 27.20 24.4

Pay load (t) 58.81 54.08 56.9

Gross load (Pay + Tare) (t) 81.28 81.28 81.3

Ratio Gross Load/Tare 3.62 2.99 3.33

Loading density (t/m) 7.59 5.27 5.55

Floor Area (Sq. m) 28.86 42.67 39

Cubic Capacity (Cu. m) 56.28 104.37

Total Brake power- Empty (Kg) 18900 18900 18900

Total Brake power – Loaded (Kg) 33642 33642 33642

TABLE 1.3 OPEN FOUR WHEELER WAGONS

Particulars Broad gauge Metre gauge

Mechanical code O OM MO MOX MOM

Description Open general Open military Open Open Open

purpose heavy military

Tare (t) 10.31 10.62 5.69 5.84 5.5

Pay load (t) 22.29 21.98 18.71 18.56 18.9

Axle load(t) 16.30 16.30 12.2 12.2 12.2

Length over buffers/couplers 7214 9652 7786 7786 7786

(mm)

Floor area (Sq.m) 16.91 23.85 14.98 14.97 14.98

Cubic capacity (Cu.m) 27.00 15.07 17.5 21.28 9.5

Journal centre (mm) 2235 2235 1475 1475 1475

Journal size (mm) 255x127 255x127 230x115 230x115 230x115

Wheel dia on tread (mm) 1090 1090 725 725 725

Wheel base (mm) 3504 4877 3657 3657 3657

Type of coupler Screw Screw ABC ABC ABC

coupling coupling

Type of bearing Plain Plain Plain Plain Plain

Type of brakes Vacuum Vacuum Vacuum Vacuum Vacuum

CHAPTER 1- INTRODUCTION Ver. 2.0

WAGON MAINTENANCE MANUAL Page 6 of 12

Fig. 1.3 BOXN WAGON (Ref: RDSO WD 80007-S-02)

CHAPTER 1- INTRODUCTION Ver. 2.0

WAGON MAINTENANCE MANUAL Page 7 of 12

Fig. 1.4 BCN WAGON (Ref: RDSO WD-84014-S/1)

CHAPTER 1- INTRODUCTION Ver. 2.0

WAGON MAINTENANCE MANUAL Page 8 of 12

Fig. 1.5 BRN WAGON (Ref: RDSO WD-84013-S-1)

TABLE 1.4 OTHER STANDARD WAGONS

Particulars Broad gauge Metre gauge Narrow

gauge

Mechanical code TP CRT BOI BOY MBO MBOC NOL

Description Tank Cover- Open Open Bogie Open Bogie

Petrol ed gondo gondo open coal open

wagon -la -la

Tare (t) 12.2 13.1 22.80 19.9 10.82 13.98 8.48

Pay load (t) 20.4 27.54 58.48 71.7 37.98 35.82 24.03

Axle load(t) 16.3 20.32 20.32 22.9 12.2 12.2 8.1

Length over buffers/ 8280 8822 11629 11929 12511 14340 11430

couplers (mm)

Floor area (Sq.m) 23.2 30.47 32.13 25.78 29.96 22.76

Cubic capacity (Cu.m) 25.5 61.9 32.0 37.75 16.32 35.0 29.02

Journal centre (mm) 2235 2240 2240 2260 1475 1475 1220

Journal size (mm) 255 x RB 130 144.5 230x115 230x115 180x95

127 130

Wheel dia on tread 1090 1000 1000 1000 725 725 585

(mm)

Wheel base (mm) 4572 4900 6700 7330 7620 9449 7925

Type of coupler Draw Tran. CBC CBC ABC ABC ABC

bar CBC

Type of bearing Plain/ RB RB RB Plain Plain Plain

RB

Type of brakes Vac Vac Vac/ Air Vac Vac Vac

Air brake

CHAPTER 1- INTRODUCTION Ver. 2.0

WAGON MAINTENANCE MANUAL Page 9 of 12

TABLE 1.5 TANK WAGON

Particulars Broad gauge

Mechanical code TBT TR TM TPGL TPGLR

Description Bitumen Coal Tar Molasses Liquid Liquid

tank tank tank petrolium petrolium gas

gas tank tank

Tare (t) 13.00 10.8 10.75 20.66 17.1

Pay load (t) 19.5 21.7 21.76 11.84 15.4

Axle load(t) 16.3 16.3 16.3 16.3 16.3

Length over buffers/ 7215 7215 7215 9652 9652

couplers (mm)

Dia inside barrel (mm) 2362 2143 2143 2000 2300

Cubic capacity (Cu.m) 23.5 19.4 19.4 24.1 33.1

Journal centre (mm) 2235 2235 2235 2235 2235

Journal size (mm) RB120 dia RB120 dia RB120 dia RB120 dia RB120 dia

Wheel dia on tread 1090 1090 1090 1090 1090

(mm)

Wheel base (mm) 3505 3505 3505 4877 4878

Type of coupler Screw Screw Screw Screw Screw

coupling coupling coupling coupling coupling

Type of bearing RB RB RB RB RB

Type of brakes Vacuum Vacuum Vacuum Vacuum Vacuum

TABLE 1.6 BRAKE VAN

Particulars Broad Gauge

Mechanical code BVG BVM

Description Brake van goods Brake van match truck

Tare (t) 10.77 12.7

Pay load (t)

Axle load(t) 16.3 16.3

Length over buffers/ couplers 7213 7213

(mm)

Journal centre (mm) 2235 2235

Journal size (mm) 225 x 127 225 x 127

Wheel dia on tread (mm) 1090 1090

Wheel base (mm) 3505 3505

Type of coupler Screw coupling CBC

Type of bearing Plain Plain

Type of brakes Vacuum Vacuum

CHAPTER 1- INTRODUCTION Ver. 2.0

WAGON MAINTENANCE MANUAL Page 10 of 12

Fig. 1.6 CRT WAGON (Ref: RDSO SK. 71605)

103. IMPORTANT RULE BOOKS AND REFERENCES

List of technical monograms/instructions relevant to maintenance of freight stock

are included in the compendium of instructions/ technical monograms issued vide

Railway Board’s letter No. 99/EAR/3400/21 dt. 4.5.99. The following rule books,

pamphlets and monograms contain information required to supplement this manual.

These may be referred to for details not available in this manual.

i. IRCA Conference Rules Part III (2000) - Rules for Maintenance, Examination

and Interchange of Goods Stock (BG & MG System) of Indian Government

Railways

ii. Prevention of Hot Boxes - A Guide (Published by Railway Board)

iii. RDSO’s Technical Pamphlet G-16 - Instructions for Maintenance and Operation

of Box Wagons

iv. RDSO’s Technical Pamphlet G-37 - Recommended practice for welded

fabrication in wagons

v. RDSO’s Technical Pamphlet G-38 - Instructions for Maintenance and Operation

of ‘TCL’ Tank wagon

vi. RDSO’s Technical Pamphlet G-40 - Manual of Instructions for Anhydrous

Ammonia Tank.

vii. RDSO’s tech. Pamphlet No. G-44H/Jan 78 Instructions for operating staff hump

shunting and marshalling of BOX wagon

viii. RDSO’s tech. Pamphlet No. G-45H Instructions for fitting trapauling equipment

on BOX wagon.

ix. RDSO’s tech. Pamphlet No. G-55H/Aug.76 Instructions for maintenance and

operation of hydrochloric acid tank wagon type THA.

x. RDSO’s tech. Pamphlet No. G-62/June.77 Maintenance manual of alliance II

coupler

xi. Indian Railways Code for the Mechanical Department (Workshops)

CHAPTER 1- INTRODUCTION Ver. 2.0

WAGON MAINTENANCE MANUAL Page 11 of 12

xii. RDSO’s Technical Pamphlet G-65 Instructions for inspection and maintenance of

TPGLR

xiii. RDSO’s tech. Pamphlet No. G-66/1983 Maintenance manual for TSA.

xiv. RDSO’s Technical Pamphlet G-70 Instructions for inspection and maintenance of

BOXN wagons fitted with CASNUB Bogies and twin pipe air brake system.

xv. RDSO’s tech. Pamphlet No. G-71 Maintenance manual for phosphoric acid tank

wagon.

xvi. RDSO’s tech. Pamphlet No. G-72 General standard specification for fabrication

of wagon U frame and bogies.

xvii. RDSO’s Technical Pamphlet G-73 Instructions for inspection and maintenance of

BOBR

xviii. RDSO’s Technical Pamphlet No.G-76 (Supersedes old pamphlet No.G-46)

xix. RDSO’s tech. Pamphlet No. G-79 Instructions for operation and maintenance for

BTAL/BTALN

xx. RDSO’s Technical Pamphlet No. G-80(Supersedes old pamphlet No. G-47)

xxi. RDSO’s Technical Pamphlet G-81 Instructions for inspection and maintenance of

CTRB

xxii. RDSO’s tech. Pamphlet No. G-82 Instructions for operation and maintenance BG

bogie tank wagon for alumina type BTAL.

xxiii. RDSO’s tech. Pamphlet No. G-83 Instructions for operation for maintenance of

BTCS wagon

xxiv. RDSO’s Technical Pamphlet G-86 Instructions for inspection and maintenance of

BTPGL/BTPGLN

xxv. RDSO’s tech. Pamphlet No. G-87 Safe handling of hazardous chemicals

transported in rail tankers.

xxvi. RDSO’s Technical Pamphlet G-90 Instructions for inspection and maintenance of

BTPN

xxvii. RDSO’s Technical Pamphlet G-92 Instructions for inspection and maintenance of

Slack Adjuster type IRSA 450 & 600

xxviii. RDSO’s Technical Pamphlet G-95 Instructions for inspection and maintenance of

CASNUB Bogies

xxix. RDSO’s Technical Pamphlet G-97 Instructions for inspection and maintenance of

Air Brakes

xxx. RDSO’s Technical Pamphlet No. WT-77-1 & WT-79-1 for inspection and

maintenance of 20.3 Tonnes Roller Bearing and 16.3 Tonnes Roller Bearing axle

boxes fitted wagons.

104. EXISTING WAGON FLEET

The strength of present wagon fleet on Indian Railways is given at the end of this

manual in Appendix-I.

CHAPTER 1- INTRODUCTION Ver. 2.0

WAGON MAINTENANCE MANUAL Page 12 of 12

105. STANDARD INFRASTRUCTURE FOR WAGON DEPOT

The standard infrastructure required in wagon depot is given in Appendix-II.

106. IMPORTANT WAGON MODIFICATIONS

The list of important modifications to be carried out on freight stock is given in

Appendix-III.

107. NUMBERING CONVENTION IN THE MANUAL

For convenience of indexing of reference, the paragraphs have been numbered

according to a 3 /4 figure “Code”, in which the last two figures give the number of the

paragraphs and the remaining figures the number of the chapter. Thus paragraph 101 of

any code is paragraph 1 of chapter 1 of that code and paragraph 1103, paragraph 3 of

chapter 11.

The page number in each chapter in this manual starts from 1. The reader can

easily identify the chapter number to which a page belongs by reading the footer of the

page at the bottom where chapter number as well as chapter title is given. This scheme of

page numbering is adopted to provide flexibility of easily revising the chapters in future,

on account of design or procedure changes or induction of new stock without disturbing

the page numbers of succeeding chapters.

108. NUMBERING OF TABLES AND FIGURES IN THE MANUAL

The tables in each chapter consist of two numbers separated by a decimal point.

The number before decimal point indicates the chapter number whereas the number after

the decimal point indicates the running serial number of the table which start from 1 in

every chapter. The convention adopted for numbering the figures is also identical to the

numbering scheme adopted for the tables.

CHAPTER 1- INTRODUCTION Ver. 2.0

You might also like

- VOLVO EC460B LC EC460BLC EXCAVATOR Service Repair Manual PDFDocument18 pagesVOLVO EC460B LC EC460BLC EXCAVATOR Service Repair Manual PDFjkdmsmemmd67% (9)

- Manual de Taller Fork Lift Komatsu FG25TDocument370 pagesManual de Taller Fork Lift Komatsu FG25TCristian Barra Guajardo79% (14)

- EX40UDocument467 pagesEX40UALEJO100% (3)

- Acroba SerManual FA15-30Document190 pagesAcroba SerManual FA15-30Vasile Vrabie100% (4)

- Grapho CyberneticsDocument3 pagesGrapho CyberneticsmysticblissNo ratings yet

- VLCCDocument9 pagesVLCCAnonymous b68EQRNo ratings yet

- Volvo EC60C Compact Excavator Service Repair Manual PDFDocument22 pagesVolvo EC60C Compact Excavator Service Repair Manual PDFjfjkkskemmdm50% (2)

- XD 30 DieselDocument4 pagesXD 30 Dieselanupthatta0% (1)

- Diesel engines for fast vessels with high load factorsDocument1 pageDiesel engines for fast vessels with high load factorsghostt123No ratings yet

- Nuclear Radioactivity WorksheetDocument3 pagesNuclear Radioactivity Worksheet14569874No ratings yet

- Banas Bio-Gas PlantDocument30 pagesBanas Bio-Gas Plantjugal rana100% (1)

- Soft Tissue InfectionsDocument3 pagesSoft Tissue InfectionsGerardLum100% (1)

- BOXNDocument12 pagesBOXNpandeydbNo ratings yet

- BOXN wagon manualDocument45 pagesBOXN wagon manualGame RajNo ratings yet

- Silent Feature of Goods WagonDocument6 pagesSilent Feature of Goods WagonAnish DasNo ratings yet

- Type of WagonsDocument24 pagesType of WagonsCaspian DattaNo ratings yet

- Linde EN Ds lt10 lt20c B BM 8970 01 en A 1021 ViewDocument8 pagesLinde EN Ds lt10 lt20c B BM 8970 01 en A 1021 ViewNadeem AhmedNo ratings yet

- Design of 2 Seated Fighter AircraftDocument17 pagesDesign of 2 Seated Fighter AircraftSudharshanNo ratings yet

- Calculation - MWIDocument9 pagesCalculation - MWIfarhan_82No ratings yet

- Doosan B15T - 1.5Document8 pagesDoosan B15T - 1.5rendimax insumos agricolasNo ratings yet

- Linde EN Ds t25 t30 1153 en B 0620 WebDocument6 pagesLinde EN Ds t25 t30 1153 en B 0620 WebNadeem AhmedNo ratings yet

- BAOLI Forklift KBG15-20 Operator's ManualDocument95 pagesBAOLI Forklift KBG15-20 Operator's ManualSARAMQR100% (1)

- KOMATSU CX50 Pneumatic 4 5.5 TonDocument8 pagesKOMATSU CX50 Pneumatic 4 5.5 TonHatef SardariNo ratings yet

- Kent Pás CarregadorasDocument1 pageKent Pás CarregadorasMOZAMBiCARNo ratings yet

- Mitsubishi's New 8-16 T Forklift Trucks Realize World-Class Environmental Efficiency and Operator ComfortDocument2 pagesMitsubishi's New 8-16 T Forklift Trucks Realize World-Class Environmental Efficiency and Operator Comfortalfan nashNo ratings yet

- Guía Cargadores PDFDocument60 pagesGuía Cargadores PDFJOSENo ratings yet

- New Designs of WagonsDocument54 pagesNew Designs of WagonsAnurag SinghNo ratings yet

- CQDBDocument4 pagesCQDBDiana LiesegangNo ratings yet

- Excavator Performance Specs and Dimensions E220.8 E215.9 E240.9 E270.9Document1 pageExcavator Performance Specs and Dimensions E220.8 E215.9 E240.9 E270.9roni roniNo ratings yet

- Chapter 1 General InformationDocument8 pagesChapter 1 General InformationChristian BedoyaNo ratings yet

- DFG16 25XDDocument2 pagesDFG16 25XDTomaszNo ratings yet

- General Information: Scope Truck Models Covered Dimensions Dimensions Chart General Information (Standard Models)Document5 pagesGeneral Information: Scope Truck Models Covered Dimensions Dimensions Chart General Information (Standard Models)Noe CuandonNo ratings yet

- Baoli KBG25-35 LPG BrochureDocument4 pagesBaoli KBG25-35 LPG BrochureAvishay TufikianNo ratings yet

- Mining-Truck-Spec CMT96Document2 pagesMining-Truck-Spec CMT96Roger MendozaNo ratings yet

- Komatsu ®: Model Komatsu WA900-3E0 Komatsu WA1200-6 Caterpillar 993 K (T4) GeneralDocument4 pagesKomatsu ®: Model Komatsu WA900-3E0 Komatsu WA1200-6 Caterpillar 993 K (T4) GeneralGaming BebasNo ratings yet

- f2d TaylorTX160SpecSheetandBrochureDocument6 pagesf2d TaylorTX160SpecSheetandBrochureFher AraujoNo ratings yet

- TATA T.16 ULTRA DAY Overview - Specs, Features & ImagesDocument2 pagesTATA T.16 ULTRA DAY Overview - Specs, Features & ImagesTata Light TrucksNo ratings yet

- MC99759 8b110genDocument8 pagesMC99759 8b110genANGELES NIETONo ratings yet

- Design Features of Various WagonsDocument11 pagesDesign Features of Various WagonssaraNo ratings yet

- Linde EN Ds x20 x35 1252 en A 0621 ViewDocument8 pagesLinde EN Ds x20 x35 1252 en A 0621 ViewNadeem AhmedNo ratings yet

- TATA T.9 ULTRA NARROW Overview Specs, Features & ImagesDocument2 pagesTATA T.9 ULTRA NARROW Overview Specs, Features & ImagesTata Light TrucksNo ratings yet

- Very Narrow Aisle K: Capacity 1500 KG - Series 5231Document6 pagesVery Narrow Aisle K: Capacity 1500 KG - Series 5231Lực NguyễnNo ratings yet

- Kent Bulldozer T160SDocument1 pageKent Bulldozer T160SMOZAMBiCARNo ratings yet

- Preliminary Design of 25,000-Ton General Cargo VesselDocument32 pagesPreliminary Design of 25,000-Ton General Cargo VesselRama KrishnaNo ratings yet

- AE20/BE20: SeriesDocument7 pagesAE20/BE20: SeriesPatricio Acuña0% (1)

- TC4208 ManualDocument34 pagesTC4208 ManualPepNo ratings yet

- FG10/15/18-21 Service ManualDocument51 pagesFG10/15/18-21 Service ManualDmitryNo ratings yet

- Linde EN Ds t20rw t25rw br1154 en A 0618Document6 pagesLinde EN Ds t20rw t25rw br1154 en A 0618Nadeem AhmedNo ratings yet

- Bruksanvisning Staplare ST El 2 5 MDocument16 pagesBruksanvisning Staplare ST El 2 5 MJOSE PALACIOSNo ratings yet

- BOX Culvert Load DetailsDocument7 pagesBOX Culvert Load Detailsragalwar100% (1)

- Comparison Loader XCMG X SHANTUIDocument2 pagesComparison Loader XCMG X SHANTUIkresna febriansyahNo ratings yet

- Motor 2.5 HP - ShakersDocument2 pagesMotor 2.5 HP - ShakersAlex SinissNo ratings yet

- EN 06SpecSheet C60-80 S0611E.pdf-IVECODocument6 pagesEN 06SpecSheet C60-80 S0611E.pdf-IVECOYakupovmmNo ratings yet

- 1.5 To 3.5 DP GP SeriesDocument6 pages1.5 To 3.5 DP GP Seriesyeremia kristianNo ratings yet

- Chapter Load Charts-20080904Document21 pagesChapter Load Charts-20080904Bishoo ShenoudaNo ratings yet

- Specification Reference Drawing for Mitsubishi FD70-100NH Forklift TrucksDocument42 pagesSpecification Reference Drawing for Mitsubishi FD70-100NH Forklift TrucksLui DavidNo ratings yet

- B Series Single Drum Vibratory Rollers SpecsDocument1 pageB Series Single Drum Vibratory Rollers SpecsYodi Eko PrasetyoNo ratings yet

- Symposium On The Lift and Escalator TechnologiesDocument5 pagesSymposium On The Lift and Escalator TechnologiesfreddyjoertyNo ratings yet

- Reachstacker Performance & SpecsDocument8 pagesReachstacker Performance & SpecsHugo Julian Sanchez MayorgaNo ratings yet

- La 4532 Tce5 Machine CardDocument2 pagesLa 4532 Tce5 Machine CardSamakab-Abdek Salah AouledNo ratings yet

- Cylinder Head Valves: SpecificationsDocument3 pagesCylinder Head Valves: SpecificationsMbahdiro KolenxNo ratings yet

- E2.2 3.5xn A268 Ss 12 2015 Emea Rev04 enDocument8 pagesE2.2 3.5xn A268 Ss 12 2015 Emea Rev04 enAli SoykanNo ratings yet

- Food Fundamentals 10 - E - Margaret McWilliamsDocument497 pagesFood Fundamentals 10 - E - Margaret McWilliamspedropereza88No ratings yet

- Soal Bahasa Inggris 7,8,9Document5 pagesSoal Bahasa Inggris 7,8,9Jo windyNo ratings yet

- Diabetic Retinopathy: Basic InformationDocument12 pagesDiabetic Retinopathy: Basic InformationipkNo ratings yet

- Can Capitalism Bring Inclusive Growth?: - Suneel SheoranDocument4 pagesCan Capitalism Bring Inclusive Growth?: - Suneel SheoranSandeepkumar SgNo ratings yet

- Glycodur Cat enDocument52 pagesGlycodur Cat enjhhvgNo ratings yet

- What Is Newborn ScreeningDocument2 pagesWhat Is Newborn ScreeningroksanmiNo ratings yet

- Review of Accounting CycleDocument2 pagesReview of Accounting CycleAnnie RapanutNo ratings yet

- DD Cen TS 15534-3-2007Document14 pagesDD Cen TS 15534-3-2007MladenMarkovicNo ratings yet

- Trail/Beaver Valley/Rossland Apr. 9, 2019Document39 pagesTrail/Beaver Valley/Rossland Apr. 9, 2019Pennywise PublishingNo ratings yet

- Tupad Orientation Presentation 2017Document54 pagesTupad Orientation Presentation 2017Anonymous EvbW4o1U7100% (5)

- Long Test MILDocument3 pagesLong Test MILBern PabNo ratings yet

- Learn English for Free at thichtienganh.comDocument30 pagesLearn English for Free at thichtienganh.comNhân Đăng NguyễnNo ratings yet

- Lady Wachter's Cult of Darkness InvestigationDocument11 pagesLady Wachter's Cult of Darkness InvestigationWellington Valentin100% (1)

- LEC 5 Elements of An Offence and Their QualificationsDocument27 pagesLEC 5 Elements of An Offence and Their QualificationsEliezer Charles Ngahyoma67% (3)

- Metal Hose Manual 1301 - Uk - 8 - 05 - 20 - PDFDocument388 pagesMetal Hose Manual 1301 - Uk - 8 - 05 - 20 - PDFklich77No ratings yet

- Radial UnoDocument5 pagesRadial Unobhupi dagarNo ratings yet

- Clay Types PDFDocument40 pagesClay Types PDFHafiz Mudaser AhmadNo ratings yet

- CattabrigaF45 90 120Document21 pagesCattabrigaF45 90 120Fernando William Rivera CuadrosNo ratings yet

- Aims & ObjectiveDocument80 pagesAims & Objectivevishaldhande007No ratings yet

- Long-Term Memory - ProcessDocument30 pagesLong-Term Memory - ProcessALEXANDRA SAN PEDRONo ratings yet

- External Beam Planning RGDocument870 pagesExternal Beam Planning RGrubenNo ratings yet

- The Yale-Brown Obsessive Compulsive Scale I. Development, Use, and ReliabilityDocument6 pagesThe Yale-Brown Obsessive Compulsive Scale I. Development, Use, and Reliabilitynurulhafizhah01No ratings yet

- Supply Chain Operations Manager in Indianapolis IN Resume Robert McVeighDocument2 pagesSupply Chain Operations Manager in Indianapolis IN Resume Robert McVeighRobertMcVeighNo ratings yet

- Deccan 12Document4 pagesDeccan 12Ehtesam khanNo ratings yet

- Pulseless Arrest Algorithm For Managing AsystoleDocument1 pagePulseless Arrest Algorithm For Managing AsystoleLady MuffinsNo ratings yet

- Pinatubo Eruption Case Study: Disaster Readiness and Risk ReductionDocument5 pagesPinatubo Eruption Case Study: Disaster Readiness and Risk ReductionAndrie PaydoenNo ratings yet